saturable reactor (now water ballast)

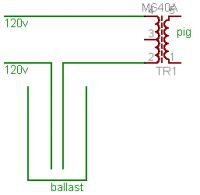

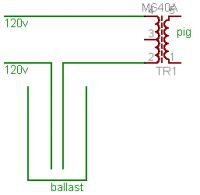

teslacoolguy, Mon Oct 06 2008, 01:23AMHi. I am brainstorming ways to ballast my pig and i think a saturable reactor will work best. I was thinking of taking this

three phase reactor and replacing the center winding with a control winding and having the 2 outer windings, one for each 120v line kinda like this.

three phase reactor and replacing the center winding with a control winding and having the 2 outer windings, one for each 120v line kinda like this. I have looked through this thread

and it gave me some info but i still need to know if my transformer would work. It seams to me rated for a nice amount of amperage so tell me what you think and what i would have to do. Now getting into the control winding, would it be better for me to have the same amount of turns as the ballast windings or if lets say if i have twice as many control windings will i have to increase the voltage but divide the needed current in half? I am also assuming that the current on the dc winding is proportional to the current on the ballast windings?

and it gave me some info but i still need to know if my transformer would work. It seams to me rated for a nice amount of amperage so tell me what you think and what i would have to do. Now getting into the control winding, would it be better for me to have the same amount of turns as the ballast windings or if lets say if i have twice as many control windings will i have to increase the voltage but divide the needed current in half? I am also assuming that the current on the dc winding is proportional to the current on the ballast windings?Re: saturable reactor (now water ballast)

Dr. Dark Current, Mon Oct 06 2008, 05:18AM

I'm 90% sure that when the reactor starts saturating, it will "chop" the mains waveform much like a SCR/TRIAC angle controller does (it'll be a bit softer but still)

The result will be large short circuit current, poor power output and non-optimal (higher) coil heating.

Things would get better if you could connect a ballast inductor in series with the pig which would set the maximum current (without the reactor connected).

Dr. Dark Current, Mon Oct 06 2008, 05:18AM

I'm 90% sure that when the reactor starts saturating, it will "chop" the mains waveform much like a SCR/TRIAC angle controller does (it'll be a bit softer but still)

The result will be large short circuit current, poor power output and non-optimal (higher) coil heating.

Things would get better if you could connect a ballast inductor in series with the pig which would set the maximum current (without the reactor connected).

Re: saturable reactor (now water ballast)

101111, Mon Oct 06 2008, 06:14AM

Why not just make a big solid state variac of SCRs?

101111, Mon Oct 06 2008, 06:14AM

Why not just make a big solid state variac of SCRs?

Re: saturable reactor (now water ballast)

Dr. Dark Current, Mon Oct 06 2008, 06:25AM

Dr. Dark Current, Mon Oct 06 2008, 06:25AM

101111 wrote ...

Why not just make a big solid state variac of SCRs?

because of the problems I mentioned, you could only control voltage, but would have no way to limit the current,Why not just make a big solid state variac of SCRs?

Re: saturable reactor (now water ballast)

Steve Conner, Mon Oct 06 2008, 09:21AM

Use a small ballast choke in series with a SCR controller, then. Same result with less iron, since the ballast only needs the same inductance that the saturable reactor has when saturated. (dr. kV: this is not zero, it's greater than or equal to the inductance of the coils with the core removed)

I'm a big fan of the solid-state variac thing, I've never managed to blow a single SCR with it. Fuses and breakers always seem to pop before the SCRs do. The only drawback I'm aware of is DC offset from uneven firing.

The OP's original diagram is bass ackwards: the AC current must be such as to magnetize the core, and the way he has it, the flux will cancel. The control winding should be two windings out of phase such that the induced EMF from the AC winding cancels. This induced EMF would otherwise be thousands of volts for a reactor with a useful amount of current gain, since this implies more turns on the control windings than the load windings.

By the same token, since all three windings have the same turn count, a reactor made from an old three-phase line reactor will have a current gain of about 2: if you want 40A out, you'll need to put 20A DC at a few volts through the control winding. That's if it works: these line reactors have an airgap to prevent saturation, which is the last thing you want!

If it was me, I'd remove the I part of the core, connect all three coils in series, and just hook it up as a fixed ballast.

Oh and I wouldn't ground the middle of the pig.

Steve Conner, Mon Oct 06 2008, 09:21AM

Use a small ballast choke in series with a SCR controller, then. Same result with less iron, since the ballast only needs the same inductance that the saturable reactor has when saturated. (dr. kV: this is not zero, it's greater than or equal to the inductance of the coils with the core removed)

I'm a big fan of the solid-state variac thing, I've never managed to blow a single SCR with it. Fuses and breakers always seem to pop before the SCRs do. The only drawback I'm aware of is DC offset from uneven firing.

The OP's original diagram is bass ackwards: the AC current must be such as to magnetize the core, and the way he has it, the flux will cancel. The control winding should be two windings out of phase such that the induced EMF from the AC winding cancels. This induced EMF would otherwise be thousands of volts for a reactor with a useful amount of current gain, since this implies more turns on the control windings than the load windings.

By the same token, since all three windings have the same turn count, a reactor made from an old three-phase line reactor will have a current gain of about 2: if you want 40A out, you'll need to put 20A DC at a few volts through the control winding. That's if it works: these line reactors have an airgap to prevent saturation, which is the last thing you want!

If it was me, I'd remove the I part of the core, connect all three coils in series, and just hook it up as a fixed ballast.

Oh and I wouldn't ground the middle of the pig.

Re: saturable reactor (now water ballast)

Bamacoiler, Mon Oct 06 2008, 11:25AM

If your really interested in a saturable reactor, check this out.

Pretty infoormative and it explains how the current is controlled and what kind of turns ratio you need to be looking for.

Bamacoiler, Mon Oct 06 2008, 11:25AM

If your really interested in a saturable reactor, check this out.

Pretty infoormative and it explains how the current is controlled and what kind of turns ratio you need to be looking for.

Re: saturable reactor (now water ballast)

J. Aaron Holmes, Mon Oct 06 2008, 03:24PM

Needless to say, I have a rather low opinion of him and his group! The picture of the "naked" pole pig at the bottom of that page is also an uncredited picture of one of my pole pigs!

Needless to say, I have a rather low opinion of him and his group! The picture of the "naked" pole pig at the bottom of that page is also an uncredited picture of one of my pole pigs!

Anyway, this schematic does work, but it IS dangerous; if you look at what you're actually doing, you're feeding low-voltage DC into the HV windings of MOTs under power, and you're counting on their high voltages to cancel out. This will never quite happen, so your control needs to be designed with this in mind. For example, isolation on the AC line feeding the control is a good idea, as is transient voltage suppression on the control. And don't forget a long plastic handle on that variac!

Since proposing this idea I haven't tried scaling it up, but the third schematic in the following image is where I'd intended to go:

http://silicon-arcana.com/MMSR.gif

Note that the pig neutral is connected to the AC line neutral, and the 120V legs are controlled by separate banks of MOTs which are subject to the same control source. One advantage I see with this arrangement is that the even distribution of voltage across the transformer's LV windings would (I think) serve to somewhat limit the degree to which the "error" in the MOT HV windings would accumulate, hopefully limiting the amount of AC seen at the control. Plus, it just gave me a warm, fuzzy feeling inside to think that I could actually connect the neutral instead of letting it float, but that also could have been a premonition of being electrocuted

If you try this, BE EXTREEEEEMELY CAREFUL!! You MUST regard the control side as dangerous and take precautions.

Cheers,

Aaron, N7OE

EDIT: I should add, I suppose, that the reason why I never proceeded to implement a large-scale version of this is that I decided other methods were easier and safer. Slide chokes, for example, are easy to build. And, despite their lossiness, I am actually a big fan of resistor ballasts, having built one with little more than a garbage can full of water and a few PVC and copper pipes. Sure, it heats up, but man is it smoooooth. Slide chokes can be almost as easy to build. Just put a few hundred turns of #6 on some six-inch PVC and throw a few bundles of ceiling wire in there. Remove or add bundles as needed for more/less current. Lots of people agonize over what to use for the core material until they ultimately give up. Just toss some wire or welding rods or whatever in there. It'll heat up a little, but who cares; you're not going to run the thing 24x7!

J. Aaron Holmes, Mon Oct 06 2008, 03:24PM

Bamacoiler wrote ...

If your really interested in a saturable reactor, check this out.

Pretty infoormative and it explains how the current is controlled and what kind of turns ratio you need to be looking for.

Yes, the page you reference was made by Carl Litton of the Memphis HV Group, who posted this idea after I suggested he try it and then decided not to credit me when he discovered that it worked If your really interested in a saturable reactor, check this out.

Pretty infoormative and it explains how the current is controlled and what kind of turns ratio you need to be looking for.

Needless to say, I have a rather low opinion of him and his group! The picture of the "naked" pole pig at the bottom of that page is also an uncredited picture of one of my pole pigs!

Needless to say, I have a rather low opinion of him and his group! The picture of the "naked" pole pig at the bottom of that page is also an uncredited picture of one of my pole pigs!

Anyway, this schematic does work, but it IS dangerous; if you look at what you're actually doing, you're feeding low-voltage DC into the HV windings of MOTs under power, and you're counting on their high voltages to cancel out. This will never quite happen, so your control needs to be designed with this in mind. For example, isolation on the AC line feeding the control is a good idea, as is transient voltage suppression on the control. And don't forget a long plastic handle on that variac!

Since proposing this idea I haven't tried scaling it up, but the third schematic in the following image is where I'd intended to go:

http://silicon-arcana.com/MMSR.gif

Note that the pig neutral is connected to the AC line neutral, and the 120V legs are controlled by separate banks of MOTs which are subject to the same control source. One advantage I see with this arrangement is that the even distribution of voltage across the transformer's LV windings would (I think) serve to somewhat limit the degree to which the "error" in the MOT HV windings would accumulate, hopefully limiting the amount of AC seen at the control. Plus, it just gave me a warm, fuzzy feeling inside to think that I could actually connect the neutral instead of letting it float, but that also could have been a premonition of being electrocuted

If you try this, BE EXTREEEEEMELY CAREFUL!! You MUST regard the control side as dangerous and take precautions.

Cheers,

Aaron, N7OE

EDIT: I should add, I suppose, that the reason why I never proceeded to implement a large-scale version of this is that I decided other methods were easier and safer. Slide chokes, for example, are easy to build. And, despite their lossiness, I am actually a big fan of resistor ballasts, having built one with little more than a garbage can full of water and a few PVC and copper pipes. Sure, it heats up, but man is it smoooooth. Slide chokes can be almost as easy to build. Just put a few hundred turns of #6 on some six-inch PVC and throw a few bundles of ceiling wire in there. Remove or add bundles as needed for more/less current. Lots of people agonize over what to use for the core material until they ultimately give up. Just toss some wire or welding rods or whatever in there. It'll heat up a little, but who cares; you're not going to run the thing 24x7!

Re: saturable reactor (now water ballast)

teslacoolguy, Mon Oct 06 2008, 06:16PM

well seeing how difficult it may be to make the saturable reactor from that particular reactor i am starting to shift my ideas to a water ballast or a slide choke ballast. can you elaborate on how you made the water ballast? size of trash can, size of electrodes, or any other thing that i may need to know. as a more permanent solution when i can get my hands on some #6 wire i will probably make a slide choke ballast but for right now just drawing arcs, i think a water ballast will do.

teslacoolguy, Mon Oct 06 2008, 06:16PM

J. Aaron Holmes wrote ...

EDIT: I should add, I suppose, that the reason why I never proceeded to implement a large-scale version of this is that I decided other methods were easier and safer. Slide chokes, for example, are easy to build. And, despite their lossiness, I am actually a big fan of resistor ballasts, having built one with little more than a garbage can full of water and a few PVC and copper pipes. Sure, it heats up, but man is it smoooooth. Slide chokes can be almost as easy to build. Just put a few hundred turns of #6 on some six-inch PVC and throw a few bundles of ceiling wire in there. Remove or add bundles as needed for more/less current. Lots of people agonize over what to use for the core material until they ultimately give up. Just toss some wire or welding rods or whatever in there. It'll heat up a little, but who cares; you're not going to run the thing 24x7!

EDIT: I should add, I suppose, that the reason why I never proceeded to implement a large-scale version of this is that I decided other methods were easier and safer. Slide chokes, for example, are easy to build. And, despite their lossiness, I am actually a big fan of resistor ballasts, having built one with little more than a garbage can full of water and a few PVC and copper pipes. Sure, it heats up, but man is it smoooooth. Slide chokes can be almost as easy to build. Just put a few hundred turns of #6 on some six-inch PVC and throw a few bundles of ceiling wire in there. Remove or add bundles as needed for more/less current. Lots of people agonize over what to use for the core material until they ultimately give up. Just toss some wire or welding rods or whatever in there. It'll heat up a little, but who cares; you're not going to run the thing 24x7!

well seeing how difficult it may be to make the saturable reactor from that particular reactor i am starting to shift my ideas to a water ballast or a slide choke ballast. can you elaborate on how you made the water ballast? size of trash can, size of electrodes, or any other thing that i may need to know. as a more permanent solution when i can get my hands on some #6 wire i will probably make a slide choke ballast but for right now just drawing arcs, i think a water ballast will do.

Re: saturable reactor (now water ballast)

J. Aaron Holmes, Mon Oct 06 2008, 10:48PM

Eventually, the copper oxidizes a bit and the pipes and water become greenish in color. This didn't seem to impact performance too much. In fact, I didn't discard the water until things started growing in it

Anyway, more later!

Cheers,

Aaron, N7OE

J. Aaron Holmes, Mon Oct 06 2008, 10:48PM

teslacoolguy wrote ...

can you elaborate on how you made the water ballast?

Certainly. I wish I had some good photos of mine to share. It's been in pieces since I moved last year, but I'll try to whip up a diagram of it and post it here later tonight. It's really very, very simple. Nothing is too critical; I just made it all up as I went. There are two copper pipes held in parallel and immersed in a plastic garbage can full of water. One pipe has a PVC sleeve over it that slides up and down, allowing more or less of that particular pipe to be exposed to open water. My garbage can was ~40gal, I think, but I'll check when I get home. Anyway, after building the copper pipe assembly and filling the can with water, I just added baking soda until the maximum current was what I wanted it to be: About 40A at 240V. Since conduction begins at the bottom of the assembly when the PVC sleeve is raised, convection currents make very efficient use of the total water volume in the can, heating it uniformly. Thus, for longer runs, the design should scale well (i.e., get a bigger can and/or use more water). I was actually thinking that the next one of these I build will use multiple pipe pairs wired in parallel so that the heat production is more distributed, and also so that less doping of the water (with baking soda) is required.can you elaborate on how you made the water ballast?

Eventually, the copper oxidizes a bit and the pipes and water become greenish in color. This didn't seem to impact performance too much. In fact, I didn't discard the water until things started growing in it

Anyway, more later!

Cheers,

Aaron, N7OE

Re: saturable reactor (now water ballast)

Coronafix, Tue Oct 07 2008, 02:41AM

I've always seen the slide choke as probably the easiest to control the current.

I've seen some ugly ones around (big and bulky), but I reckon with a bit of creativity

it shouldn't be too hard to make it into a practical design.

Coronafix, Tue Oct 07 2008, 02:41AM

I've always seen the slide choke as probably the easiest to control the current.

I've seen some ugly ones around (big and bulky), but I reckon with a bit of creativity

it shouldn't be too hard to make it into a practical design.

Re: saturable reactor (now water ballast)

J. Aaron Holmes, Tue Oct 07 2008, 04:26AM

Here's an illustration of my water ballast that takes maximum advantage of my feeble Paint skills This illustration does not attempt to show the support structure that holds the pair of pipes in the center of the garbage can, as that would have made the picture too complicated.

This illustration does not attempt to show the support structure that holds the pair of pipes in the center of the garbage can, as that would have made the picture too complicated.

This worked well for me. However it wasn't a very safe design. For one, the fact that the copper pipes tower above the garbage can is a hazard; they may fall over, and you'd better not be in their way! One solution might be to find a way to hold the pipes in parallel by the bottom ends only, leaving the top ends unconnected and completely under water. I have a few ideas for that, and that's my next design. Another approach might be to make the PVC sleeve slotted on one side so that instead of raising/lowering it, you rotate it (the copper may then be attached at both ends, but needn't extend above the water). This latter approach would probably give up some of the range that the former method has, and then you also loose the advantage that, with the former method, gravity is naturally trying to turn the power down. So I like the raise/lower idea best.

One thing I forgot to draw in the picture is an end cap on the control handle. Good measure to guard against the possibility that water works its way up in there. PVC fittings are all PVC-welded together.

Anyway, hopefully this has at least served to illustrate how the water ballast works. There is plenty of room for improvement and/or experimentation, however.

Cheers,

Aaron, N7OE

J. Aaron Holmes, Tue Oct 07 2008, 04:26AM

Here's an illustration of my water ballast that takes maximum advantage of my feeble Paint skills

This illustration does not attempt to show the support structure that holds the pair of pipes in the center of the garbage can, as that would have made the picture too complicated.

This illustration does not attempt to show the support structure that holds the pair of pipes in the center of the garbage can, as that would have made the picture too complicated.This worked well for me. However it wasn't a very safe design. For one, the fact that the copper pipes tower above the garbage can is a hazard; they may fall over, and you'd better not be in their way! One solution might be to find a way to hold the pipes in parallel by the bottom ends only, leaving the top ends unconnected and completely under water. I have a few ideas for that, and that's my next design. Another approach might be to make the PVC sleeve slotted on one side so that instead of raising/lowering it, you rotate it (the copper may then be attached at both ends, but needn't extend above the water). This latter approach would probably give up some of the range that the former method has, and then you also loose the advantage that, with the former method, gravity is naturally trying to turn the power down. So I like the raise/lower idea best.

One thing I forgot to draw in the picture is an end cap on the control handle. Good measure to guard against the possibility that water works its way up in there. PVC fittings are all PVC-welded together.

Anyway, hopefully this has at least served to illustrate how the water ballast works. There is plenty of room for improvement and/or experimentation, however.

Cheers,

Aaron, N7OE

Re: saturable reactor (now water ballast)

Mates, Tue Oct 07 2008, 08:45AM

That's really good idea... I will have a use for such device, but I will switch to stainless steel to avoid any additive unwanted chemical reactions in the basket...

Thanks...

Mates, Tue Oct 07 2008, 08:45AM

J. Aaron Holmes wrote ...

Here's an illustration of my water ballast that takes maximum advantage of my feeble Paint skills This illustration does not attempt to show the support structure that holds the pair of pipes in the center of the garbage can, as that would have made the picture too complicated.

This illustration does not attempt to show the support structure that holds the pair of pipes in the center of the garbage can, as that would have made the picture too complicated.

Here's an illustration of my water ballast that takes maximum advantage of my feeble Paint skills

This illustration does not attempt to show the support structure that holds the pair of pipes in the center of the garbage can, as that would have made the picture too complicated.

This illustration does not attempt to show the support structure that holds the pair of pipes in the center of the garbage can, as that would have made the picture too complicated.That's really good idea... I will have a use for such device, but I will switch to stainless steel to avoid any additive unwanted chemical reactions in the basket...

Thanks...

Re: saturable reactor (now water ballast)

J. Aaron Holmes, Tue Oct 07 2008, 10:22AM

Cheers,

Aaron, N7OE

J. Aaron Holmes, Tue Oct 07 2008, 10:22AM

Mates wrote ...

I will switch to stainless steel to avoid any additive

Yeah, that would probably be goodness! If I find some available inexpensively, I'll have to give that a shot as well. Cheapness being a major goal here, however, I start to wonder as soon as real money gets involved. Of course, if your purpose is something other than a ballast, the "cost" argument may or may not apply.I will switch to stainless steel to avoid any additive

Cheers,

Aaron, N7OE

Re: saturable reactor (now water ballast)

teslacoolguy, Tue Oct 07 2008, 03:50PM

Ok thanks for all the help. I will start making the ballast after i do my schoolwork but i have one last question. How far are the electrodes spaced apart? I am also assuming that you are using standard 1/2" copper pipe as the electrodes and i am also assuming that the further the plastic pipe is out of the water the more current it lets through?

teslacoolguy, Tue Oct 07 2008, 03:50PM

Ok thanks for all the help. I will start making the ballast after i do my schoolwork but i have one last question. How far are the electrodes spaced apart? I am also assuming that you are using standard 1/2" copper pipe as the electrodes and i am also assuming that the further the plastic pipe is out of the water the more current it lets through?

Re: saturable reactor (now water ballast)

J. Aaron Holmes, Tue Oct 07 2008, 04:04PM

And yes, up = more current, down = less.

Cheers,

Aaron, N7OE

J. Aaron Holmes, Tue Oct 07 2008, 04:04PM

teslacoolguy wrote ...

How far are the electrodes spaced apart?

It's not critical. Mine were probably 3/8" apart or something close. I never measured and didn't figure it much mattered. Just do whatever is convenient given the materials you manage to find, and if the conductivity isn't what you want, just dope with more baking soda and it will be ok. If you build what I have illustrated (again, one of a zillion ways to build such a device!), then the minimum separation will be dictated by the outer diameter of the PVC tee joint. You probably don't want the spacing to be too tight, or else the control handle won't slide easily up and down.How far are the electrodes spaced apart?

And yes, up = more current, down = less.

Cheers,

Aaron, N7OE

Re: saturable reactor (now water ballast)

Myke, Wed Oct 08 2008, 12:39AM

I would assume that the water would heat more evenly if the electrodes were spaced farther apart. You don't want water that's too hot in one area I suppose.

Myke, Wed Oct 08 2008, 12:39AM

I would assume that the water would heat more evenly if the electrodes were spaced farther apart. You don't want water that's too hot in one area I suppose.

Re: saturable reactor (now water ballast)

J. Aaron Holmes, Wed Oct 08 2008, 01:11AM

Cheers,

Aaron, N7OE

J. Aaron Holmes, Wed Oct 08 2008, 01:11AM

Myke wrote ...

I would assume that the water would heat more evenly if the electrodes were spaced farther apart. You don't want water that's too hot in one area I suppose.

Not really. The heat production would be more diffuse, but convection currents develop very quickly and result in nice even heating of the whole water volume. That's because conduction generally occurs near the bottom of the can. It would be a different story if you were to lower parallel electrodes into the water, starting conduction at the top. In that case, the water volume in the lower regions of the can wouldn't be buying you much.I would assume that the water would heat more evenly if the electrodes were spaced farther apart. You don't want water that's too hot in one area I suppose.

Cheers,

Aaron, N7OE

Re: saturable reactor (now water ballast)

teslacoolguy, Fri Oct 10 2008, 01:17AM

Today i got around to making the copper pipe assembly and tomorrow i will finish the base that will be submerged to the bottom of thr trash can and then i have to figure out how to connect the 2 pipes to wires. I cant really put connectors on there because they are to close together so any suggestions would be appereciated. Also seeing that this is becoming more of a project can a mod please transfer it to the projects section?

teslacoolguy, Fri Oct 10 2008, 01:17AM

Today i got around to making the copper pipe assembly and tomorrow i will finish the base that will be submerged to the bottom of thr trash can and then i have to figure out how to connect the 2 pipes to wires. I cant really put connectors on there because they are to close together so any suggestions would be appereciated. Also seeing that this is becoming more of a project can a mod please transfer it to the projects section?

Re: saturable reactor (now water ballast)

rp181, Fri Oct 10 2008, 01:21AM

put two copper 90 degree bends, put a flatned pipe in it.

rp181, Fri Oct 10 2008, 01:21AM

put two copper 90 degree bends, put a flatned pipe in it.

Re: saturable reactor (now water ballast)

Coronafix, Fri Oct 10 2008, 01:50AM

You can also separate the electrodes to either side of the bucket and then saturate

the water with copper sulfate.

Coronafix, Fri Oct 10 2008, 01:50AM

You can also separate the electrodes to either side of the bucket and then saturate

the water with copper sulfate.

Re: saturable reactor (now water ballast)

teslacoolguy, Fri Oct 10 2008, 02:00AM

eh... probably but less chemicals = less cost and seeing that it is a use materials that are lying around budget it is not necessary. Also here is a pic of the electrode setup.

teslacoolguy, Fri Oct 10 2008, 02:00AM

eh... probably but less chemicals = less cost and seeing that it is a use materials that are lying around budget it is not necessary. Also here is a pic of the electrode setup.

Re: saturable reactor (now water ballast)

J. Aaron Holmes, Fri Oct 10 2008, 04:14PM

Hey, groovy! Lookin' good. Once it seems to be working, you might do what I *didn't* do, and try to mount some PVC over the top half of the assembly to make it safer. Cut a slot down the side of some larger-diameter PVC so that the handle can slide up and down freely, but so that you don't have all that exposed copper.

...or just conjure your own design that doesn't require having anything extend above the water besides the control handle. I have one in mind that I should draw up and see if it makes any sense. Basically, the idea would be that the conductors would be fixed in place at the bottom of the can much as they are in the above design, but would be held together at the top only by the control sleeve, which in addition to the long section in the design above, would have another "mini sleeve" that would go around the second pipe just to hold them together. Don't know if I did a good job explaining that. As usual, a picture is worth a zillion (or so) words.

Cheers,

Aaron, N7OE

J. Aaron Holmes, Fri Oct 10 2008, 04:14PM

Hey, groovy! Lookin' good. Once it seems to be working, you might do what I *didn't* do, and try to mount some PVC over the top half of the assembly to make it safer. Cut a slot down the side of some larger-diameter PVC so that the handle can slide up and down freely, but so that you don't have all that exposed copper.

...or just conjure your own design that doesn't require having anything extend above the water besides the control handle. I have one in mind that I should draw up and see if it makes any sense. Basically, the idea would be that the conductors would be fixed in place at the bottom of the can much as they are in the above design, but would be held together at the top only by the control sleeve, which in addition to the long section in the design above, would have another "mini sleeve" that would go around the second pipe just to hold them together. Don't know if I did a good job explaining that. As usual, a picture is worth a zillion (or so) words.

Cheers,

Aaron, N7OE

Re: saturable reactor (now water ballast)

Bamacoiler, Fri Oct 10 2008, 05:12PM

I would like to see a picture. I have a pig project going if I can ever get it off the ground.

Bamacoiler, Fri Oct 10 2008, 05:12PM

Basically, the idea would be that the conductors would be fixed in place at the bottom of the can much as they are in the above design, but would be held together at the top only by the control sleeve, which in addition to the long section in the design above, would have another "mini sleeve" that would go around the second pipe just to hold them together. Don't know if I did a good job explaining that. As usual, a picture is worth a zillion (or so) words.

I would like to see a picture. I have a pig project going if I can ever get it off the ground.

Re: saturable reactor (now water ballast)

J. Aaron Holmes, Fri Oct 10 2008, 05:33PM

Actually "mini" isn't even required; just imagine two sleeves, one on each pipe, but fastened together so that you're exposing each pipe simultaneously. The only advantage of doing this versus a single sleeve like above is that the sleeves hold the pipes in parallel, so you needn't bolt the pipes together at the top. Then you just need to make sure you can't lift the sleeves above the tops of the pipes, or else they'll do bad things (like fall into each other and cause a short circuit ).

).

In this design, you'd be forced (although that's not necessarily bad) to connect the wires to the bottoms of the pipes instead of the tops.

Cheers,

Aaron, N7OE

EDIT: Ok, first, I found a really crappy video frame showing my old setup. Looks an awful lot like the diagram above, I expect!

Next, here's a diagram showing my proposed "2.0" design. This drawing is far from complete. Explanation below.

In this new version, you see that there are two sleeves bolted together at the top. The only real purpose of two would be to keep the copper pipes in parallel (pretend the copper pipes only run up as high as the surface of the water in this diagram; they are not connected at the top like in the first diagram posted earlier). To keep the whole assembly from tipping over, you'd have to get a little tricky. You'll see in the photo of my v1.0 water ballast that the assembly is held in place at the top by a crossbeam of PVC that's attached to the rim of the can and to the non-sleeved copper pipe. In the v2.0 design, you'd have to run the whole assembly through some kind of collar at the top of the can. It would be tempting to simply use the garbage can's lid with a hole cut in the middle, but more holes might be a good idea if you did that just to make sure the gasses are vented efficiently. The bottom of the assembly would be mounted in the same way as the first (in mine, I just made a cross shape with PVC and fastened it to the bottom of the assembly). In either design, the wires could be connected to the bottom. I used the top in mine only because it was convenient and I was mainly fiddling.

The other trick that needs to be worked out in v2.0 is keeping the operator from raising the control handle too high, which would set the copper pipes loose! A neat way to do that would probaby be to add some protrusion (e.g., bolts) to the sides of one of the control sleeves so that it would stop when it contacted the bottom of the collar that's holding the assembly in the center at the top of the can. I'm sure people can think of other ways, too.

A neat way to do that would probaby be to add some protrusion (e.g., bolts) to the sides of one of the control sleeves so that it would stop when it contacted the bottom of the collar that's holding the assembly in the center at the top of the can. I'm sure people can think of other ways, too.

Obviously, the v1.0 design is easier to build. v2.0 seems a little safer, but put a cover over the top half of the assmebly in v1.0 and it's probably a wash.

Hope this discussion is remaining interesting I feel like I might be babbling a bit...

I feel like I might be babbling a bit...

Cheers,

Aaron, N7OE

J. Aaron Holmes, Fri Oct 10 2008, 05:33PM

Bamacoiler wrote ...

I would like to see a picture. I have a pig project going if I can ever get it off the ground.

Sure. I'll try and draw something tonight.I would like to see a picture. I have a pig project going if I can ever get it off the ground.

Actually "mini" isn't even required; just imagine two sleeves, one on each pipe, but fastened together so that you're exposing each pipe simultaneously. The only advantage of doing this versus a single sleeve like above is that the sleeves hold the pipes in parallel, so you needn't bolt the pipes together at the top. Then you just need to make sure you can't lift the sleeves above the tops of the pipes, or else they'll do bad things (like fall into each other and cause a short circuit

).

).In this design, you'd be forced (although that's not necessarily bad) to connect the wires to the bottoms of the pipes instead of the tops.

Cheers,

Aaron, N7OE

EDIT: Ok, first, I found a really crappy video frame showing my old setup. Looks an awful lot like the diagram above, I expect!

Next, here's a diagram showing my proposed "2.0" design. This drawing is far from complete. Explanation below.

In this new version, you see that there are two sleeves bolted together at the top. The only real purpose of two would be to keep the copper pipes in parallel (pretend the copper pipes only run up as high as the surface of the water in this diagram; they are not connected at the top like in the first diagram posted earlier). To keep the whole assembly from tipping over, you'd have to get a little tricky. You'll see in the photo of my v1.0 water ballast that the assembly is held in place at the top by a crossbeam of PVC that's attached to the rim of the can and to the non-sleeved copper pipe. In the v2.0 design, you'd have to run the whole assembly through some kind of collar at the top of the can. It would be tempting to simply use the garbage can's lid with a hole cut in the middle, but more holes might be a good idea if you did that just to make sure the gasses are vented efficiently. The bottom of the assembly would be mounted in the same way as the first (in mine, I just made a cross shape with PVC and fastened it to the bottom of the assembly). In either design, the wires could be connected to the bottom. I used the top in mine only because it was convenient and I was mainly fiddling.

The other trick that needs to be worked out in v2.0 is keeping the operator from raising the control handle too high, which would set the copper pipes loose!

A neat way to do that would probaby be to add some protrusion (e.g., bolts) to the sides of one of the control sleeves so that it would stop when it contacted the bottom of the collar that's holding the assembly in the center at the top of the can. I'm sure people can think of other ways, too.

A neat way to do that would probaby be to add some protrusion (e.g., bolts) to the sides of one of the control sleeves so that it would stop when it contacted the bottom of the collar that's holding the assembly in the center at the top of the can. I'm sure people can think of other ways, too.Obviously, the v1.0 design is easier to build. v2.0 seems a little safer, but put a cover over the top half of the assmebly in v1.0 and it's probably a wash.

Hope this discussion is remaining interesting

I feel like I might be babbling a bit...

I feel like I might be babbling a bit...Cheers,

Aaron, N7OE

Re: saturable reactor (now water ballast)

teslacoolguy, Sat Oct 11 2008, 11:44PM

Well here is a update on my work. I flattened out some copper pipe and connected it to elbows like rp181 suggested and it made a nice bussbar connector. All the hookup wire is 4awg battery cable i got it for free thanks to my oldest cousin who is a bmw mechanic. Tomorrow i will probably make the base and put everything together for testing on Monday. I am really happy with how it is coming along and i hope it will work well. Here are some pic's of what i got done.

i got it for free thanks to my oldest cousin who is a bmw mechanic. Tomorrow i will probably make the base and put everything together for testing on Monday. I am really happy with how it is coming along and i hope it will work well. Here are some pic's of what i got done.

teslacoolguy, Sat Oct 11 2008, 11:44PM

Well here is a update on my work. I flattened out some copper pipe and connected it to elbows like rp181 suggested and it made a nice bussbar connector. All the hookup wire is 4awg battery cable

i got it for free thanks to my oldest cousin who is a bmw mechanic. Tomorrow i will probably make the base and put everything together for testing on Monday. I am really happy with how it is coming along and i hope it will work well. Here are some pic's of what i got done.

i got it for free thanks to my oldest cousin who is a bmw mechanic. Tomorrow i will probably make the base and put everything together for testing on Monday. I am really happy with how it is coming along and i hope it will work well. Here are some pic's of what i got done.

Re: saturable reactor (now water ballast)

J. Aaron Holmes, Sun Oct 12 2008, 05:41AM

Coolness, I can't wait to see it go! Don't be surprised if you need to add quite a bit of baking soda to get the conductivity of the water up where you want it. I forget how much I had to add, I just remember being surprised!

Don't let those spacers fall out! I can't quite tell how they're held in place, so maybe you're ok; I'm just sayin'!

I can't quite tell how they're held in place, so maybe you're ok; I'm just sayin'!

Looking forward to some arc pics!

Cheers,

Aaron, N7OE

J. Aaron Holmes, Sun Oct 12 2008, 05:41AM

Coolness, I can't wait to see it go! Don't be surprised if you need to add quite a bit of baking soda to get the conductivity of the water up where you want it. I forget how much I had to add, I just remember being surprised!

Don't let those spacers fall out!

I can't quite tell how they're held in place, so maybe you're ok; I'm just sayin'!

I can't quite tell how they're held in place, so maybe you're ok; I'm just sayin'!Looking forward to some arc pics!

Cheers,

Aaron, N7OE

Re: saturable reactor (now water ballast)

Myke, Sun Oct 12 2008, 09:27AM

Looks like there is some black plastic between the pipes. Maybe it's ABS?

Looks cool so far.

I can't wait to see a video.

Myke, Sun Oct 12 2008, 09:27AM

J. Aaron Holmes wrote ...

Don't let those spacers fall out! I can't quite tell how they're held in place, so maybe you're ok; I'm just sayin'!

I can't quite tell how they're held in place, so maybe you're ok; I'm just sayin'!

Don't let those spacers fall out!

I can't quite tell how they're held in place, so maybe you're ok; I'm just sayin'!

I can't quite tell how they're held in place, so maybe you're ok; I'm just sayin'!Looks like there is some black plastic between the pipes. Maybe it's ABS?

Looks cool so far.

I can't wait to see a video.

Re: saturable reactor (now water ballast)

teslacoolguy, Sun Oct 12 2008, 12:04PM

Actually it is just some tinted 1/4" plexi i had laying around. Then as you can see it is clamped down by some clamps i made out of pvc pipe. Before i test it i will probably glue the spacers in just to be safe.

Actually it is just some tinted 1/4" plexi i had laying around. Then as you can see it is clamped down by some clamps i made out of pvc pipe. Before i test it i will probably glue the spacers in just to be safe.

teslacoolguy, Sun Oct 12 2008, 12:04PM

Myke wrote ...

Looks like there is some black plastic between the pipes. Maybe it's ABS?

Looks cool so far.

I can't wait to see a video.

You were close J. Aaron Holmes wrote ...

Don't let those spacers fall out! I can't quite tell how they're held in place, so maybe you're ok; I'm just sayin'!

I can't quite tell how they're held in place, so maybe you're ok; I'm just sayin'!

Don't let those spacers fall out!

I can't quite tell how they're held in place, so maybe you're ok; I'm just sayin'!

I can't quite tell how they're held in place, so maybe you're ok; I'm just sayin'!Looks like there is some black plastic between the pipes. Maybe it's ABS?

Looks cool so far.

I can't wait to see a video.

Actually it is just some tinted 1/4" plexi i had laying around. Then as you can see it is clamped down by some clamps i made out of pvc pipe. Before i test it i will probably glue the spacers in just to be safe.

Actually it is just some tinted 1/4" plexi i had laying around. Then as you can see it is clamped down by some clamps i made out of pvc pipe. Before i test it i will probably glue the spacers in just to be safe.Re: saturable reactor (now water ballast)

Bamacoiler, Sun Oct 12 2008, 01:56PM

Sorry for the dumb question but how is this connected? In series with 1 leg of the pig?

Bamacoiler, Sun Oct 12 2008, 01:56PM

Sorry for the dumb question but how is this connected? In series with 1 leg of the pig?

Re: saturable reactor (now water ballast)

teslacoolguy, Sun Oct 12 2008, 02:30PM

correct, and i also attached a schematic in case anybody would like to build one.

teslacoolguy, Sun Oct 12 2008, 02:30PM

correct, and i also attached a schematic in case anybody would like to build one.

Re: saturable reactor (now water ballast)

teslacoolguy, Tue Oct 14 2008, 07:54PM

BUMP:: It is complete. I had worked on it over the weekend and it is finally complete All i need to do is well.....add water

All i need to do is well.....add water  I am very pleased on how well it came together seeing that i dident have any specific design in mind. Anyway here are some pics of it completed and hopefully after i get a 50A 4 prong dryer plug you will see some amazing arcs.

I am very pleased on how well it came together seeing that i dident have any specific design in mind. Anyway here are some pics of it completed and hopefully after i get a 50A 4 prong dryer plug you will see some amazing arcs.

Be sure to tell me what you think or if tthere is anything that i can improve on the design. Thanks.

teslacoolguy, Tue Oct 14 2008, 07:54PM

BUMP:: It is complete. I had worked on it over the weekend and it is finally complete

All i need to do is well.....add water

All i need to do is well.....add water  I am very pleased on how well it came together seeing that i dident have any specific design in mind. Anyway here are some pics of it completed and hopefully after i get a 50A 4 prong dryer plug you will see some amazing arcs.

I am very pleased on how well it came together seeing that i dident have any specific design in mind. Anyway here are some pics of it completed and hopefully after i get a 50A 4 prong dryer plug you will see some amazing arcs.

Be sure to tell me what you think or if tthere is anything that i can improve on the design. Thanks.

Re: saturable reactor (now water ballast)

J. Aaron Holmes, Tue Oct 14 2008, 08:09PM

Excellent! Looks like you got a good-sized garbage can, too. Bigger than mine. I bet you'll be able to dump 15+kVA or so through there for more than a few mins before it needs a break.

Cheers,

Aaron, N7OE

J. Aaron Holmes, Tue Oct 14 2008, 08:09PM

Excellent! Looks like you got a good-sized garbage can, too. Bigger than mine. I bet you'll be able to dump 15+kVA or so through there for more than a few mins before it needs a break.

Cheers,

Aaron, N7OE

Re: saturable reactor (now water ballast)

Arcstarter, Tue Oct 14 2008, 10:09PM

You COULD get a radiator from the air conditioner of a car and have a dirty water pump pump the water through it and have a fan on the radiator to cool it. I would not use submersible though because i do not trust them, especially when the water is highly conductive, and because i do not know of any submersibles that are dirty water capable.

Arcstarter, Tue Oct 14 2008, 10:09PM

You COULD get a radiator from the air conditioner of a car and have a dirty water pump pump the water through it and have a fan on the radiator to cool it. I would not use submersible though because i do not trust them, especially when the water is highly conductive, and because i do not know of any submersibles that are dirty water capable.

Re: saturable reactor (now water ballast)

rp181, Tue Oct 14 2008, 11:13PM

yay, someone used my idea =) For future referance, when you solder, use WAY more flux, it should be the same color as copper =) It might even affect conductivity

rp181, Tue Oct 14 2008, 11:13PM

yay, someone used my idea =) For future referance, when you solder, use WAY more flux, it should be the same color as copper =) It might even affect conductivity

Re: saturable reactor (now water ballast)

teslacoolguy, Wed Oct 15 2008, 12:42AM

teslacoolguy, Wed Oct 15 2008, 12:42AM

rp181 wrote ...

For future referance, when you solder, use WAY more flux, it should be the same color as copper =) It might even affect conductivity

EH... yea i know. My problem was that i was running out of flux and dident want to run out when i have one connection left. If i have problems ill just take it off and resolder it when i get more flux.For future referance, when you solder, use WAY more flux, it should be the same color as copper =) It might even affect conductivity

Print this page