Preparing High Voltage Oil.

Patrick, Sun Jul 08 2018, 08:07AMDrawing a high vacuum is ideal do de-gas a insulating oil. But can boiling oil accomplish a useful result at least similar? not as good of course.

Re: Preparing High Voltage Oil.

the_anomaly, Sun Jul 08 2018, 01:12PM

Not sure about de-gasing, heating is recommended for brake fluid to remove moisture, I am guessing most oils will release moisture when heated.

Ultrasound can be used to help de-gas, it is used at least for heavy potting compounds. I don't believe anything other than a high vacuum will be very effective.

the_anomaly, Sun Jul 08 2018, 01:12PM

Not sure about de-gasing, heating is recommended for brake fluid to remove moisture, I am guessing most oils will release moisture when heated.

Ultrasound can be used to help de-gas, it is used at least for heavy potting compounds. I don't believe anything other than a high vacuum will be very effective.

Re: Preparing High Voltage Oil.

Patrick, Sun Jul 08 2018, 04:06PM

i guess vacuum pumps are getting cheap and i need it for carbon and fiberglass'ing building any way.

I was looking at this one :

with free shipping from Los Angeles.

Patrick, Sun Jul 08 2018, 04:06PM

i guess vacuum pumps are getting cheap and i need it for carbon and fiberglass'ing building any way.

I was looking at this one :

with free shipping from Los Angeles.

Re: Preparing High Voltage Oil.

the_anomaly, Sun Jul 08 2018, 04:58PM

Looks good to me! I found a name brand pump Robinair on craigslist for cheap. I would ask the seller what the fitting size is. 7/16-20 is the standard HVAC fitting. There is a larger fitting size for 1/2 inch hose which is commonly used but I forget its dimensions. I mention the fitting size because if you buy HVAC hoses to connect it, the hoses are mostly standardized. I bought an off brand manifold guage set and the fittings did not match any hoses I had...

the_anomaly, Sun Jul 08 2018, 04:58PM

Looks good to me! I found a name brand pump Robinair on craigslist for cheap. I would ask the seller what the fitting size is. 7/16-20 is the standard HVAC fitting. There is a larger fitting size for 1/2 inch hose which is commonly used but I forget its dimensions. I mention the fitting size because if you buy HVAC hoses to connect it, the hoses are mostly standardized. I bought an off brand manifold guage set and the fittings did not match any hoses I had...

Re: Preparing High Voltage Oil.

Sulaiman, Sun Jul 08 2018, 07:38PM

My pump looks like it came from the same factory as yours (China)

- no complaints so far but I hardly use it. It seems fairly rugged.

Mine is the dual-stage version, 0.3 pa, but I can't measure such low pressure.

I have no idea whether or not the internal pumped lubrication helps or not.

The extra low pressure has been of no use to me yet,

but if you are considering vacuum electronics it may be worth the difference.

(that is how I justified the extra cost to myself :)

Be sure to buy extra oil, some for an emergency flush,

some to flush the newly manufactured (in China) precision instrument of any debris.

For short runs you can use small diameter (>=4mm i.d.) tubing,

long runs with large vessels need larger diameters for lower pressures - or a long time

(like trying to change the voltage across a large capacitance via a large resistance)

I changed the HVAC connector on mine for a 1/2" hose connector - I may go larger.

Most of the de-gassing YT videos that I've watched use a single-stage pump

and it should be easily able to evaporate water down to ice.

So I can't recommend 'upgrading' to a dual-stage,

that pup looks good to me.

(no idea if that is the cheapest in your area but the price looks good to me)

Based on other vacuum pumps that I have - most of the noise comes from the exhaust port, (along with a little oil vapour)

So if you can pipe-away the exhaust it will be much quieter.

As I rarely use this type of pump I have not moddifed the exhaust port of mine yet.

Sulaiman, Sun Jul 08 2018, 07:38PM

My pump looks like it came from the same factory as yours (China)

- no complaints so far but I hardly use it. It seems fairly rugged.

Mine is the dual-stage version, 0.3 pa, but I can't measure such low pressure.

I have no idea whether or not the internal pumped lubrication helps or not.

The extra low pressure has been of no use to me yet,

but if you are considering vacuum electronics it may be worth the difference.

(that is how I justified the extra cost to myself :)

Be sure to buy extra oil, some for an emergency flush,

some to flush the newly manufactured (in China) precision instrument of any debris.

For short runs you can use small diameter (>=4mm i.d.) tubing,

long runs with large vessels need larger diameters for lower pressures - or a long time

(like trying to change the voltage across a large capacitance via a large resistance)

I changed the HVAC connector on mine for a 1/2" hose connector - I may go larger.

Most of the de-gassing YT videos that I've watched use a single-stage pump

and it should be easily able to evaporate water down to ice.

So I can't recommend 'upgrading' to a dual-stage,

that pup looks good to me.

(no idea if that is the cheapest in your area but the price looks good to me)

Based on other vacuum pumps that I have - most of the noise comes from the exhaust port, (along with a little oil vapour)

So if you can pipe-away the exhaust it will be much quieter.

As I rarely use this type of pump I have not moddifed the exhaust port of mine yet.

Re: Preparing High Voltage Oil.

Patrick, Sun Jul 08 2018, 09:36PM

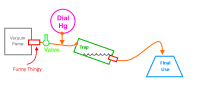

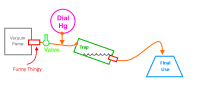

this is my plan :

i was thinking this way its all nice and neat and storable. hose collapse is also something i worry about.

I guess there should be a valve in between the dial and pump ?

Im also looking for collapse resistant hose. all i see on ebay or amazon is the silicone engine vacuum hose, i dont think those are collapse resistant. would normal shop air hose work ? or will that "inhale" external air ?

Patrick, Sun Jul 08 2018, 09:36PM

this is my plan :

i was thinking this way its all nice and neat and storable. hose collapse is also something i worry about.

I guess there should be a valve in between the dial and pump ?

Im also looking for collapse resistant hose. all i see on ebay or amazon is the silicone engine vacuum hose, i dont think those are collapse resistant. would normal shop air hose work ? or will that "inhale" external air ?

Re: Preparing High Voltage Oil.

the_anomaly, Mon Jul 09 2018, 01:50PM

You will need a valve and you have it in the correct spot.

The pump should have a switch on it so you can at least skip that.

I like the idea of a hose rack for storing the hose. Since the pump has a handle, you can bolt it to the skid and just carry the whole unit by the pump maybe.

the_anomaly, Mon Jul 09 2018, 01:50PM

You will need a valve and you have it in the correct spot.

The pump should have a switch on it so you can at least skip that.

I like the idea of a hose rack for storing the hose. Since the pump has a handle, you can bolt it to the skid and just carry the whole unit by the pump maybe.

Re: Preparing High Voltage Oil.

Patrick, Wed Jul 11 2018, 02:32AM

so what do many use for the connections ? im thinking a hose barb with screw hose clamp with the shop hose that is normally pressurized for air-tools ?

Patrick, Wed Jul 11 2018, 02:32AM

so what do many use for the connections ? im thinking a hose barb with screw hose clamp with the shop hose that is normally pressurized for air-tools ?

Re: Preparing High Voltage Oil.

Sulaiman, Wed Jul 11 2018, 04:24AM

Although some plastics (e.g. ptfe) can be porous to gasses,

at the pressure that you will be using it will not be significant.

Tubing that I can use in winter may collapse during the summer.

I am using some very thick walled silicone tubing that I happened to have

but the most popular type is clear braided pvc. e.g.

A little grease on the hose barb gives a good vacuum seal,

hose clamps are not really required as vacuum makes the hose grip the barb.

A vacuum-safe container with some oily stainless steel wool in front of the pump is a really useful item;

. the volume acts as a 'reservoir' of vacuum

. the oily wool catches dust

. the volume can 'catch' any liquid or foam accidentally sucked by the pump

For de-gassing I strongly recommend having the trap,

if needed only once it pays for itself,

and it is not difficult for me to have an accident

Sulaiman, Wed Jul 11 2018, 04:24AM

Although some plastics (e.g. ptfe) can be porous to gasses,

at the pressure that you will be using it will not be significant.

Tubing that I can use in winter may collapse during the summer.

I am using some very thick walled silicone tubing that I happened to have

but the most popular type is clear braided pvc. e.g.

A little grease on the hose barb gives a good vacuum seal,

hose clamps are not really required as vacuum makes the hose grip the barb.

A vacuum-safe container with some oily stainless steel wool in front of the pump is a really useful item;

. the volume acts as a 'reservoir' of vacuum

. the oily wool catches dust

. the volume can 'catch' any liquid or foam accidentally sucked by the pump

For de-gassing I strongly recommend having the trap,

if needed only once it pays for itself,

and it is not difficult for me to have an accident

Re: Preparing High Voltage Oil.

Patrick, Fri Jul 13 2018, 12:20AM

ok Sulaiman i will be following those bits of advise. Ill add a trap-tank too.

Now how long do i hold an ultra low vacuum on permanent transformer oil, and two part epoxy ? 2 minutes ? 2 hours, 2 days ?

ill degas the A and B parts seperate, then mix with out bubbles (sort-of) then degas mixed for like 20 minuets (75-90 pot life) then start to pour or toss in the dry transformer, and let the vacuum in.

does this sound good ?

Patrick, Fri Jul 13 2018, 12:20AM

ok Sulaiman i will be following those bits of advise. Ill add a trap-tank too.

Now how long do i hold an ultra low vacuum on permanent transformer oil, and two part epoxy ? 2 minutes ? 2 hours, 2 days ?

ill degas the A and B parts seperate, then mix with out bubbles (sort-of) then degas mixed for like 20 minuets (75-90 pot life) then start to pour or toss in the dry transformer, and let the vacuum in.

does this sound good ?

Re: Preparing High Voltage Oil.

klugesmith, Fri Jul 13 2018, 01:11AM

I've got spiral-reinforced vacuum hose available for the cost of shipping.

And know that when industrial pad-mounted transformers are vacuum potted,

they evacuate the chamber without oil. Then admit dry, degassed oil into the vacuum. This is better than putting in the oil first, then expecting all tiny bubbles to escape just because they expand under partial vacuum. (High vacuum is impossible under oil, unless you turn off the gravity. Even then, the internal pressure & expansion ratio of gas bubbles would be limited by surface tension of the oil).

For simply applying vacuum to oil, it's silly to aim for vacuum pressure lower than the hydrostatic pressure at the bottom of whatever depth of oil is in your container. A few torr?

klugesmith, Fri Jul 13 2018, 01:11AM

I've got spiral-reinforced vacuum hose available for the cost of shipping.

And know that when industrial pad-mounted transformers are vacuum potted,

they evacuate the chamber without oil. Then admit dry, degassed oil into the vacuum. This is better than putting in the oil first, then expecting all tiny bubbles to escape just because they expand under partial vacuum. (High vacuum is impossible under oil, unless you turn off the gravity. Even then, the internal pressure & expansion ratio of gas bubbles would be limited by surface tension of the oil).

For simply applying vacuum to oil, it's silly to aim for vacuum pressure lower than the hydrostatic pressure at the bottom of whatever depth of oil is in your container. A few torr?

Re: Preparing High Voltage Oil.

Ash Small, Fri Jul 13 2018, 04:52PM

I'd reccomend an old Welch roughing pump your side of the pond, the older belt driven ones are pretty simple to maintain.

If you use a chamber with a window (I designed one once that was cylindrical steel, with a plate welded on one end, with a 1/2" thick perspex or similar window in the top), you can see when it stops bubbling.

You can buy 'L' shaped rubber seals for bell jars, they stretch, so you need a steel tube slightly larger than the nominal seal size.

There's a recent thread here somewhere where John F advises using a glass storage jar as a bell jar. Always best to use a perspex or similar safety screen, although I've even used a cracked bell jar without incident. As the crack enlarged, it started leaking more.

Ash Small, Fri Jul 13 2018, 04:52PM

I'd reccomend an old Welch roughing pump your side of the pond, the older belt driven ones are pretty simple to maintain.

If you use a chamber with a window (I designed one once that was cylindrical steel, with a plate welded on one end, with a 1/2" thick perspex or similar window in the top), you can see when it stops bubbling.

You can buy 'L' shaped rubber seals for bell jars, they stretch, so you need a steel tube slightly larger than the nominal seal size.

There's a recent thread here somewhere where John F advises using a glass storage jar as a bell jar. Always best to use a perspex or similar safety screen, although I've even used a cracked bell jar without incident. As the crack enlarged, it started leaking more.

Re: Preparing High Voltage Oil.

Patrick, Sat Jul 14 2018, 04:31AM

ok take a look at the series of elements.

some trains from Dad too.

there is that mysterous thing. i'd like to change it to FIP or something, not compression and not flare. but that thing looks important.

Patrick, Sat Jul 14 2018, 04:31AM

ok take a look at the series of elements.

some trains from Dad too.

there is that mysterous thing. i'd like to change it to FIP or something, not compression and not flare. but that thing looks important.

Re: Preparing High Voltage Oil.

2Spoons, Sat Jul 14 2018, 06:10AM

I disagree. Oil by itself in a container will allow both diffusion and convection to occur - so any water deep in the oil will eventually make its way to the surface and evaporate. Though obviously this will happen faster in a wide shallow container.

What you don't want to do is go below the vapor pressure of the oil - or it will boil off and contaminate your vacuum pump oil. Which will then limit your ultimate vacuum when you try to use the pump for other things.

That 'funny thing' looks like it might be a valve meant to stop pump oil getting back into the evacuated system.

2Spoons, Sat Jul 14 2018, 06:10AM

klugesmith wrote ...

For simply applying vacuum to oil, it's silly to aim for vacuum pressure lower than the hydrostatic pressure at the bottom of whatever depth of oil is in your container. A few torr?

For simply applying vacuum to oil, it's silly to aim for vacuum pressure lower than the hydrostatic pressure at the bottom of whatever depth of oil is in your container. A few torr?

I disagree. Oil by itself in a container will allow both diffusion and convection to occur - so any water deep in the oil will eventually make its way to the surface and evaporate. Though obviously this will happen faster in a wide shallow container.

What you don't want to do is go below the vapor pressure of the oil - or it will boil off and contaminate your vacuum pump oil. Which will then limit your ultimate vacuum when you try to use the pump for other things.

That 'funny thing' looks like it might be a valve meant to stop pump oil getting back into the evacuated system.

Re: Preparing High Voltage Oil.

the_anomaly, Sat Jul 14 2018, 12:43PM

For epoxy you might have a hard time degassing if the viscosity is much higher than water/oil. I used a thermal epoxy with a CPS around 30,000 which gave dismal performance after vacuum. We cut a side view of the bond and looking under a microscope, I saw lots of voids still. I've used 15 mins under vacuum and had good results with oil.

One thing I have wanted to try is using an old cell phone vibrator motor. It's not the same as ultrasound but I wonder if its vibration would be enough to aid degassing/mixing.

the_anomaly, Sat Jul 14 2018, 12:43PM

For epoxy you might have a hard time degassing if the viscosity is much higher than water/oil. I used a thermal epoxy with a CPS around 30,000 which gave dismal performance after vacuum. We cut a side view of the bond and looking under a microscope, I saw lots of voids still. I've used 15 mins under vacuum and had good results with oil.

One thing I have wanted to try is using an old cell phone vibrator motor. It's not the same as ultrasound but I wonder if its vibration would be enough to aid degassing/mixing.

Re: Preparing High Voltage Oil.

Patrick, Sat Jul 14 2018, 09:53PM

Patrick, Sat Jul 14 2018, 09:53PM

the_anomaly wrote ...

For epoxy you might have a hard time degassing if the viscosity is much higher than water/oil.

Its water thin.For epoxy you might have a hard time degassing if the viscosity is much higher than water/oil.

Re: Preparing High Voltage Oil.

ConKbot of Doom, Tue Jul 17 2018, 04:39PM

Definitely mind your hose ID as the flow rate on the vacuum side is pretty much constant, and with a small hose, the pressure drop can limit your ultimate vacuum more than you'd imagine, so a gauge mounted on the pump skid may show a nice low pressure, when the transformer tank is still at the vapor pressure of the water, misleading you to think your oil has dried out.

So at 1-2 CFM that a nice belt drive rotary vane can move, trying to keep your pressure drop at a few millibar/torr/unit-of-choice you end up with 1/2"-1"ID wire reinforced hose.

For drying operations, keep the gas ballast open to reduce pump oil water contamination, and mind your exhaust, which will have a lovely oil mist.

ConKbot of Doom, Tue Jul 17 2018, 04:39PM

Ash Small wrote ...

I'd reccomend an old Welch roughing pump your side of the pond, the older belt driven ones are pretty simple to maintain.

Seconded on the belt drive Welch pumps. I've had a 20+ year old one at work used for degassing epoxy spit out a wad of dried epoxy when using something with high solvent content. Apparently years back before I even worked there it had ingested some epoxy that had overflowed and just kept on going. I'd reccomend an old Welch roughing pump your side of the pond, the older belt driven ones are pretty simple to maintain.

Definitely mind your hose ID as the flow rate on the vacuum side is pretty much constant, and with a small hose, the pressure drop can limit your ultimate vacuum more than you'd imagine, so a gauge mounted on the pump skid may show a nice low pressure, when the transformer tank is still at the vapor pressure of the water, misleading you to think your oil has dried out.

So at 1-2 CFM that a nice belt drive rotary vane can move, trying to keep your pressure drop at a few millibar/torr/unit-of-choice you end up with 1/2"-1"ID wire reinforced hose.

For drying operations, keep the gas ballast open to reduce pump oil water contamination, and mind your exhaust, which will have a lovely oil mist.

Re: Preparing High Voltage Oil.

Patrick, Thu Jul 19 2018, 04:47AM

pics

Here we see the string of tubes valve and ball valve.

Pretty strong it seems, i like small robust modular "pull it out of storage and use it" solutions. I dont like chasing components all over the place.

I think this shows it pretty well,

The vacuum trap at an angle. Im going to make a label that says "Vacuum trap, Not a bomb." and put it on that pipe side. or i can sew together a canvas tube-like bag that has two holes.

Im wondering if i can make an oil exhaust trap with cloth and a open pipe end, like one of those tiny 2-cycle pocket bike exhausts. Its an open ended pipe with no restriction, just has cloth around the length and ID of the pipe. The guage is just to reveal the presence of near or zero pressure or atmopsheric pressure or what not. many experiments may only need like 1/3 of an atmosphere or whatever, this will be use for many things not just super low pressure. obviously the guage of this quality (12$) doest show the real low pressure stuff.

Patrick, Thu Jul 19 2018, 04:47AM

pics

Here we see the string of tubes valve and ball valve.

Pretty strong it seems, i like small robust modular "pull it out of storage and use it" solutions. I dont like chasing components all over the place.

I think this shows it pretty well,

The vacuum trap at an angle. Im going to make a label that says "Vacuum trap, Not a bomb." and put it on that pipe side. or i can sew together a canvas tube-like bag that has two holes.

Im wondering if i can make an oil exhaust trap with cloth and a open pipe end, like one of those tiny 2-cycle pocket bike exhausts. Its an open ended pipe with no restriction, just has cloth around the length and ID of the pipe. The guage is just to reveal the presence of near or zero pressure or atmopsheric pressure or what not. many experiments may only need like 1/3 of an atmosphere or whatever, this will be use for many things not just super low pressure. obviously the guage of this quality (12$) doest show the real low pressure stuff.

ConKbot of Doom wrote ...

....keep the gas ballast open to reduce pump oil water contamination...

i dont know what this means, please elaborate. Ive read some simple articles.....keep the gas ballast open to reduce pump oil water contamination...

Re: Preparing High Voltage Oil.

Patrick, Sun Aug 19 2018, 07:54PM

ok i solved the compression MIP FIP fiasco.

I milled the original end off, opened up the threaded end to a tight fit, milled the barbed end down to a tight fit and then pressed the two together with "no clean" flux. removing the plastic end i then soldered the two together then fully air-tight i then cleaned it thoroughly with acetone. i then used aircraft epoxy with added glass microfiber to mechanically prevent the barbed end from breaking off if its hit by something.

i reassembled it and it seems to work well, better than a long string of magic conversion pieces.

Patrick, Sun Aug 19 2018, 07:54PM

ok i solved the compression MIP FIP fiasco.

I milled the original end off, opened up the threaded end to a tight fit, milled the barbed end down to a tight fit and then pressed the two together with "no clean" flux. removing the plastic end i then soldered the two together then fully air-tight i then cleaned it thoroughly with acetone. i then used aircraft epoxy with added glass microfiber to mechanically prevent the barbed end from breaking off if its hit by something.

i reassembled it and it seems to work well, better than a long string of magic conversion pieces.

Re: Preparing High Voltage Oil.

vircator, Sat Aug 25 2018, 08:23AM

What kind of oil do you guys use for HV application and from where did you get it? I have several big capacitors in need for a refill.

vircator, Sat Aug 25 2018, 08:23AM

What kind of oil do you guys use for HV application and from where did you get it? I have several big capacitors in need for a refill.

Re: Preparing High Voltage Oil.

Patrick, Sat Aug 25 2018, 06:25PM

Canola oil clear for transform and caps, and clear olive oil for instruments like high frequency probes.

Patrick, Sat Aug 25 2018, 06:25PM

Canola oil clear for transform and caps, and clear olive oil for instruments like high frequency probes.

Re: Preparing High Voltage Oil.

johnf, Sun Aug 26 2018, 04:49AM

Why not go to shell and buy some Diala high voltage oil

Here in NZ I pay US$0.75 per liter for it in 20 liter lots

johnf, Sun Aug 26 2018, 04:49AM

Why not go to shell and buy some Diala high voltage oil

Here in NZ I pay US$0.75 per liter for it in 20 liter lots

Re: Preparing High Voltage Oil.

Patrick, Sun Aug 26 2018, 05:48PM

yes but i dont want hydrocarbon oil, and for our purposes i find little difference in oils so long as they dont have a green clorophyll color left in them. Dont use corn oil. it turns to garbage in a few weeks.

Many HV companies are moving to soy bean oil for 20 gal to 300 gal tank transformers.

20 liters is quite a large volume what do you use it for ?

Patrick, Sun Aug 26 2018, 05:48PM

yes but i dont want hydrocarbon oil, and for our purposes i find little difference in oils so long as they dont have a green clorophyll color left in them. Dont use corn oil. it turns to garbage in a few weeks.

Many HV companies are moving to soy bean oil for 20 gal to 300 gal tank transformers.

20 liters is quite a large volume what do you use it for ?

Re: Preparing High Voltage Oil.

johnf, Sun Aug 26 2018, 07:55PM

It is used in my SEM high voltage tank (70kV)

johnf, Sun Aug 26 2018, 07:55PM

It is used in my SEM high voltage tank (70kV)

Re: Preparing High Voltage Oil.

vircator, Tue Aug 28 2018, 08:46AM

Thank you for pointing me to Diala johnf. I found a local supplier. It's cheeper than many food oils and is specifically designed for HV applications and has good aging properties.

vircator, Tue Aug 28 2018, 08:46AM

Thank you for pointing me to Diala johnf. I found a local supplier. It's cheeper than many food oils and is specifically designed for HV applications and has good aging properties.

Re: Preparing High Voltage Oil.

Nickel, Mon Feb 04 2019, 10:00AM

For the vacuum pump, a cheap experiment would be to connect two old scrap refrigerator compressors in sequence. This can get you quite a low absolute pressure at minimum cost, before you commit $zillions to a professional unit.

(We use them on my local miniature railway to provide vacuum to operate switches and points remotely.)

Nickel, Mon Feb 04 2019, 10:00AM

For the vacuum pump, a cheap experiment would be to connect two old scrap refrigerator compressors in sequence. This can get you quite a low absolute pressure at minimum cost, before you commit $zillions to a professional unit.

(We use them on my local miniature railway to provide vacuum to operate switches and points remotely.)

Re: Preparing High Voltage Oil.

Patrick, Tue Feb 05 2019, 05:58AM

it was 59$ for the pump, $40 for the plumbing, with zero risk of leaks from brazing, and contamination from refrigerant im happy. besides i make a lot of carbon fiber.

Patrick, Tue Feb 05 2019, 05:58AM

it was 59$ for the pump, $40 for the plumbing, with zero risk of leaks from brazing, and contamination from refrigerant im happy. besides i make a lot of carbon fiber.

Print this page