ETG trigger

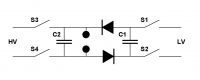

Ash Small, Mon Apr 21 2014, 05:05PMI had an idea for an ETG trigger mechanism, and after checking that stud diodes are available from Ebay for a few £'s each, with free postage, that are rated for 1200V and ~10,000Amps for <10mS, I sketched the circuit below:

C1 is a capacitor bank (electrolytics?), diodes are strings of the above, string length depends on breakdown voltage of 'spark gap'. C2 is a small value high voltage capacitor.

When switches S1 and S2 are closed, both capacitors charge up to the 'low voltage' supply voltage, then S1 and S2 are opened.

When switches S3 and S4 are closed, C2 charges up until breakdown voltage of the spark gap is reached, and C2 discharges through the spark gap. When C2 discharges, initiating breakdown, C1 is able to discharge through the spark gap, creating a 'HUGE' spark.

Can anyone see any problems with this idea? I realise I may want to add a resistor to the HV supply line. Any other reccomendations? Any other comments will be appreciated.

Re: ETG trigger

Steve Conner, Mon Apr 21 2014, 06:28PM

There is no fundamental problem with it, other than conduction losses in the diodes and the risk of blowing them up.

You might also like to try a setup like a high pressure arc lamp ignitor or TIG welder HF unit. In other words, instead of putting diodes in series with the main power supply, you put an inductor in series and induce a high voltage pulse in it by transformer (or Tesla coil) action. An inductor may well be less lossy than a string of diodes.

I've seen both the diode method and the inductor method used for starting arc lamps.

Steve Conner, Mon Apr 21 2014, 06:28PM

There is no fundamental problem with it, other than conduction losses in the diodes and the risk of blowing them up.

You might also like to try a setup like a high pressure arc lamp ignitor or TIG welder HF unit. In other words, instead of putting diodes in series with the main power supply, you put an inductor in series and induce a high voltage pulse in it by transformer (or Tesla coil) action. An inductor may well be less lossy than a string of diodes.

I've seen both the diode method and the inductor method used for starting arc lamps.

Re: ETG trigger

Ash Small, Mon Apr 21 2014, 07:13PM

Yes, we've discussed the HF TIG welder type circuit here before. I've a couple of questions regarding this. If I remove S3 and S4, along with C2 and the diodes, and place the HV pulse transformer where one of the diodes is, won't C1 'see' the voltage induced accross the transformer secondary? (I know I used HV capacitors and chokes when I built an HF TIG welder to keep the HV away from the lower voltage rated components.)

Ash Small, Mon Apr 21 2014, 07:13PM

Steve Conner wrote ...

There is no fundamental problem with it, other than conduction losses in the diodes and the risk of blowing them up.

You might also like to try a setup like a high pressure arc lamp ignitor or TIG welder HF unit. In other words, instead of putting diodes in series with the main power supply, you put an inductor in series and induce a high voltage pulse in it by transformer (or Tesla coil) action. An inductor may well be less lossy than a string of diodes.

I've seen both the diode method and the inductor method used for starting arc lamps.

There is no fundamental problem with it, other than conduction losses in the diodes and the risk of blowing them up.

You might also like to try a setup like a high pressure arc lamp ignitor or TIG welder HF unit. In other words, instead of putting diodes in series with the main power supply, you put an inductor in series and induce a high voltage pulse in it by transformer (or Tesla coil) action. An inductor may well be less lossy than a string of diodes.

I've seen both the diode method and the inductor method used for starting arc lamps.

Yes, we've discussed the HF TIG welder type circuit here before. I've a couple of questions regarding this. If I remove S3 and S4, along with C2 and the diodes, and place the HV pulse transformer where one of the diodes is, won't C1 'see' the voltage induced accross the transformer secondary? (I know I used HV capacitors and chokes when I built an HF TIG welder to keep the HV away from the lower voltage rated components.)

Re: ETG trigger

Ash Small, Tue Apr 22 2014, 06:50PM

I've looked at this again, and even if I put a transformer where C2 is, I still see the same problem, ie C1 will 'see' the transformer.

As I see it, any blocking inductors would impede the discharge of C1, although a 10mS pulse from C1 (the figure I quoted from the data sheet for the diodes) equates to one half cycle at 50Hz, I expect C1 to discharge much faster than this.

The original idea was for minimum parts count. Low voltage capacitor bank will be smaller than a higher voltage one, the only 'issue' is the string of stud diodes, although from what I've read in other threads on ETG's, spark gap size doesn't make much difference, so spark gap (and hence voltage) doesn't need to be that high, especially if the electrodes are designed correctly.

I'm not sure what voltage Neil's CCFL tripler is putting out here: , but this looks like a simple circuit for the HV, although I assume it runs from mains power. Maybe I should post a few questions in his thread?

, but this looks like a simple circuit for the HV, although I assume it runs from mains power. Maybe I should post a few questions in his thread?

Ash Small, Tue Apr 22 2014, 06:50PM

I've looked at this again, and even if I put a transformer where C2 is, I still see the same problem, ie C1 will 'see' the transformer.

As I see it, any blocking inductors would impede the discharge of C1, although a 10mS pulse from C1 (the figure I quoted from the data sheet for the diodes) equates to one half cycle at 50Hz, I expect C1 to discharge much faster than this.

The original idea was for minimum parts count. Low voltage capacitor bank will be smaller than a higher voltage one, the only 'issue' is the string of stud diodes, although from what I've read in other threads on ETG's, spark gap size doesn't make much difference, so spark gap (and hence voltage) doesn't need to be that high, especially if the electrodes are designed correctly.

I'm not sure what voltage Neil's CCFL tripler is putting out here:

, but this looks like a simple circuit for the HV, although I assume it runs from mains power. Maybe I should post a few questions in his thread?

, but this looks like a simple circuit for the HV, although I assume it runs from mains power. Maybe I should post a few questions in his thread?Re: ETG trigger

Steve Conner, Tue Apr 22 2014, 07:54PM

It doesn't matter that C1 sees the high voltage pulse. It is a short pulse so only contains high frequencies.

The inductor will slow the discharge a little, but this may not be a problem either. If you think of the inductor in a TIG welder HF unit, it is air cored with only about half a dozen turns.

Steve Conner, Tue Apr 22 2014, 07:54PM

It doesn't matter that C1 sees the high voltage pulse. It is a short pulse so only contains high frequencies.

The inductor will slow the discharge a little, but this may not be a problem either. If you think of the inductor in a TIG welder HF unit, it is air cored with only about half a dozen turns.

Re: ETG trigger

Ash Small, Tue Apr 22 2014, 11:04PM

Ok, it only contains high frequencies, but I'd expect C1 to 'absorb' some of the energy. With an HF TIG welder it's usually DC (or 50-60Hz AC if welding aluminium), and DC is just 'smoothed' by inductance (50-60Hz AC shouldn't be greatly affected either, as long as the inductance isn't too great).

I suppose I should run some tests, but I do have a few other projects underway.

My TIG welder has ten turns on the air core transformer, slightly over an inch in diameter.

I should have some spare cash next month so maybe I'll order some of those stud diodes from Ebay.

Ash Small, Tue Apr 22 2014, 11:04PM

Steve Conner wrote ...

It doesn't matter that C1 sees the high voltage pulse. It is a short pulse so only contains high frequencies.

The inductor will slow the discharge a little, but this may not be a problem either. If you think of the inductor in a TIG welder HF unit, it is air cored with only about half a dozen turns.

It doesn't matter that C1 sees the high voltage pulse. It is a short pulse so only contains high frequencies.

The inductor will slow the discharge a little, but this may not be a problem either. If you think of the inductor in a TIG welder HF unit, it is air cored with only about half a dozen turns.

Ok, it only contains high frequencies, but I'd expect C1 to 'absorb' some of the energy. With an HF TIG welder it's usually DC (or 50-60Hz AC if welding aluminium), and DC is just 'smoothed' by inductance (50-60Hz AC shouldn't be greatly affected either, as long as the inductance isn't too great).

I suppose I should run some tests, but I do have a few other projects underway.

My TIG welder has ten turns on the air core transformer, slightly over an inch in diameter.

I should have some spare cash next month so maybe I'll order some of those stud diodes from Ebay.

Re: ETG trigger

Steve Conner, Wed Apr 23 2014, 08:15AM

C1 won't absorb any of the energy, it will appear as a short circuit to the high frequencies that the ignition pulse is composed of.

Steve Conner, Wed Apr 23 2014, 08:15AM

C1 won't absorb any of the energy, it will appear as a short circuit to the high frequencies that the ignition pulse is composed of.

Re: ETG trigger

Ash Small, Wed Apr 23 2014, 11:34AM

OK, I'll give it a try. My concerns were the ESR of a bank of electrolytics, although I can see that the HF shouldn't be a problem for the polarity of the electrolytics, as they won't actually be 'reverse charged'. I'll post an alternative circuit later. I'm assuming the transformer would need to be in series with C1 and the spark gap, rather than in parallel with them?

Ash Small, Wed Apr 23 2014, 11:34AM

Steve Conner wrote ...

C1 won't absorb any of the energy, it will appear as a short circuit to the high frequencies that the ignition pulse is composed of.

C1 won't absorb any of the energy, it will appear as a short circuit to the high frequencies that the ignition pulse is composed of.

OK, I'll give it a try. My concerns were the ESR of a bank of electrolytics, although I can see that the HF shouldn't be a problem for the polarity of the electrolytics, as they won't actually be 'reverse charged'. I'll post an alternative circuit later. I'm assuming the transformer would need to be in series with C1 and the spark gap, rather than in parallel with them?

Re: ETG trigger

Steve Conner, Wed Apr 23 2014, 11:43AM

Yes, in series.

The ignition pulse will be low current and high voltage, so the ESR of the bank shouldn't be an issue.

Steve Conner, Wed Apr 23 2014, 11:43AM

Yes, in series.

The ignition pulse will be low current and high voltage, so the ESR of the bank shouldn't be an issue.

Print this page