What's the best off-the-shelf solution for a vacuum encapsulation chamber?

jpsmith123, Tue Oct 27 2009, 11:59PMI thought possibly something like this.

Or like this.

But considering that I probably won't be using it very often (maybe only once or twice), these seem too expensive.

Maybe a modified low-end pressure cooker? But then there'd be no way to see what's going on inside...unless a viewport of some sort was added, which would add to the cost in time and money.

Anybody have any other ideas?

Re: What's the best off-the-shelf solution for a vacuum encapsulation chamber?

Proud Mary, Wed Oct 28 2009, 12:46AM

You haven't said what kind of dielectric you intend to use, Mr Smith.

Anything other than oil will be extremely expensive in those large capacity containers in your illustrations.

If you intend to use eco-freindly vegetable oil dielectric, get back to me for further advice and opinion.

Proud Mary, Wed Oct 28 2009, 12:46AM

You haven't said what kind of dielectric you intend to use, Mr Smith.

Anything other than oil will be extremely expensive in those large capacity containers in your illustrations.

If you intend to use eco-freindly vegetable oil dielectric, get back to me for further advice and opinion.

Re: What's the best off-the-shelf solution for a vacuum encapsulation chamber?

jpsmith123, Wed Oct 28 2009, 02:00AM

Harry what I was planning to do was to fill the bobbin assemblies with epoxy or RTV (I haven't selected one yet, but I'm leaning toward MG Chemicals' encapsulating epoxy), and then put the assemblies into the chamber and pump it down.

I don't know yet exactly what the volume of the assemblies will be, but I can't imagine it being more than 150 ml or so.

BTW, here's a nice setup someone is putting together and selling on ebay:

I already have a pump and all the necessary hardware (i.e., gauge, valve, tubing)...all I need is the chamber. An aluminum stock pot like he's got there seems like a good idea. And as for the lid, it looks like it's 12" x 12" x 1" thick plastic, probably plexiglass rather than polycarbonate, considering the price he's asking.

jpsmith123, Wed Oct 28 2009, 02:00AM

Harry what I was planning to do was to fill the bobbin assemblies with epoxy or RTV (I haven't selected one yet, but I'm leaning toward MG Chemicals' encapsulating epoxy), and then put the assemblies into the chamber and pump it down.

I don't know yet exactly what the volume of the assemblies will be, but I can't imagine it being more than 150 ml or so.

BTW, here's a nice setup someone is putting together and selling on ebay:

I already have a pump and all the necessary hardware (i.e., gauge, valve, tubing)...all I need is the chamber. An aluminum stock pot like he's got there seems like a good idea. And as for the lid, it looks like it's 12" x 12" x 1" thick plastic, probably plexiglass rather than polycarbonate, considering the price he's asking.

Re: What's the best off-the-shelf solution for a vacuum encapsulation chamber?

MinorityCarrier, Wed Oct 28 2009, 03:32AM

If you can find a nice thick panel of acrylic and a sheet of good gasket material you can make something like what that guy is selling, at a reasonable cost. The dessicator chamber would be kind of flimsy, may work, but would certainly cost more than the cooking pot/acrylic plate approach. You can also heat the metal cooking pot to help with the evacuation process.

I would recommend you de-gas epoxy first before potting an assembly. Trying to degas after potting may trap gas bubbles inside your assemblies. With an acrylic plate, you could add another port through which you could flow epoxy to your assemblies while they are in a vacuum.

MinorityCarrier, Wed Oct 28 2009, 03:32AM

If you can find a nice thick panel of acrylic and a sheet of good gasket material you can make something like what that guy is selling, at a reasonable cost. The dessicator chamber would be kind of flimsy, may work, but would certainly cost more than the cooking pot/acrylic plate approach. You can also heat the metal cooking pot to help with the evacuation process.

I would recommend you de-gas epoxy first before potting an assembly. Trying to degas after potting may trap gas bubbles inside your assemblies. With an acrylic plate, you could add another port through which you could flow epoxy to your assemblies while they are in a vacuum.

Re: What's the best off-the-shelf solution for a vacuum encapsulation chamber?

jpsmith123, Wed Oct 28 2009, 03:52AM

As far as the acrylic plate, I found a nice 12" x 12" x 1" piece for $24.59 here:

I'm still debating what to do for a gasket.

I think I'll go down to the local restaurant supply house tomorrow and see if they have any 12 quart aluminum stock pots with welded-on handles. Once I see what the edges look like, maybe that'll generate some ideas for gasketing.

And yes, I agree that flowing the epoxy in while the assemblies are under vacuum would be better, but in this case it may not be worth the extra hassle. I'll have to think about it some more.

jpsmith123, Wed Oct 28 2009, 03:52AM

As far as the acrylic plate, I found a nice 12" x 12" x 1" piece for $24.59 here:

I'm still debating what to do for a gasket.

I think I'll go down to the local restaurant supply house tomorrow and see if they have any 12 quart aluminum stock pots with welded-on handles. Once I see what the edges look like, maybe that'll generate some ideas for gasketing.

And yes, I agree that flowing the epoxy in while the assemblies are under vacuum would be better, but in this case it may not be worth the extra hassle. I'll have to think about it some more.

Re: What's the best off-the-shelf solution for a vacuum encapsulation chamber?

Proud Mary, Wed Oct 28 2009, 04:54AM

The argument against using epoxy is that if you make a mistake, or if arcing should start inside, you have no means of repair.

Oil dielectric has the advantage of being self-healing, so if a minor flash-over should occur between windings, it will be automatically repaired by the ingress of fresh oil.

Proud Mary, Wed Oct 28 2009, 04:54AM

The argument against using epoxy is that if you make a mistake, or if arcing should start inside, you have no means of repair.

Oil dielectric has the advantage of being self-healing, so if a minor flash-over should occur between windings, it will be automatically repaired by the ingress of fresh oil.

Re: What's the best off-the-shelf solution for a vacuum encapsulation chamber?

jpsmith123, Wed Oct 28 2009, 11:25AM

What about this thing?

That would seem to be ideal...if it's heavy enough to withstand vacuum. At $14.99 the price is certainly right.

jpsmith123, Wed Oct 28 2009, 11:25AM

What about this thing?

That would seem to be ideal...if it's heavy enough to withstand vacuum. At $14.99 the price is certainly right.

Re: What's the best off-the-shelf solution for a vacuum encapsulation chamber?

Bored Chemist, Wed Oct 28 2009, 06:40PM

Just a quick "heads up".

The polycarbonate vessels in the first post are perfect for many things.

Unfortunately they will craze then implode if used with any organic solvents (such as might be present in the potting resins).

You would probaly get away with it once- maybe twice but I'd not try it.

Bored Chemist, Wed Oct 28 2009, 06:40PM

Just a quick "heads up".

The polycarbonate vessels in the first post are perfect for many things.

Unfortunately they will craze then implode if used with any organic solvents (such as might be present in the potting resins).

You would probaly get away with it once- maybe twice but I'd not try it.

Re: What's the best off-the-shelf solution for a vacuum encapsulation chamber?

mikeselectricstuff, Wed Oct 28 2009, 11:24PM

Something I used a while ago, purely because it was available, was a paint pot designed for use with compressed air - no window, but nice and strong, with ful-diameter removable lid ane air fittings already there.

mikeselectricstuff, Wed Oct 28 2009, 11:24PM

Something I used a while ago, purely because it was available, was a paint pot designed for use with compressed air - no window, but nice and strong, with ful-diameter removable lid ane air fittings already there.

Re: What's the best off-the-shelf solution for a vacuum encapsulation chamber?

teravolt, Thu Oct 29 2009, 03:22AM

I don't know how intent on epoxy you are but I use parifin wax. its cheap and a grate insulator and repairable. its great for insulating old style flybacks for more output

teravolt, Thu Oct 29 2009, 03:22AM

I don't know how intent on epoxy you are but I use parifin wax. its cheap and a grate insulator and repairable. its great for insulating old style flybacks for more output

Re: What's the best off-the-shelf solution for a vacuum encapsulation chamber?

Steve Conner, Thu Oct 29 2009, 07:06PM

Paraffin wax is cool. You can vacuum impregnate it in while it's molten, then let it cool and solidify. I think Tesla himself used this trick.

Steve Conner, Thu Oct 29 2009, 07:06PM

Paraffin wax is cool. You can vacuum impregnate it in while it's molten, then let it cool and solidify. I think Tesla himself used this trick.

Re: What's the best off-the-shelf solution for a vacuum encapsulation chamber?

jpsmith123, Thu Oct 29 2009, 07:11PM

Well I went to a local company that supplies restaurants, and all of their aluminum stock pots had riveted-on handles, and not the welded-on handles I was looking for, so I didn't buy anything.

I suppose I'll take a chance and get the food storage canister.

@Teravolt: Paraffin with its low melting point and high thermal expansion is probably ok for quick kitchen table experiments, etc., but for what I'm doing, especially with the time and money invested so far, I need something better suited to the purpose.

Edit:

Today I happened to find a hermetically sealed canister made by Oggi in a department store (although it was a smaller model than the one I linked to above), and unfortunately, it just doesn't seem robust enough to handle full vacuum. Mainly, the lid seems too thin to accomodate the over 700 lbs of force that will have to be supported as the air gets pumped out.

So it looks like I'm back to the stock pot and plexiglass sheet idea.

jpsmith123, Thu Oct 29 2009, 07:11PM

Well I went to a local company that supplies restaurants, and all of their aluminum stock pots had riveted-on handles, and not the welded-on handles I was looking for, so I didn't buy anything.

I suppose I'll take a chance and get the food storage canister.

@Teravolt: Paraffin with its low melting point and high thermal expansion is probably ok for quick kitchen table experiments, etc., but for what I'm doing, especially with the time and money invested so far, I need something better suited to the purpose.

Edit:

Today I happened to find a hermetically sealed canister made by Oggi in a department store (although it was a smaller model than the one I linked to above), and unfortunately, it just doesn't seem robust enough to handle full vacuum. Mainly, the lid seems too thin to accomodate the over 700 lbs of force that will have to be supported as the air gets pumped out.

So it looks like I'm back to the stock pot and plexiglass sheet idea.

Re: What's the best off-the-shelf solution for a vacuum encapsulation chamber?

jpsmith123, Mon Nov 02 2009, 01:52PM

This is an update for anyone that may be interested.

The only aluminum stock pots I can find that have spot-welded handles (rather than riveted-on handles), are those made by Vollrath; like the following for example:

If this will suffice for a vacuum chamber (and it seems to me it should), then the two remaining issues are the gasket and the lid.

As it turns out, the 8, 10 and 12 quart Vollrath stock pots all have a 10" ID (and I think the wall thickness is close to 0.125"), so a standard off-the-shelf L-gasket for a 10" bell jar may work.

The last issue is the clear plastic cover. It seems that polycarbonate sheet is available in 12" x 12" x 1/2" sizes for $20 to $25 (for greater thicknesses the price gets ridiculous); and acrylic sheets are available in 3/4" to 1" thicknesses for about the same price.

Having never worked with such thicknesses of these plastics before, I have no feel for what would be required here. Would 1/2" thick polycarbonate be stiff enough and strong enough to reliably seal a 10" OD vacuum vessel, or would it be better to use 3/4" or 1" thick acrylic?

jpsmith123, Mon Nov 02 2009, 01:52PM

This is an update for anyone that may be interested.

The only aluminum stock pots I can find that have spot-welded handles (rather than riveted-on handles), are those made by Vollrath; like the following for example:

If this will suffice for a vacuum chamber (and it seems to me it should), then the two remaining issues are the gasket and the lid.

As it turns out, the 8, 10 and 12 quart Vollrath stock pots all have a 10" ID (and I think the wall thickness is close to 0.125"), so a standard off-the-shelf L-gasket for a 10" bell jar may work.

The last issue is the clear plastic cover. It seems that polycarbonate sheet is available in 12" x 12" x 1/2" sizes for $20 to $25 (for greater thicknesses the price gets ridiculous); and acrylic sheets are available in 3/4" to 1" thicknesses for about the same price.

Having never worked with such thicknesses of these plastics before, I have no feel for what would be required here. Would 1/2" thick polycarbonate be stiff enough and strong enough to reliably seal a 10" OD vacuum vessel, or would it be better to use 3/4" or 1" thick acrylic?

Re: What's the best off-the-shelf solution for a vacuum encapsulation chamber?

klugesmith, Tue Nov 03 2009, 04:16PM

1. Are handle rivets a big problem? I would think it very easy to seal them against leakage, using (for example) epoxy or silicone on the outside. Just makes it ugly when you use the pot to cook for guests.

2. A) wait for someone that knows the answer.

B) Work it out as a standard strength-of-materials problem -- see handbooks or online calculator such as

C) Test an inexpensive 1/4 inch plate at proportionally lower vacuum. I think you get same stress at 1/4 of the vacuum, and same deflection at 1/8 of the vacuum.

D) You might be surprised how much stiffer are steel and Al compared to strong plastics. If 1/2 inch polycarbonate deflects too much, it could be reinforced with a metal bar across the diameter.

Or make a lid from metal plate, with plastic windows of less then 1/2 the pot's diameter.

klugesmith, Tue Nov 03 2009, 04:16PM

jpsmith123 wrote ...

The only aluminum stock pots I can find that have spot-welded handles (rather than riveted-on handles), ...

Would 1/2" thick polycarbonate be stiff enough and strong enough to reliably seal a 10" OD vacuum vessel, or would it be better to use 3/4" or 1" thick acrylic?

The only aluminum stock pots I can find that have spot-welded handles (rather than riveted-on handles), ...

Would 1/2" thick polycarbonate be stiff enough and strong enough to reliably seal a 10" OD vacuum vessel, or would it be better to use 3/4" or 1" thick acrylic?

1. Are handle rivets a big problem? I would think it very easy to seal them against leakage, using (for example) epoxy or silicone on the outside. Just makes it ugly when you use the pot to cook for guests.

2. A) wait for someone that knows the answer.

B) Work it out as a standard strength-of-materials problem -- see handbooks or online calculator such as

C) Test an inexpensive 1/4 inch plate at proportionally lower vacuum. I think you get same stress at 1/4 of the vacuum, and same deflection at 1/8 of the vacuum.

D) You might be surprised how much stiffer are steel and Al compared to strong plastics. If 1/2 inch polycarbonate deflects too much, it could be reinforced with a metal bar across the diameter.

Or make a lid from metal plate, with plastic windows of less then 1/2 the pot's diameter.

Re: What's the best off-the-shelf solution for a vacuum encapsulation chamber?

MinorityCarrier, Tue Nov 03 2009, 05:02PM

If you can get 3/4" or 1" acrylic for little extra cost, I'd go with that. LAM AutoEtch plasma etchers used 3/4' Acrylic plates to cover their loadlocks, these run at millitorr vacuum. You could see a little surface deflection during pumpdown, but not much.

The advantage of thick plastic is the ability to machine threaded holes for ports, without losing too much structural strength.

Clear acrylic covers also allows one to see what's going on inside their vacuum chamber, something I personally prefer. Watching RTV12A silicone degas for example; when it's done frothing, and the suds collapse down to the liquid I know its ready to be removed from the vacuum chamber.

MinorityCarrier, Tue Nov 03 2009, 05:02PM

If you can get 3/4" or 1" acrylic for little extra cost, I'd go with that. LAM AutoEtch plasma etchers used 3/4' Acrylic plates to cover their loadlocks, these run at millitorr vacuum. You could see a little surface deflection during pumpdown, but not much.

The advantage of thick plastic is the ability to machine threaded holes for ports, without losing too much structural strength.

Clear acrylic covers also allows one to see what's going on inside their vacuum chamber, something I personally prefer. Watching RTV12A silicone degas for example; when it's done frothing, and the suds collapse down to the liquid I know its ready to be removed from the vacuum chamber.

Re: What's the best off-the-shelf solution for a vacuum encapsulation chamber?

jpsmith123, Tue Nov 03 2009, 11:35PM

Hello Klugesmith:

In the sense that I hate to introduce unnecessary variables into a vacuum system, yes, I see the rivets as a problem...so I decided to spend the extra $10 or so for the Vollrath pot rather than bother with with sealants.

As far as the plastics go, theory and calculations are always a useful guide, but nothing beats real-world experience/examples, IMO.

@MinorityCarrier:

It's nice to know that acrylic plates were used in a commercial vacuum system. Do you know roughly how big the 3/4" plates were in the example you mentioned?

jpsmith123, Tue Nov 03 2009, 11:35PM

Hello Klugesmith:

In the sense that I hate to introduce unnecessary variables into a vacuum system, yes, I see the rivets as a problem...so I decided to spend the extra $10 or so for the Vollrath pot rather than bother with with sealants.

As far as the plastics go, theory and calculations are always a useful guide, but nothing beats real-world experience/examples, IMO.

@MinorityCarrier:

It's nice to know that acrylic plates were used in a commercial vacuum system. Do you know roughly how big the 3/4" plates were in the example you mentioned?

Re: What's the best off-the-shelf solution for a vacuum encapsulation chamber?

MinorityCarrier, Wed Nov 04 2009, 05:38AM

It was a ~18cm by ~28cm rectangle. I'll take a photo of the loadlock cover of a LAM Rainbow plasma etcher tomorrow and post it, it's a bigger piece of plastic.

MinorityCarrier, Wed Nov 04 2009, 05:38AM

It was a ~18cm by ~28cm rectangle. I'll take a photo of the loadlock cover of a LAM Rainbow plasma etcher tomorrow and post it, it's a bigger piece of plastic.

Re: What's the best off-the-shelf solution for a vacuum encapsulation chamber?

MinorityCarrier, Wed Nov 04 2009, 08:35PM

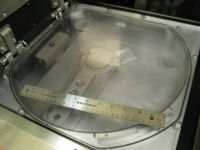

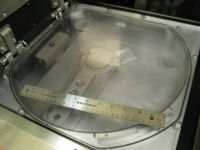

Here's a photo of the plastic loadlock cover for a LAM Rainbow etcher. The plastic cover is 32mm or 7/8" thick. The ruler gives a sense of area dimension.

The loadlock chamber is pumped down to 200mT, the pressure crossover point where the main process chamber door opens up.

MinorityCarrier, Wed Nov 04 2009, 08:35PM

Here's a photo of the plastic loadlock cover for a LAM Rainbow etcher. The plastic cover is 32mm or 7/8" thick. The ruler gives a sense of area dimension.

The loadlock chamber is pumped down to 200mT, the pressure crossover point where the main process chamber door opens up.

Re: What's the best off-the-shelf solution for a vacuum encapsulation chamber?

Scott Fusare, Wed Nov 04 2009, 09:42PM

Now that brings back memories. Spent 12 years working as a field rep for Lam. Rainbow 4600s were my specialty.

Can't say I miss the semi industry much.

Scott

Scott Fusare, Wed Nov 04 2009, 09:42PM

Now that brings back memories. Spent 12 years working as a field rep for Lam. Rainbow 4600s were my specialty.

Can't say I miss the semi industry much.

Scott

Re: What's the best off-the-shelf solution for a vacuum encapsulation chamber?

MinorityCarrier, Wed Nov 04 2009, 10:57PM

We don't have anyone here who knows how to rebuild the LL harmonic drives. You probaly understand the ordeal I am experiencing trying to develop processes on this tool, but at least I am still employed.

BTW, the plastic cover looks to me to be Lexan, one of our Maint folks thinks it is acrylic, but it has the Lexan bluish cast. Since you were in LAM Field Service, what is the plastic this cover is made of?

MinorityCarrier, Wed Nov 04 2009, 10:57PM

We don't have anyone here who knows how to rebuild the LL harmonic drives. You probaly understand the ordeal I am experiencing trying to develop processes on this tool, but at least I am still employed.

BTW, the plastic cover looks to me to be Lexan, one of our Maint folks thinks it is acrylic, but it has the Lexan bluish cast. Since you were in LAM Field Service, what is the plastic this cover is made of?

Re: What's the best off-the-shelf solution for a vacuum encapsulation chamber?

Scott Fusare, Wed Nov 04 2009, 11:48PM

It's polycarbonate as I recall.

Don't think I ever got beyond replacing those two toothed timing belts on the harmonic drives. Always avoided the complete rebuild. I do have terrible memories of trying to remove one of them, I think it was the exit load lock, that was blocked by the "PLL" pump line on the 4600. What a mess, 10 lbs. of s**t in a 5 lbs. box, all caked in aluminum chloride and coiled in heating tape. Copper has obsoleted most of this I would assume...

What system are you working with? Each had it's own set of idiosyncrasies. Is Lam even supporting these things anymore?

What is the process you are trying to develop? I would think these etcher a bit "long in the tooth" for modern process'.

Scott Fusare, Wed Nov 04 2009, 11:48PM

It's polycarbonate as I recall.

Don't think I ever got beyond replacing those two toothed timing belts on the harmonic drives. Always avoided the complete rebuild. I do have terrible memories of trying to remove one of them, I think it was the exit load lock, that was blocked by the "PLL" pump line on the 4600. What a mess, 10 lbs. of s**t in a 5 lbs. box, all caked in aluminum chloride and coiled in heating tape. Copper has obsoleted most of this I would assume...

What system are you working with? Each had it's own set of idiosyncrasies. Is Lam even supporting these things anymore?

What is the process you are trying to develop? I would think these etcher a bit "long in the tooth" for modern process'.

Re: What's the best off-the-shelf solution for a vacuum encapsulation chamber?

MinorityCarrier, Thu Nov 05 2009, 12:28AM

Lexan is polycarbonate, so I was right.

It's a 4500, note the 100mm handler, so you know where we are technologically. LAM still supports them, but we had to buy a site license for the Envision O.S. or they wouldn't talk to us.

Copper Damascene/CMP is used for the small stuff, companies like Microchip and Linear Technology still use Aluminum.

I was responsible for a TCP9600 at a previous company. That was a good etch tool as long as the VAT pendulum valve didn't get fouled with AlCl3 and we changed out the quartz DSQ chamber every 6 months. The water vapor DSQ passivation process was a pile of poo, I went back to CF4/O2 plasma passivation which is kinda harsh on quartz.

Anyway, jpsmith, here's some real-world examples of thick transparent plastic vacuum chamber covers. They really do work well.

MinorityCarrier, Thu Nov 05 2009, 12:28AM

Lexan is polycarbonate, so I was right.

It's a 4500, note the 100mm handler, so you know where we are technologically. LAM still supports them, but we had to buy a site license for the Envision O.S. or they wouldn't talk to us.

Copper Damascene/CMP is used for the small stuff, companies like Microchip and Linear Technology still use Aluminum.

I was responsible for a TCP9600 at a previous company. That was a good etch tool as long as the VAT pendulum valve didn't get fouled with AlCl3 and we changed out the quartz DSQ chamber every 6 months. The water vapor DSQ passivation process was a pile of poo, I went back to CF4/O2 plasma passivation which is kinda harsh on quartz.

Anyway, jpsmith, here's some real-world examples of thick transparent plastic vacuum chamber covers. They really do work well.

Re: What's the best off-the-shelf solution for a vacuum encapsulation chamber?

klugesmith, Thu Nov 05 2009, 02:50AM

Deflection goes as the inverse cube of thickness, so it matters.

Respectfully,

Rich F.

klugesmith, Thu Nov 05 2009, 02:50AM

MinorityCarrier wrote ...

Here's a photo of the plastic loadlock cover for a LAM Rainbow etcher. The plastic cover is 32mm or 7/8" thick.

Sorry, I'm trying to butt out. But jpsmith asked about the actual thickness -- is it 32mm or 7/8" (22mm)?Here's a photo of the plastic loadlock cover for a LAM Rainbow etcher. The plastic cover is 32mm or 7/8" thick.

Deflection goes as the inverse cube of thickness, so it matters.

Respectfully,

Rich F.

Re: What's the best off-the-shelf solution for a vacuum encapsulation chamber?

MinorityCarrier, Thu Nov 05 2009, 04:18AM

22mm. Typing too fast and sloppy again.

MinorityCarrier, Thu Nov 05 2009, 04:18AM

22mm. Typing too fast and sloppy again.

Re: What's the best off-the-shelf solution for a vacuum encapsulation chamber?

Voltwad, Thu Nov 05 2009, 05:24AM

This seems an appropriate thread for my vac setup. It's a ~1/2 gallon glass cookie jar from target. Over that is a larger, clear polycarb jar just in case. They both sit upside down on a base. The base is a 1/2 inch thick polyethylene cutting board from target with holes drilled and tapped for some fittings. The gasket is some foamy sort of shelf lining, also from target. The whole setup, including a $15 water aspirator from cole parmer was less than $40. Using an overturned vessel on a base, as opposed to a pot with a lid may not scale up beyond a gallon or so, (not with glass anyway) but my aspirator goes to ~28 in. Hg with no problem so far and a clear vessel all round gives a better perspective than just a window or a clear lid I think. Just be careful when using glass you know. I wonder if there'd be a significant difference in stress between the pressures created by a water aspirator vs. a vane pump.

Voltwad, Thu Nov 05 2009, 05:24AM

This seems an appropriate thread for my vac setup. It's a ~1/2 gallon glass cookie jar from target. Over that is a larger, clear polycarb jar just in case. They both sit upside down on a base. The base is a 1/2 inch thick polyethylene cutting board from target with holes drilled and tapped for some fittings. The gasket is some foamy sort of shelf lining, also from target. The whole setup, including a $15 water aspirator from cole parmer was less than $40. Using an overturned vessel on a base, as opposed to a pot with a lid may not scale up beyond a gallon or so, (not with glass anyway) but my aspirator goes to ~28 in. Hg with no problem so far and a clear vessel all round gives a better perspective than just a window or a clear lid I think. Just be careful when using glass you know. I wonder if there'd be a significant difference in stress between the pressures created by a water aspirator vs. a vane pump.

Re: What's the best off-the-shelf solution for a vacuum encapsulation chamber?

jpsmith123, Fri Nov 06 2009, 04:51PM

The Vollrath stock pot came today, and with the exception of one small rough spot on the rim, I have to say it's a nice looking vessel. It's 10" ID and about 10.3" OD.

As far as the plastic cover goes, although calculations show that 0.5" thick acrylic or polycarbonate would work (i.e., the stress would be below the flexural strength limit by about a factor of 10 or so), the unknown factor is the loss of strength that will result from the hole I will have to drill in the cover to connect the vacuum system; thus I've decided to go with the 0.75" acrylic, which, if undrilled would present a safety factor of over 20.

jpsmith123, Fri Nov 06 2009, 04:51PM

The Vollrath stock pot came today, and with the exception of one small rough spot on the rim, I have to say it's a nice looking vessel. It's 10" ID and about 10.3" OD.

As far as the plastic cover goes, although calculations show that 0.5" thick acrylic or polycarbonate would work (i.e., the stress would be below the flexural strength limit by about a factor of 10 or so), the unknown factor is the loss of strength that will result from the hole I will have to drill in the cover to connect the vacuum system; thus I've decided to go with the 0.75" acrylic, which, if undrilled would present a safety factor of over 20.

Re: What's the best off-the-shelf solution for a vacuum encapsulation chamber?

IntraWinding, Sat Nov 07 2009, 02:30AM

Could you drill the stock pot instead of the plastic?

IntraWinding, Sat Nov 07 2009, 02:30AM

Could you drill the stock pot instead of the plastic?

Re: What's the best off-the-shelf solution for a vacuum encapsulation chamber?

Voltwad, Sat Nov 07 2009, 02:41PM

I actually built a similar device to use my aspirator to draw hot wort into a boiling pot from a mash tank. It was a 30 qt. pot and a 16" x 16" x 1/4" piece of polycarb. I couldn't get the holes drilled and tapped without crazing. Then I got a large polyethylene cutting board. That's much easier to tap, and stronger and more flexible. I then cut a large hole in the board and glued a piece of lexan over it for a window.

Voltwad, Sat Nov 07 2009, 02:41PM

I actually built a similar device to use my aspirator to draw hot wort into a boiling pot from a mash tank. It was a 30 qt. pot and a 16" x 16" x 1/4" piece of polycarb. I couldn't get the holes drilled and tapped without crazing. Then I got a large polyethylene cutting board. That's much easier to tap, and stronger and more flexible. I then cut a large hole in the board and glued a piece of lexan over it for a window.

Re: What's the best off-the-shelf solution for a vacuum encapsulation chamber?

ConKbot of Doom, Tue Nov 17 2009, 02:23PM

We splurged and got a 12"x18" tall pyrex bell jar here at work for vacuum potting. It works well, with the pump we have it goes down to around 2 torr. Our potting specified to be degassed at 1-5 torr, which I found suprisingly low for how thin (non viscous) it is.

We had one of those lexan bell jars... its now my trash can, the flat of the top would suck down 3-4" and would be generally unnerving to use, even with the small dainty pumps we used to have. Definitely not on the cheap, but nice and effective.

The 3/4" acrylic/poly sounds like it should work better though, the edges of my trashcan/poly bell jar is only 1/8" and my calibrated finger calipers say the top is about the same too

ConKbot of Doom, Tue Nov 17 2009, 02:23PM

We splurged and got a 12"x18" tall pyrex bell jar here at work for vacuum potting. It works well, with the pump we have it goes down to around 2 torr. Our potting specified to be degassed at 1-5 torr, which I found suprisingly low for how thin (non viscous) it is.

We had one of those lexan bell jars... its now my trash can, the flat of the top would suck down 3-4" and would be generally unnerving to use, even with the small dainty pumps we used to have. Definitely not on the cheap, but nice and effective.

The 3/4" acrylic/poly sounds like it should work better though, the edges of my trashcan/poly bell jar is only 1/8" and my calibrated finger calipers say the top is about the same too

Re: What's the best off-the-shelf solution for a vacuum encapsulation chamber?

Bored Chemist, Tue Nov 17 2009, 06:18PM

If it's big enough you might want to get thepolycarb jar out of the trashcan and use it as an implosion shield.

If the glass belljar breaks it won't be pretty.

Bored Chemist, Tue Nov 17 2009, 06:18PM

If it's big enough you might want to get thepolycarb jar out of the trashcan and use it as an implosion shield.

If the glass belljar breaks it won't be pretty.

Re: What's the best off-the-shelf solution for a vacuum encapsulation chamber?

ConKbot of Doom, Tue Nov 17 2009, 08:32PM

ConKbot of Doom, Tue Nov 17 2009, 08:32PM

Bored Chemist wrote ...

If it's big enough you might want to get thepolycarb jar out of the trashcan and use it as an implosion shield.

If the glass belljar breaks it won't be pretty.

It is the trash can ;) and unfortunately its not big enough.If it's big enough you might want to get thepolycarb jar out of the trashcan and use it as an implosion shield.

If the glass belljar breaks it won't be pretty.

Re: What's the best off-the-shelf solution for a vacuum encapsulation chamber?

jpsmith123, Thu Nov 19 2009, 09:41PM

Here's a picture of the completed vacuum chamber.

I didn't get a chance to test it yet, but hopefully tomorrow I can do that.

It took a little effort to get the viton gasket onto the stock pot, but now that it's on there, it seems very good.

jpsmith123, Thu Nov 19 2009, 09:41PM

Here's a picture of the completed vacuum chamber.

I didn't get a chance to test it yet, but hopefully tomorrow I can do that.

It took a little effort to get the viton gasket onto the stock pot, but now that it's on there, it seems very good.

Re: What's the best off-the-shelf solution for a vacuum encapsulation chamber?

jpsmith123, Fri Nov 20 2009, 09:03PM

Well with it set up as shown it pumped down to a little less than 500 mT, which isn't very good, IMO, but there's a leak at one of the adapters near the pump.

The only thing I had to do was to push down on the acrylic a little bit when it first started pumping, but then it was self sealing after that.

jpsmith123, Fri Nov 20 2009, 09:03PM

Well with it set up as shown it pumped down to a little less than 500 mT, which isn't very good, IMO, but there's a leak at one of the adapters near the pump.

The only thing I had to do was to push down on the acrylic a little bit when it first started pumping, but then it was self sealing after that.

Re: What's the best off-the-shelf solution for a vacuum encapsulation chamber?

ConKbot of Doom, Sun Nov 22 2009, 03:51AM

nice setup :) and yeah those L profile gaskets are a trick to put on... ours was buna rubber, and definitely took some work to get on.

ConKbot of Doom, Sun Nov 22 2009, 03:51AM

nice setup :) and yeah those L profile gaskets are a trick to put on... ours was buna rubber, and definitely took some work to get on.

Re: What's the best off-the-shelf solution for a vacuum encapsulation chamber?

jpsmith123, Sun Nov 22 2009, 05:54AM

Hello C of D,

The only problem now is that my vacuum pump is junk. Actually it's not the pump, per se, but the inlet fitting that came on the pump. I never really looked at it/studied it very closely until now, when I realized there's a leak there somewhere.

It looks like a little kid designed it, or at least someone who doesn't know much about vacuum systems.

The pump is supposed to be capable of going to 15 mtorr, but I can't get it below 200 mtorr...so I either have to try to modify the fitting or make a new one, or possibly just get another pump.

jpsmith123, Sun Nov 22 2009, 05:54AM

Hello C of D,

The only problem now is that my vacuum pump is junk. Actually it's not the pump, per se, but the inlet fitting that came on the pump. I never really looked at it/studied it very closely until now, when I realized there's a leak there somewhere.

It looks like a little kid designed it, or at least someone who doesn't know much about vacuum systems.

The pump is supposed to be capable of going to 15 mtorr, but I can't get it below 200 mtorr...so I either have to try to modify the fitting or make a new one, or possibly just get another pump.

Re: What's the best off-the-shelf solution for a vacuum encapsulation chamber?

Bored Chemist, Sun Nov 22 2009, 09:55AM

500mTorr is pretty poor- but it should be good enough to degas stuff. If you get the pressure low enough you will boil the potting compound and that won't help.

Bored Chemist, Sun Nov 22 2009, 09:55AM

500mTorr is pretty poor- but it should be good enough to degas stuff. If you get the pressure low enough you will boil the potting compound and that won't help.

Re: What's the best off-the-shelf solution for a vacuum encapsulation chamber?

ConKbot of Doom, Mon Nov 23 2009, 03:58PM

When I'm encapsulating stuff, I pull out potting down to 5 torr or so (it rises, falls, boils for a bit... slows down, but stays expanded some) then I put the potting into the assembly, and pull it down to ~20 torr or so, our potting expands too much below 20 torr, and I'd need a larger reservoir at the mouth of the assembly. Your system should be more then adequate for vacuum potting, even of high voltage stuff. If youre trying to oil impregnate something and you wanna be really sure, heat the object and oil before you put it in.

looks like you wont have to worry about boiling the mineral oil (if youre oil impregnating), unless you get it to ~ 200C

looks like you wont have to worry about boiling the mineral oil (if youre oil impregnating), unless you get it to ~ 200C

ConKbot of Doom, Mon Nov 23 2009, 03:58PM

Bored Chemist wrote ...

500mTorr is pretty poor- but it should be good enough to degas stuff. If you get the pressure low enough you will boil the potting compound and that won't help.

+1 to that, our only goes down to 1 torr or so, but all our tubing is just slip fit connections, plus our gauge is only graduated in torr, not using any vacuum grease, and our valve setup isnt anything fancy. But it works great for what I use it for. After I clean out the inside of the assembly with flux remover, I put whatever assembly in the chamber, run it down to dry it out, and the gauge hangs at ~20 torr for a while while the solvent evaporates. Then again around 8-5 while water evaporates, then down to 1 slowly.500mTorr is pretty poor- but it should be good enough to degas stuff. If you get the pressure low enough you will boil the potting compound and that won't help.

When I'm encapsulating stuff, I pull out potting down to 5 torr or so (it rises, falls, boils for a bit... slows down, but stays expanded some) then I put the potting into the assembly, and pull it down to ~20 torr or so, our potting expands too much below 20 torr, and I'd need a larger reservoir at the mouth of the assembly. Your system should be more then adequate for vacuum potting, even of high voltage stuff. If youre trying to oil impregnate something and you wanna be really sure, heat the object and oil before you put it in.

looks like you wont have to worry about boiling the mineral oil (if youre oil impregnating), unless you get it to ~ 200C

looks like you wont have to worry about boiling the mineral oil (if youre oil impregnating), unless you get it to ~ 200CRe: What's the best off-the-shelf solution for a vacuum encapsulation chamber?

jpsmith123, Mon Nov 23 2009, 04:21PM

What kind of vacuum pump are you using? Just based on your description of your use of the pump, I'm thinking it may be a dry scroll pump like an Edwards XDS-10? Or is it a common rotary vane pump with gas ballast?

I used to have an old Welch pump and know if I pumped any quantity of anything volatile, it contaminated the oil and became a real PITA.

I can't afford a dry scroll pump right now, so I'm leaning toward buying the Viot pump over the Harbor Freight pump...just because the Viot has the gas ballast feature. Having never had a pump with gas ballast though, I don't know how effective it really is in practice.

jpsmith123, Mon Nov 23 2009, 04:21PM

What kind of vacuum pump are you using? Just based on your description of your use of the pump, I'm thinking it may be a dry scroll pump like an Edwards XDS-10? Or is it a common rotary vane pump with gas ballast?

I used to have an old Welch pump and know if I pumped any quantity of anything volatile, it contaminated the oil and became a real PITA.

I can't afford a dry scroll pump right now, so I'm leaning toward buying the Viot pump over the Harbor Freight pump...just because the Viot has the gas ballast feature. Having never had a pump with gas ballast though, I don't know how effective it really is in practice.

Re: What's the best off-the-shelf solution for a vacuum encapsulation chamber?

ConKbot of Doom, Tue Nov 24 2009, 04:49AM

rotary vane gas ballast pump, you got it

Hmm looks like they say its a lot more capable then what we are getting it to, but I suspect the tubing and fittings, and no grease on the seal, are the culpret there. I should probably run it for a while with the gas ballast open to 'freshen up' the oil too.

ConKbot of Doom, Tue Nov 24 2009, 04:49AM

jpsmith123 wrote ...

What kind of vacuum pump are you using? Just based on your description of your use of the pump, I'm thinking it may be a dry scroll pump like an Edwards XDS-10? Or is it a common rotary vane pump with gas ballast?

I used to have an old Welch pump and know if I pumped any quantity of anything volatile, it contaminated the oil and became a real PITA.

I can't afford a dry scroll pump right now, so I'm leaning toward buying the Viot pump over the Harbor Freight pump...just because the Viot has the gas ballast feature. Having never had a pump with gas ballast though, I don't know how effective it really is in practice.

What kind of vacuum pump are you using? Just based on your description of your use of the pump, I'm thinking it may be a dry scroll pump like an Edwards XDS-10? Or is it a common rotary vane pump with gas ballast?

I used to have an old Welch pump and know if I pumped any quantity of anything volatile, it contaminated the oil and became a real PITA.

I can't afford a dry scroll pump right now, so I'm leaning toward buying the Viot pump over the Harbor Freight pump...just because the Viot has the gas ballast feature. Having never had a pump with gas ballast though, I don't know how effective it really is in practice.

rotary vane gas ballast pump, you got it

Hmm looks like they say its a lot more capable then what we are getting it to, but I suspect the tubing and fittings, and no grease on the seal, are the culpret there. I should probably run it for a while with the gas ballast open to 'freshen up' the oil too.

Re: What's the best off-the-shelf solution for a vacuum encapsulation chamber?

jpsmith123, Tue Dec 01 2009, 12:31AM

Well I made a new inlet fitting for this "Dosivac" vacuum pump I got from ebay, out of a brass flare fitting, and I attached the thermocouple tube to it, and it pumped right down to about "0" on the meter.

So I guess the pump itself is pretty good...as good or better than my old Welch belt-drive pump.

It's mind-boggling to me that a company could make a pump like that and then compromise the whole design...throw away the performance the customers want and are paying for...by mating the pump to an inlet/valve assy. that can't help but leak.

Anyway, hopefully now I can get back to finishing the coils...

jpsmith123, Tue Dec 01 2009, 12:31AM

Well I made a new inlet fitting for this "Dosivac" vacuum pump I got from ebay, out of a brass flare fitting, and I attached the thermocouple tube to it, and it pumped right down to about "0" on the meter.

So I guess the pump itself is pretty good...as good or better than my old Welch belt-drive pump.

It's mind-boggling to me that a company could make a pump like that and then compromise the whole design...throw away the performance the customers want and are paying for...by mating the pump to an inlet/valve assy. that can't help but leak.

Anyway, hopefully now I can get back to finishing the coils...

Print this page