Diable Tonnere – my latest project.

Daniel Uhrenholt, Wed Aug 19 2009, 07:58PMHi Folks,

This week I will start on a new DRSSTC, and it will probably be the biggest I will ever build.

Some specs:

500nF primary capacitor

One secondary coil 200*920mm AWG ??, I got this coil from Finn + a toroid similar to the one I designed for Thumber, but a “little†smaller, so the Fo should be around 40kHz.

A trusty full bridge(the one I use at the Universitarium in Aalborg)

3 phase power

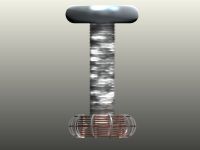

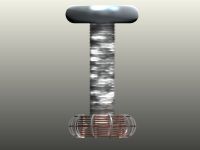

I just started drawing the parts in SolidWorks, and hopefully I can start CNC milling the parts sometime next week. So the first pictures you will se is a 3D rendering of the coil.

There is not much new to this project, as it's only the mechanical part I need to do, and the driver is Finn Hammer's design...

I`m hoping for 2meter+ sparks:-)

Project goals:

It has to be a cool design

It has to be driven without a breakout point, so a lot of decoupling in the primary circuit, and a lot of strike rails...

It need to be mounted upside down (I need this for a show sometime in November)

It has to be easy to take apart, and setting up where ever I go...

Higher power audio modulation is a must

I just finished my MIDI interrupter this week

I just finished my MIDI interrupter this week

And it has to be done before Cambridge Teslathon... So just a little stress from the beginning:-)

Cheers, Daniel Uhrenholt

Re: Diable Tonnere – my latest project.

Daniel Uhrenholt, Mon Aug 24 2009, 07:15PM

Hi Folks,

I did some drawing this afternoon, and I think it turned out really nice:-)

This is just the overall design, I have some other ideas regarding the primary coil, that I want to move up and down easily to change the coupling. And a nice way to mount the secondary coil, without having to screw it all together, just put it down the middle and turn it for a little click, and I will be ready to make sparks all day long

I'm a bit stressed this week, so the final design will be made next Monday...

I know that the strike rails on the drawing will act as shorted turns, but it was the easiest way to draw it like that

Oh yes, the primary will be a pain in the a** to wind...

Cheers, Daniel Uhrenholt

Daniel Uhrenholt, Mon Aug 24 2009, 07:15PM

Hi Folks,

I did some drawing this afternoon, and I think it turned out really nice:-)

This is just the overall design, I have some other ideas regarding the primary coil, that I want to move up and down easily to change the coupling. And a nice way to mount the secondary coil, without having to screw it all together, just put it down the middle and turn it for a little click, and I will be ready to make sparks all day long

I'm a bit stressed this week, so the final design will be made next Monday...

I know that the strike rails on the drawing will act as shorted turns, but it was the easiest way to draw it like that

Oh yes, the primary will be a pain in the a** to wind...

Cheers, Daniel Uhrenholt

Re: Diable Tonnere – my latest project.

Finn Hammer, Mon Aug 24 2009, 08:17PM

Naming it after a Haitian Loa is wicked indeed.

And making it unnecessary complicated is also very wicked.

You have my attention.

Cheers, Finn Hammer

Finn Hammer, Mon Aug 24 2009, 08:17PM

Naming it after a Haitian Loa is wicked indeed.

And making it unnecessary complicated is also very wicked.

You have my attention.

Cheers, Finn Hammer

Re: Diable Tonnere – my latest project.

Marko, Mon Aug 24 2009, 10:11PM

Daniel,

This is easily one of most badass looking primary coils I've seen... Although it's easy to be made jealous by CNC machining! :P

Is the secondary indeed going to be entirely corrugated like shown on the drawing? Is the winding going to be inside some sort of a plastic pipe?

Looking at that primary I feel like some copper tube grading rings on the secondary and a multi-ring toroid (themed like the primary) would be more fitting in appearance... Just cake care for the Rule of Cool not to make your design impractical! :P

Cheers,

Marko

Marko, Mon Aug 24 2009, 10:11PM

Daniel,

This is easily one of most badass looking primary coils I've seen... Although it's easy to be made jealous by CNC machining! :P

Is the secondary indeed going to be entirely corrugated like shown on the drawing? Is the winding going to be inside some sort of a plastic pipe?

Looking at that primary I feel like some copper tube grading rings on the secondary and a multi-ring toroid (themed like the primary) would be more fitting in appearance... Just cake care for the Rule of Cool not to make your design impractical! :P

Cheers,

Marko

Re: Diable Tonnere – my latest project.

Sulaiman, Mon Aug 24 2009, 11:20PM

If you're going to run it 'upside-down' would a spherical 'bottomload' be better?

Lovely rendering of the primary.

Sulaiman, Mon Aug 24 2009, 11:20PM

If you're going to run it 'upside-down' would a spherical 'bottomload' be better?

Lovely rendering of the primary.

Re: Diable Tonnere – my latest project.

Daniel Uhrenholt, Tue Aug 25 2009, 03:57PM

Hi Marco,

The secondary is placed inside a really neat PVC pipe that Finn helped me to get, it's the same as he used for his V twin.

And of course it need a multi-ring toroid

The only problem I have, is that I don't have the time it takes to make it now, and neither the money for having the parts laser cut...

Sulaiman,

Probably, but why bother when it will work just fine with a toroid

Cheers, Daniel

Daniel Uhrenholt, Tue Aug 25 2009, 03:57PM

Hi Marco,

The secondary is placed inside a really neat PVC pipe that Finn helped me to get, it's the same as he used for his V twin.

And of course it need a multi-ring toroid

The only problem I have, is that I don't have the time it takes to make it now, and neither the money for having the parts laser cut...

Sulaiman,

Probably, but why bother when it will work just fine with a toroid

Cheers, Daniel

Re: Diable Tonnere – my latest project.

Daniel Uhrenholt, Fri Nov 20 2009, 10:10PM

I'm back on the project:-)

Now the plan has totally changed, as I would like to change the tapping point when the coil runs, and also change the coupling. This is a really big project, but I am almost done with the CAD model of the primary, and I will start CNC milling the parts tomorrow morning.

CAD model of the primary and pictures of some of the parts will be posted tomorrow.

Cheers, Daniel

Daniel Uhrenholt, Fri Nov 20 2009, 10:10PM

I'm back on the project:-)

Now the plan has totally changed, as I would like to change the tapping point when the coil runs, and also change the coupling. This is a really big project, but I am almost done with the CAD model of the primary, and I will start CNC milling the parts tomorrow morning.

CAD model of the primary and pictures of some of the parts will be posted tomorrow.

Cheers, Daniel

Re: Diable Tonnere – my latest project.

Daniel Uhrenholt, Sat Nov 21 2009, 03:04PM

Hi all,

Today I made the first part of the primary holder, but it is actually 10 smaller parts that fits nicely like a puzzle.

Here is some pictures:

Unfortunately I had to leave the shop early, because of the annual Christmas lunch in the local Taekwondo club. But tomorrow I will make some more parts, and hopefully sometime next week you can see the primary holder...

Cheers, Daniel

Daniel Uhrenholt, Sat Nov 21 2009, 03:04PM

Hi all,

Today I made the first part of the primary holder, but it is actually 10 smaller parts that fits nicely like a puzzle.

Here is some pictures:

Unfortunately I had to leave the shop early, because of the annual Christmas lunch in the local Taekwondo club. But tomorrow I will make some more parts, and hopefully sometime next week you can see the primary holder...

Cheers, Daniel

Re: Diable Tonnere – my latest project.

Daniel Uhrenholt, Thu Nov 26 2009, 09:32PM

Hi all,

Today I milled some nice Tufnol spur gears for the secondary lifting system:-) Tomorrow I will mill the rest of the parts, and sometime Saturday I hope it all will be done... But there is still a lot of work to do.

Cheers, Daniel

Daniel Uhrenholt, Thu Nov 26 2009, 09:32PM

Hi all,

Today I milled some nice Tufnol spur gears for the secondary lifting system:-) Tomorrow I will mill the rest of the parts, and sometime Saturday I hope it all will be done... But there is still a lot of work to do.

Cheers, Daniel

Re: Diable Tonnere – my latest project.

rp181, Thu Nov 26 2009, 10:02PM

thats awesome! do you do it manually, or use a CNC?

BTW, great machining on the primary holder, can't even see the seams.

rp181, Thu Nov 26 2009, 10:02PM

thats awesome! do you do it manually, or use a CNC?

BTW, great machining on the primary holder, can't even see the seams.

Re: Diable Tonnere – my latest project.

Daniel Uhrenholt, Thu Nov 26 2009, 10:36PM

I used a older Maho Deckel DMU 50 CNC machine:-) It's fantastic with such a tool, and when you have Mastercam X4, there is almost no limits for what you can do

Thanks about the comment about the primary holder, I'm almost done with the holders now, but for the moment it's more fun to make the lifting system:-)

Daniel Uhrenholt, Thu Nov 26 2009, 10:36PM

I used a older Maho Deckel DMU 50 CNC machine:-) It's fantastic with such a tool, and when you have Mastercam X4, there is almost no limits for what you can do

Thanks about the comment about the primary holder, I'm almost done with the holders now, but for the moment it's more fun to make the lifting system:-)

Re: Diable Tonnere – my latest project.

doctor electrons, Thu Nov 26 2009, 10:39PM

Seriously! Im impressed! I want your job!

You have a lot of talent and some serious skills. Did you do your modeling in solidworks? Or something else, autocad mabe?

doctor electrons, Thu Nov 26 2009, 10:39PM

Seriously! Im impressed! I want your job!

You have a lot of talent and some serious skills. Did you do your modeling in solidworks? Or something else, autocad mabe?

Re: Diable Tonnere – my latest project.

Daniel Uhrenholt, Thu Nov 26 2009, 11:00PM

I do all the modelling in SolidWorks, but for the gears I bought some DXF llibrary's from hobbing.com. I don't have the brain or time to calculate gear tooth's myself, so I go for the easiest way possible:-)

It is a part of my job to be creative and innovative, as I work with mechanical parts for robots and satellites every day. I don't get any drawings from a mechanical engineer, so I have to figure out how to make the parts by my own:-) But that's what I'm there for, and I love it!

Cheers, Daniel

Daniel Uhrenholt, Thu Nov 26 2009, 11:00PM

I do all the modelling in SolidWorks, but for the gears I bought some DXF llibrary's from hobbing.com. I don't have the brain or time to calculate gear tooth's myself, so I go for the easiest way possible:-)

It is a part of my job to be creative and innovative, as I work with mechanical parts for robots and satellites every day. I don't get any drawings from a mechanical engineer, so I have to figure out how to make the parts by my own:-) But that's what I'm there for, and I love it!

Cheers, Daniel

Re: Diable Tonnere – my latest project.

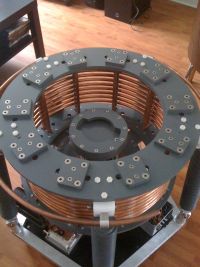

Daniel Uhrenholt, Thu Dec 03 2009, 07:49PM

Just a little update on the secondary lifting system.

The first picture is the stainless steel screw, PTFE bushings and planetary gear motor. The motor is just what I had in hand, I will change it for a powerful stepper motor when I can afford it.

This is the final assembly, the bigger disc is 300mm in diameter...

.

I hope to have the internal gear machined this weekend, but I have to go to fight night at the Taekwondo club Saturday, and some training Sunday. So I don't think I can get the time to mount it before next week.

Cheers, Daniel

Daniel Uhrenholt, Thu Dec 03 2009, 07:49PM

Just a little update on the secondary lifting system.

The first picture is the stainless steel screw, PTFE bushings and planetary gear motor. The motor is just what I had in hand, I will change it for a powerful stepper motor when I can afford it.

This is the final assembly, the bigger disc is 300mm in diameter...

.

I hope to have the internal gear machined this weekend, but I have to go to fight night at the Taekwondo club Saturday, and some training Sunday. So I don't think I can get the time to mount it before next week.

Cheers, Daniel

Re: Diable Tonnere – my latest project.

Finn Hammer, Thu Dec 03 2009, 08:39PM

Daniel,

Your pictures show the mechanism which will enable you to adjust the position of the secondary relative to the primary, in axial direction, in other words, make it possible to adjust the coupling on the fly.

You are building the dream machine!

Cheers, Finn Hammer

Finn Hammer, Thu Dec 03 2009, 08:39PM

Daniel,

Your pictures show the mechanism which will enable you to adjust the position of the secondary relative to the primary, in axial direction, in other words, make it possible to adjust the coupling on the fly.

You are building the dream machine!

Cheers, Finn Hammer

Re: Diable Tonnere – my latest project.

Daniel Uhrenholt, Thu Dec 03 2009, 08:56PM

Hi Finn,

Yes, It's the secondary and not the primary lifting system:-) I'm a bit tired after 13 hours in the shop:-)

Dream machine it is my friend, I can't wait until first light. I'll probably be ready to wind the primary next weekend, so if you have time to help with all the soldering, then I will bring bread and coffee to the shop:-)

Cheers, Daniel

Daniel Uhrenholt, Thu Dec 03 2009, 08:56PM

Hi Finn,

Yes, It's the secondary and not the primary lifting system:-) I'm a bit tired after 13 hours in the shop:-)

Dream machine it is my friend, I can't wait until first light. I'll probably be ready to wind the primary next weekend, so if you have time to help with all the soldering, then I will bring bread and coffee to the shop:-)

Cheers, Daniel

Re: Diable Tonnere – my latest project.

tobias, Fri Dec 04 2009, 02:28AM

Excellent job!! We can see attention to every detail and every chamfer =)

You said you bought DXF llibrary's from hobbing.com... Can I ask why not to use the SolidWorks toolbox ones?

tobias, Fri Dec 04 2009, 02:28AM

Excellent job!! We can see attention to every detail and every chamfer =)

You said you bought DXF llibrary's from hobbing.com... Can I ask why not to use the SolidWorks toolbox ones?

Re: Diable Tonnere – my latest project.

Daniel Uhrenholt, Fri Dec 04 2009, 07:10AM

Hi tobias,

Unfortunately the University only offer the student version to the staff... Probably this is the cheapest to do, as there is a lot of people using this out there:-) And I think that I would need one hell of explanation to get the Professional version:-)

Cheers, Daniel

Daniel Uhrenholt, Fri Dec 04 2009, 07:10AM

Hi tobias,

Unfortunately the University only offer the student version to the staff... Probably this is the cheapest to do, as there is a lot of people using this out there:-) And I think that I would need one hell of explanation to get the Professional version:-)

Cheers, Daniel

Re: Diable Tonnere – my latest project.

tobias, Fri Dec 04 2009, 01:22PM

Alright then! Probably you are using the SDK version (that does not have the toolbox). But if you have the Student version the toolbox and browser need to be activated at "Tools - Addins", at least for the software selled here in Brazil.

I just asked because I aways use the toolbox gears and after you post I though if there was a reason not to use it! hehehe

If you need any help with SolidWorks just PM me..

Again.. Great job!

tobias, Fri Dec 04 2009, 01:22PM

Alright then! Probably you are using the SDK version (that does not have the toolbox). But if you have the Student version the toolbox and browser need to be activated at "Tools - Addins", at least for the software selled here in Brazil.

I just asked because I aways use the toolbox gears and after you post I though if there was a reason not to use it! hehehe

If you need any help with SolidWorks just PM me..

Again.. Great job!

Re: Diable Tonnere – my latest project.

Daniel Uhrenholt, Fri Dec 04 2009, 04:23PM

tobias,

The version of SolidWorks I got, only have the bearing calculator and cam library:-) But I don't mind that, Ive been working with this program for 6 years now, and I`m happy with it.

And now for one more update:

This is the assembled bottom of the primary, Its bolted together with stainless steel screws.

And here with the secondary coil mounted on it!

This baby will weight a ton when it`s done, so I have to weld a aluminum base for it at some point... But there is still a lot to do;-)

Cheers, Daniel

Daniel Uhrenholt, Fri Dec 04 2009, 04:23PM

tobias,

The version of SolidWorks I got, only have the bearing calculator and cam library:-) But I don't mind that, Ive been working with this program for 6 years now, and I`m happy with it.

And now for one more update:

This is the assembled bottom of the primary, Its bolted together with stainless steel screws.

And here with the secondary coil mounted on it!

This baby will weight a ton when it`s done, so I have to weld a aluminum base for it at some point... But there is still a lot to do;-)

Cheers, Daniel

Re: Diable Tonnere – my latest project.

Killa-X, Fri Dec 04 2009, 04:56PM

Yeah looks like your going to need some good wheels on that! Looks like a lot of money, and hard work, looks good I had that idea also awhile back when i was trying to do my 2ft SGTC, a rise/lower base..but I decided not to go forth on doing so. Nice to see you have though, Keep up the good work

I had that idea also awhile back when i was trying to do my 2ft SGTC, a rise/lower base..but I decided not to go forth on doing so. Nice to see you have though, Keep up the good work

Killa-X, Fri Dec 04 2009, 04:56PM

Yeah looks like your going to need some good wheels on that! Looks like a lot of money, and hard work, looks good

I had that idea also awhile back when i was trying to do my 2ft SGTC, a rise/lower base..but I decided not to go forth on doing so. Nice to see you have though, Keep up the good work

I had that idea also awhile back when i was trying to do my 2ft SGTC, a rise/lower base..but I decided not to go forth on doing so. Nice to see you have though, Keep up the good work

Re: Diable Tonnere – my latest project.

Andyman, Fri Dec 04 2009, 09:55PM

It seems like ACME threads would have been better for the lifting system, but finding nuts and bolts with acme threads wouldn't exactly be an easy task.

Andyman, Fri Dec 04 2009, 09:55PM

It seems like ACME threads would have been better for the lifting system, but finding nuts and bolts with acme threads wouldn't exactly be an easy task.

Re: Diable Tonnere – my latest project.

Coronafix, Tue Dec 08 2009, 10:28AM

Daniel, awesome work as usual, but a step up again as a true artist does!

A question about the stainless steel screws you are using. I know that stainless is not ferrous but do you think that they will interfere with the magnetic field at all?

Coronafix, Tue Dec 08 2009, 10:28AM

Daniel, awesome work as usual, but a step up again as a true artist does!

A question about the stainless steel screws you are using. I know that stainless is not ferrous but do you think that they will interfere with the magnetic field at all?

Re: Diable Tonnere – my latest project.

Daniel Uhrenholt, Tue Dec 08 2009, 08:21PM

Hi Coronafix,

I have no idea if the stainless steel screws will make some interference with the magnetic field, but if it does, I doubt it will be much:-) But time will tell...

I'm currently making the primary holders, so maybe I will wind the primary this weekend:-) Then I can test if any of the stainless steel screws get hot...

Cheers, Daniel

Daniel Uhrenholt, Tue Dec 08 2009, 08:21PM

Hi Coronafix,

I have no idea if the stainless steel screws will make some interference with the magnetic field, but if it does, I doubt it will be much:-) But time will tell...

I'm currently making the primary holders, so maybe I will wind the primary this weekend:-) Then I can test if any of the stainless steel screws get hot...

Cheers, Daniel

Re: Diable Tonnere – my latest project.

Dalus, Tue Dec 08 2009, 09:34PM

Allready have some info on the new MMC? Quite curious to see how you'll build it.

Dalus, Tue Dec 08 2009, 09:34PM

Allready have some info on the new MMC? Quite curious to see how you'll build it.

Re: Diable Tonnere – my latest project.

rp181, Tue Dec 08 2009, 11:10PM

If you don't mind answering, what is the expected total cost of such a system?

And what are the range insulators you and finn have used from?

again, impressive.

rp181, Tue Dec 08 2009, 11:10PM

If you don't mind answering, what is the expected total cost of such a system?

And what are the range insulators you and finn have used from?

again, impressive.

Re: Diable Tonnere – my latest project.

Daniel Uhrenholt, Wed Dec 09 2009, 09:05PM

Well, at the moment I don't have a clue about what the total cost will be, but it ain't free, I can tell you that much:-) I think the mechanical parts will cost me around 1700$ when I'm done, and then I need some stepper motors, drivers, power supply and a new MMC...

I'm just glad I don't have to pay anybody to have the parts machined, then the price would be sky high:-) In the shop I work at, we take just around 100$/hour... And this is really cheap in Denmark for mechanical jobs... I worked on the primary coil for 8 hours today, just to make the holders for the primary coil...

The “insulators†we use is actually sewer pipes made out of PVC, they look amazing!!!

Cheers, Daniel

Daniel Uhrenholt, Wed Dec 09 2009, 09:05PM

rp181 wrote ...

If you don't mind answering, what is the expected total cost of such a system?

And what are the range insulators you and finn have used from?

again, impressive.

If you don't mind answering, what is the expected total cost of such a system?

And what are the range insulators you and finn have used from?

again, impressive.

Well, at the moment I don't have a clue about what the total cost will be, but it ain't free, I can tell you that much:-) I think the mechanical parts will cost me around 1700$ when I'm done, and then I need some stepper motors, drivers, power supply and a new MMC...

I'm just glad I don't have to pay anybody to have the parts machined, then the price would be sky high:-) In the shop I work at, we take just around 100$/hour... And this is really cheap in Denmark for mechanical jobs... I worked on the primary coil for 8 hours today, just to make the holders for the primary coil...

The “insulators†we use is actually sewer pipes made out of PVC, they look amazing!!!

Cheers, Daniel

Re: Diable Tonnere – my latest project.

brtaman, Wed Dec 09 2009, 09:56PM

Wow, looking good, really taking it to another level with this one. The engineering, machining everything top notch. Congrats!

Will be looking for updates on this one.

BTW: Something I don't quite get, how will you wind that wire onto the secondary coil-form? Will you make "holes" through the ribs to pass the wire through?

brtaman, Wed Dec 09 2009, 09:56PM

Wow, looking good, really taking it to another level with this one. The engineering, machining everything top notch. Congrats!

Will be looking for updates on this one.

BTW: Something I don't quite get, how will you wind that wire onto the secondary coil-form? Will you make "holes" through the ribs to pass the wire through?

Re: Diable Tonnere – my latest project.

rp181, Wed Dec 09 2009, 10:05PM

I think the orange pipe goes over the actual secondary.

rp181, Wed Dec 09 2009, 10:05PM

I think the orange pipe goes over the actual secondary.

Re: Diable Tonnere – my latest project.

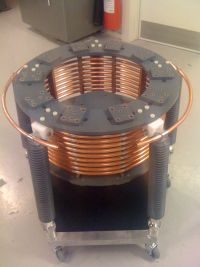

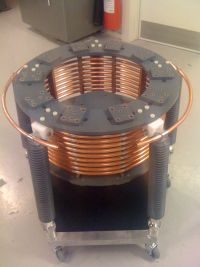

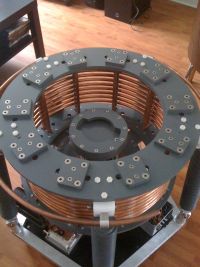

Daniel Uhrenholt, Mon Dec 14 2009, 12:36PM

Hi All,

This weekend I had Finn in the shop to help me with the soldering on the primary coil. This is a true helix coil, and the soldering was a pain in the ***

If I were to make such a primary again, I would solder the last 3 turns instead of all 10...

Here are some pictures for your eyes:

Unfortunately we don't have more Argon in the shop, so I have to wait until January to weld the base for the coil...

Cheers, Daniel

Daniel Uhrenholt, Mon Dec 14 2009, 12:36PM

Hi All,

This weekend I had Finn in the shop to help me with the soldering on the primary coil. This is a true helix coil, and the soldering was a pain in the ***

If I were to make such a primary again, I would solder the last 3 turns instead of all 10...

Here are some pictures for your eyes:

Unfortunately we don't have more Argon in the shop, so I have to wait until January to weld the base for the coil...

Cheers, Daniel

Re: Diable Tonnere – my latest project.

Bennem, Mon Dec 14 2009, 03:20PM

Hi Daniel,

Wow....as per usual, your craftmanship is excellent!

i take it that you have designed you primary that way

so as to mechanically adjust the tuning whilst the coil

is functioning?

Yourself and Finn are becoming great pioneers in the TC world,

i look forward to seeing more of your updates!

once again....Nice Work!!

Mel

Bennem, Mon Dec 14 2009, 03:20PM

Hi Daniel,

Wow....as per usual, your craftmanship is excellent!

i take it that you have designed you primary that way

so as to mechanically adjust the tuning whilst the coil

is functioning?

Yourself and Finn are becoming great pioneers in the TC world,

i look forward to seeing more of your updates!

once again....Nice Work!!

Mel

Re: Diable Tonnere – my latest project.

Coronafix, Mon Dec 14 2009, 10:17PM

Geez Daniel, that shouldn't fall apart too soon!! You have a crane to move the thing around, don't you? ;)

Coronafix, Mon Dec 14 2009, 10:17PM

Geez Daniel, that shouldn't fall apart too soon!! You have a crane to move the thing around, don't you? ;)

Re: Diable Tonnere – my latest project.

Daniel Uhrenholt, Tue Dec 15 2009, 04:39PM

Thanks for the kind words Mel,

Yes I make the primary this way because I need the arm with carbon contacts to slide on the outside of the primary winding. I really hope I can make the arm and contacts in my Christmas holiday, but unfortunately it's winter now, and I cant take the darn coil outside to test it when I'm done...

This idea was something Finn and I discussed a while back, and then Finn pushed me into doing this project:-) The plan is to do something similar on Thumber at some point, but lets see how my â€prototype†works first... This is REALLY a big project, hopefully I´ll be done with the mechanical parts sometime in January, and then I just need to make the drivers for the motors, new MMC, and maybe a new bridge with CM600... So if I'm lucky I will be done sometime around summer next year:-)

I just got a big 3phase variac build in a cabinet on wheels, with fuses, on and off switches... for FREE:-) So that is one thing I don't have to worry about any more...

Coronafix,

Oh yes, it's some heavy gear I'm making here:-) I don't need a crane at the moment to move it around, but when it's done and it has to be moved from the shop, I would wish that there was a elevator in the building I am living in:-)

Cheers, Daniel

Daniel Uhrenholt, Tue Dec 15 2009, 04:39PM

Bennem wrote ...

Wow....as per usual, your craftmanship is excellent!

i take it that you have designed you primary that way

so as to mechanically adjust the tuning whilst the coil

is functioning?

Yourself and Finn are becoming great pioneers in the TC world,

i look forward to seeing more of your updates!

Wow....as per usual, your craftmanship is excellent!

i take it that you have designed you primary that way

so as to mechanically adjust the tuning whilst the coil

is functioning?

Yourself and Finn are becoming great pioneers in the TC world,

i look forward to seeing more of your updates!

Thanks for the kind words Mel,

Yes I make the primary this way because I need the arm with carbon contacts to slide on the outside of the primary winding. I really hope I can make the arm and contacts in my Christmas holiday, but unfortunately it's winter now, and I cant take the darn coil outside to test it when I'm done...

This idea was something Finn and I discussed a while back, and then Finn pushed me into doing this project:-) The plan is to do something similar on Thumber at some point, but lets see how my â€prototype†works first... This is REALLY a big project, hopefully I´ll be done with the mechanical parts sometime in January, and then I just need to make the drivers for the motors, new MMC, and maybe a new bridge with CM600... So if I'm lucky I will be done sometime around summer next year:-)

I just got a big 3phase variac build in a cabinet on wheels, with fuses, on and off switches... for FREE:-) So that is one thing I don't have to worry about any more...

Coronafix,

Oh yes, it's some heavy gear I'm making here:-) I don't need a crane at the moment to move it around, but when it's done and it has to be moved from the shop, I would wish that there was a elevator in the building I am living in:-)

Cheers, Daniel

Re: Diable Tonnere – my latest project.

Daniel Uhrenholt, Sat Dec 19 2009, 07:26PM

Hi all,

Friday I did a prototype high voltage insulator on my lathe, it is made out of POM-C with a toolbit steel that I made by hand.

This is the result:

I want the primary coil to be “flying†on five of these insulators, so the arm can slide on the outside the primary, without bumping in to anything:-) Tuesday Finn will be coming by the shop with the materials I need to make the arm, so hopefully I will have that part done before new year...

Cheers, Daniel

Daniel Uhrenholt, Sat Dec 19 2009, 07:26PM

Hi all,

Friday I did a prototype high voltage insulator on my lathe, it is made out of POM-C with a toolbit steel that I made by hand.

This is the result:

I want the primary coil to be “flying†on five of these insulators, so the arm can slide on the outside the primary, without bumping in to anything:-) Tuesday Finn will be coming by the shop with the materials I need to make the arm, so hopefully I will have that part done before new year...

Cheers, Daniel

Re: Diable Tonnere – my latest project.

Daniel Uhrenholt, Mon Jan 11 2010, 07:14PM

Hi all,

Just a little update on the project, but unfortunately I didn't bring my camera to the shop today, so I don't have any pictures to show.

Before Christmas I milled a internal gear in PVC, where the arm for the tapping point will be mounted. This is now mounted on the coil with the motor that will be moving it around, but because of lack of resources it's not a stepper motor, just a normal geared DC motor that I will control with PWM to adjust the speed.

Today I welded the the base for the coil in Aluminium, and mounted some wheels on it, as the coil is getting really heavy, and is becoming a problem for me to move it around:-)

So what I need to do now is:

Make the insulators that will be holding the primary.

Make the tapping point with carbon brushes, but I still need to do some CNC milling on them, so they will fit nicely on the primary. (Finn brought some rather big carbon brushes to the shop, they are probably from some really heavy starter motors or something)

Find some money to buy a new MMC... If there is some European coilers that will be interested in a bulk buy please give me a PM, or we can start a thread in sale and trade. I think we can get a nice price at Mouser, if we buy enough of them:-) I need a lot, as the impedance of my primary circuit will be around 10 Ohms, and I will be pumping 1400Amps through it...

And make a motor driver... This is something I will start on this week:-)

I will post some pictures tomorrow.

Cheers, Daniel

Daniel Uhrenholt, Mon Jan 11 2010, 07:14PM

Hi all,

Just a little update on the project, but unfortunately I didn't bring my camera to the shop today, so I don't have any pictures to show.

Before Christmas I milled a internal gear in PVC, where the arm for the tapping point will be mounted. This is now mounted on the coil with the motor that will be moving it around, but because of lack of resources it's not a stepper motor, just a normal geared DC motor that I will control with PWM to adjust the speed.

Today I welded the the base for the coil in Aluminium, and mounted some wheels on it, as the coil is getting really heavy, and is becoming a problem for me to move it around:-)

So what I need to do now is:

Make the insulators that will be holding the primary.

Make the tapping point with carbon brushes, but I still need to do some CNC milling on them, so they will fit nicely on the primary. (Finn brought some rather big carbon brushes to the shop, they are probably from some really heavy starter motors or something)

Find some money to buy a new MMC... If there is some European coilers that will be interested in a bulk buy please give me a PM, or we can start a thread in sale and trade. I think we can get a nice price at Mouser, if we buy enough of them:-) I need a lot, as the impedance of my primary circuit will be around 10 Ohms, and I will be pumping 1400Amps through it...

And make a motor driver... This is something I will start on this week:-)

I will post some pictures tomorrow.

Cheers, Daniel

Re: Diable Tonnere – my latest project.

Daniel Uhrenholt, Wed Jan 13 2010, 09:24PM

Hi All,

Here are some pictures of the parts I made.

Cheers, Daniel

Daniel Uhrenholt, Wed Jan 13 2010, 09:24PM

Hi All,

Here are some pictures of the parts I made.

Cheers, Daniel

Re: Diable Tonnere – my latest project.

rp181, Wed Jan 13 2010, 11:02PM

How wonderfully complicated looking! Great job again.

rp181, Wed Jan 13 2010, 11:02PM

How wonderfully complicated looking! Great job again.

Re: Diable Tonnere – my latest project.

Daniel Uhrenholt, Tue Mar 02 2010, 05:59AM

Hi all,

It's been a while since my last post, but I have been busy and haven't had time to do anything before last night. This is just a quick update, as I will go to work soon.

Last night I made the PVC high voltage insulators that will hold the primary coil, it still need some work but I will be done with most of the mechanical parts by Friday.

Cheers, Daniel

Daniel Uhrenholt, Tue Mar 02 2010, 05:59AM

Hi all,

It's been a while since my last post, but I have been busy and haven't had time to do anything before last night. This is just a quick update, as I will go to work soon.

Last night I made the PVC high voltage insulators that will hold the primary coil, it still need some work but I will be done with most of the mechanical parts by Friday.

Cheers, Daniel

Re: Diable Tonnere – my latest project.

Daniel Uhrenholt, Fri Mar 05 2010, 06:52AM

Hi all,

Just a couple of photos of the assembled primary coil, I am almost ready to move it from the shop and home to my apartment to work on the fiber optic motor controllers.

I will start on the tapping point today, and hopefully it will be almost as cool as Finn's:-)

Cheers, Daniel

Daniel Uhrenholt, Fri Mar 05 2010, 06:52AM

Hi all,

Just a couple of photos of the assembled primary coil, I am almost ready to move it from the shop and home to my apartment to work on the fiber optic motor controllers.

I will start on the tapping point today, and hopefully it will be almost as cool as Finn's:-)

Cheers, Daniel

Re: Diable Tonnere – my latest project.

thehappyelectron, Sun Mar 14 2010, 09:58AM

you sir, are awesome.

thehappyelectron, Sun Mar 14 2010, 09:58AM

you sir, are awesome.

Re: Diable Tonnere – my latest project.

Daniel Uhrenholt, Sat May 29 2010, 09:23AM

Hi all,

It's been a while since my last update, my girlfriend just moved in, so now I'm trying to have a life besides just doing fun projects:-)

First of all there is a battle of who will have first light between Finn and I, but I think it is Finn that gets the credit for that, because I have to move all of my stuff to another city before I can make sparks all day long:-) I live in a small apartment in Aalborg, and the coil takes half of the space in the bedroom...

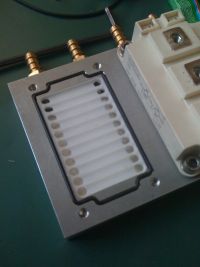

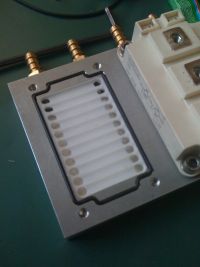

Here are some pictures of the water cooling for the new H bridge, and the new bus for the capacitors. I wanted water cooling because of bad design from the beginning, as there wasn't enough space for the bridge I had in hand, and it is cool when I can make this kind of things myself:-)

I also had to make myself a new toroid for the coil, so I made a drawing of the rings I needed and went to the local metal college, and had some students make the rings for me. Then I welded the parts together at the University, and had to transport the toroid by bus to get it home:-)

And some pictures of the coil as it looks now:

Another larger project is the motor controllers that I am making for Finn and I. They are build on two Arduino platforms, communicating with ASCII over fiberoptics. The controller box will also have MIDI in it, but I am having some minor problems with the code for that, but I will have it done sometime next week when I get to the University again:-)

Now I will go to Hobro to visit Finn and make some stuff on Thumper:-)

Cheers, Daniel

Daniel Uhrenholt, Sat May 29 2010, 09:23AM

Hi all,

It's been a while since my last update, my girlfriend just moved in, so now I'm trying to have a life besides just doing fun projects:-)

First of all there is a battle of who will have first light between Finn and I, but I think it is Finn that gets the credit for that, because I have to move all of my stuff to another city before I can make sparks all day long:-) I live in a small apartment in Aalborg, and the coil takes half of the space in the bedroom...

Here are some pictures of the water cooling for the new H bridge, and the new bus for the capacitors. I wanted water cooling because of bad design from the beginning, as there wasn't enough space for the bridge I had in hand, and it is cool when I can make this kind of things myself:-)

I also had to make myself a new toroid for the coil, so I made a drawing of the rings I needed and went to the local metal college, and had some students make the rings for me. Then I welded the parts together at the University, and had to transport the toroid by bus to get it home:-)

And some pictures of the coil as it looks now:

Another larger project is the motor controllers that I am making for Finn and I. They are build on two Arduino platforms, communicating with ASCII over fiberoptics. The controller box will also have MIDI in it, but I am having some minor problems with the code for that, but I will have it done sometime next week when I get to the University again:-)

Now I will go to Hobro to visit Finn and make some stuff on Thumper:-)

Cheers, Daniel

Re: Diable Tonnere – my latest project.

Steve Conner, Sat May 29 2010, 10:16AM

This looks awesome

Just one word of warning: In your bus design, you have the current flowing through the bolts. If they're steel, they'll get extremely hot by induction heating.

Ideally the current path should be all copper and brass, but non-magnetic stainless steel will probably be OK.

Steve Conner, Sat May 29 2010, 10:16AM

This looks awesome

Just one word of warning: In your bus design, you have the current flowing through the bolts. If they're steel, they'll get extremely hot by induction heating.

Ideally the current path should be all copper and brass, but non-magnetic stainless steel will probably be OK.

Re: Diable Tonnere – my latest project.

Dalus, Sun May 30 2010, 09:09AM

Wow your picking up speed. Love the idea of directly cooling the IGBT's with water. Is it going to be a closed loop system? And how are you going to tackle corrosion due to the different metals?

Dalus, Sun May 30 2010, 09:09AM

Wow your picking up speed. Love the idea of directly cooling the IGBT's with water. Is it going to be a closed loop system? And how are you going to tackle corrosion due to the different metals?

Re: Diable Tonnere – my latest project.

Dr. H., Sun May 30 2010, 02:59PM

Great job Daniel

and that is one CLEAN workshop you have there.

Cheers.

Dr. H., Sun May 30 2010, 02:59PM

Great job Daniel

and that is one CLEAN workshop you have there.

Cheers.

Re: Diable Tonnere – my latest project.

Daniel Uhrenholt, Sun May 30 2010, 09:06PM

Steve,

Thanks for the comment.

I don't use the bolts at connections between the bus bars, I have some distance pieces made out of brass hidden under the black plastic:-)

Linas,

I also like the idea of direct cooling of the IGBT`s, the idea came to me while I was working on a set-up for a company who makes the power electronics for windmills. I had a look inside the water cooling system on a 4MW windmill:-) They use direct cooling on their power stacks, and I was so lucky to see how it looked under the HUGE IGBT`s

I don't think that corrosion will be that big a deal, most of the parts is made out of brass, I think that I just have to change the water once a year...

I am still loking for radiators and pumps for it, so for first light it probably just the water hose from my parents garden:-)

Huben,

Thanks:-) It has to look clean when you have costumers running around all day there:-)

Cheers, Daniel

Daniel Uhrenholt, Sun May 30 2010, 09:06PM

Steve,

Thanks for the comment.

I don't use the bolts at connections between the bus bars, I have some distance pieces made out of brass hidden under the black plastic:-)

Linas,

I also like the idea of direct cooling of the IGBT`s, the idea came to me while I was working on a set-up for a company who makes the power electronics for windmills. I had a look inside the water cooling system on a 4MW windmill:-) They use direct cooling on their power stacks, and I was so lucky to see how it looked under the HUGE IGBT`s

I don't think that corrosion will be that big a deal, most of the parts is made out of brass, I think that I just have to change the water once a year...

I am still loking for radiators and pumps for it, so for first light it probably just the water hose from my parents garden:-)

Huben,

Thanks:-) It has to look clean when you have costumers running around all day there:-)

Cheers, Daniel

Re: Diable Tonnere – my latest project.

Dalus, Mon May 31 2010, 08:52AM

Pst I'm not Linas, if your worried about the corrosion you can use those watercooling liquids that are used in PC cooling systems. Those are designed to minimize any redox reactions between the different metals.

Dalus, Mon May 31 2010, 08:52AM

Pst I'm not Linas, if your worried about the corrosion you can use those watercooling liquids that are used in PC cooling systems. Those are designed to minimize any redox reactions between the different metals.

Re: Diable Tonnere – my latest project.

Daniel Uhrenholt, Mon May 31 2010, 09:06AM

Woops, Dalus i`m sorry about that:-)

I`m looking at some cooling systems for computers, that I would like to use for the coil. But the problem for now is the lack of $$ to use on coiling at the moment. This project has taken a lot of my time and money for some while, and I want some kind of vacation this summer with my girlfriend...

Daniel Uhrenholt, Mon May 31 2010, 09:06AM

Woops, Dalus i`m sorry about that:-)

I`m looking at some cooling systems for computers, that I would like to use for the coil. But the problem for now is the lack of $$ to use on coiling at the moment. This project has taken a lot of my time and money for some while, and I want some kind of vacation this summer with my girlfriend...

Re: Diable Tonnere – my latest project.

Dalus, Mon May 31 2010, 09:55AM

Understandable. I have exactly the same problem I do want to continue my coil but everything is going so slowly. A 20 year old student doesn't earn that much. I'll be glad if I can pay for the MMC this year :S

Dalus, Mon May 31 2010, 09:55AM

Understandable. I have exactly the same problem I do want to continue my coil but everything is going so slowly. A 20 year old student doesn't earn that much. I'll be glad if I can pay for the MMC this year :S

Re: Diable Tonnere – my latest project.

Finn Hammer, Mon May 31 2010, 09:28PM

There is an article about the Danfoss way of cooling those very IGBT's in the current issue of Power Systems Design:

Cheers, Finn Hammer

Finn Hammer, Mon May 31 2010, 09:28PM

Daniel Uhrenholt wrote ...

I had a look inside the water cooling system on a 4MW windmill:-) They use direct cooling on their power stacks, and I was so lucky to see how it looked under the HUGE IGBT`s

I had a look inside the water cooling system on a 4MW windmill:-) They use direct cooling on their power stacks, and I was so lucky to see how it looked under the HUGE IGBT`s

There is an article about the Danfoss way of cooling those very IGBT's in the current issue of Power Systems Design:

Cheers, Finn Hammer

Re: Diable Tonnere – my latest project.

Daniel Uhrenholt, Tue Jun 01 2010, 05:45AM

That fine piece of machined aluminum that we used for the system, is similar to the one seen in the second picture:-)

The university is making a intelligent system for fault detection in the cooling nozzles, this is all about big $$, as there is a lot of money to be saved if they can detect if the nozzles get stopped due to dirt in the system. Burnt IGBT`s in a sea windmill is NOT a cheap thing to replace:-)

Cheers, Daniel

Daniel Uhrenholt, Tue Jun 01 2010, 05:45AM

That fine piece of machined aluminum that we used for the system, is similar to the one seen in the second picture:-)

The university is making a intelligent system for fault detection in the cooling nozzles, this is all about big $$, as there is a lot of money to be saved if they can detect if the nozzles get stopped due to dirt in the system. Burnt IGBT`s in a sea windmill is NOT a cheap thing to replace:-)

Cheers, Daniel

Re: Diable Tonnere – my latest project.

Daniel Uhrenholt, Mon Oct 11 2010, 12:30PM

Hi all,

Diable Tonnere is done now, and here is a small video for you all to enjoy

It breaks the 2.4 meter barrier, and the sparks truly looks awesome! The sparks have the appearance of a spruce branch, which I newer seen before. I will post some pictures of the coil when I get home, I`m at work right now taking a break...

Cheers, Daniel

Daniel Uhrenholt, Mon Oct 11 2010, 12:30PM

Hi all,

Diable Tonnere is done now, and here is a small video for you all to enjoy

It breaks the 2.4 meter barrier, and the sparks truly looks awesome! The sparks have the appearance of a spruce branch, which I newer seen before. I will post some pictures of the coil when I get home, I`m at work right now taking a break...

Cheers, Daniel

Re: Diable Tonnere – my latest project.

Linas, Mon Oct 11 2010, 02:13PM

Very nice

How lot voltage is one the bridge ? and what is rms current ?

Linas, Mon Oct 11 2010, 02:13PM

Very nice

How lot voltage is one the bridge ? and what is rms current ?

Re: Diable Tonnere – my latest project.

Daniel Uhrenholt, Mon Oct 11 2010, 02:37PM

There was around 650V on the bridge, and the ocd is set to trip at 1400 Amps :) I have no idea what the rms current is...

Daniel Uhrenholt, Mon Oct 11 2010, 02:37PM

There was around 650V on the bridge, and the ocd is set to trip at 1400 Amps :) I have no idea what the rms current is...

Re: Diable Tonnere – my latest project.

Mads Barnkob, Mon Oct 11 2010, 02:53PM

Its good to see this finally blasting sparks :D

Great job!

Mads Barnkob, Mon Oct 11 2010, 02:53PM

Its good to see this finally blasting sparks :D

Great job!

Re: Diable Tonnere – my latest project.

Adam Munich, Mon Oct 11 2010, 05:35PM

That sir is one beautiful coil.

Adam Munich, Mon Oct 11 2010, 05:35PM

That sir is one beautiful coil.

Re: Diable Tonnere – my latest project.

Daniel Uhrenholt, Mon Oct 11 2010, 08:07PM

Thanks for the comments:-)

This has without doubt been the biggest project I've ever made, and also the hardest. A lot of headache and a lot of hard work has been put in this project. It has also survived a time where I was sick with stress, and thought about putting coiling and electronics on the shelf... But I am a nerd and a little illness can not stop me:-)

Here are some pictures of the coil, taken at the location where Finn and I have our mechanical workshop, and test location for our further research on tuning.

This machine is going to kick some arse when I ramp the variac up to 100% as I am only at 70-80% at the moment:-)

Cheers, Daniel

Daniel Uhrenholt, Mon Oct 11 2010, 08:07PM

Thanks for the comments:-)

This has without doubt been the biggest project I've ever made, and also the hardest. A lot of headache and a lot of hard work has been put in this project. It has also survived a time where I was sick with stress, and thought about putting coiling and electronics on the shelf... But I am a nerd and a little illness can not stop me:-)

Here are some pictures of the coil, taken at the location where Finn and I have our mechanical workshop, and test location for our further research on tuning.

This machine is going to kick some arse when I ramp the variac up to 100% as I am only at 70-80% at the moment:-)

Cheers, Daniel

Re: Diable Tonnere – my latest project.

Arcstarter, Mon Oct 11 2010, 08:41PM

omgomgomg

Every time i look at that thing i start to sweat and have anxiety attacks. That this is MEAN looking! I love the tubing topload with the spun topload. And that cooling scheme is awesome, and will (obviously) cool the hell out of some IGBTs.

Good work, i look forward to seeing more about the coil. Maybe even some videos?

Arcstarter, Mon Oct 11 2010, 08:41PM

omgomgomg

Every time i look at that thing i start to sweat and have anxiety attacks. That this is MEAN looking! I love the tubing topload with the spun topload. And that cooling scheme is awesome, and will (obviously) cool the hell out of some IGBTs.

Good work, i look forward to seeing more about the coil. Maybe even some videos?

Re: Diable Tonnere – my latest project.

dmg, Mon Oct 11 2010, 11:03PM

Yeah, damn, this coil seriously owns!

Where did you get that corrogated pipe for the secondary? or did you make it yourself?

Id love to use one.

dmg, Mon Oct 11 2010, 11:03PM

Yeah, damn, this coil seriously owns!

Where did you get that corrogated pipe for the secondary? or did you make it yourself?

Id love to use one.

Re: Diable Tonnere – my latest project.

Daniel Uhrenholt, Tue Oct 12 2010, 07:39AM

Thanks,

There is a video of the coil running on my Youtube channel

There will be more videos soon, taken with a better camera, and under other circumstances

There will be more videos soon, taken with a better camera, and under other circumstances

Gatedbreakdown,

The pipe is some kind of sewer pipe, Finn used this on his V-twin BRISG coil. I thought it looked cool, so I asked him to buy one for me

Daniel Uhrenholt, Tue Oct 12 2010, 07:39AM

Thanks,

There is a video of the coil running on my Youtube channel

There will be more videos soon, taken with a better camera, and under other circumstances

There will be more videos soon, taken with a better camera, and under other circumstances

Gatedbreakdown,

The pipe is some kind of sewer pipe, Finn used this on his V-twin BRISG coil. I thought it looked cool, so I asked him to buy one for me

Re: Diable Tonnere – my latest project.

Steve Conner, Tue Oct 12 2010, 09:24AM

Yeah baby! :D

That stuff is "Ultrarib" sewer pipe.

What IGBTs did you use again Daniel, the white Semikron ones?

Steve Conner, Tue Oct 12 2010, 09:24AM

Yeah baby! :D

That stuff is "Ultrarib" sewer pipe.

What IGBTs did you use again Daniel, the white Semikron ones?

Re: Diable Tonnere – my latest project.

Daniel Uhrenholt, Tue Oct 12 2010, 09:56AM

Hi Steve,

Yes, I use the white Semikron SKM400GB124, they are extremely robust, ultra fast, and are easy to drive. The IGBT`s in the coil ran for 3 months 4 times per hour, 15 seconds each time, 8 hours a day at 360V 600 Amps last year. That`s 12 whole hours on pulsed mode.

I think that they are worth the price:-)

Didn`t you use the same bricks for something in the past?

Cheers, Daniel

Daniel Uhrenholt, Tue Oct 12 2010, 09:56AM

Hi Steve,

Yes, I use the white Semikron SKM400GB124, they are extremely robust, ultra fast, and are easy to drive. The IGBT`s in the coil ran for 3 months 4 times per hour, 15 seconds each time, 8 hours a day at 360V 600 Amps last year. That`s 12 whole hours on pulsed mode.

I think that they are worth the price:-)

Didn`t you use the same bricks for something in the past?

Cheers, Daniel

Re: Diable Tonnere – my latest project.

Steve Conner, Tue Oct 12 2010, 10:26AM

I had the SKM400GB123D, but I sold them to Marko. They're a bit slower than the 124 series, but Marko now has no excuse.

Did you buy yours new? The 124 series is a newer generation and I haven't seen them on the surplus market.

Steve Conner, Tue Oct 12 2010, 10:26AM

I had the SKM400GB123D, but I sold them to Marko. They're a bit slower than the 124 series, but Marko now has no excuse.

Did you buy yours new? The 124 series is a newer generation and I haven't seen them on the surplus market.

Re: Diable Tonnere – my latest project.

Dalus, Tue Oct 12 2010, 07:37PM

Awesome looking coil Daniel. Let's hope it'll be throwing arcs for some long distances and for a long time to come

Dalus, Tue Oct 12 2010, 07:37PM

Awesome looking coil Daniel. Let's hope it'll be throwing arcs for some long distances and for a long time to come

Re: Diable Tonnere – my latest project.

Finn Hammer, Tue Oct 12 2010, 09:01PM

You bet! Ribbed for your pleasure

Cheers, Finn Hammer

Finn Hammer, Tue Oct 12 2010, 09:01PM

Steve McConner wrote ...

Yeah baby! :D

That stuff is "Ultrarib" sewer pipe.

Yeah baby! :D

That stuff is "Ultrarib" sewer pipe.

You bet! Ribbed for your pleasure

Cheers, Finn Hammer

Re: Diable Tonnere – my latest project.

Coronafix, Tue Oct 12 2010, 09:08PM

Does it make your coil more sensitive?!

Coronafix, Tue Oct 12 2010, 09:08PM

Finn Hammer wrote ...

You bet! Ribbed for your pleasure

Steve McConner wrote ...

Yeah baby! :D

That stuff is "Ultrarib" sewer pipe.

Yeah baby! :D

That stuff is "Ultrarib" sewer pipe.

You bet! Ribbed for your pleasure

Does it make your coil more sensitive?!

Re: Diable Tonnere – my latest project.

Steve Conner, Wed Oct 13 2010, 09:18AM

If the ribs didn't do it for you, I'm sure the 500,000 volts would.

Steve Conner, Wed Oct 13 2010, 09:18AM

If the ribs didn't do it for you, I'm sure the 500,000 volts would.

Re: Diable Tonnere – my latest project.

Dalus, Thu Oct 14 2010, 08:03PM

It's one hell of a toy, that's for sure

Dalus, Thu Oct 14 2010, 08:03PM

It's one hell of a toy, that's for sure

Re: Diable Tonnere – my latest project.

Daniel Uhrenholt, Tue Oct 19 2010, 08:49AM

Steve,

I didn`t buy them used, but from a guy in Denmark who had them in the original box for a fair price

I`m having some problems with the coil at the moment, the spark output is falling drastic and is now just around 2 meters. I think that I need a new and better cap that can take some more RMS current, as the one that I have now only can take around 100A. And a new bus cap made from some large RIFA caps that I`m looking at... Finn and I took a cap out of the mmc, and unrolled the film and isolation layer to see if the cap was dead, but it had almost no self healing spots.

One headache just takes on another, and this may take some while before I can finish it... And there is getting cold outside, so there will be no coiling for the months to come...

I`m also making a new MIDI interrupter with a friend of mine at the university, but more info on that later

Cheers, Daniel

Daniel Uhrenholt, Tue Oct 19 2010, 08:49AM

Steve,

I didn`t buy them used, but from a guy in Denmark who had them in the original box for a fair price

I`m having some problems with the coil at the moment, the spark output is falling drastic and is now just around 2 meters. I think that I need a new and better cap that can take some more RMS current, as the one that I have now only can take around 100A. And a new bus cap made from some large RIFA caps that I`m looking at... Finn and I took a cap out of the mmc, and unrolled the film and isolation layer to see if the cap was dead, but it had almost no self healing spots.

One headache just takes on another, and this may take some while before I can finish it... And there is getting cold outside, so there will be no coiling for the months to come...

I`m also making a new MIDI interrupter with a friend of mine at the university, but more info on that later

Cheers, Daniel

Print this page