Yet another coil gun prototype

Zuckerstange47, Thu Oct 25 2018, 05:27PMI finished my first prototype gauss cannon that contains a microprocessor to control the power supply to the coil, and a phototransistor light-barrier to determine the time for deactivating the magnet.

The design is very simple and faulty, but I hope to be able to improve and expand it in the future.

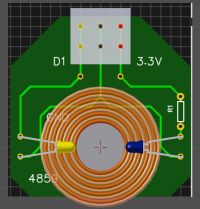

The construction consists of an ESP32, one working light-barrier (another one is not connected yet), a 1mm-wire spool (4 cm outer diameter, 1.4 cm length) that is wound on an acrylic tube (1.2 and 1.0 cm diameter). As a switch I am using a MOSFET (IRFP 2907, 75V, 209A), triggered by a MOSFET driver. The projectile is cut from of a steel nail (0.95 x 3.5 cm) and has a weight of 18g.

Power is delivered by a capacitor specified with 50V, 15mF, that is only charged up to 40V at the moment.

The next steps will be to enhance the wiring, set it up to measure the projectile's speed, test bigger capacitors and increase the voltage. In the future I also would like to add more stages and see how it goes...

edit:

I soldered shorter wires to the capacitor which resulted in an extremely fast projectile - the light-barrier was reached in about half the time. I also tested a 22 mF capacitor and combining the 15 and the 22 mF capacitor, resulting in a slightly shorter passing time.

New video:

Re: Yet another coil gun prototype

V2006, Sat Oct 27 2018, 09:50PM

It is possible that 50 volts would be an acceptable voltage. The model for 100 volts was successfully tested by me:

V2006, Sat Oct 27 2018, 09:50PM

It is possible that 50 volts would be an acceptable voltage. The model for 100 volts was successfully tested by me:

Re: Yet another coil gun prototype

Zuckerstange47, Tue Oct 30 2018, 04:16PM

My plan is to go near 100 V and use multiple coils with 1mm-wire, 9 rows and 10 layers. The first shots utilized only 40 V because I did not have a fitting step-up converter then (still I do not have 100V-capacitors, so I will not put the plan into practice soon).

The current version is much more powerful than the one on the last video. I did attach the second light barrier, so the display shows the speed and the energy after each shot. Also the wiring at the coil is much better.

Yesterday I shot a 128g-nail (because I cannot find the small projectile anymore), which was measured at 0.88 joule at about 40V. Today I connected another step-up converter and went up to 46 V with a new 20g-projectile, which resulted in a speed of about 9.9 m/s and 0.98 joule (if my math is correct).

Now I need to design something to catch the projectiles safely

When I click you first link @V2006, I am forwarded to a page asking for my youtube-login data, but I do not see any video. I noticed that before, as I watched your videos in the past.

Zuckerstange47, Tue Oct 30 2018, 04:16PM

My plan is to go near 100 V and use multiple coils with 1mm-wire, 9 rows and 10 layers. The first shots utilized only 40 V because I did not have a fitting step-up converter then (still I do not have 100V-capacitors, so I will not put the plan into practice soon).

The current version is much more powerful than the one on the last video. I did attach the second light barrier, so the display shows the speed and the energy after each shot. Also the wiring at the coil is much better.

Yesterday I shot a 128g-nail (because I cannot find the small projectile anymore), which was measured at 0.88 joule at about 40V. Today I connected another step-up converter and went up to 46 V with a new 20g-projectile, which resulted in a speed of about 9.9 m/s and 0.98 joule (if my math is correct).

Now I need to design something to catch the projectiles safely

When I click you first link @V2006, I am forwarded to a page asking for my youtube-login data, but I do not see any video. I noticed that before, as I watched your videos in the past.

Re: Yet another coil gun prototype

V2006, Tue Oct 30 2018, 09:49PM

1 mm wire is very small - it is better to increase the cross section

V2006, Tue Oct 30 2018, 09:49PM

1 mm wire is very small - it is better to increase the cross section

Re: Yet another coil gun prototype

Zuckerstange47, Tue Oct 30 2018, 11:33PM

I will think about the wire size, what kind of wire are you using? I remember reading somewhere in this forum, that wire above 1mm would be almost impossible to roll up properly, so that might have been the reason why I chose this diameter.

However that may be, here is another video I just made. At the end there is also an old shot, that I made about one day ago.

Zuckerstange47, Tue Oct 30 2018, 11:33PM

I will think about the wire size, what kind of wire are you using? I remember reading somewhere in this forum, that wire above 1mm would be almost impossible to roll up properly, so that might have been the reason why I chose this diameter.

However that may be, here is another video I just made. At the end there is also an old shot, that I made about one day ago.

Re: Yet another coil gun prototype

V2006, Thu Nov 01 2018, 09:07PM

Take at least 1.5 mm or 1mm but with two wires

and better than 2 mm and more

V2006, Thu Nov 01 2018, 09:07PM

Take at least 1.5 mm or 1mm but with two wires

and better than 2 mm and more

Re: Yet another coil gun prototype

Tomspol, Sat Nov 03 2018, 09:58AM

Hi, I like how your project is made modular but I would recommend you to make all the power wires as short as possible especially that mosfet connection. Also you might achieve better results with coil with the same length as the projectile and place that light barrier on the other end of coil and switch it off when projectile reaches it. I would also like to ask where did you buy the acrylic tube? Anyway I'm looking forward to new updates.

Tomspol, Sat Nov 03 2018, 09:58AM

Hi, I like how your project is made modular but I would recommend you to make all the power wires as short as possible especially that mosfet connection. Also you might achieve better results with coil with the same length as the projectile and place that light barrier on the other end of coil and switch it off when projectile reaches it. I would also like to ask where did you buy the acrylic tube? Anyway I'm looking forward to new updates.

Re: Yet another coil gun prototype

Zuckerstange47, Sat Nov 03 2018, 11:56AM

I will make the wires shorter in the next versions, this is not meant to be highly efficient, yet.

Why should the coil be the same length as the projectile? Could you give me a hint towards the pysics behind it? I was thinking about using a much longer, heavier projectile, to be able to transfer more energy because of longer influence of the magnetic fields, especially in the later coils.

I read, that the best results would be achieved when the length and diameter of the coil would roughly be identical; If you double the length of a coil, the magnetic field strength is halved (provided the length of the wire stays the same), right?

In case there are no/few experiments on that matter, I might try to build two coils with different length/diameter-ratios and test the resulting speeds... but I assume that the analysis will be tricky, when also bringing the energy consumption into accout.

When calculating coils with a thicker wire I had the impression that (striving for the same amperage as a thinner-wired coil) the time for the magnetic field to strengthen would be much longer. When comparing a 1mm to a 1.9mm wired coil, the time to reach 90% of the maximum current rises from 3.8 ms to 21 ms. Also the time for the current to go to zero after deactivating the coil should be much longer, so in conclusion the coil would have to be activated earlier and deactivated some time before the projectile reaches it's center, to prevent retardation after exceeding the center? I am not sure if the results of my calculator are dependable, and my physical knowledge might be not sufficient to interpret it correctly, but I have the feeling that the advantages and disadvantages of different sizes of wires about even themselves out (with much higher costs and weight when using thick wires).

What do you mean by placing the light barrier on the other side of the coil? So that the projectile interrupts the light before reaching the coil (to get reproducable starting positions?)? At the moment, the projectile is placed before the coil manually, and the magnet is turned off when the projectile reaches the first light barrier behind the coil. The second coil is only for measuring the speed.

Maybe it would be the best to start from scratch (apart from the wooden wall), because there are so many thing I would like to change. Then I would do a much more stable mount for the unmeant moving parts, that would allow adjusting the distances of the components easily; meter the voltage of the capacitors by the ESP32, so the energy consumption after each shot could be displayed, and so on...

I bought the tube in a german shop "Holzmaus" (=Wood/lumber mouse) that has a large variety of tubes (but also other materials and forms):

They only deliver to Germoney, Austria, the Netherlands, Luxembourg and Belgium.

Zuckerstange47, Sat Nov 03 2018, 11:56AM

I will make the wires shorter in the next versions, this is not meant to be highly efficient, yet.

Tomspol wrote ...

Also you might achieve better results with coil with the same length as the projectile and place that light barrier on the other end of coil and switch it off when projectile reaches it. I would also like to ask where did you buy the acrylic tube? Anyway I'm looking forward to new updates.

Also you might achieve better results with coil with the same length as the projectile and place that light barrier on the other end of coil and switch it off when projectile reaches it. I would also like to ask where did you buy the acrylic tube? Anyway I'm looking forward to new updates.

Why should the coil be the same length as the projectile? Could you give me a hint towards the pysics behind it? I was thinking about using a much longer, heavier projectile, to be able to transfer more energy because of longer influence of the magnetic fields, especially in the later coils.

I read, that the best results would be achieved when the length and diameter of the coil would roughly be identical; If you double the length of a coil, the magnetic field strength is halved (provided the length of the wire stays the same), right?

In case there are no/few experiments on that matter, I might try to build two coils with different length/diameter-ratios and test the resulting speeds... but I assume that the analysis will be tricky, when also bringing the energy consumption into accout.

When calculating coils with a thicker wire I had the impression that (striving for the same amperage as a thinner-wired coil) the time for the magnetic field to strengthen would be much longer. When comparing a 1mm to a 1.9mm wired coil, the time to reach 90% of the maximum current rises from 3.8 ms to 21 ms. Also the time for the current to go to zero after deactivating the coil should be much longer, so in conclusion the coil would have to be activated earlier and deactivated some time before the projectile reaches it's center, to prevent retardation after exceeding the center? I am not sure if the results of my calculator are dependable, and my physical knowledge might be not sufficient to interpret it correctly, but I have the feeling that the advantages and disadvantages of different sizes of wires about even themselves out (with much higher costs and weight when using thick wires).

What do you mean by placing the light barrier on the other side of the coil? So that the projectile interrupts the light before reaching the coil (to get reproducable starting positions?)? At the moment, the projectile is placed before the coil manually, and the magnet is turned off when the projectile reaches the first light barrier behind the coil. The second coil is only for measuring the speed.

Maybe it would be the best to start from scratch (apart from the wooden wall), because there are so many thing I would like to change. Then I would do a much more stable mount for the unmeant moving parts, that would allow adjusting the distances of the components easily; meter the voltage of the capacitors by the ESP32, so the energy consumption after each shot could be displayed, and so on...

I bought the tube in a german shop "Holzmaus" (=Wood/lumber mouse) that has a large variety of tubes (but also other materials and forms):

They only deliver to Germoney, Austria, the Netherlands, Luxembourg and Belgium.

Re: Yet another coil gun prototype

Tomspol, Sat Nov 03 2018, 02:02PM

I'm sorry, I didn't write it right. I meant placing light barrier on the beginning of the coil such that when you load the projectile into coil the light beam is interrupted. When you fire the projectile starts moving and when its whole in the coil (if the projectile has same length as coil) it clears the light barrier and coil is switched off. It looked like if you have the light barrier behind the coil the projectile is being pulled back before it reaches the light barrier. But on second thought it pretty much depends on length of projectile.

From my experiments I've got the impression that identical length of coil an projectile would be better than coil with large diameter and longer projectile. But I might be mistaken, it would definitely deserve more look into.

I'm not quite sure what do you want to achieve by increasing wire diameter. You could increase current through coil just by using higher voltage.

Tomspol, Sat Nov 03 2018, 02:02PM

I'm sorry, I didn't write it right. I meant placing light barrier on the beginning of the coil such that when you load the projectile into coil the light beam is interrupted. When you fire the projectile starts moving and when its whole in the coil (if the projectile has same length as coil) it clears the light barrier and coil is switched off. It looked like if you have the light barrier behind the coil the projectile is being pulled back before it reaches the light barrier. But on second thought it pretty much depends on length of projectile.

From my experiments I've got the impression that identical length of coil an projectile would be better than coil with large diameter and longer projectile. But I might be mistaken, it would definitely deserve more look into.

I'm not quite sure what do you want to achieve by increasing wire diameter. You could increase current through coil just by using higher voltage.

Re: Yet another coil gun prototype

Zuckerstange47, Sun Nov 04 2018, 07:03PM

You are right about the placement of the light barrier, another advantage would be that the triggering might be more exact, when using a projectile that has a flat back, but a pointy tip. I already thought about that and might change my design in the future. At the moment I am not sure, how to shape the projectile, if it needs fletchings, like a arrow, to get a stable flight... so far, my idea is to hollow out the rear part of the nail to make it lighter than the front.

The increased wire-diameter was a thought based on V2006's reply directly above yours. I think the reason behind it would be to increase the magnetic field strength and the amperage, or the length of the coil to have a longer time of energy transfer. Using a higher voltage would also lead to changing many other parts, like MOSFETs and capacitors, so I think I will stay at 1mm for now.

Zuckerstange47, Sun Nov 04 2018, 07:03PM

Tomspol wrote ...

I'm sorry, I didn't write it right. I meant placing light barrier on the beginning of the coil such that when you load the projectile into coil the light beam is interrupted. When you fire the projectile starts moving and when its whole in the coil (if the projectile has same length as coil) it clears the light barrier and coil is switched off. It looked like if you have the light barrier behind the coil the projectile is being pulled back before it reaches the light barrier. But on second thought it pretty much depends on length of projectile.

From my experiments I've got the impression that identical length of coil an projectile would be better than coil with large diameter and longer projectile. But I might be mistaken, it would definitely deserve more look into.

I'm not quite sure what do you want to achieve by increasing wire diameter. You could increase current through coil just by using higher voltage.

I'm sorry, I didn't write it right. I meant placing light barrier on the beginning of the coil such that when you load the projectile into coil the light beam is interrupted. When you fire the projectile starts moving and when its whole in the coil (if the projectile has same length as coil) it clears the light barrier and coil is switched off. It looked like if you have the light barrier behind the coil the projectile is being pulled back before it reaches the light barrier. But on second thought it pretty much depends on length of projectile.

From my experiments I've got the impression that identical length of coil an projectile would be better than coil with large diameter and longer projectile. But I might be mistaken, it would definitely deserve more look into.

I'm not quite sure what do you want to achieve by increasing wire diameter. You could increase current through coil just by using higher voltage.

You are right about the placement of the light barrier, another advantage would be that the triggering might be more exact, when using a projectile that has a flat back, but a pointy tip. I already thought about that and might change my design in the future. At the moment I am not sure, how to shape the projectile, if it needs fletchings, like a arrow, to get a stable flight... so far, my idea is to hollow out the rear part of the nail to make it lighter than the front.

The increased wire-diameter was a thought based on V2006's reply directly above yours. I think the reason behind it would be to increase the magnetic field strength and the amperage, or the length of the coil to have a longer time of energy transfer. Using a higher voltage would also lead to changing many other parts, like MOSFETs and capacitors, so I think I will stay at 1mm for now.

Re: Yet another coil gun prototype

V2006, Tue Nov 06 2018, 10:43AM

On these videos, the coil is wound with a wire of 2.6 mm (winding diameter 5.5 mm, 3 layers of 20 turns each)

Moisten at least 1.5 mm - it will be much better than 1 mm - you will immediately see.

V2006, Tue Nov 06 2018, 10:43AM

On these videos, the coil is wound with a wire of 2.6 mm (winding diameter 5.5 mm, 3 layers of 20 turns each)

Moisten at least 1.5 mm - it will be much better than 1 mm - you will immediately see.

Re: Yet another coil gun prototype

Zuckerstange47, Thu Nov 08 2018, 01:49AM

I tried to use the ESP32 as some kind of oszilloscope (not sure though, because I do not own an oszilloscope nor used one before) to measure voltages while and after activating the coil.

The top graphs show the capacitor's voltage for two activations, the first starting at 40V, the second at a lower voltage.

The bottom graphs display the voltage over the coil (the first with an initial capacitor's voltage of about 19V, the second with 30V). I don't understand why the first datapoint and the ones after deactivating the coil are 4095 (the maximum value that the ESP32 can give out) and not zero as I expected. Also I am not sure what to make with the data, but I am happy that the measurement worked.

My interpretation is, that the coil takes at least about 2000 microseconds to get full amperage after activation, but when considering the overlaying drainage of the capacitors the maximum would be farther to the right when having a constant power source. From my calculations the current should reach about 50% of the maximum in about 1500 microseconds and 90% in almost 5000 microseconds. I do not know if my interpretation and calculations are correct, but they seem to harmonize well enough.

(Unfortunately the ESP32 cannot measure voltages accurately, the output is quite noisy and imprecise, but a least it is good enough to make out a trend. I only saved a reading, when the difference to the last saved measurement exceeded a specific value, so it would be possible to get a higher resolution in regard of the time - I chose a coarse resolution because I had to read the values manually from the small blue screen).

Zuckerstange47, Thu Nov 08 2018, 01:49AM

I tried to use the ESP32 as some kind of oszilloscope (not sure though, because I do not own an oszilloscope nor used one before) to measure voltages while and after activating the coil.

The top graphs show the capacitor's voltage for two activations, the first starting at 40V, the second at a lower voltage.

The bottom graphs display the voltage over the coil (the first with an initial capacitor's voltage of about 19V, the second with 30V). I don't understand why the first datapoint and the ones after deactivating the coil are 4095 (the maximum value that the ESP32 can give out) and not zero as I expected. Also I am not sure what to make with the data, but I am happy that the measurement worked.

My interpretation is, that the coil takes at least about 2000 microseconds to get full amperage after activation, but when considering the overlaying drainage of the capacitors the maximum would be farther to the right when having a constant power source. From my calculations the current should reach about 50% of the maximum in about 1500 microseconds and 90% in almost 5000 microseconds. I do not know if my interpretation and calculations are correct, but they seem to harmonize well enough.

(Unfortunately the ESP32 cannot measure voltages accurately, the output is quite noisy and imprecise, but a least it is good enough to make out a trend. I only saved a reading, when the difference to the last saved measurement exceeded a specific value, so it would be possible to get a higher resolution in regard of the time - I chose a coarse resolution because I had to read the values manually from the small blue screen).

Re: Yet another coil gun prototype

V2006, Thu Nov 08 2018, 12:54PM

Looks impressive. But as practice shows, any calculations are significantly different from the facts.

V2006, Thu Nov 08 2018, 12:54PM

Looks impressive. But as practice shows, any calculations are significantly different from the facts.

Re: Yet another coil gun prototype

Plasma, Tue Nov 13 2018, 06:54AM

Zuckerstange47 the second and forth graph looks like you increased the resistance, ssmaller wire diameter maybe, that is forward emf after switch off, switched off current before the coil I think,

Nice work.

Plasma, Tue Nov 13 2018, 06:54AM

Zuckerstange47 the second and forth graph looks like you increased the resistance, ssmaller wire diameter maybe, that is forward emf after switch off, switched off current before the coil I think,

Nice work.

Re: Yet another coil gun prototype

Zuckerstange47, Wed Nov 14 2018, 09:42PM

Plasma: I do not understand why it looks like I increased the resistance, as my knowledge is very limited. To me, the first and second look almost the same. The only change between the shots was that the capacitors were not charged as much on the second and forth graph.

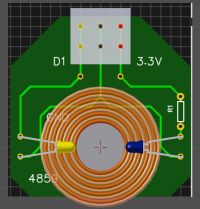

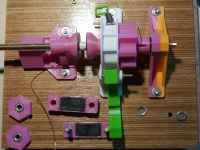

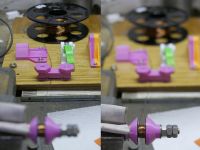

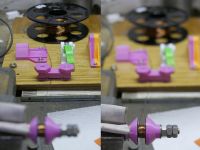

My next planned steps are to tidy up the construction. I designed a simple PCB to produce multiple, more beautiful light barriers easily (on the image the coil and a spring-type terminal block is overlayed).

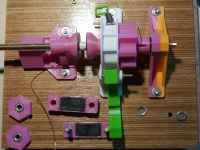

Also I am printing an apparatus to help making coils, based on a previous design of mine (that is shown on the other images). The new one will be more stable (I hope) and the distance-adjustment should not lose it's setting by mistake, when rotating the pipe.

Zuckerstange47, Wed Nov 14 2018, 09:42PM

Plasma: I do not understand why it looks like I increased the resistance, as my knowledge is very limited. To me, the first and second look almost the same. The only change between the shots was that the capacitors were not charged as much on the second and forth graph.

My next planned steps are to tidy up the construction. I designed a simple PCB to produce multiple, more beautiful light barriers easily (on the image the coil and a spring-type terminal block is overlayed).

Also I am printing an apparatus to help making coils, based on a previous design of mine (that is shown on the other images). The new one will be more stable (I hope) and the distance-adjustment should not lose it's setting by mistake, when rotating the pipe.

Re: Yet another coil gun prototype

Shrad, Thu Nov 15 2018, 08:01AM

if you need ultra fast detection, a small laser module and a reverse biased PIN photodiode will be top gear

Shrad, Thu Nov 15 2018, 08:01AM

if you need ultra fast detection, a small laser module and a reverse biased PIN photodiode will be top gear

Re: Yet another coil gun prototype

Zuckerstange47, Mon Nov 19 2018, 12:14AM

I think the ones I am using are fast enough for my experiments, but thank you for the information nevertheless.

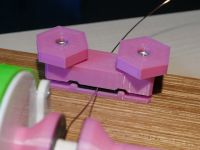

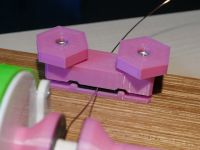

My current big problem is that I cannot build coils the way I want to. Does anyone have a tip for making a good transition between one layer and the following one? In the last image one can see that I finished the first layer, wound from right to left, and consequently want the wire of the first winding of the second layer to stay between the two leftmost windings of the first layer. Maybe the end plates (black disks) should be mounted in a more rigid way, so that the wire cannot slip into the gap...? How do professional coil-winder solve this problem?

I am afraid that my new winding-machine was printed in vain

Zuckerstange47, Mon Nov 19 2018, 12:14AM

Shrad wrote ...

if you need ultra fast detection, a small laser module and a reverse biased PIN photodiode will be top gear

if you need ultra fast detection, a small laser module and a reverse biased PIN photodiode will be top gear

I think the ones I am using are fast enough for my experiments, but thank you for the information nevertheless.

My current big problem is that I cannot build coils the way I want to. Does anyone have a tip for making a good transition between one layer and the following one? In the last image one can see that I finished the first layer, wound from right to left, and consequently want the wire of the first winding of the second layer to stay between the two leftmost windings of the first layer. Maybe the end plates (black disks) should be mounted in a more rigid way, so that the wire cannot slip into the gap...? How do professional coil-winder solve this problem?

I am afraid that my new winding-machine was printed in vain

Re: Yet another coil gun prototype

DerAlbi, Mon Nov 19 2018, 11:51PM

Ger: Orthozyklische wicklung

En: orthocyclic winding

DerAlbi, Mon Nov 19 2018, 11:51PM

Ger: Orthozyklische wicklung

En: orthocyclic winding

Re: Yet another coil gun prototype

Zuckerstange47, Mon Nov 19 2018, 11:57PM

Okay, I partly found a solution, but the result is still very bad. I put the coil between some nuts on a threaded rod, and adjusted it in the way that the number of windings on the first layer was right. The second layer looks okay, too, but later ones look a bit messy and probably I missed some windings. At the end I had 3 meters too much remaining on the spool (assumed the sellers specification was correct), but the outer diameter of the coil was the one my coil-calculator had generated.

The winding-procedure was not pleasant also, because rotating the printed parts seemed to result in tightening the nuts, and so the resistance got stronger after each turn, and now I got several blisters on my hand. That was one reason why I changed the first winding machine's design (the pink one) in the first place...

I do not want to unwind this thing again, but at least I learned a bit from it: Next time I will measure the wire length beforehand and mark it every meter or so. Also I might print something to have a better grip on the rod and turn the complete thing instead of clamping the pole and only turning the coil with the printed parts. I suppose the coil will work in an acceptable way even if it looks ugly, but at least I would like to know how much wire I used, and how many windings I made.

@DerAlbi: The Orthozyklische Wicklung looks very promising, but because of tight tolerances and the need for a very precise positioning of the wire it seems to be impossible to implement for me. Have you succeded in realizing this technique?

Zuckerstange47, Mon Nov 19 2018, 11:57PM

Okay, I partly found a solution, but the result is still very bad. I put the coil between some nuts on a threaded rod, and adjusted it in the way that the number of windings on the first layer was right. The second layer looks okay, too, but later ones look a bit messy and probably I missed some windings. At the end I had 3 meters too much remaining on the spool (assumed the sellers specification was correct), but the outer diameter of the coil was the one my coil-calculator had generated.

The winding-procedure was not pleasant also, because rotating the printed parts seemed to result in tightening the nuts, and so the resistance got stronger after each turn, and now I got several blisters on my hand. That was one reason why I changed the first winding machine's design (the pink one) in the first place...

I do not want to unwind this thing again, but at least I learned a bit from it: Next time I will measure the wire length beforehand and mark it every meter or so. Also I might print something to have a better grip on the rod and turn the complete thing instead of clamping the pole and only turning the coil with the printed parts. I suppose the coil will work in an acceptable way even if it looks ugly, but at least I would like to know how much wire I used, and how many windings I made.

@DerAlbi: The Orthozyklische Wicklung looks very promising, but because of tight tolerances and the need for a very precise positioning of the wire it seems to be impossible to implement for me. Have you succeded in realizing this technique?

Re: Yet another coil gun prototype

DerAlbi, Tue Nov 20 2018, 12:41AM

Well.. lets just say: i got so far that it seemed plausible with better equipment

I have built a 3d printed winding machine too (fully automatic) but it was way too flexible. Today i know what would need changing, and can tell you right now that your setup will never succeed. Inconsistent wire tension is the first issue - not only is the force unknown, but it will vary over time.

So what works in your case is to use a small stiff plastic piece and manually lay down every turn. But even that will result in wild winidng after a few layers. Try to make the coil former either exactly n*WireDiameter or (n+0.5)*WireDiameter, anything in between will fail. Use the highest wire tension the wire allows (can be calculated) which helps with laying down the wire consistently. Your picture shows kinks in the wire even after the wire tensioner - this may never be the case. Straighten the wire through a pulley labyrinth and pull it really hard. 1mm diameter must be pulled with around 5kg equivalent (50N). It can withstand 17kg before breaking. So dont hesitate.

However I have found that there is no substantial loss in performance of the coil, if wound wild. It is really more a cosmetic thing. Keep going. Dont invest too much time in printing. Its too far from viable.

DerAlbi, Tue Nov 20 2018, 12:41AM

Well.. lets just say: i got so far that it seemed plausible with better equipment

I have built a 3d printed winding machine too (fully automatic) but it was way too flexible. Today i know what would need changing, and can tell you right now that your setup will never succeed. Inconsistent wire tension is the first issue - not only is the force unknown, but it will vary over time.

So what works in your case is to use a small stiff plastic piece and manually lay down every turn. But even that will result in wild winidng after a few layers. Try to make the coil former either exactly n*WireDiameter or (n+0.5)*WireDiameter, anything in between will fail. Use the highest wire tension the wire allows (can be calculated) which helps with laying down the wire consistently. Your picture shows kinks in the wire even after the wire tensioner - this may never be the case. Straighten the wire through a pulley labyrinth and pull it really hard. 1mm diameter must be pulled with around 5kg equivalent (50N). It can withstand 17kg before breaking. So dont hesitate.

However I have found that there is no substantial loss in performance of the coil, if wound wild. It is really more a cosmetic thing. Keep going. Dont invest too much time in printing. Its too far from viable.

Re: Yet another coil gun prototype

V2006, Wed Nov 21 2018, 08:14AM

Very beautiful. But with such an investment of time and labor, I would have wound it up manually a long time ago. And thicker wire

V2006, Wed Nov 21 2018, 08:14AM

Very beautiful. But with such an investment of time and labor, I would have wound it up manually a long time ago. And thicker wire

Re: Yet another coil gun prototype

Zuckerstange47, Thu Nov 22 2018, 12:01AM

Wow, I can hardly imagine how long that machine took you to make. You do not have any images/videos of it, or do you? Did you construct it for mass facturing your coil gun?

I will not try to get perfect coils anymore, the wild winding style should be sufficient, but of course I still want to make some improvements. The last coil created the problem that I could not remove it from the acrylic tube without damaging the coil (see photo), even though I had several layers of paper wrapped around the tube to prevent this from happening. On the next try I will have stronger printed limitation-discs that can be slides without deformation, and I will take more care of the paperwork. Is this a common problem?

I only changed a little bit on my winding machine: The two pink big cog-wheels are directly connected to the nuts on the threaded rod (melted into it), so I can move the complete rod instead of just the central part like last time to prevent it from clogging up. Also I improved the wire routing and other minor things, but I know it is still very primitive. At least the conversion was fast and simple. Unfortunately I do not have enough wire to test it at the moment.

Zuckerstange47, Thu Nov 22 2018, 12:01AM

DerAlbi wrote ...

I have built a 3d printed winding machine too (fully automatic) but it was way too flexible.[...] However I have found that there is no substantial loss in performance of the coil, if wound wild. It is really more a cosmetic thing. Keep going. Dont invest too much time in printing. Its too far from viable.

I have built a 3d printed winding machine too (fully automatic) but it was way too flexible.[...] However I have found that there is no substantial loss in performance of the coil, if wound wild. It is really more a cosmetic thing. Keep going. Dont invest too much time in printing. Its too far from viable.

Wow, I can hardly imagine how long that machine took you to make. You do not have any images/videos of it, or do you? Did you construct it for mass facturing your coil gun?

I will not try to get perfect coils anymore, the wild winding style should be sufficient, but of course I still want to make some improvements. The last coil created the problem that I could not remove it from the acrylic tube without damaging the coil (see photo), even though I had several layers of paper wrapped around the tube to prevent this from happening. On the next try I will have stronger printed limitation-discs that can be slides without deformation, and I will take more care of the paperwork. Is this a common problem?

I only changed a little bit on my winding machine: The two pink big cog-wheels are directly connected to the nuts on the threaded rod (melted into it), so I can move the complete rod instead of just the central part like last time to prevent it from clogging up. Also I improved the wire routing and other minor things, but I know it is still very primitive. At least the conversion was fast and simple. Unfortunately I do not have enough wire to test it at the moment.

V2006 wrote ...

But with such an investment of time and labor, I would have wound it up manually a long time ago.

I guess you might be right, but I thought the procedure would have been too complex for a two handed person like me without some helping device. In the end my machine is just a mounting for the rod and a clamp for the wire, so I have to confess that a lot of time was wasted.But with such an investment of time and labor, I would have wound it up manually a long time ago.

Re: Yet another coil gun prototype

DerAlbi, Thu Nov 22 2018, 01:23AM

It was during the time i was new to CAD and 3D-Printing. It took about 10 weeks i guess. But i also wrote the software for the stepper motors, the wire tension system and the PC (usb) user interface where i could program the machine. I have the machine still in my room, but i dont plan to ever use it again - its not in shape for a photo. I didnt had full automatization in mind, but just to get a high quality coil (which i didnt get from the machine). It was basically a hind-winding machine, where my hands executed stepper motor sequences. Once refined i could ususally play sequences that wound 2 layers failry quickly.

Your coils look fine. You might want to make the sides of the coil former aluminum to make the sides stiffer. Put a layer of this brown packaging tape on it and treat it with vaseline (this makes the epoxy not stick to the sides). For the inner coil former i recommend POM plastic rods (get some from ebay). Epoxy does not stick to POM plastics.

Then use epoxy that does not hardens quickly. 1h minimum - better 3h to give you time to work. After every wound layer apply epoxy with a brush (you can clean the brush with acetone afterwards). Dont use too much epoxy or it will ooze out. After you are done, heat the coil up to 80 - 100°C which is easy by running current through it. You can use step-downs from ebay that can deliver 20A or more ; Heat the coil with high power, then let it sit at 10W power consumption to keep it warm.

; Heat the coil with high power, then let it sit at 10W power consumption to keep it warm.

With high temperature your epoxy will cure fast after you are done winding. It should give you very good coils and disassembly of the coilf ormer wont rip apart the coil.

That said, your coil shape seems a bit weird. They are very short and fat. Got such a short projectile?

DerAlbi, Thu Nov 22 2018, 01:23AM

It was during the time i was new to CAD and 3D-Printing. It took about 10 weeks i guess. But i also wrote the software for the stepper motors, the wire tension system and the PC (usb) user interface where i could program the machine. I have the machine still in my room, but i dont plan to ever use it again - its not in shape for a photo. I didnt had full automatization in mind, but just to get a high quality coil (which i didnt get from the machine). It was basically a hind-winding machine, where my hands executed stepper motor sequences. Once refined i could ususally play sequences that wound 2 layers failry quickly.

Your coils look fine. You might want to make the sides of the coil former aluminum to make the sides stiffer. Put a layer of this brown packaging tape on it and treat it with vaseline (this makes the epoxy not stick to the sides). For the inner coil former i recommend POM plastic rods (get some from ebay). Epoxy does not stick to POM plastics.

Then use epoxy that does not hardens quickly. 1h minimum - better 3h to give you time to work. After every wound layer apply epoxy with a brush (you can clean the brush with acetone afterwards). Dont use too much epoxy or it will ooze out. After you are done, heat the coil up to 80 - 100°C which is easy by running current through it. You can use step-downs from ebay that can deliver 20A or more

; Heat the coil with high power, then let it sit at 10W power consumption to keep it warm.

; Heat the coil with high power, then let it sit at 10W power consumption to keep it warm.With high temperature your epoxy will cure fast after you are done winding. It should give you very good coils and disassembly of the coilf ormer wont rip apart the coil.

That said, your coil shape seems a bit weird. They are very short and fat. Got such a short projectile?

Re: Yet another coil gun prototype

V2006, Thu Nov 22 2018, 09:04AM

Zuckerstange47, I can send you my coils.

V2006, Thu Nov 22 2018, 09:04AM

Zuckerstange47, I can send you my coils.

Re: Yet another coil gun prototype

Zuckerstange47, Thu Nov 22 2018, 06:20PM

Thanks for the thorough advice! As Epoxy I was using "UHU Endfest", which has a very long hardening time. On the subject of the short coils: "Tomspol" wrote that ealier (14 posts above), too, but I did not understand why the coil should be of the same length as the projectile. From my little knowledge a shorter coil should have a stronger magnetic field, but I would like to be corrected if that is wrong. My plan was to make two different coils as a short-term objective and test which one works better.

Thank you for that offering, but I would like to make my own ones ("the route is the goal"). I already wasted too much time on the machine to stop making coils now Furthermore I already got new wire today.

Furthermore I already got new wire today.

Zuckerstange47, Thu Nov 22 2018, 06:20PM

DerAlbi wrote ...

Your coils look fine. You might want to make the sides of the coil former aluminum to make the sides stiffer. Put a layer of this brown packaging tape on it and treat it with vaseline (this makes the epoxy not stick to the sides). For the inner coil former i recommend POM plastic rods (get some from ebay). Epoxy does not stick to POM plastics.

Then use epoxy that does not hardens quickly. 1h minimum - better 3h to give you time to work. After every wound layer apply epoxy with a brush (you can clean the brush with acetone afterwards). Dont use too much epoxy or it will ooze out. After you are done, heat the coil up to 80 - 100°C which is easy by running current through it. You can use step-downs from ebay that can deliver 20A or more ; Heat the coil with high power, then let it sit at 10W power consumption to keep it warm.

; Heat the coil with high power, then let it sit at 10W power consumption to keep it warm.

With high temperature your epoxy will cure fast after you are done winding. It should give you very good coils and disassembly of the coilf ormer wont rip apart the coil.

That said, your coil shape seems a bit weird. They are very short and fat. Got such a short projectile?

Your coils look fine. You might want to make the sides of the coil former aluminum to make the sides stiffer. Put a layer of this brown packaging tape on it and treat it with vaseline (this makes the epoxy not stick to the sides). For the inner coil former i recommend POM plastic rods (get some from ebay). Epoxy does not stick to POM plastics.

Then use epoxy that does not hardens quickly. 1h minimum - better 3h to give you time to work. After every wound layer apply epoxy with a brush (you can clean the brush with acetone afterwards). Dont use too much epoxy or it will ooze out. After you are done, heat the coil up to 80 - 100°C which is easy by running current through it. You can use step-downs from ebay that can deliver 20A or more

; Heat the coil with high power, then let it sit at 10W power consumption to keep it warm.

; Heat the coil with high power, then let it sit at 10W power consumption to keep it warm.With high temperature your epoxy will cure fast after you are done winding. It should give you very good coils and disassembly of the coilf ormer wont rip apart the coil.

That said, your coil shape seems a bit weird. They are very short and fat. Got such a short projectile?

Thanks for the thorough advice! As Epoxy I was using "UHU Endfest", which has a very long hardening time. On the subject of the short coils: "Tomspol" wrote that ealier (14 posts above), too, but I did not understand why the coil should be of the same length as the projectile. From my little knowledge a shorter coil should have a stronger magnetic field, but I would like to be corrected if that is wrong. My plan was to make two different coils as a short-term objective and test which one works better.

V2006 wrote ...

Zuckerstange47, I can send you my coils.

Zuckerstange47, I can send you my coils.

Thank you for that offering, but I would like to make my own ones ("the route is the goal"). I already wasted too much time on the machine to stop making coils now

Furthermore I already got new wire today.

Furthermore I already got new wire today.Re: Yet another coil gun prototype

V2006, Thu Nov 22 2018, 09:12PM

OK. Good luck

V2006, Thu Nov 22 2018, 09:12PM

OK. Good luck

Re: Yet another coil gun prototype

Zuckerstange47, Thu Nov 29 2018, 05:51PM

I just realized that I might not be able to build a coil gun the way I planned to, because I did not read the fineprint on some component's manual (and as mentioned earlier I am a newbee on the subject of electronics).

When looking at the datasheet I thought my MOSFET could be used for switching 209A @ 75V, but when looking at the "Maximum Safe Operating Area"-Graph it seems that the 209A (continuously) are only permitted at a voltage of about 1.4V, and that only 0.5A can be switched @75V for a time of 10ms. Is my interpretation correct?

PS: Attaching the file did not work...

There is the image:

Zuckerstange47, Thu Nov 29 2018, 05:51PM

I just realized that I might not be able to build a coil gun the way I planned to, because I did not read the fineprint on some component's manual (and as mentioned earlier I am a newbee on the subject of electronics).

When looking at the datasheet I thought my MOSFET could be used for switching 209A @ 75V, but when looking at the "Maximum Safe Operating Area"-Graph it seems that the 209A (continuously) are only permitted at a voltage of about 1.4V, and that only 0.5A can be switched @75V for a time of 10ms. Is my interpretation correct?

PS: Attaching the file did not work...

There is the image:

Re: Yet another coil gun prototype

DerAlbi, Thu Nov 29 2018, 06:05PM

Well, if your mosfet is on, then there is just little voltage drop across the mosfet (since Drain sopurce is virtually shorted), so the specs make sense. Also if your mosfet is off (Drain-Source not "shorted"), which allows the 75V across drain.source, then NO current will flow, so you are below the 0.5A rating as well.

The only critical thing is, switching from On to Off. There is a transition period where there is actually 200Amps AND 75V across the mosfet. the faster you switch the shorter the time. And you will switch faster than 10µs. So dont worry about the 10ms rating.

However the energy from the coil must go somewhere. The current will continue to flow even if the mosfet is off. A freewheeling diode wont conduct instantaniously but it will also take time for it to "turn on". This effect (forward recovery) does not exist in Schottky diodes, but they often dont have a beefy current rating and only 2x overload safety - in contrast to silicon diodes which suffer from slow forward recovery but are much more resistant to overloading.

Why am i telling you that? The time it takes the diode to take over the current is time that the mosfet spends in the transition state between on and off - this is what is (mainly) shown in the SOA diagram.

Honestly, just try and see what happens.

DerAlbi, Thu Nov 29 2018, 06:05PM

Well, if your mosfet is on, then there is just little voltage drop across the mosfet (since Drain sopurce is virtually shorted), so the specs make sense. Also if your mosfet is off (Drain-Source not "shorted"), which allows the 75V across drain.source, then NO current will flow, so you are below the 0.5A rating as well.

The only critical thing is, switching from On to Off. There is a transition period where there is actually 200Amps AND 75V across the mosfet. the faster you switch the shorter the time. And you will switch faster than 10µs. So dont worry about the 10ms rating.

However the energy from the coil must go somewhere. The current will continue to flow even if the mosfet is off. A freewheeling diode wont conduct instantaniously but it will also take time for it to "turn on". This effect (forward recovery) does not exist in Schottky diodes, but they often dont have a beefy current rating and only 2x overload safety - in contrast to silicon diodes which suffer from slow forward recovery but are much more resistant to overloading.

Why am i telling you that? The time it takes the diode to take over the current is time that the mosfet spends in the transition state between on and off - this is what is (mainly) shown in the SOA diagram.

Honestly, just try and see what happens.

Re: Yet another coil gun prototype

V2006, Thu Nov 29 2018, 09:05PM

Zuckerstange47 My offer is still valid.

Buy coils from me and become the first designer on this miserable planet.

V2006, Thu Nov 29 2018, 09:05PM

Zuckerstange47 My offer is still valid.

Buy coils from me and become the first designer on this miserable planet.

Re: Yet another coil gun prototype

the_anomaly, Thu Nov 29 2018, 11:29PM

The joy of learning is in the journey not the final result. Zuckerstange47 is learning by doing.

the_anomaly, Thu Nov 29 2018, 11:29PM

Zuckerstange47 My offer is still valid.

Buy coils from me and become the first designer on this miserable planet.

The joy of learning is in the journey not the final result. Zuckerstange47 is learning by doing.

Re: Yet another coil gun prototype

Zuckerstange47, Fri Nov 30 2018, 12:37AM

I guess my question must have been really stupid I am very grateful for your patient explanation!

I am very grateful for your patient explanation!

For the switching to be as fast as possible I was thinking about using a MOSFET-driver for each MOSFET. My driver has a rise time of about 35 ns for my MOSFET, so I assume that should be fast enough.

As a suppressor ("Schutzbeschaltung" in germon, is this the right word?) I am using a Zener diode (1N 5908, 5V, 1500W) and a diode (P600M, 1000V, 6A) but I have not figured out how to calculate the time for the transition state.

Does your last suggestion indicate that I will notice the MOSFET beeing destroyed if my suppressor it not good enough, or do you mean to see the result on the oscilloscope (which I do not own)? So far there were no defects on my prototype (as far as I know).

( Zener and diode:

)

)

I do not really understand what the designer-part means, but my coil construction line is ready for production

Exactly!

Zuckerstange47, Fri Nov 30 2018, 12:37AM

DerAlbi wrote ...

Well, if your mosfet is on, then there is just little voltage drop across the mosfet (since Drain sopurce is virtually shorted), so the specs make sense. Also if your mosfet is off (Drain-Source not "shorted"), which allows the 75V across drain.source, then NO current will flow, so you are below the 0.5A rating as well.

The only critical thing is, switching from On to Off. There is a transition period where there is actually 200Amps AND 75V across the mosfet. the faster you switch the shorter the time. And you will switch faster than 10µs. So dont worry about the 10ms rating.

However the energy from the coil must go somewhere. The current will continue to flow even if the mosfet is off. A freewheeling diode wont conduct instantaniously but it will also take time for it to "turn on". This effect (forward recovery) does not exist in Schottky diodes, but they often dont have a beefy current rating and only 2x overload safety - in contrast to silicon diodes which suffer from slow forward recovery but are much more resistant to overloading.

Why am i telling you that? The time it takes the diode to take over the current is time that the mosfet spends in the transition state between on and off - this is what is (mainly) shown in the SOA diagram.

Honestly, just try and see what happens.

Well, if your mosfet is on, then there is just little voltage drop across the mosfet (since Drain sopurce is virtually shorted), so the specs make sense. Also if your mosfet is off (Drain-Source not "shorted"), which allows the 75V across drain.source, then NO current will flow, so you are below the 0.5A rating as well.

The only critical thing is, switching from On to Off. There is a transition period where there is actually 200Amps AND 75V across the mosfet. the faster you switch the shorter the time. And you will switch faster than 10µs. So dont worry about the 10ms rating.

However the energy from the coil must go somewhere. The current will continue to flow even if the mosfet is off. A freewheeling diode wont conduct instantaniously but it will also take time for it to "turn on". This effect (forward recovery) does not exist in Schottky diodes, but they often dont have a beefy current rating and only 2x overload safety - in contrast to silicon diodes which suffer from slow forward recovery but are much more resistant to overloading.

Why am i telling you that? The time it takes the diode to take over the current is time that the mosfet spends in the transition state between on and off - this is what is (mainly) shown in the SOA diagram.

Honestly, just try and see what happens.

I guess my question must have been really stupid

I am very grateful for your patient explanation!

I am very grateful for your patient explanation!For the switching to be as fast as possible I was thinking about using a MOSFET-driver for each MOSFET. My driver has a rise time of about 35 ns for my MOSFET, so I assume that should be fast enough.

As a suppressor ("Schutzbeschaltung" in germon, is this the right word?) I am using a Zener diode (1N 5908, 5V, 1500W) and a diode (P600M, 1000V, 6A) but I have not figured out how to calculate the time for the transition state.

Does your last suggestion indicate that I will notice the MOSFET beeing destroyed if my suppressor it not good enough, or do you mean to see the result on the oscilloscope (which I do not own)? So far there were no defects on my prototype (as far as I know).

( Zener and diode:

)

)V2006 wrote ...

Zuckerstange47 My offer is still valid.

Buy coils from me and become the first designer on this miserable planet.

Zuckerstange47 My offer is still valid.

Buy coils from me and become the first designer on this miserable planet.

I do not really understand what the designer-part means, but my coil construction line is ready for production

the_anomaly wrote ...

The joy of learning is in the journey not the final result. Zuckerstange47 is learning by doing.

Zuckerstange47 My offer is still valid.

Buy coils from me and become the first designer on this miserable planet.

The joy of learning is in the journey not the final result. Zuckerstange47 is learning by doing.

Exactly!

Re: Yet another coil gun prototype

DerAlbi, Fri Nov 30 2018, 08:05AM

Dont worry about the life of your mosfets right now. They will blow anyway at some point, so just buy enough instead of being overwhelmed by complexity.

1.5kW-Zener: sounds sketchy. at 5V that gives your 300A, but a (is it really a Zener or is it a TVS?) Diode will suck up that heat energy in its silicon - once that gets hot enough it will die.

TVS diodes with 1.5kW will never dissipate the 1.5kW, its only a theoretical rating because a pulse load is assumed. This pulse load (Transients) arent supposed to be longer than 10µs at some points.

There are people who built Coilguns with Zeners and it worked, but i think you need to use a much bigger Zener.

For a start, you can simply use a normal diode in forward conduction and see where it gets you. But try your Zener first. But check it after every pulse.

Regarding your switching speed: dont worry. Knowing the usual Coilgun setup, the actual switching speed of your mosfet wont be an issue. The time it takes for the current to stop flowing through the mosfet is another issue. I guess your mosfet will be fine.

Just try. Post a picture of your setup first ^_^

DerAlbi, Fri Nov 30 2018, 08:05AM

Dont worry about the life of your mosfets right now. They will blow anyway at some point, so just buy enough instead of being overwhelmed by complexity.

1.5kW-Zener: sounds sketchy. at 5V that gives your 300A, but a (is it really a Zener or is it a TVS?) Diode will suck up that heat energy in its silicon - once that gets hot enough it will die.

TVS diodes with 1.5kW will never dissipate the 1.5kW, its only a theoretical rating because a pulse load is assumed. This pulse load (Transients) arent supposed to be longer than 10µs at some points.

There are people who built Coilguns with Zeners and it worked, but i think you need to use a much bigger Zener.

For a start, you can simply use a normal diode in forward conduction and see where it gets you. But try your Zener first. But check it after every pulse.

Regarding your switching speed: dont worry. Knowing the usual Coilgun setup, the actual switching speed of your mosfet wont be an issue. The time it takes for the current to stop flowing through the mosfet is another issue. I guess your mosfet will be fine.

Just try. Post a picture of your setup first ^_^

Re: Yet another coil gun prototype

V2006, Fri Nov 30 2018, 09:08AM

Zuckerstange47 The part is a coil of unique design.

But everything else is possible

There are no more such coils on this planet.

Better learn from the best tutorials

Good luck

V2006, Fri Nov 30 2018, 09:08AM

Zuckerstange47 The part is a coil of unique design.

But everything else is possible

There are no more such coils on this planet.

Better learn from the best tutorials

Good luck

Re: Yet another coil gun prototype

DerAlbi, Fri Nov 30 2018, 09:42AM

WTF.

V2006.. sometimes... i am just not sure if you are a troll or actually that ...... weird.

DerAlbi, Fri Nov 30 2018, 09:42AM

WTF.

V2006.. sometimes... i am just not sure if you are a troll or actually that ...... weird.

Re: Yet another coil gun prototype

V2006, Fri Nov 30 2018, 05:37PM

DerAlbi mutually))

here 15 years they write the same thing

I just wanted to help

V2006, Fri Nov 30 2018, 05:37PM

DerAlbi mutually))

here 15 years they write the same thing

I just wanted to help

Re: Yet another coil gun prototype

V2006, Fri Nov 30 2018, 05:45PM

they have been discussing the same thing here for 15 years - mosfet , diode ...

I wanted to help

V2006, Fri Nov 30 2018, 05:45PM

they have been discussing the same thing here for 15 years - mosfet , diode ...

I wanted to help

Re: Yet another coil gun prototype

Plasma, Sat Dec 01 2018, 11:08AM

This might help limit the damage to the MOSFET,,a diode will only protect against forward emf not back emf. If you place a capacitor and resistor in series and then parrellel across the coil it will asobe the spike if it has a large enough storage

Edit picture isn't showing

Plasma, Sat Dec 01 2018, 11:08AM

This might help limit the damage to the MOSFET,,a diode will only protect against forward emf not back emf. If you place a capacitor and resistor in series and then parrellel across the coil it will asobe the spike if it has a large enough storage

Edit picture isn't showing

Re: Yet another coil gun prototype

V2006, Sat Dec 01 2018, 12:33PM

I know it.

I wanted to say that in the discussion of small details, the very essence was lost here

So you can do another hundred years the Electromagnetic Projectile Accelerators

No success

It's not like you think

You lost the essence here the Electromagnetic Projectile Accelerators

V2006, Sat Dec 01 2018, 12:33PM

I know it.

I wanted to say that in the discussion of small details, the very essence was lost here

So you can do another hundred years the Electromagnetic Projectile Accelerators

No success

It's not like you think

You lost the essence here the Electromagnetic Projectile Accelerators

Re: Yet another coil gun prototype

DerAlbi, Sat Dec 01 2018, 03:18PM

The essence of the hobbyist coilgun is learning electronics. Communicating about effects in electronics and how to read datasheets, understand the SOA and so on, is therefore extremely on topic. And everyone has to learn it again and again, that is natural.

The essence of a professional coilgun is very different. Its technically a linear reluctance motor which is very complicated. Its metic is power densitiy - nothing else matters; the often discussed efficiency is only the means to achieve a good power efficiency.

So "Shots per second" * "Kinetic Energy per Shot" / "Device weight" gives you a number in Watt per Kilogram. This is generally the figure of merit a motors engineering is judged on.

I have never seen you having any credible scientific description of what you achieved except shaky 240p camera footage shooting at a door or tin cans. Actually, seeing t´any built in action is the least interesting thing: numbers are the only thing that counts in the professional league. I didnt find anything relevant from your side until now.

I dont really understand how you complain about the state of things.

It seems strange to reply to Plasmas "put a snubber circuit around the mosfet" (thats what he tried to say - just paraphrasing for better google words ) with "i know it" as if the thread was made for you.

) with "i know it" as if the thread was made for you.

Generally you hijack a lot of threads and post your coilgun videos that are without any information or relevance to the thread.

The spam in one of your previous posts for example linked to 2 videos: and

and  .

.

Whats the point?

Do you think that video without any numbers or description of how its built or what exactly is innovative is any contribution to the community?

All anyone sees is that something moves. How is that any superior to what Zuckerstange is trying?

Please make your own thread, provide the world with the wonders you engineered there and please provide real numbers including the procedure how you obtained them. If you have done anything ground breaking, people will acknowledge it.

DerAlbi, Sat Dec 01 2018, 03:18PM

The essence of the hobbyist coilgun is learning electronics. Communicating about effects in electronics and how to read datasheets, understand the SOA and so on, is therefore extremely on topic. And everyone has to learn it again and again, that is natural.

The essence of a professional coilgun is very different. Its technically a linear reluctance motor which is very complicated. Its metic is power densitiy - nothing else matters; the often discussed efficiency is only the means to achieve a good power efficiency.

So "Shots per second" * "Kinetic Energy per Shot" / "Device weight" gives you a number in Watt per Kilogram. This is generally the figure of merit a motors engineering is judged on.

I have never seen you having any credible scientific description of what you achieved except shaky 240p camera footage shooting at a door or tin cans. Actually, seeing t´any built in action is the least interesting thing: numbers are the only thing that counts in the professional league. I didnt find anything relevant from your side until now.

I dont really understand how you complain about the state of things.

It seems strange to reply to Plasmas "put a snubber circuit around the mosfet" (thats what he tried to say - just paraphrasing for better google words

) with "i know it" as if the thread was made for you.

) with "i know it" as if the thread was made for you.Generally you hijack a lot of threads and post your coilgun videos that are without any information or relevance to the thread.

The spam in one of your previous posts for example linked to 2 videos:

and

and  .

.Whats the point?

Do you think that video without any numbers or description of how its built or what exactly is innovative is any contribution to the community?

All anyone sees is that something moves. How is that any superior to what Zuckerstange is trying?

Please make your own thread, provide the world with the wonders you engineered there and please provide real numbers including the procedure how you obtained them. If you have done anything ground breaking, people will acknowledge it.

Re: Yet another coil gun prototype

Zuckerstange47, Sat Dec 01 2018, 03:25PM

I have been using the zener + diode for about 20 - 50 shots with no problem so far, but the voltages were not very high yet. I will post an image when I plan to change the setup.

I cannot upload pictures as well, thats why I used this uploading service last time:

(It belongs to the blender 3d-software community)

I would be very interested in learning more about that topic.

Zuckerstange47, Sat Dec 01 2018, 03:25PM

DerAlbi wrote ...

For a start, you can simply use a normal diode in forward conduction and see where it gets you. But try your Zener first. But check it after every pulse.

For a start, you can simply use a normal diode in forward conduction and see where it gets you. But try your Zener first. But check it after every pulse.

I have been using the zener + diode for about 20 - 50 shots with no problem so far, but the voltages were not very high yet. I will post an image when I plan to change the setup.

Plasma wrote ...

This might help limit the damage to the MOSFET,,a diode will only protect against forward emf not back emf. If you place a capacitor and resistor in series and then parrellel across the coil it will asobe the spike if it has a large enough storage

Edit picture isn't showing

This might help limit the damage to the MOSFET,,a diode will only protect against forward emf not back emf. If you place a capacitor and resistor in series and then parrellel across the coil it will asobe the spike if it has a large enough storage

Edit picture isn't showing

I cannot upload pictures as well, thats why I used this uploading service last time:

(It belongs to the blender 3d-software community)

I would be very interested in learning more about that topic.

Re: Yet another coil gun prototype

V2006, Sat Dec 01 2018, 06:23PM

DerAlbi : it will take another hundred years and you will not do anything

V2006, Sat Dec 01 2018, 06:23PM

DerAlbi : it will take another hundred years and you will not do anything

Re: Yet another coil gun prototype

Zuckerstange47, Sat Dec 01 2018, 07:13PM

Your links do not work, again.

I modified them here:

Anyhoo, I do not understand why this link-posting is happening right here, and also in the comments of many youtube videos, that are distantly related to the topic.

Zuckerstange47, Sat Dec 01 2018, 07:13PM

Your links do not work, again.

I modified them here:

Anyhoo, I do not understand why this link-posting is happening right here, and also in the comments of many youtube videos, that are distantly related to the topic.

Re: Yet another coil gun prototype

V2006, Sat Dec 01 2018, 07:23PM

Zuckerstange47 Thank you

V2006, Sat Dec 01 2018, 07:23PM

Zuckerstange47 Thank you

Re: Yet another coil gun prototype

DerAlbi, Sat Dec 01 2018, 07:24PM

And what do those videos show in particular? Some coilgun shooting.. so what?

What efficiency? What device weight? What shot rate? What projectile energy? There is none of the really important information in those videos.

2kJ @ 100V with 400mF... is exactly zero information except how much money you put in. Everyone can do that and accelerate some projectile with this energy.

I am not sure what i have not done and what exactly will take 100 years. My coilgun is finished and as far as i know with 27W/kg my linear accelerator has the best power density in the world (regarding the devices powered from capacitors), but i love to hear other results..

DerAlbi, Sat Dec 01 2018, 07:24PM

And what do those videos show in particular? Some coilgun shooting.. so what?

What efficiency? What device weight? What shot rate? What projectile energy? There is none of the really important information in those videos.

2kJ @ 100V with 400mF... is exactly zero information except how much money you put in. Everyone can do that and accelerate some projectile with this energy.

I am not sure what i have not done and what exactly will take 100 years. My coilgun is finished and as far as i know with 27W/kg my linear accelerator has the best power density in the world (regarding the devices powered from capacitors), but i love to hear other results..

Re: Yet another coil gun prototype

V2006, Sat Dec 01 2018, 11:22PM

DerAlbi

you have no such video

money spent many times less than you spent

for the money that you spend, I would do even better

coefficient of performance not less than 30%

projectile energy not less than 600 joules

*2kJ @ 100V Ñ 400mF

device weight:

V2006, Sat Dec 01 2018, 11:22PM

DerAlbi

you have no such video

money spent many times less than you spent

for the money that you spend, I would do even better

coefficient of performance not less than 30%

projectile energy not less than 600 joules

*2kJ @ 100V Ñ 400mF

device weight:

Re: Yet another coil gun prototype

DerAlbi, Sun Dec 02 2018, 01:45AM

Sry, i dont find a weight nor shot rate

I found however that your projectile weight is given as "370 to 480g" which is an uncertainty of 20% for the weight alone. How is that even possible?

Your build uses a very big projectile. With such a design it is not complicated go get into the 3 digit energy range. You can think about it as if you have built a bigger and heavier motor: more iron and copper, more power, but also more weight. The tricky thing is to get more power out of the same build volume and materials. Also it is not difficult to put a lot of energy in the projectile as long as the projectile is fat and slow. Small projectiles at high speed is there the engineering begins.

I dont think you can compare my goals with yours. I have a magazine, automatic reloading, quite some complicated software and a complete case for my gun - it also adheres to local laws and is battery powered for as much as 200 shot per battery charge. I dont think that you have any idea what it took to get to this state, so sorry if i ignore your comment on my resource spending.

May i ask what you think you have done differently to anyone else to get the performance you see? (except building a really big gun)

You criticize that everyone builds the same stuff and there is too little development in the community..

Hands down, what is your invention here? (beside the size)

Can your technology be scaled down to achieve a 100J version with an 8mm diameter 30mm long projectile? If you build a small, light and compact demonstrator, i would be impressed!

For a start: is it an SCR-design, or resonant, or halfbridge?

DerAlbi, Sun Dec 02 2018, 01:45AM

Sry, i dont find a weight nor shot rate

I found however that your projectile weight is given as "370 to 480g" which is an uncertainty of 20% for the weight alone. How is that even possible?

Your build uses a very big projectile. With such a design it is not complicated go get into the 3 digit energy range. You can think about it as if you have built a bigger and heavier motor: more iron and copper, more power, but also more weight. The tricky thing is to get more power out of the same build volume and materials. Also it is not difficult to put a lot of energy in the projectile as long as the projectile is fat and slow. Small projectiles at high speed is there the engineering begins.

I dont think you can compare my goals with yours. I have a magazine, automatic reloading, quite some complicated software and a complete case for my gun - it also adheres to local laws and is battery powered for as much as 200 shot per battery charge. I dont think that you have any idea what it took to get to this state, so sorry if i ignore your comment on my resource spending.

May i ask what you think you have done differently to anyone else to get the performance you see? (except building a really big gun)

You criticize that everyone builds the same stuff and there is too little development in the community..

Hands down, what is your invention here? (beside the size)

Can your technology be scaled down to achieve a 100J version with an 8mm diameter 30mm long projectile? If you build a small, light and compact demonstrator, i would be impressed!

For a start: is it an SCR-design, or resonant, or halfbridge?

Re: Yet another coil gun prototype

V2006, Sun Dec 02 2018, 08:51AM

DerAlbi

370 до 480 г - optimization experiments

370 г. - for 10300 J (450 V) optimally

for 2000 J (100 V) optimally 550 g

I can do everything

but I have almost nothing

if i lived in dresden and had that kind of money like yours i would do everything

my material base is outdated

with modern material base everything is possible

8mm diameter 30mm long projectile - also possible

but this is unnecessary complexity

diameter of 12 - 14 mm will be more optimal

V2006, Sun Dec 02 2018, 08:51AM

DerAlbi

370 до 480 г - optimization experiments

370 г. - for 10300 J (450 V) optimally

for 2000 J (100 V) optimally 550 g

I can do everything

but I have almost nothing

if i lived in dresden and had that kind of money like yours i would do everything

my material base is outdated

with modern material base everything is possible

8mm diameter 30mm long projectile - also possible

but this is unnecessary complexity

diameter of 12 - 14 mm will be more optimal

Re: Yet another coil gun prototype

V2006, Sun Dec 02 2018, 08:57AM

here you can understand that the velocity of the projectile is great

370 gramm, diametr 22 мм, long 145 mm

V2006, Sun Dec 02 2018, 08:57AM

here you can understand that the velocity of the projectile is great

370 gramm, diametr 22 мм, long 145 mm

Re: Yet another coil gun prototype

DerAlbi, Sun Dec 02 2018, 11:59AM

Ok, you totally misunderstand why i spend resources. You think that it spend all this time to get a 20J gun and find that pathetic - i get that; if you phrase it like this, you are right. But you totally miss the point of my build.

As far as i can tell from everything you say you have scaled up your coilgun and got a very big and powerful device - maybe the strongest hobbyist coilgun in the world currently.

Scaling up is a matter of resources - i totally agree and understand why you think you could have done better in different circumstances. You spent your resources to get to 600J; but scaling up is the most trivial thing to do in a coilgun. Nothing changes, everything just becomes bigger and with this, naturally things become stronger and up to some point also more efficient.

But you have not built anything new or innovative - its just big. You seem to use the optimization routine every hobbyist uses and you also seem to use the same concept as everyone else uses.

If your goal was to create the ultimate big gun, you succeeded, but this was far away from my goal, so dont compare us.

My gun is the smallest possible with high shot rate and decent output energy with scalable concepts behind it. I broke several usual design rules of coilguns and reinvented a lot of components to get the most energy transfer out of the least volume and weight.

I am sorry to say, but having had those ideas was more a matter of sleeping, walking and shitting than the fact that i spend all my money on the gun. Money made the quality possible, but the performance is not a budget issue. This is about engineering skill and creativity and understanding the device in depth, not scaling up the known concepts.

So i really do not understand your criticism that the community is not moving forward: scaling up has nothing to do with evolving the technology. The last time this forum has seen something truly innovative was the member "Yandersen" with his resonant foil capacitor design.

If you could spend more money, i am quite certain you would get in the kJ-range quite easily. But it would still be the basic SCR design. How would that move the community forward? Kinetic kJ-range coilguns had been done, so whats the point of scaling? New concepts (that are in reach for hobbyist) is what we would need. My design unfortunately isnt suitable for hobbyists.

DerAlbi, Sun Dec 02 2018, 11:59AM

Ok, you totally misunderstand why i spend resources. You think that it spend all this time to get a 20J gun and find that pathetic - i get that; if you phrase it like this, you are right. But you totally miss the point of my build.

As far as i can tell from everything you say you have scaled up your coilgun and got a very big and powerful device - maybe the strongest hobbyist coilgun in the world currently.