Chimney covers

klugesmith, Mon Dec 14 2015, 08:19AMThis non-electrical project has been driving me nuts, but it's almost done. I want to share a few things I learned from it, and ask for advice about a couple of details that could still be changed.

My wife asked me to put durable, but removable, covers on the chimneys of two unused fireplaces. The young family renting the house does not want to set indoor fires, and in fact is using one fireplace as a shrine place. Now we have cold and wet weather, but the original flue dampers can't be closed properly. They are rusty and warped after many years of being open to the sky.

This became a DIY fabrication project when I could not find a ready-made solution, and don't know a suitable handyman. Roof access is with an extension ladder borrowed from friend 4 houses away. For convenience of the tenants, I want to make only two brief trips up there. One: measure and photograph the chimneys. Two: install the covers.

Top covers are supposed to keep rain and cold air out, and warm air in, but need to allow enough airflow to prevent condensation of household moisture in cold flues. Metal seemed more appropriate than wood. I made rectangular pans out of galvanized sheet metal, for the first time since high school. Took advantage of a new tool in the maintenance shop at work: a combination shear, press brake, slip roll similar to

.

. The pans will overlap the terra cotta flue tiles but not the whole mortar-topped brick chimneys, one of which is wider than the sheet metal tool capacity. As a result, wind load will be much smaller but holding the covers down is more challenging.

Lesson 1: mind the thickness when buying sheet metal. A 36x48" piece from my brother was too big for the guillotine shear. I found roof flashing metal of unspecified gauge, sold by the lineal foot & snipped from a coil by a hardware store employee. Later measurement showed it to be less than 11 mils thick (0.28 mm), compared to almost 17 mils (0.43 mm) for the big sheet. On the morning of panmaking day I took a caliper to hardware store & checked the 24x36" precut rectangles, nominally 26 gauge. Found shockingly large variation among the four specimens in stock: roughly 18, 16, 19, and 23½ mils (0.41 to 0.60 mm). Happily bought the thickest one, after checking that its bar code sticker from SteelWorks matched the other three.

Tried to make a pan from the flashing metal, for practice, but the straight shear could not cut it. Even after adjusting the blade clearance, the too-thin metal simply folded over the edge of fixed blade.

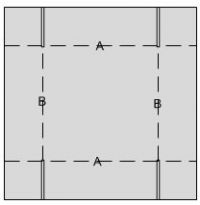

Lesson 2: mind the order of folding. My tutor suggested sawing slots instead of completely removing the corners of unfolded rectangle, to leave little square tabs that wrap around the corners when folded.

For the first pan we folded the A edges before the B edges, with good results. For the second pan we folded the B edges first, then realized that that was just plain wrong. The corner tabs stick out and interfere with making the A folds. We had to bend the tabs with pliers, almost 180 degrees, to be out of the way for the A folds. Two tabs broke off when I bent them back later.

All 8 corners were soldered with no trouble, using a 100 watt unregulated electric soldering iron.

Re: Chimney covers

Ash Small, Mon Dec 14 2015, 11:19PM

The house was designed for open fireplaces. I can see it's not built of stone, but it was still designed for them.

Just my opinion

Ash Small, Mon Dec 14 2015, 11:19PM

The house was designed for open fireplaces. I can see it's not built of stone, but it was still designed for them.

Just my opinion

Re: Chimney covers

klugesmith, Thu Dec 24 2015, 07:55AM

OK, they're up.

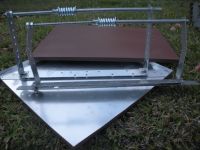

To hold 'em down without adhesives or drilling into masonry, I thought about spring-loaded "tension rods" like those for holding up shower curtains or window curtains. My brother suggested a threaded rod with sharp ends, in two sections with a coupling nut in the middle for tightening. Commercial "Vacu Stack" adaptors have a similar screw adjustment:

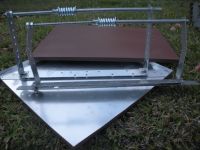

My design combines all three concepts. Spring allows the bar to stay tight during seasonal temperature excursions. Pointy ends might bite into the tile surfaces. Wingnut allows adjustment in place with one hand, if jam nuts & Loctite prevent the all-thread rod from turning.

The design evolved slightly in the direction of easier fabrication.

I learned that the maximum load on compression springs correlates closely with the wire diameter. In this case 0.16" wire makes a spring that can carry more than 100 pounds. Nominal 3/8"-16 Tee-nuts keep the oversize springs aligned with the 5/16"-18 rods.

More details to follow...

klugesmith, Thu Dec 24 2015, 07:55AM

OK, they're up.

To hold 'em down without adhesives or drilling into masonry, I thought about spring-loaded "tension rods" like those for holding up shower curtains or window curtains. My brother suggested a threaded rod with sharp ends, in two sections with a coupling nut in the middle for tightening. Commercial "Vacu Stack" adaptors have a similar screw adjustment:

My design combines all three concepts. Spring allows the bar to stay tight during seasonal temperature excursions. Pointy ends might bite into the tile surfaces. Wingnut allows adjustment in place with one hand, if jam nuts & Loctite prevent the all-thread rod from turning.

The design evolved slightly in the direction of easier fabrication.

I learned that the maximum load on compression springs correlates closely with the wire diameter. In this case 0.16" wire makes a spring that can carry more than 100 pounds. Nominal 3/8"-16 Tee-nuts keep the oversize springs aligned with the 5/16"-18 rods.

More details to follow...

Re: Chimney covers

twist2b, Thu Dec 31 2015, 03:24PM

Hey man! That's a really neat project!!! Good work they look really well done. Compression springs! That is so cool and simple. So you just bought kits? What was the price? If the total was under $150 that's a really solid investment even if you have a fireplace and obviously don't use it in the summer.

twist2b, Thu Dec 31 2015, 03:24PM

Hey man! That's a really neat project!!! Good work they look really well done. Compression springs! That is so cool and simple. So you just bought kits? What was the price? If the total was under $150 that's a really solid investment even if you have a fireplace and obviously don't use it in the summer.

Print this page