My new CNC - COMPLETED

Dr. H., Mon Jul 12 2010, 06:46PMGood day guys

First - I know this is not a mechanical forum but still - it is my favourite place to post so here goes...

Some of you might have seen my old crappy CNC. Its purpose was educational rather than actually doing work, but I've used it for more than 1 year... and it was finally time to start building a new one.

Here are some pics of the progress - the Z axis is pretty much done. The only thing missing is the spindle. It uses 12x3mm leadscrew and teflone-graphite nuts. We've made a "tapper" from a piece of the lead screw.

I've been also working on the electronics for quite a while now.

Pics: servo motors, tapper, Z-axis and X- linear guides and assembly

Cheers

Re: My new CNC - COMPLETED

Linas, Mon Jul 12 2010, 06:51PM

It looks like real deal, nice job

Really impressive, solid look :)

Linas, Mon Jul 12 2010, 06:51PM

It looks like real deal, nice job

Really impressive, solid look :)

Re: My new CNC - COMPLETED

Dr. Drone, Mon Jul 12 2010, 07:33PM

Dr. Drone, Mon Jul 12 2010, 07:33PM

Re: My new CNC - COMPLETED

Anon01, Mon Jul 12 2010, 10:38PM

Are you going to make the spindle or buy one?

Anon01, Mon Jul 12 2010, 10:38PM

Are you going to make the spindle or buy one?

Re: My new CNC - COMPLETED

Patrick, Tue Jul 13 2010, 11:09PM

i have made my own CNC vertical mill too! yours is better than mine. my spindle is a 35,000 rpm DeWalt cut-out mini router, and its no dam good. (1/3 Hp) and louder than hell. It has too much radial run-out. i will switch over to a DC 6000rpm motor.

in my experience the spindle is the most vulnerable part, your set up looks excellent.

i use steppers and Kcam, but your using servos, i like servos much more, post your motor and electrical stuff soon please!

Patrick, Tue Jul 13 2010, 11:09PM

i have made my own CNC vertical mill too! yours is better than mine. my spindle is a 35,000 rpm DeWalt cut-out mini router, and its no dam good. (1/3 Hp) and louder than hell. It has too much radial run-out. i will switch over to a DC 6000rpm motor.

in my experience the spindle is the most vulnerable part, your set up looks excellent.

i use steppers and Kcam, but your using servos, i like servos much more, post your motor and electrical stuff soon please!

Re: My new CNC - COMPLETED

rp181, Tue Jul 13 2010, 11:46PM

Awesome. How much is it costing? I find linear slides, shafts, leadscrews, and bearings are very expensive

rp181, Tue Jul 13 2010, 11:46PM

Awesome. How much is it costing? I find linear slides, shafts, leadscrews, and bearings are very expensive

Re: My new CNC - COMPLETED

Dr. H., Wed Jul 14 2010, 07:59AM

Good day guys

First - thanks for the kind replies

Now on the questions:

About the spindle - we are going to make it ourselves (well ... not me as I am suck with lathes).

Patrick - it looks like an excellent machine - and if it does the job - it is perfect. A piece of advise - it turns out that in 70% of the cases the trouble of milling something comes from the fact that a wrong tool bit is used or the spindle RPMs are wrong.

I am about 60% done with the electronics but will post info soon.

rp181 - the total price of the whole Z-axis is about 150$ (the target price for the whole CNC is under 600$ so I am using as much of scrap parts as possible (but not compromising the accuracy).

Some exact prices - the smaller linear bearings are 10$ a piece, the bigger - 19$ a piece.

The round linear guide - 20mm is 21$ for meter and the 30mm guide is 32$ a meter. I was amazed how expensive the pulleys and belts are. This is why - we are making the other two sets of pulleys ourselves.

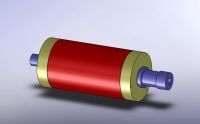

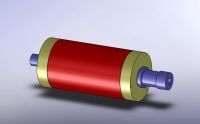

As there is interest I've decided to do a more detailed thread, starting with the servos:

They are "Dynamo Sliven" motors - an old Bulgarian firm. The motors were donated to me from a good fellow HAM. Needed new bearings and two magnets needed epoxying (came loose from the housing). The encoders - they are from some kind of assembly line (I took them from the scrapyard for no charge). They are Japanese, industrial grade - so are very robustly build, 500ppr, quadrature. And some pics of the parts.

Cheers

Dr. H., Wed Jul 14 2010, 07:59AM

Good day guys

First - thanks for the kind replies

Now on the questions:

About the spindle - we are going to make it ourselves (well ... not me as I am suck with lathes).

Patrick - it looks like an excellent machine - and if it does the job - it is perfect. A piece of advise - it turns out that in 70% of the cases the trouble of milling something comes from the fact that a wrong tool bit is used or the spindle RPMs are wrong.

I am about 60% done with the electronics but will post info soon.

rp181 - the total price of the whole Z-axis is about 150$ (the target price for the whole CNC is under 600$ so I am using as much of scrap parts as possible (but not compromising the accuracy).

Some exact prices - the smaller linear bearings are 10$ a piece, the bigger - 19$ a piece.

The round linear guide - 20mm is 21$ for meter and the 30mm guide is 32$ a meter. I was amazed how expensive the pulleys and belts are. This is why - we are making the other two sets of pulleys ourselves.

As there is interest I've decided to do a more detailed thread, starting with the servos:

They are "Dynamo Sliven" motors - an old Bulgarian firm. The motors were donated to me from a good fellow HAM. Needed new bearings and two magnets needed epoxying (came loose from the housing). The encoders - they are from some kind of assembly line (I took them from the scrapyard for no charge). They are Japanese, industrial grade - so are very robustly build, 500ppr, quadrature. And some pics of the parts.

Cheers

Re: My new CNC - COMPLETED

Mads Barnkob, Wed Jul 14 2010, 07:28PM

Nice project you got going here, a invaluable tool at a affordable price :D

How big work pieces will it be able to take?

Mads Barnkob, Wed Jul 14 2010, 07:28PM

Nice project you got going here, a invaluable tool at a affordable price :D

How big work pieces will it be able to take?

Re: My new CNC - COMPLETED

IntraWinding, Wed Jul 14 2010, 08:57PM

That looks really good!

I'm going to need a CNC Milling machine before too long, but I doubt it will be anywhere near as good as yours!

Is the only machine tool you're using to build it a lathe?

You say:

'We've made a "tapper" from a piece of the lead screw'.

Is that for cutting a thread in your graphite/teflon nuts?

What will you use to feed back the XYZ position?

IntraWinding, Wed Jul 14 2010, 08:57PM

That looks really good!

I'm going to need a CNC Milling machine before too long, but I doubt it will be anywhere near as good as yours!

Is the only machine tool you're using to build it a lathe?

You say:

'We've made a "tapper" from a piece of the lead screw'.

Is that for cutting a thread in your graphite/teflon nuts?

What will you use to feed back the XYZ position?

Re: My new CNC - COMPLETED

Dr. H., Thu Jul 15 2010, 09:42AM

Good day guys

Mads - the moving table is 600x600mm and the movements of the X and Y are 550x550mm, the Z has 110mm move.

Intra - we are using lathe and manual mill mostly

(well ... a BIG heavy duty guillotine and bender but I pay for using them - pics coming soon to see for what we used them )

)

Yep - we used it for making the thread in the nut - here some more pics of the nut and "taper" (P.S. Is it correct to be called taper ??? )

The nuts came out really nice (didn't expect soo smooth movements with absolutelly no play ... for now.

For feedback the motors have encoders - and the pulses from it is fed into the drive electronics (servo motor controller, with STEP and DIR input).

Pics: making the taper, one of the Z axis aluminum plates (phone quality )

)

Dr. H., Thu Jul 15 2010, 09:42AM

Good day guys

Mads - the moving table is 600x600mm and the movements of the X and Y are 550x550mm, the Z has 110mm move.

Intra - we are using lathe and manual mill mostly

(well ... a BIG heavy duty guillotine and bender but I pay for using them - pics coming soon to see for what we used them

)

) Yep - we used it for making the thread in the nut - here some more pics of the nut and "taper" (P.S. Is it correct to be called taper ??? )

The nuts came out really nice (didn't expect soo smooth movements with absolutelly no play ... for now.

For feedback the motors have encoders - and the pulses from it is fed into the drive electronics (servo motor controller, with STEP and DIR input).

Pics: making the taper, one of the Z axis aluminum plates (phone quality

)

)

Re: My new CNC - COMPLETED

IntraWinding, Thu Jul 15 2010, 01:25PM

Great stuff.

I'm a big fan of PTFE, but I haven't tried the graphite loaded stuff. I'm getting my first lathe later this year - sorry, just a mini-lathe - yours looks big enough to build a lorry!

Is there good software out there that you'll be able to use to control your mill?

-

It's just called a Tap, that's what confused me

IntraWinding, Thu Jul 15 2010, 01:25PM

Great stuff.

I'm a big fan of PTFE, but I haven't tried the graphite loaded stuff. I'm getting my first lathe later this year - sorry, just a mini-lathe - yours looks big enough to build a lorry!

Is there good software out there that you'll be able to use to control your mill?

-

It's just called a Tap, that's what confused me

Re: My new CNC - COMPLETED

Killa-X, Fri Jul 16 2010, 02:04AM

Looking good! I get my Nema 23's tomorrow :D Working on a laser carving CNC machine to be used with a 60W CO2 laser for slow-cutting acrylic and engraving.

What program are you going to use? I decided on Mach 3

Killa-X, Fri Jul 16 2010, 02:04AM

Looking good! I get my Nema 23's tomorrow :D Working on a laser carving CNC machine to be used with a 60W CO2 laser for slow-cutting acrylic and engraving.

What program are you going to use? I decided on Mach 3

Re: My new CNC - COMPLETED

IntraWinding, Fri Jul 16 2010, 02:26AM

Mach 3 is the one I keep seeing mentioned everywhere.

IntraWinding, Fri Jul 16 2010, 02:26AM

Mach 3 is the one I keep seeing mentioned everywhere.

Re: My new CNC - COMPLETED

Killa-X, Fri Jul 16 2010, 04:41AM

Probably because it's easy to set up, runs on windows XP/Vista/7. It installs a driver so it can manage your ports without any issues. It cannot drive phase motors, so you need a special driver. I made a driver of decaders and counters so when it will work with my NEMA 23.

The output for motors, in Moch 3, you assign ports to Step and Direction. I think it's free? I might have got a demo if it wasnt, because I downloaded it off their site and installed it to a old Dell 4600

Killa-X, Fri Jul 16 2010, 04:41AM

Probably because it's easy to set up, runs on windows XP/Vista/7. It installs a driver so it can manage your ports without any issues. It cannot drive phase motors, so you need a special driver. I made a driver of decaders and counters so when it will work with my NEMA 23.

The output for motors, in Moch 3, you assign ports to Step and Direction. I think it's free? I might have got a demo if it wasnt, because I downloaded it off their site and installed it to a old Dell 4600

Re: My new CNC - COMPLETED

Dr. H., Fri Jul 16 2010, 05:21AM

Hi guys

Sorry about the confusion with the tap ...

About the software - I've been using Mach3 for a LOOONG time and I am really happy with it. The only thig is that if you are going to do big speeds - you need a relatively "fast" PC - in the range of 1.5+Gh. I've used a 800mhz and I had problems above 700mm/s - the software begins to "jerks" and the movement of the mill isn't smooth anymore. The free version will take up to 1000 lines of code if I remember correctly.

Another program that I used in the beginning was the TurboCNC - the advantage is that it takes control over the parallel port without using special drivers, but It had some problems with the G90 and G91 commands.

Killa-X - the CO2 engraver sounds great - post some pics if it is not a secret project

About different drivers for stepper motors (DIY) - for newer motors - the chopper type IC drivers is my personal best. It is just a single chip, capable of micro stepping, up to few amps of current. It just have step/dir inputs and everything else is in the IC (except the current feedback resistors). TA8435H comes to my mind in the moment. It costs in the range of 10$ here.

Other driver I used is the LiniStepper - a GREAT driver. There is a BIG site devoted to it - so plenty of info.

Now - on the progress of the mill - yesterday after a whole day of work we've erected the supports And surprisingly it needed a very little centering.

And surprisingly it needed a very little centering.

Dr. H., Fri Jul 16 2010, 05:21AM

Hi guys

Sorry about the confusion with the tap ...

About the software - I've been using Mach3 for a LOOONG time and I am really happy with it. The only thig is that if you are going to do big speeds - you need a relatively "fast" PC - in the range of 1.5+Gh. I've used a 800mhz and I had problems above 700mm/s - the software begins to "jerks" and the movement of the mill isn't smooth anymore. The free version will take up to 1000 lines of code if I remember correctly.

Another program that I used in the beginning was the TurboCNC - the advantage is that it takes control over the parallel port without using special drivers, but It had some problems with the G90 and G91 commands.

Killa-X - the CO2 engraver sounds great - post some pics if it is not a secret project

About different drivers for stepper motors (DIY) - for newer motors - the chopper type IC drivers is my personal best. It is just a single chip, capable of micro stepping, up to few amps of current. It just have step/dir inputs and everything else is in the IC (except the current feedback resistors). TA8435H comes to my mind in the moment. It costs in the range of 10$ here.

Other driver I used is the LiniStepper - a GREAT driver. There is a BIG site devoted to it - so plenty of info.

Now - on the progress of the mill - yesterday after a whole day of work we've erected the supports

And surprisingly it needed a very little centering.

And surprisingly it needed a very little centering.

Re: My new CNC - COMPLETED

Killa-X, Fri Jul 16 2010, 06:49AM

Its more a future set. I have a source to get a 60W CO2 laser and power supply. I might have to cool it my self with some peltier or something.

For now, I'm starting the project with a 1W blue laser for tuning the machine until I get a hold of the 60W. Will use it for cutting thin plastics maybe, and etching words/decals in wood...plastic..PVC..anything

I too started with TurboCNC! Then I installed XP and no longer can do a MS-DOS boot. Then I got Mach 3 and found it doesn't work with my stepper type, so I have to make a driver.

Hope yours comes along good, Mines just going to be an X-Y

This schematic is for 1 stepper connection with MACH 3

Killa-X, Fri Jul 16 2010, 06:49AM

Its more a future set. I have a source to get a 60W CO2 laser and power supply. I might have to cool it my self with some peltier or something.

For now, I'm starting the project with a 1W blue laser for tuning the machine until I get a hold of the 60W. Will use it for cutting thin plastics maybe, and etching words/decals in wood...plastic..PVC..anything

I too started with TurboCNC! Then I installed XP and no longer can do a MS-DOS boot. Then I got Mach 3 and found it doesn't work with my stepper type, so I have to make a driver.

Hope yours comes along good, Mines just going to be an X-Y

This schematic is for 1 stepper connection with MACH 3

Re: My new CNC - COMPLETED

rp181, Fri Jul 16 2010, 10:42AM

I have used a commercial 40W laser a lot, 40W is only good for engraving. It can cut thin plastics, the hardest I have ever cut was 1/16" garolite, it had a tough time getting through that. It ran about 1" a sec (.8% speed on their scale), and I had to run it again at around 2" a sec to get some points it missed).

rp181, Fri Jul 16 2010, 10:42AM

I have used a commercial 40W laser a lot, 40W is only good for engraving. It can cut thin plastics, the hardest I have ever cut was 1/16" garolite, it had a tough time getting through that. It ran about 1" a sec (.8% speed on their scale), and I had to run it again at around 2" a sec to get some points it missed).

Re: My new CNC - COMPLETED

Killa-X, Fri Jul 16 2010, 04:29PM

Hmmm, I seen videos of 50W cutting acrylic that was 1/4" thick.

So I figured for me, doing probably a max of 1/4" 60W will be plenty :)

Killa-X, Fri Jul 16 2010, 04:29PM

rp181 wrote ...

I have used a commercial 40W laser a lot, 40W is only good for engraving. It can cut thin plastics, the hardest I have ever cut was 1/16" garolite, it had a tough time getting through that. It ran about 1" a sec (.8% speed on their scale), and I had to run it again at around 2" a sec to get some points it missed).

I have used a commercial 40W laser a lot, 40W is only good for engraving. It can cut thin plastics, the hardest I have ever cut was 1/16" garolite, it had a tough time getting through that. It ran about 1" a sec (.8% speed on their scale), and I had to run it again at around 2" a sec to get some points it missed).

Hmmm, I seen videos of 50W cutting acrylic that was 1/4" thick.

So I figured for me, doing probably a max of 1/4" 60W will be plenty :)

Re: My new CNC - COMPLETED

rp181, Fri Jul 16 2010, 04:58PM

Oops. I should have been more clear. It will probably cut 1/4" acrylic, I was speaking of harder materials like garolite.

For some runs, I would suggest making several lower power passes to prevent burning. Here is some 1/16" FR4 garolite.

rp181, Fri Jul 16 2010, 04:58PM

Oops. I should have been more clear. It will probably cut 1/4" acrylic, I was speaking of harder materials like garolite.

For some runs, I would suggest making several lower power passes to prevent burning. Here is some 1/16" FR4 garolite.

Re: My new CNC - COMPLETED

Dr. H., Mon Jul 19 2010, 07:43PM

Hi guys

I've been working on the electronics for more than a month now and it is starting to get together now

The servo controller is based on the Elm Chan's design.

Dr. H., Mon Jul 19 2010, 07:43PM

Hi guys

I've been working on the electronics for more than a month now and it is starting to get together now

The servo controller is based on the Elm Chan's design.

Re: My new CNC - COMPLETED

..., Mon Jul 19 2010, 08:26PM

Thats looking nice, good job recycling

What are all of the analog meters for?

..., Mon Jul 19 2010, 08:26PM

Thats looking nice, good job recycling

What are all of the analog meters for?

Re: My new CNC - COMPLETED

Dr. H., Tue Aug 17 2010, 04:49AM

Good day guys

Hi ... - the meters are for the servo motors and for the spindle.

It's been a while since I posted but I was absent for more than 10 days and the work on the CNC has been slow... but we've picked it up again.

Pics of the progress - all of the mechanical work on the electronics is done, time for wiring. Yesterday we've got the table done (the slides for now). I hope in a couple of days to mount the lead screw and the motor.

Also we've started working on the spindle - pics of it soon.

Cheers

Dr. H., Tue Aug 17 2010, 04:49AM

Good day guys

Hi ... - the meters are for the servo motors and for the spindle.

It's been a while since I posted but I was absent for more than 10 days and the work on the CNC has been slow... but we've picked it up again.

Pics of the progress - all of the mechanical work on the electronics is done, time for wiring. Yesterday we've got the table done (the slides for now). I hope in a couple of days to mount the lead screw and the motor.

Also we've started working on the spindle - pics of it soon.

Cheers

Re: My new CNC - COMPLETED

Killa-X, Tue Aug 17 2010, 05:21AM

Looks great! Lots of parts, should be a good CNC machine! I got mine on hold, yet I know where to get all my parts finally.

Hope you can get it running up soon, Be nice to see how it runs :D

Killa-X, Tue Aug 17 2010, 05:21AM

Looks great! Lots of parts, should be a good CNC machine! I got mine on hold, yet I know where to get all my parts finally.

Hope you can get it running up soon, Be nice to see how it runs :D

Re: My new CNC - COMPLETED

Dr. Drone, Tue Aug 17 2010, 04:24PM

Dr. Drone, Tue Aug 17 2010, 04:24PM

Re: My new CNC - COMPLETED

Dr. H., Tue Sept 07 2010, 06:45AM

Hi guys

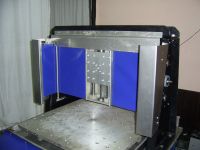

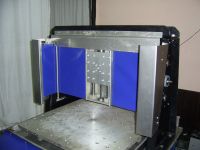

it's been a while since I last posted but a lot of work has been done on the mill. I got the servos running, the wiring of the electronics is 90% done, the Y-axis is almost completed. Last night we did some test and it reached 60 inch per minute but at half the supply voltage. So 80 even 100 inch per minute should be reachable.

Working on the covers and protective "belts" for the linear guides now.

Here some pics

Cheers

Dr. H., Tue Sept 07 2010, 06:45AM

Hi guys

it's been a while since I last posted but a lot of work has been done on the mill. I got the servos running, the wiring of the electronics is 90% done, the Y-axis is almost completed. Last night we did some test and it reached 60 inch per minute but at half the supply voltage. So 80 even 100 inch per minute should be reachable.

Working on the covers and protective "belts" for the linear guides now.

Here some pics

Cheers

Re: My new CNC - COMPLETED

Patrick, Tue Sept 07 2010, 07:10AM

NICE! a bridge frame too!! ive never used graphite-PTFE, how strong is it? if your spindle binds, will they strip!?

(PS look everybody ive got my sixth star!!!)

Patrick, Tue Sept 07 2010, 07:10AM

NICE! a bridge frame too!! ive never used graphite-PTFE, how strong is it? if your spindle binds, will they strip!?

(PS look everybody ive got my sixth star!!!)

Re: My new CNC - COMPLETED

Mads Barnkob, Tue Sept 07 2010, 08:19AM

Very professional looking :)

Good craftmanship in hobbies and thoughtful construction is what makes a special project, looking forward to see some serious milling!

Mads Barnkob, Tue Sept 07 2010, 08:19AM

Very professional looking :)

Good craftmanship in hobbies and thoughtful construction is what makes a special project, looking forward to see some serious milling!

Re: My new CNC - COMPLETED

Dr. H., Tue Sept 07 2010, 06:05PM

Hi guys

thanks for the kind words

The PTFE is quite hard. This one is specially designed for industrial air compressors(for the segments) .

We had a small incident - a screwdriver got between the support of the linear guide and the linear bearing - it got bent without even noticing it (and it is 6mm thick).

Also the nuts sit in a "clamp" - if the load becomes too great - they slide out of it. This was tested by deliberately "jamming" the axis - it worked perfectly.

Here are the pics of today's progress

Cheers :)

Dr. H., Tue Sept 07 2010, 06:05PM

Hi guys

thanks for the kind words

The PTFE is quite hard. This one is specially designed for industrial air compressors(for the segments) .

We had a small incident - a screwdriver got between the support of the linear guide and the linear bearing - it got bent without even noticing it (and it is 6mm thick).

Also the nuts sit in a "clamp" - if the load becomes too great - they slide out of it. This was tested by deliberately "jamming" the axis - it worked perfectly.

Here are the pics of today's progress

Cheers :)

Re: My new CNC - COMPLETED

Patrick, Wed Sept 08 2010, 12:37AM

also, do those blue plastic sheets roll and unroll as your quill moves? how did you make those?

Patrick, Wed Sept 08 2010, 12:37AM

Dr. H. wrote ...

The PTFE is quite hard. This one is specially designed for industrial air compressors(for the segments) .

We had a small incident - a screwdriver got between the support of the linear guide and the linear bearing - it got bent without even noticing it (and it is 6mm thick).

Also the nuts sit in a "clamp" - if the load becomes too great - they slide out of it. This was tested by deliberately "jamming" the axis - it worked perfectly.

Cheers :)

you do good work Dr.H The PTFE is quite hard. This one is specially designed for industrial air compressors(for the segments) .

We had a small incident - a screwdriver got between the support of the linear guide and the linear bearing - it got bent without even noticing it (and it is 6mm thick).

Also the nuts sit in a "clamp" - if the load becomes too great - they slide out of it. This was tested by deliberately "jamming" the axis - it worked perfectly.

Cheers :)

also, do those blue plastic sheets roll and unroll as your quill moves? how did you make those?

Re: My new CNC - COMPLETED

rp181, Wed Sept 08 2010, 02:12AM

I am trying to figure out the purpose of the vertical blue sheet. The bottom one is to trap waste I assumed, but I can't think of a use for the vertical one.

rp181, Wed Sept 08 2010, 02:12AM

I am trying to figure out the purpose of the vertical blue sheet. The bottom one is to trap waste I assumed, but I can't think of a use for the vertical one.

Re: My new CNC - COMPLETED

Patrick, Wed Sept 08 2010, 03:41AM

Patrick, Wed Sept 08 2010, 03:41AM

rp181 wrote ...

I am trying to figure out the purpose of the vertical blue sheet. The bottom one is to trap waste I assumed, but I can't think of a use for the vertical one.

I think they are to keep his leadscrews/guides clear of chaff. mine get fowled easily.I am trying to figure out the purpose of the vertical blue sheet. The bottom one is to trap waste I assumed, but I can't think of a use for the vertical one.

Re: My new CNC - COMPLETED

Dr. H., Wed Sept 08 2010, 05:09AM

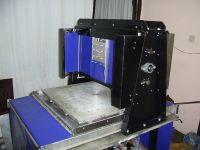

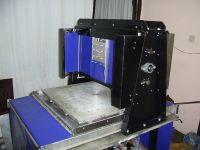

Hi guys

yep - those sheets roll and unroll. We used car seat belt mechanisms to do it. I will be taking parts down for painting today and will take few pics of them and post them tonight.

The mill is designed to work with water cooling and as the linear guides (and screws) are not stainless they get rust easily. Also hate to clean constantly debris from the mechanisma (as I had to do on my previous mill)- sooo we decided to close everything.

Cheers

Dr. H., Wed Sept 08 2010, 05:09AM

Hi guys

yep - those sheets roll and unroll. We used car seat belt mechanisms to do it. I will be taking parts down for painting today and will take few pics of them and post them tonight.

The mill is designed to work with water cooling and as the linear guides (and screws) are not stainless they get rust easily. Also hate to clean constantly debris from the mechanisma (as I had to do on my previous mill)- sooo we decided to close everything.

Cheers

Re: My new CNC - COMPLETED

Patrick, Wed Sept 08 2010, 05:57AM

pick 'n' pull .

Patrick, Wed Sept 08 2010, 05:57AM

Dr. H. wrote ...

...yep - those sheets roll and unroll. We used car seat belt mechanisms to do it....

please show detail, about your seatbelt device. I want to duplicate what youve done, I ll get my stuff from...yep - those sheets roll and unroll. We used car seat belt mechanisms to do it....

pick 'n' pull .

Re: My new CNC - COMPLETED

Dr. H., Sat Sept 11 2010, 07:18PM

Hi guys

I am proud to show you the finished mill ... well almost - the spindle is missing - it is in the process of making. Everything else is ready. I've almost finished the electronics but the school is coming soo progress will be slow from now on.

Patric - here is the assembly of the belt rollers. Nothing special - just two seatbealt mechanisms, halfway cut and fixed inside a PVC pipe - but you have to make sure that one is from the driver's side and one is from passenger's side because that way you can use both in the opposite ends of the tube (they are "mirrored" - I used from Fiat Tipo)

Cheers

Dr. H., Sat Sept 11 2010, 07:18PM

Hi guys

I am proud to show you the finished mill ... well almost - the spindle is missing - it is in the process of making. Everything else is ready. I've almost finished the electronics but the school is coming soo progress will be slow from now on.

Patric - here is the assembly of the belt rollers. Nothing special - just two seatbealt mechanisms, halfway cut and fixed inside a PVC pipe - but you have to make sure that one is from the driver's side and one is from passenger's side because that way you can use both in the opposite ends of the tube (they are "mirrored" - I used from Fiat Tipo)

Cheers

Re: My new CNC - COMPLETED

Patrick, Sun Sept 12 2010, 06:08AM

thats amazing i never would have thought of that in a million years. i will make mods on my CNC after this semester.

Patrick, Sun Sept 12 2010, 06:08AM

thats amazing i never would have thought of that in a million years. i will make mods on my CNC after this semester.

Re: My new CNC - COMPLETED

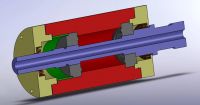

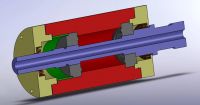

Dr. H., Wed Dec 29 2010, 08:45AM

Good day guys

it is the winter break now and it is time to get back on the project

First things first we've got the spindle finished. It has dual tapered roller bearings with a tightening nut (to adjust the "backlash" of the spindle).

It is forced oil cooled/lubricated. Here are the pics and the CAD model.

Have in mind that all the parts are made from scratch (except the gear wheel and oil connectors).

Please excuse the bad quality - I only had cell phone on hand.

Cheers

Dr. H., Wed Dec 29 2010, 08:45AM

Good day guys

it is the winter break now and it is time to get back on the project

First things first we've got the spindle finished. It has dual tapered roller bearings with a tightening nut (to adjust the "backlash" of the spindle).

It is forced oil cooled/lubricated. Here are the pics and the CAD model.

Have in mind that all the parts are made from scratch (except the gear wheel and oil connectors).

Please excuse the bad quality - I only had cell phone on hand.

Cheers

Re: My new CNC - COMPLETED

Finn Hammer, Wed Dec 29 2010, 08:34PM

Huben,

This is wonderfull, looking forward to see "First run".

Cheers, Finn Hammer

Finn Hammer, Wed Dec 29 2010, 08:34PM

Huben,

This is wonderfull, looking forward to see "First run".

Cheers, Finn Hammer

Re: My new CNC - COMPLETED

Dr. Drone, Wed Dec 29 2010, 08:43PM

Dr. Drone, Wed Dec 29 2010, 08:43PM

Re: My new CNC - COMPLETED

Dr Hankenstein, Wed Dec 29 2010, 09:38PM

Nice professional job, Huben. Looking forward to seeing this beauty in action!

Hank

Dr Hankenstein, Wed Dec 29 2010, 09:38PM

Nice professional job, Huben. Looking forward to seeing this beauty in action!

Hank

Re: My new CNC - COMPLETED

rp181, Thu Dec 30 2010, 02:42AM

Agree with Henry, looks massive!

rp181, Thu Dec 30 2010, 02:42AM

Agree with Henry, looks massive!

Re: My new CNC - COMPLETED

IntraWinding, Thu Dec 30 2010, 07:24PM

Brilliant stuff! It looks extremely solid. What sort of RPM will this run at and what factors led you to choose forced oil cooling?

IntraWinding, Thu Dec 30 2010, 07:24PM

Brilliant stuff! It looks extremely solid. What sort of RPM will this run at and what factors led you to choose forced oil cooling?

Re: My new CNC - COMPLETED

Dr. H., Thu Dec 30 2010, 09:08PM

Good day guys

thanks for the kind replies Yep it is built to last.

Yep it is built to last.

I've decided on forced oil because that is the manufacturers reccomendation for those types of bearings. They are sad to work at 12k RPM. The motor I am using is capable of runing it up to about 6k RPM (looking for a bit bigger/faster motor). But in most cases it will be running in the range of 2k RPM. Also from past experience with spindles they tend to get quite hot after a while under hevy loads and high RPMs.

P.S. Working on a power supply for the spindle motor in the moment. Pics soon.

Cheers

Dr. H., Thu Dec 30 2010, 09:08PM

Good day guys

thanks for the kind replies

Yep it is built to last.

Yep it is built to last. I've decided on forced oil because that is the manufacturers reccomendation for those types of bearings. They are sad to work at 12k RPM. The motor I am using is capable of runing it up to about 6k RPM (looking for a bit bigger/faster motor). But in most cases it will be running in the range of 2k RPM. Also from past experience with spindles they tend to get quite hot after a while under hevy loads and high RPMs.

P.S. Working on a power supply for the spindle motor in the moment. Pics soon.

Cheers

Re: My new CNC - COMPLETED

IntraWinding, Mon Jan 03 2011, 02:09AM

I was comparing it to my mini lathe headstock which uses grease. It looks similar but only runs at up to 2500rpm and the lathe's only manual. Do you use a preload of some sort on the bearings?

IntraWinding, Mon Jan 03 2011, 02:09AM

I was comparing it to my mini lathe headstock which uses grease. It looks similar but only runs at up to 2500rpm and the lathe's only manual. Do you use a preload of some sort on the bearings?

Re: My new CNC - COMPLETED

Dr. H., Mon Apr 04 2011, 05:50PM

Good day guys

I was 4 days home so I had a bit of time to work on the project. I've built a power supply to run the spindle motor. I've used what ever I had on hand. First run is approaching

IntraWinding - sorry for the late reply - I've missed your post - yes there is a nut on the shaft to adjust the preload.

Cheers

Dr. H., Mon Apr 04 2011, 05:50PM

Good day guys

I was 4 days home so I had a bit of time to work on the project. I've built a power supply to run the spindle motor. I've used what ever I had on hand. First run is approaching

IntraWinding - sorry for the late reply - I've missed your post - yes there is a nut on the shaft to adjust the preload.

Cheers

Re: My new CNC - COMPLETED

IntraWinding, Wed Apr 06 2011, 12:41AM

Do you have an estimate of when it will be ready to test?

IntraWinding, Wed Apr 06 2011, 12:41AM

Do you have an estimate of when it will be ready to test?

Re: My new CNC - COMPLETED

Dr. H., Fri Apr 08 2011, 07:15PM

Good day Intra

most of the stuff is ready (I am "fighting" with the electronics in the moment and that is the last big thing left). I really hope to get it going till the beginning of the summer (I am not home and can't work on it a lot - only in the weekends when I get home).

P.S. But sure is fun to be able to work on the electronic stuff if the dorm hee hee

Dr. H., Fri Apr 08 2011, 07:15PM

Good day Intra

most of the stuff is ready (I am "fighting" with the electronics in the moment and that is the last big thing left). I really hope to get it going till the beginning of the summer (I am not home and can't work on it a lot - only in the weekends when I get home).

P.S. But sure is fun to be able to work on the electronic stuff if the dorm hee hee

Re: My new CNC - COMPLETED

Dr. H., Tue Apr 19 2011, 07:22PM

Good day guys

after quite a bit of work the electronics are finally ready. All of the safety features are working and the servos are turning fine now. I've finally got one axis of the mill moving but there is still a lot of tuning to be done on the servos. Hope to get all of the axis working in the next few days. First cut is in sight

Dr. H., Tue Apr 19 2011, 07:22PM

Good day guys

after quite a bit of work the electronics are finally ready. All of the safety features are working and the servos are turning fine now. I've finally got one axis of the mill moving but there is still a lot of tuning to be done on the servos. Hope to get all of the axis working in the next few days. First cut is in sight

Re: My new CNC - COMPLETED

Dr. H., Wed Apr 20 2011, 07:00PM

A fast update

I've spent most of the morning and big part of the afternoon fixing a problem with one of the axes - it is OK now. I've mounted the spindle and wired the limit switches. Also tested the power supply for it for about 30mins ... no problems there Tomorrow I have more work to do on the Y (mostly adjusting things and fixing small problems).

Tomorrow I have more work to do on the Y (mostly adjusting things and fixing small problems).

Cheers

Dr. H., Wed Apr 20 2011, 07:00PM

A fast update

I've spent most of the morning and big part of the afternoon fixing a problem with one of the axes - it is OK now. I've mounted the spindle and wired the limit switches. Also tested the power supply for it for about 30mins ... no problems there

Tomorrow I have more work to do on the Y (mostly adjusting things and fixing small problems).

Tomorrow I have more work to do on the Y (mostly adjusting things and fixing small problems). Cheers

Re: My new CNC - COMPLETED

Dr. H., Thu Apr 21 2011, 05:48PM

FIRST CUT wheeeee

after almost 9 months of build time it finally started cutting A few problems have shown up but nothing critical. I've spent about 3 hours testing different tools and different feed speeds and RPMs - starting to collect data

A few problems have shown up but nothing critical. I've spent about 3 hours testing different tools and different feed speeds and RPMs - starting to collect data  . I was amazed how well it handled 8mm end mill at 100/min feedrate and 1mm deep groove in aluminum - it cut really nice. No real code for now - just a fast test program I wrote to cut a square out of plexy. Other tests were done with manual feed on the PC.

. I was amazed how well it handled 8mm end mill at 100/min feedrate and 1mm deep groove in aluminum - it cut really nice. No real code for now - just a fast test program I wrote to cut a square out of plexy. Other tests were done with manual feed on the PC.

things remaining -get the cooling system working

- get the oil system working

- build an RPM meter for the spindle

Cheers from a very happy Dr. H.

Dr. H., Thu Apr 21 2011, 05:48PM

FIRST CUT wheeeee

after almost 9 months of build time it finally started cutting

A few problems have shown up but nothing critical. I've spent about 3 hours testing different tools and different feed speeds and RPMs - starting to collect data

A few problems have shown up but nothing critical. I've spent about 3 hours testing different tools and different feed speeds and RPMs - starting to collect data  . I was amazed how well it handled 8mm end mill at 100/min feedrate and 1mm deep groove in aluminum - it cut really nice. No real code for now - just a fast test program I wrote to cut a square out of plexy. Other tests were done with manual feed on the PC.

. I was amazed how well it handled 8mm end mill at 100/min feedrate and 1mm deep groove in aluminum - it cut really nice. No real code for now - just a fast test program I wrote to cut a square out of plexy. Other tests were done with manual feed on the PC.things remaining -get the cooling system working

- get the oil system working

- build an RPM meter for the spindle

Cheers from a very happy Dr. H.

Re: My new CNC - COMPLETED

Finn Hammer, Thu Apr 21 2011, 06:27PM

Huben,

This has been one of the greater projects this and last year, and you are the man!

No end to the fine curved parts you are going to spit out from now on!

A "Hats off" from this Danish Toolmaker.

Cheers, Finn Hammer

Finn Hammer, Thu Apr 21 2011, 06:27PM

Huben,

This has been one of the greater projects this and last year, and you are the man!

No end to the fine curved parts you are going to spit out from now on!

A "Hats off" from this Danish Toolmaker.

Cheers, Finn Hammer

Re: My new CNC - COMPLETED

Turkey9, Thu Apr 21 2011, 10:34PM

Nice!!!! That is quite amazing and a real accomplishment!!!!

Turkey9, Thu Apr 21 2011, 10:34PM

Nice!!!! That is quite amazing and a real accomplishment!!!!

Re: My new CNC - COMPLETED

Dr Hankenstein, Fri Apr 22 2011, 01:52AM

Bitchen Job, Huben! You're quite the talented guy.

Hank

Dr Hankenstein, Fri Apr 22 2011, 01:52AM

Bitchen Job, Huben! You're quite the talented guy.

Hank

Re: My new CNC - COMPLETED

Dr. Drone, Fri Apr 22 2011, 07:39PM

Dr. Drone, Fri Apr 22 2011, 07:39PM

Re: My new CNC - COMPLETED

Arcstarter, Fri Apr 22 2011, 08:23PM

Kick ass!

Arcstarter, Fri Apr 22 2011, 08:23PM

Kick ass!

Re: My new CNC - COMPLETED

IntraWinding, Sat Apr 23 2011, 03:03AM

Congratulations Even my imaginary CNC milling machine isn't as good as your real one!

Even my imaginary CNC milling machine isn't as good as your real one!

IntraWinding, Sat Apr 23 2011, 03:03AM

Congratulations

Even my imaginary CNC milling machine isn't as good as your real one!

Even my imaginary CNC milling machine isn't as good as your real one!Re: My new CNC - COMPLETED

Dr. H., Mon Apr 25 2011, 08:26PM

Good day guys

I have been "off the grid" for few days so I was unable to reply.

Thanks for the kind words guys. This has been one hard project indeed ... and it is far from complete - I am working on few other things for it. Will be posting some more updates soon.

Cheers

Dr. H., Mon Apr 25 2011, 08:26PM

Good day guys

I have been "off the grid" for few days so I was unable to reply.

Thanks for the kind words guys. This has been one hard project indeed ... and it is far from complete - I am working on few other things for it. Will be posting some more updates soon.

Cheers

Re: My new CNC - COMPLETED

Dr. H., Thu May 05 2011, 06:13PM

Good day guys

Some spare time so i've built an RPM counter and mounted it. Also working on the water cooling and the oil system. More pics soon

Cheers

Dr. H., Thu May 05 2011, 06:13PM

Good day guys

Some spare time so i've built an RPM counter and mounted it. Also working on the water cooling and the oil system. More pics soon

Cheers

Re: My new CNC - COMPLETED

Dr. H., Mon May 09 2011, 06:13PM

Hi guys

after two days of work and a lot of problems - a major oil leak because of a torn oil seal, damaged (burnt) Z-axis motor (during heavy tests) and now replaced with 3 times as big it was time for some real cutting. I've draw something really fast (my call sign) and milled it - it turned really well

it was time for some real cutting. I've draw something really fast (my call sign) and milled it - it turned really well

Here is a pic of the oil pump (yep ... from an old alu saucepan... )

)

Dr. H., Mon May 09 2011, 06:13PM

Hi guys

after two days of work and a lot of problems - a major oil leak because of a torn oil seal, damaged (burnt) Z-axis motor (during heavy tests) and now replaced with 3 times as big

it was time for some real cutting. I've draw something really fast (my call sign) and milled it - it turned really well

it was time for some real cutting. I've draw something really fast (my call sign) and milled it - it turned really well

Here is a pic of the oil pump (yep ... from an old alu saucepan...

)

)

Re: My new CNC - COMPLETED

Dr. H., Sat May 21 2011, 07:40PM

Good day guys

I have few spare days at home (holidays) so I am working on the liquit cooling system. Also tested the mill on some real aluminum cutting earlier this evening (a friend of mine needed a bizare part for a project he is doing.

Cheers

Dr. H., Sat May 21 2011, 07:40PM

Good day guys

I have few spare days at home (holidays) so I am working on the liquit cooling system. Also tested the mill on some real aluminum cutting earlier this evening (a friend of mine needed a bizare part for a project he is doing.

Cheers

Re: My new CNC - COMPLETED

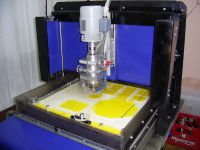

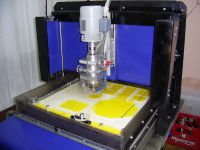

Dr. H., Tue Jul 26 2011, 06:04PM

Hi guys

finally completed after almost an year of work

after almost an year of work

thinks that I have done in the past week or so

- new spindle motor (3 phase - now it can run all day long without overheat as the previous motor ... )

- improved the water cooling system

- fixed a problem with one of the lead screws

- added a "water skirt"

- dedicated space for the cutting tools, collets and stuff for the mill

Hope you like it - and a prove that it actually works hee hee

P.S. It really takes a lot of cables and hoses hee hee (last pic)

(last pic)

Dr. H., Tue Jul 26 2011, 06:04PM

Hi guys

finally completed

after almost an year of work

after almost an year of work thinks that I have done in the past week or so

- new spindle motor (3 phase - now it can run all day long without overheat as the previous motor ... )

- improved the water cooling system

- fixed a problem with one of the lead screws

- added a "water skirt"

- dedicated space for the cutting tools, collets and stuff for the mill

Hope you like it - and a prove that it actually works hee hee

P.S. It really takes a lot of cables and hoses hee hee

(last pic)

(last pic)

Re: My new CNC - COMPLETED

Chip Fixes, Tue Jul 26 2011, 06:37PM

It's beautiful

Chip Fixes, Tue Jul 26 2011, 06:37PM

It's beautiful

Re: My new CNC - COMPLETED

Finn Hammer, Tue Jul 26 2011, 09:18PM

Huben,

It is a remarkable acheivement. This toolmaker is envious and impressed!

Cheers, Finn Hammer

Finn Hammer, Tue Jul 26 2011, 09:18PM

Huben,

It is a remarkable acheivement. This toolmaker is envious and impressed!

Cheers, Finn Hammer

Print this page