Grenadier's big thread of Röntgen related shenanigans

Adam Munich, Mon Jun 07 2010, 01:41AMSo i decided not to quit on my ray machine.

Any input? Please have some input.

Re: Grenadier's big thread of Röntgen related shenanigans

Wolfram, Mon Jun 07 2010, 10:24AM

Was the head an S.S. White?

I'm almost certain the transformer is a 60Hz unit with a 110V primary, the reason you got such a high voltage from it when giving it 12V on the primary is that when the voltage on the primary was removed, the magnetic field in the core collapsed and induced a high voltage in both the primary and the secondary. If you had connected an oscilloscope across the primary when doing the test, I bet you would see spikes of a couple of hundred volts.

The way you are driving the transformer with a pulsed relay is not right, it will give you some high voltage, but at very limited power, and you might excite resonances in the transformer secondaries, giving you a much higher output voltage than expected, risking the transformer and making the output voltage hard to predict. The transformer is made to be driven by a 60Hz sine wave, and this is certainly the best way to do it.

The transformer has two secondaries that are wound in the opposite direction, and there should be a black wire from the inner end of each secondary. These two wires should be connected to each other and to the core at all times when you are operating the transformer, or else there is a very real risk of arc-over between the inner windings of the secondaries and the core. If you want to measure the current through the transformer (which is also the current flowing through the x-ray tube), you can connect an AC milliampere meter in series with one of these wires.

Here is the schematic of a typical x-ray head, I hope this clears up any confusion

is the schematic of a typical x-ray head, I hope this clears up any confusion

The transformer should be immersed in oil unless you are operating it at very low output voltages, I wouldn't risk running it at more than 10kVp per secondary without oil. You might be able to operate the tube at 60kVp in air before you start to get trouble with corona and arcing, but I'm a bit worried about the wooden support you're using for the tube. Wood isn't a very good insulator unless it has been thoroughly dried and laquered. Also, running the tube out of oil will limit the maximum power that you can put into it.

Doing these changes will greatly increase the the maximum radiation output of your setup. It will also increase the controllability of the system, both in the sense that you can predictably set the working voltage by giving the transformer a specific AC voltage on the input (a variac will be handy here) and in the sense that you can see what current it is running at. And if you want to run it at low power, that's no problem, just run the tube at a very low current.

Was there a ceramic radiation-shielding tube around the x-ray tube when you removed it from the head? It could be a good idea to put this back on the tube, to shield against off-axis radiation.

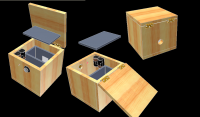

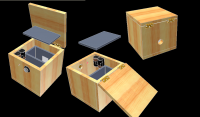

I should add the obligatory warning about ionizing radiation, but you seem to know what you're doing safery-wise, the lead shileding box that you've built is a very good protective measure, just don't assume that it will stop all radiation at all times. Normal geiger counters aren't the most suitable for measuring X-rays, but Proud Mary knows much more on this subject than me, and hopefully she can give you some tips.

Anders M.

Wolfram, Mon Jun 07 2010, 10:24AM

Was the head an S.S. White?

I'm almost certain the transformer is a 60Hz unit with a 110V primary, the reason you got such a high voltage from it when giving it 12V on the primary is that when the voltage on the primary was removed, the magnetic field in the core collapsed and induced a high voltage in both the primary and the secondary. If you had connected an oscilloscope across the primary when doing the test, I bet you would see spikes of a couple of hundred volts.

The way you are driving the transformer with a pulsed relay is not right, it will give you some high voltage, but at very limited power, and you might excite resonances in the transformer secondaries, giving you a much higher output voltage than expected, risking the transformer and making the output voltage hard to predict. The transformer is made to be driven by a 60Hz sine wave, and this is certainly the best way to do it.

The transformer has two secondaries that are wound in the opposite direction, and there should be a black wire from the inner end of each secondary. These two wires should be connected to each other and to the core at all times when you are operating the transformer, or else there is a very real risk of arc-over between the inner windings of the secondaries and the core. If you want to measure the current through the transformer (which is also the current flowing through the x-ray tube), you can connect an AC milliampere meter in series with one of these wires.

Here

is the schematic of a typical x-ray head, I hope this clears up any confusion

is the schematic of a typical x-ray head, I hope this clears up any confusionThe transformer should be immersed in oil unless you are operating it at very low output voltages, I wouldn't risk running it at more than 10kVp per secondary without oil. You might be able to operate the tube at 60kVp in air before you start to get trouble with corona and arcing, but I'm a bit worried about the wooden support you're using for the tube. Wood isn't a very good insulator unless it has been thoroughly dried and laquered. Also, running the tube out of oil will limit the maximum power that you can put into it.

Doing these changes will greatly increase the the maximum radiation output of your setup. It will also increase the controllability of the system, both in the sense that you can predictably set the working voltage by giving the transformer a specific AC voltage on the input (a variac will be handy here) and in the sense that you can see what current it is running at. And if you want to run it at low power, that's no problem, just run the tube at a very low current.

Was there a ceramic radiation-shielding tube around the x-ray tube when you removed it from the head? It could be a good idea to put this back on the tube, to shield against off-axis radiation.

I should add the obligatory warning about ionizing radiation, but you seem to know what you're doing safery-wise, the lead shileding box that you've built is a very good protective measure, just don't assume that it will stop all radiation at all times. Normal geiger counters aren't the most suitable for measuring X-rays, but Proud Mary knows much more on this subject than me, and hopefully she can give you some tips.

Anders M.

Re: Grenadier's big thread of Röntgen related shenanigans

Steve Conner, Mon Jun 07 2010, 10:51AM

I'm puzzled. Why would you take apart a working X-ray head and use the tube and transformer to build another X-ray head?

Are you doing fine art radiography, so you had to take the shielding off to let the low-energy rays out? But then, why not just take the aluminium filter off the original head?

I agree by the way, the lead shielding box is pretty cool.

Steve Conner, Mon Jun 07 2010, 10:51AM

I'm puzzled. Why would you take apart a working X-ray head and use the tube and transformer to build another X-ray head?

Are you doing fine art radiography, so you had to take the shielding off to let the low-energy rays out? But then, why not just take the aluminium filter off the original head?

I agree by the way, the lead shielding box is pretty cool.

Re: Grenadier's big thread of Röntgen related shenanigans

Proud Mary, Mon Jun 07 2010, 01:22PM

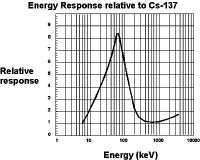

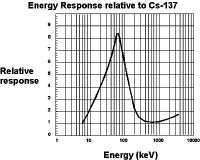

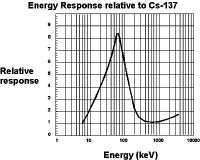

Thanks for the plug, Anders, but if you look at my Geigermania thread in the Projects section, you'll see that I'm only at the very beginning of any real understanding of gas amplification detectors, but I will say that GM tubes are wholly unsuitable for the measurement of X-rays, and nowhere worse than around 60-75keV, where the uncompensated energy response curves of typical tubes looks much like Mount Fuji.

Without measurement you have no science.

Proud Mary, Mon Jun 07 2010, 01:22PM

Anders M. wrote ...

Normal geiger counters aren't the most suitable for measuring X-rays, but Proud Mary knows much more on this subject than me, and hopefully she can give you some tips.

Normal geiger counters aren't the most suitable for measuring X-rays, but Proud Mary knows much more on this subject than me, and hopefully she can give you some tips.

Thanks for the plug, Anders, but if you look at my Geigermania thread in the Projects section, you'll see that I'm only at the very beginning of any real understanding of gas amplification detectors, but I will say that GM tubes are wholly unsuitable for the measurement of X-rays, and nowhere worse than around 60-75keV, where the uncompensated energy response curves of typical tubes looks much like Mount Fuji.

Without measurement you have no science.

Re: Grenadier's big thread of Röntgen related shenanigans

Adam Munich, Mon Jun 07 2010, 06:42PM

Well, of course the tube and transformer are immersed in cooking oil. I've had very good luck with canola oil. I've pushed that transformer to 200KV and it holds up fine. Canola oil has a D-strength of 12MV/M.

The wood is just to hold the tube. It's soaked through in oil.

The transformer is rigged to have the center tap grounded to the core.

I don't plan on any fine measurement with my GM tube, But it is a mica window model (tube, not pancake), and thus very sensitive to all kinds of radiation. It is mainly just going to be used to detect any changes over background.

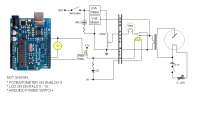

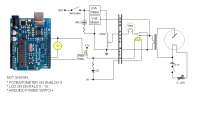

IF YOU LOOKED AT PAGE 2 OF THE THREAD... you will see that i have a new circuit to drive it. Here is the diagram..

Adam Munich, Mon Jun 07 2010, 06:42PM

Well, of course the tube and transformer are immersed in cooking oil. I've had very good luck with canola oil. I've pushed that transformer to 200KV and it holds up fine. Canola oil has a D-strength of 12MV/M.

The wood is just to hold the tube. It's soaked through in oil.

The transformer is rigged to have the center tap grounded to the core.

I don't plan on any fine measurement with my GM tube, But it is a mica window model (tube, not pancake), and thus very sensitive to all kinds of radiation. It is mainly just going to be used to detect any changes over background.

IF YOU LOOKED AT PAGE 2 OF THE THREAD... you will see that i have a new circuit to drive it. Here is the diagram..

Re: Grenadier's big thread of Röntgen related shenanigans

Wolfram, Mon Jun 07 2010, 09:52PM

That looks like a much more reasonable circuit.

I last checked that thread right after you first joined here, so I missed the updates. No need to yell.

Are you sure about the 200kV figure? How did you measure this? Resistive dividers can be inaccurate even at 60Hz if they have significant stray capacitances, and the 1kV/mm formula for sparks between needle points can overestimate the voltage when yo go above a few tens of kilovolts. You mention the transformer is a 75kV unit, and I'd bet the core saturates at less than 90kV out.

Looking at the picture of the transformer again, I see that I misunderstood at first, the two black wires are of course the primary. The silver colored braided wire from one of the secondaries is the current measurement point, so if you connect a say 100 ohm resistor between this point and and the core, you can measure the current going through the tube, 100mV/mA obviously.

Also, once you have got it working properly, I would either just remove the bulb or at least connect a wire back to the control box from the point between the bulb and the transformer. You want to know the primary voltage, because that tells you the approximate secondary voltage. And you need to know the tube voltage to get consistent exposures.

Anders M.

Wolfram, Mon Jun 07 2010, 09:52PM

That looks like a much more reasonable circuit.

I last checked that thread right after you first joined here, so I missed the updates. No need to yell.

Are you sure about the 200kV figure? How did you measure this? Resistive dividers can be inaccurate even at 60Hz if they have significant stray capacitances, and the 1kV/mm formula for sparks between needle points can overestimate the voltage when yo go above a few tens of kilovolts. You mention the transformer is a 75kV unit, and I'd bet the core saturates at less than 90kV out.

Looking at the picture of the transformer again, I see that I misunderstood at first, the two black wires are of course the primary. The silver colored braided wire from one of the secondaries is the current measurement point, so if you connect a say 100 ohm resistor between this point and and the core, you can measure the current going through the tube, 100mV/mA obviously.

Also, once you have got it working properly, I would either just remove the bulb or at least connect a wire back to the control box from the point between the bulb and the transformer. You want to know the primary voltage, because that tells you the approximate secondary voltage. And you need to know the tube voltage to get consistent exposures.

Anders M.

Re: Grenadier's big thread of Röntgen related shenanigans

Adam Munich, Mon Jun 07 2010, 10:07PM

Nah, if i run it like an induction coil i can get a 6" spark out of it. I'd say that's at least 200kv.

If I remove the bulb, i get way too much current flowing through the thing. It'll draw about 12A unballasted.

I'll definitely use the current measurement point now.

Since it is a 3 wire cord I'm using, I'll feed a line after the bulb through the ground wire. to measure it at the control box. (obviously I'm not plugging this cord into the mains)

Another problem i have is, the transformer has a 500ms voltage spike while the light bulb warms up and builds it's resistance. I was thinking of just turning the heater on a second late, but that HV needs to go somewhere... Any better ballast ideas than a 60w light bulb?

I could possibly keep the bulb warm and switch via relay to the transformer, however my extension cord has only 3 wires. I won't be able to measure the voltage and keep the bulb warm. I could put the ssr on the machine itself, but i don't want that failing in case a stray x-ray hits it.

Oh and yeah, it was an ss.white rebranded keystone

Adam Munich, Mon Jun 07 2010, 10:07PM

Nah, if i run it like an induction coil i can get a 6" spark out of it. I'd say that's at least 200kv.

If I remove the bulb, i get way too much current flowing through the thing. It'll draw about 12A unballasted.

I'll definitely use the current measurement point now.

Since it is a 3 wire cord I'm using, I'll feed a line after the bulb through the ground wire. to measure it at the control box. (obviously I'm not plugging this cord into the mains)

Another problem i have is, the transformer has a 500ms voltage spike while the light bulb warms up and builds it's resistance. I was thinking of just turning the heater on a second late, but that HV needs to go somewhere... Any better ballast ideas than a 60w light bulb?

I could possibly keep the bulb warm and switch via relay to the transformer, however my extension cord has only 3 wires. I won't be able to measure the voltage and keep the bulb warm. I could put the ssr on the machine itself, but i don't want that failing in case a stray x-ray hits it.

Oh and yeah, it was an ss.white rebranded keystone

Re: Grenadier's big thread of Röntgen related shenanigans

Wolfram, Mon Jun 07 2010, 10:35PM

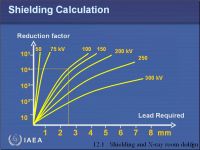

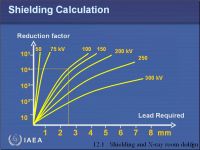

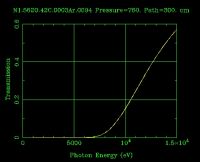

I would use a wirewound resistor instead of the bulb, a 100W or 200W one would be fine, though I'm still not convinced it's really neccesary. If the transformer draws a lot of current that's either saturation, which should only happen at close to full input voltage, or too high voltage on the filament of the x-ray tube which leads to it drawing more current than it should, and therefore also the transformer also drawing more current from mains. In the first case, just turn the variac back a little bit, and the no-load current should go down to almost zero, and in the latter case reduce the filament voltage. If you measured 12A with the transformer connected directly to mains without the variac and the secondary unloaded, it was also because of saturation. This is a picture I found that illustrates saturation, but the numbers on the scale could be different in your case. These X-ray transformers are also often made to be run at reduced mains voltage from the control unit which explains why it would saturate when connected directly to mains. Do a quick test with the variac to see at which input voltage the primary current starts to get uncomfortable at.

is a picture I found that illustrates saturation, but the numbers on the scale could be different in your case. These X-ray transformers are also often made to be run at reduced mains voltage from the control unit which explains why it would saturate when connected directly to mains. Do a quick test with the variac to see at which input voltage the primary current starts to get uncomfortable at.

A 6'' spark does not automatically indicate 200kV. See the pictures almost at the bottom of this page for a 160kV X-ray supply making 12'' arcs.

page for a 160kV X-ray supply making 12'' arcs.

Are you planning on using intensifying cassettes?

Anders M.

Wolfram, Mon Jun 07 2010, 10:35PM

I would use a wirewound resistor instead of the bulb, a 100W or 200W one would be fine, though I'm still not convinced it's really neccesary. If the transformer draws a lot of current that's either saturation, which should only happen at close to full input voltage, or too high voltage on the filament of the x-ray tube which leads to it drawing more current than it should, and therefore also the transformer also drawing more current from mains. In the first case, just turn the variac back a little bit, and the no-load current should go down to almost zero, and in the latter case reduce the filament voltage. If you measured 12A with the transformer connected directly to mains without the variac and the secondary unloaded, it was also because of saturation. This

is a picture I found that illustrates saturation, but the numbers on the scale could be different in your case. These X-ray transformers are also often made to be run at reduced mains voltage from the control unit which explains why it would saturate when connected directly to mains. Do a quick test with the variac to see at which input voltage the primary current starts to get uncomfortable at.

is a picture I found that illustrates saturation, but the numbers on the scale could be different in your case. These X-ray transformers are also often made to be run at reduced mains voltage from the control unit which explains why it would saturate when connected directly to mains. Do a quick test with the variac to see at which input voltage the primary current starts to get uncomfortable at. A 6'' spark does not automatically indicate 200kV. See the pictures almost at the bottom of this

page for a 160kV X-ray supply making 12'' arcs.

page for a 160kV X-ray supply making 12'' arcs.Are you planning on using intensifying cassettes?

Anders M.

Re: Grenadier's big thread of Röntgen related shenanigans

Adam Munich, Mon Jun 07 2010, 10:56PM

I still want a ballast, because I'd rather have a long exposure with a moderate amount of activity than a short exposure with alot of activity [more dangerous]. Plus, i don't want to accidentally blow up my tube.

With a 60w bulb and the thin sparks able to connect at Just over 6cm {wire electrodes, no balls} the transformer draws .3A, with 50V across the primary. There are no arcs formed, just sparks. This leads me to believe that the output is in the sub-ma range, which is what I'm looking for.

A cold 60w bulb has a resistance of 16 ohms, hot 240 ohms. I'd like the kvp to be higher, because even if the transformer is the 90kv model [wasn't labeled], 50v on the primary only means about 45kv on the secondary, which makes sense with the 6.2cm sparks on braided wire electrodes. That's a little low. I'd like up to 65kVp. (75 can't be achieved, because ballasting also lowers the voltage. Should've bought the 0-140V variac.) Anyone know where to find a cheap 0-250ohm 50w rheostat? I can't afford to pay $30 for one...

Also, the ballasted transformer draws .5A when the sparks can't connect.

I also really need a better way of measuring kV.

The tube isn't connected yet, because my 0-120v variac is still in the mail. I want to figure out the circuitry before i put in the tube.

Yes, i am going to use intensifying cassettes and kodak b/w paper film.

Adam Munich, Mon Jun 07 2010, 10:56PM

I still want a ballast, because I'd rather have a long exposure with a moderate amount of activity than a short exposure with alot of activity [more dangerous]. Plus, i don't want to accidentally blow up my tube.

With a 60w bulb and the thin sparks able to connect at Just over 6cm {wire electrodes, no balls} the transformer draws .3A, with 50V across the primary. There are no arcs formed, just sparks. This leads me to believe that the output is in the sub-ma range, which is what I'm looking for.

A cold 60w bulb has a resistance of 16 ohms, hot 240 ohms. I'd like the kvp to be higher, because even if the transformer is the 90kv model [wasn't labeled], 50v on the primary only means about 45kv on the secondary, which makes sense with the 6.2cm sparks on braided wire electrodes. That's a little low. I'd like up to 65kVp. (75 can't be achieved, because ballasting also lowers the voltage. Should've bought the 0-140V variac.) Anyone know where to find a cheap 0-250ohm 50w rheostat? I can't afford to pay $30 for one...

Also, the ballasted transformer draws .5A when the sparks can't connect.

I also really need a better way of measuring kV.

The tube isn't connected yet, because my 0-120v variac is still in the mail. I want to figure out the circuitry before i put in the tube.

Yes, i am going to use intensifying cassettes and kodak b/w paper film.

Re: Grenadier's big thread of Röntgen related shenanigans

Adam Munich, Mon Jun 07 2010, 11:31PM

just tried a 100w bulb as the ballast, i get .5a draw, 11cm sparks on wire [80% humidity], 100v across the primary with loud skinny sparks (no arcs).

So... this should be 50 watts drawn by the transformer, and at .6mA maximum @75kV. Perfect!

With the variac, i can lower the input voltage, thus lowering the output. Not quite sure if it will lower mA. At a lower voltage, it could possibly draw more amps to keep the 50W draw.

edit:

hmm, it draws .8A with the secondary shorted. So .8ma is still acceptable.

edit2:

So, i tried it with an equivalent resistor. Being a fixed load, it allowed the transformer to draw 2.8A when the wires were close. not good. So i will have to use a lightbulb. However, i need to keep the bulb warm, otherwise i get a voltage spike during warm-up. I can't just leave the heater off, because that spike needs to go somewhere, so i will ditch thte ssr, and use a spdt relay. The relay when de-energized will keep the bulb warm, it'll then energize and switch the bulb through the transformer. Instead of a high voltage going low [bulb warms] i'll have a low voltage going high [bulb cools].

Bad drawing.

Mod edit: Oversized picture. You also win the OMG Worst Schematic Evur award.

Adam Munich, Mon Jun 07 2010, 11:31PM

just tried a 100w bulb as the ballast, i get .5a draw, 11cm sparks on wire [80% humidity], 100v across the primary with loud skinny sparks (no arcs).

So... this should be 50 watts drawn by the transformer, and at .6mA maximum @75kV. Perfect!

With the variac, i can lower the input voltage, thus lowering the output. Not quite sure if it will lower mA. At a lower voltage, it could possibly draw more amps to keep the 50W draw.

edit:

hmm, it draws .8A with the secondary shorted. So .8ma is still acceptable.

edit2:

So, i tried it with an equivalent resistor. Being a fixed load, it allowed the transformer to draw 2.8A when the wires were close. not good. So i will have to use a lightbulb. However, i need to keep the bulb warm, otherwise i get a voltage spike during warm-up. I can't just leave the heater off, because that spike needs to go somewhere, so i will ditch thte ssr, and use a spdt relay. The relay when de-energized will keep the bulb warm, it'll then energize and switch the bulb through the transformer. Instead of a high voltage going low [bulb warms] i'll have a low voltage going high [bulb cools].

Bad drawing.

Mod edit: Oversized picture. You also win the OMG Worst Schematic Evur award.

Re: Grenadier's big thread of Röntgen related shenanigans

Adam Munich, Tue Jun 08 2010, 11:20PM

Here's the new schematic. (i forgot to put in the second reed relay but you get the picture). It should keep the bulb warm, and there will be no voltage spike.

As for a lead apron, i'm going to make one out of lead flashing and a cooking apron. Even though it's not necessary, as i'll be 250-400' away and the rays will be in the 4mm lead box; i'd feel safer in one. Mainly i won't need more than 45kVp though.

Too bad i can't use a resistor. That would've been easier. However, the light bub becomes more resistive as the transformer tries to draw more current, where as a power resistor does not. I'll start with a 60w lightbub, and if that's not enough i'll go to 75, then 100. Still, any better way?

BTW; does anyone have a schematic for an ss-white marksman?

Adam Munich, Tue Jun 08 2010, 11:20PM

Here's the new schematic. (i forgot to put in the second reed relay but you get the picture). It should keep the bulb warm, and there will be no voltage spike.

As for a lead apron, i'm going to make one out of lead flashing and a cooking apron. Even though it's not necessary, as i'll be 250-400' away and the rays will be in the 4mm lead box; i'd feel safer in one. Mainly i won't need more than 45kVp though.

Too bad i can't use a resistor. That would've been easier. However, the light bub becomes more resistive as the transformer tries to draw more current, where as a power resistor does not. I'll start with a 60w lightbub, and if that's not enough i'll go to 75, then 100. Still, any better way?

BTW; does anyone have a schematic for an ss-white marksman?

Re: Grenadier's big thread of Röntgen related shenanigans

Wolfram, Wed Jun 09 2010, 08:44AM

One possible caveat that I see is that the relay needs to stand off half of the maximum tube voltage between the coil part and the switch part. The battery and filament current rheostat will also be floating at this voltage. DO NOT consider grounding the cathode of the tube unless you've connected it to the center tap of the transformer. If you ground the output of one side of the transformer, the core will float at half of the tube voltage, and the insulation between the core and primary will break down. It is a good idea to ground the core of the transformer in any case.

Do you want a schematic of the control unit or of the x-ray head? If it's the latter, the schematic I posted earlier is going to be quite close.

Anders M.

Wolfram, Wed Jun 09 2010, 08:44AM

One possible caveat that I see is that the relay needs to stand off half of the maximum tube voltage between the coil part and the switch part. The battery and filament current rheostat will also be floating at this voltage. DO NOT consider grounding the cathode of the tube unless you've connected it to the center tap of the transformer. If you ground the output of one side of the transformer, the core will float at half of the tube voltage, and the insulation between the core and primary will break down. It is a good idea to ground the core of the transformer in any case.

Do you want a schematic of the control unit or of the x-ray head? If it's the latter, the schematic I posted earlier is going to be quite close.

Anders M.

Re: Grenadier's big thread of Röntgen related shenanigans

Adam Munich, Wed Jun 09 2010, 10:46AM

No, i planned to leave the tube floating, the transformer grounded to the big lead box grounded to a water pipe or something. When adjusting the filament voltage, the mains switch will be disengaged. The relay isn't going to be useless, because it is only switching a net voltage of 3.7V. However i'm worried about backflow into the arduino though, which is why i have one relay controlling another. besides, if anything goes wrong i can always kill the mains.

And yes, control unit if you have it.

Adam Munich, Wed Jun 09 2010, 10:46AM

Anders M. wrote ...

One possible caveat that I see is that the relay needs to stand off half of the maximum tube voltage between the coil part and the switch part. The battery and filament current rheostat will also be floating at this voltage. DO NOT consider grounding the cathode of the tube unless you've connected it to the center tap of the transformer. If you ground the output of one side of the transformer, the core will float at half of the tube voltage, and the insulation between the core and primary will break down. It is a good idea to ground the core of the transformer in any case.

Do you want a schematic of the control unit or of the x-ray head? If it's the latter, the schematic I posted earlier is going to be quite close.

Anders M.

One possible caveat that I see is that the relay needs to stand off half of the maximum tube voltage between the coil part and the switch part. The battery and filament current rheostat will also be floating at this voltage. DO NOT consider grounding the cathode of the tube unless you've connected it to the center tap of the transformer. If you ground the output of one side of the transformer, the core will float at half of the tube voltage, and the insulation between the core and primary will break down. It is a good idea to ground the core of the transformer in any case.

Do you want a schematic of the control unit or of the x-ray head? If it's the latter, the schematic I posted earlier is going to be quite close.

Anders M.

No, i planned to leave the tube floating, the transformer grounded to the big lead box grounded to a water pipe or something. When adjusting the filament voltage, the mains switch will be disengaged. The relay isn't going to be useless, because it is only switching a net voltage of 3.7V. However i'm worried about backflow into the arduino though, which is why i have one relay controlling another. besides, if anything goes wrong i can always kill the mains.

And yes, control unit if you have it.

Re: Grenadier's big thread of Röntgen related shenanigans

Wolfram, Wed Jun 09 2010, 11:19AM

There is still a problem. The cathode side of the X-ray tube is connected to one end of the HV-transformer, so its potential is half of the tube voltage above ground. This means that the switch part of the filament relay is also at this voltage. The arduino and the relay control and all that stuff should be at around ground potential, which means that the coil of the relay is at ground potential, and the switch part is at several tens of kilovolts. Unless the relay is a special high-isolation-voltage one, it will arc over for sure. Are you with me?

Unfortunately I don't have the schematics for any control units, but I do have a few patent numbers describing how they do the current control with a simple feedback system to control the filament transformer, if you're interested.

Anders M.

Wolfram, Wed Jun 09 2010, 11:19AM

There is still a problem. The cathode side of the X-ray tube is connected to one end of the HV-transformer, so its potential is half of the tube voltage above ground. This means that the switch part of the filament relay is also at this voltage. The arduino and the relay control and all that stuff should be at around ground potential, which means that the coil of the relay is at ground potential, and the switch part is at several tens of kilovolts. Unless the relay is a special high-isolation-voltage one, it will arc over for sure. Are you with me?

Unfortunately I don't have the schematics for any control units, but I do have a few patent numbers describing how they do the current control with a simple feedback system to control the filament transformer, if you're interested.

Anders M.

Re: Grenadier's big thread of Röntgen related shenanigans

klugesmith, Wed Jun 09 2010, 03:50PM

I'm also planning an x-ray system with battery-powered filament (one of these years).

Filament on/off control will either be opto-isolated (with a fiber!)

or use a mechanical switch actuated by a "remote" solenoid.

This: would be overkill.

would be overkill.

klugesmith, Wed Jun 09 2010, 03:50PM

I'm also planning an x-ray system with battery-powered filament (one of these years).

Filament on/off control will either be opto-isolated (with a fiber!)

or use a mechanical switch actuated by a "remote" solenoid.

This:

would be overkill.

would be overkill.Re: Grenadier's big thread of Röntgen related shenanigans

Adam Munich, Wed Jun 09 2010, 06:43PM

I thought about that, and the relay will be controlled by a battery separate from the arduino. (which is why the reed relay is in there) I really don't know of a better way to isolate then that. Even if the transformer arcs through the relay, it'll just hit the 12v gel-cell. There really shouldn't be any damage. I could even put the relay under oil, but that will slow down it's switching ability dramatically. I could even put a second reed relay to further isolate the system.

And sure, i'm interested.

Hmm, if the relay fails i'll definitely try the solenoid idea.

Just got the variac today. I like it. It lowers the output voltage nicely. It only lowers the current by 200ma at the low end. [this means 200ua on the secondary]

This is perfect. At 45kvp it should toss out 500ua heater full power. At 75(90?)kVp it should only supply 800ua.

Since more rays will be absorbed by the phosphor screen at 45 than 75(90?), less radiation is needed. Id rather have longer exposure times than short ones. This gives me more photographic control.

Anyway... i'm broke. Anyone know where i can get a lead apron free? If any of you have one, or lead sheet, i'd be willing to trade something. How about a prototype 741 ic? Or a cdv-700 geiger probe?

[Mod edit: merged triple post, use the edit button if you want to add info to a post]

Adam Munich, Wed Jun 09 2010, 06:43PM

Anders M. wrote ...

There is still a problem. The cathode side of the X-ray tube is connected to one end of the HV-transformer, so its potential is half of the tube voltage above ground. This means that the switch part of the filament relay is also at this voltage. The arduino and the relay control and all that stuff should be at around ground potential, which means that the coil of the relay is at ground potential, and the switch part is at several tens of kilovolts. Unless the relay is a special high-isolation-voltage one, it will arc over for sure. Are you with me?

Unfortunately I don't have the schematics for any control units, but I do have a few patent numbers describing how they do the current control with a simple feedback system to control the filament transformer, if you're interested.

Anders M.

There is still a problem. The cathode side of the X-ray tube is connected to one end of the HV-transformer, so its potential is half of the tube voltage above ground. This means that the switch part of the filament relay is also at this voltage. The arduino and the relay control and all that stuff should be at around ground potential, which means that the coil of the relay is at ground potential, and the switch part is at several tens of kilovolts. Unless the relay is a special high-isolation-voltage one, it will arc over for sure. Are you with me?

Unfortunately I don't have the schematics for any control units, but I do have a few patent numbers describing how they do the current control with a simple feedback system to control the filament transformer, if you're interested.

Anders M.

I thought about that, and the relay will be controlled by a battery separate from the arduino. (which is why the reed relay is in there) I really don't know of a better way to isolate then that. Even if the transformer arcs through the relay, it'll just hit the 12v gel-cell. There really shouldn't be any damage. I could even put the relay under oil, but that will slow down it's switching ability dramatically. I could even put a second reed relay to further isolate the system.

And sure, i'm interested.

Klugesmith wrote ...

I'm also planning an x-ray system with battery-powered filament (one of these years).

Filament on/off control will either be opto-isolated (with a fiber!)

or use a mechanical switch actuated by a "remote" solenoid.

This: would be overkill.

would be overkill.

I'm also planning an x-ray system with battery-powered filament (one of these years).

Filament on/off control will either be opto-isolated (with a fiber!)

or use a mechanical switch actuated by a "remote" solenoid.

This:

would be overkill.

would be overkill.Hmm, if the relay fails i'll definitely try the solenoid idea.

Just got the variac today. I like it. It lowers the output voltage nicely. It only lowers the current by 200ma at the low end. [this means 200ua on the secondary]

This is perfect. At 45kvp it should toss out 500ua heater full power. At 75(90?)kVp it should only supply 800ua.

Since more rays will be absorbed by the phosphor screen at 45 than 75(90?), less radiation is needed. Id rather have longer exposure times than short ones. This gives me more photographic control.

Anyway... i'm broke. Anyone know where i can get a lead apron free? If any of you have one, or lead sheet, i'd be willing to trade something. How about a prototype 741 ic? Or a cdv-700 geiger probe?

[Mod edit: merged triple post, use the edit button if you want to add info to a post]

Re: Grenadier's big thread of Röntgen related shenanigans

Wolfram, Wed Jun 09 2010, 11:13PM

The relay will still have to be controlled by the arduino, and the part between the relay and the arduino will have to stand off the full half of the tube voltage. Personally I would use a fiber optic receiver and a logic level MOSFET to switch the filament. Getting enough isolation otherwise is not particularly easy.

The patent I was talking about is US patent number 3527947, it can be viewed directly here . I don't think it's particularly useful in your case, but it gives some insight into how it's usually done, and it's a very easy way to get the tube to run at a preset current.

. I don't think it's particularly useful in your case, but it gives some insight into how it's usually done, and it's a very easy way to get the tube to run at a preset current.

Anders M.

Wolfram, Wed Jun 09 2010, 11:13PM

Grenadier wrote ...

I thought about that, and the relay will be controlled by a battery separate from the arduino. (which is why the reed relay is in there) I really don't know of a better way to isolate then that. Even if the transformer arcs through the relay, it'll just hit the 12v gel-cell. There really shouldn't be any damage. I could even put the relay under oil, but that will slow down it's switching ability dramatically. I could even put a second reed relay to further isolate the system.

And sure, i'm interested.

Anders M. wrote ...

There is still a problem. The cathode side of the X-ray tube is connected to one end of the HV-transformer, so its potential is half of the tube voltage above ground. This means that the switch part of the filament relay is also at this voltage. The arduino and the relay control and all that stuff should be at around ground potential, which means that the coil of the relay is at ground potential, and the switch part is at several tens of kilovolts. Unless the relay is a special high-isolation-voltage one, it will arc over for sure. Are you with me?

Unfortunately I don't have the schematics for any control units, but I do have a few patent numbers describing how they do the current control with a simple feedback system to control the filament transformer, if you're interested.

Anders M.

There is still a problem. The cathode side of the X-ray tube is connected to one end of the HV-transformer, so its potential is half of the tube voltage above ground. This means that the switch part of the filament relay is also at this voltage. The arduino and the relay control and all that stuff should be at around ground potential, which means that the coil of the relay is at ground potential, and the switch part is at several tens of kilovolts. Unless the relay is a special high-isolation-voltage one, it will arc over for sure. Are you with me?

Unfortunately I don't have the schematics for any control units, but I do have a few patent numbers describing how they do the current control with a simple feedback system to control the filament transformer, if you're interested.

Anders M.

I thought about that, and the relay will be controlled by a battery separate from the arduino. (which is why the reed relay is in there) I really don't know of a better way to isolate then that. Even if the transformer arcs through the relay, it'll just hit the 12v gel-cell. There really shouldn't be any damage. I could even put the relay under oil, but that will slow down it's switching ability dramatically. I could even put a second reed relay to further isolate the system.

And sure, i'm interested.

The relay will still have to be controlled by the arduino, and the part between the relay and the arduino will have to stand off the full half of the tube voltage. Personally I would use a fiber optic receiver and a logic level MOSFET to switch the filament. Getting enough isolation otherwise is not particularly easy.

The patent I was talking about is US patent number 3527947, it can be viewed directly here

. I don't think it's particularly useful in your case, but it gives some insight into how it's usually done, and it's a very easy way to get the tube to run at a preset current.

. I don't think it's particularly useful in your case, but it gives some insight into how it's usually done, and it's a very easy way to get the tube to run at a preset current.Anders M.

Re: Grenadier's big thread of Röntgen related shenanigans

Adam Munich, Wed Jun 09 2010, 11:32PM

Well, I'm hoping that the relay controlled by a reed relay under oil will be enough. It should, since canola oil is an excellent insulator. The oil won't affect the reed's function, being a sealed argon bubble and all, but it will insulate the switch from the solenoid.

I could always build a solenoid switch though. I might try that, and if it's reliable, i may use it. What should i use for contacts? I was thinking a light spring, like the ones in a pen.

Adam Munich, Wed Jun 09 2010, 11:32PM

wrote ...

The relay will still have to be controlled by the arduino, and the part between the relay and the arduino will have to stand off the full half of the tube voltage. Personally I would use a fiber optic receiver and a logic level MOSFET to switch the filament. Getting enough isolation otherwise is not particularly easy.

The patent I was talking about is US patent number 3527947, it can be viewed directly here . I don't think it's particularly useful in your case, but it gives some insight into how it's usually done, and it's a very easy way to get the tube to run at a preset current.

. I don't think it's particularly useful in your case, but it gives some insight into how it's usually done, and it's a very easy way to get the tube to run at a preset current.

Anders M.

The relay will still have to be controlled by the arduino, and the part between the relay and the arduino will have to stand off the full half of the tube voltage. Personally I would use a fiber optic receiver and a logic level MOSFET to switch the filament. Getting enough isolation otherwise is not particularly easy.

The patent I was talking about is US patent number 3527947, it can be viewed directly here

. I don't think it's particularly useful in your case, but it gives some insight into how it's usually done, and it's a very easy way to get the tube to run at a preset current.

. I don't think it's particularly useful in your case, but it gives some insight into how it's usually done, and it's a very easy way to get the tube to run at a preset current.Anders M.

Well, I'm hoping that the relay controlled by a reed relay under oil will be enough. It should, since canola oil is an excellent insulator. The oil won't affect the reed's function, being a sealed argon bubble and all, but it will insulate the switch from the solenoid.

I could always build a solenoid switch though. I might try that, and if it's reliable, i may use it. What should i use for contacts? I was thinking a light spring, like the ones in a pen.

Re: Grenadier's big thread of Röntgen related shenanigans

Adam Munich, Thu Jun 10 2010, 02:06AM

Also, my tube is made of some pretty thick brosilicate glass. I'm starting to wonder if any rays softer than 50kVp can get out...

Adam Munich, Thu Jun 10 2010, 02:06AM

Also, my tube is made of some pretty thick brosilicate glass. I'm starting to wonder if any rays softer than 50kVp can get out...

Re: Grenadier's big thread of Röntgen related shenanigans

Adam Munich, Fri Jun 11 2010, 02:12AM

Well, i built a heatsink. It's just two heat pipes crudely soldered to a piece of copper pipe that slides over the anode bar. I'm not sure if i'm going to use it though. What i've been thinking about is putting a 12v computer fan under the oil too. Just to circulate it. It won't run fast, but it'll keep the oil floating. The last thing i want is boiling oil around the anode bar and cold oil everywhere else.

Also, does polarity matter when connecting the heater. I forgot which wire went to the hv. There's an electrostatic lens around the filament, and i'm positive if it's connected to a wire; and if it is which one.

Adam Munich, Fri Jun 11 2010, 02:12AM

Well, i built a heatsink. It's just two heat pipes crudely soldered to a piece of copper pipe that slides over the anode bar. I'm not sure if i'm going to use it though. What i've been thinking about is putting a 12v computer fan under the oil too. Just to circulate it. It won't run fast, but it'll keep the oil floating. The last thing i want is boiling oil around the anode bar and cold oil everywhere else.

Also, does polarity matter when connecting the heater. I forgot which wire went to the hv. There's an electrostatic lens around the filament, and i'm positive if it's connected to a wire; and if it is which one.

Re: Grenadier's big thread of Röntgen related shenanigans

Hon1nbo, Fri Jun 11 2010, 02:26AM

just thought I'd throw this in here: a possible reason why the resistor gives a different current is because you may not have a proper resistance reading for the bulb, as it changes as the heat increases IIRC

also, for isolation, use fiber optics, it can be done for cheap, it's reliable, easy to modify and maintain (unlike an oil bath), etc

Also, if your in the US check Craigslist for things like lead shielding etc, at least here X-Ray hardware shows up at least a few times a month (sometimes a lot of listings at once!).

-Jimmy

Hon1nbo, Fri Jun 11 2010, 02:26AM

just thought I'd throw this in here: a possible reason why the resistor gives a different current is because you may not have a proper resistance reading for the bulb, as it changes as the heat increases IIRC

also, for isolation, use fiber optics, it can be done for cheap, it's reliable, easy to modify and maintain (unlike an oil bath), etc

Also, if your in the US check Craigslist for things like lead shielding etc, at least here X-Ray hardware shows up at least a few times a month (sometimes a lot of listings at once!).

-Jimmy

Re: Grenadier's big thread of Röntgen related shenanigans

Adam Munich, Fri Jun 11 2010, 02:45AM

1) The resistance of a half-hot bulb is 72 ohms, when the transformer draws more current, it raises the resistance to a maximum of 144 ohms. A resistor does not.

2) If i solve the voltage spike problem, i won't even need to switch the filament.

3) I've been looking. No luck.

Adam Munich, Fri Jun 11 2010, 02:45AM

1) The resistance of a half-hot bulb is 72 ohms, when the transformer draws more current, it raises the resistance to a maximum of 144 ohms. A resistor does not.

2) If i solve the voltage spike problem, i won't even need to switch the filament.

3) I've been looking. No luck.

Re: Grenadier's big thread of Röntgen related shenanigans

Wolfram, Fri Jun 11 2010, 07:23AM

Your tube is pretty typical as far as dental tubes go, and the glass will mabe block everything under 25-30kV.

I don't think you need to worry very much about cooling. Dental X-ray heads often run the tube at close to a kilowatt without any means to circulate the oil except for convection, so I don't think your design will need any artificial way to get oil circulation either. Not even the largest medical tubes running much higher powers need fans to circulate the oil. Convection does a very good job.

Also, stop posting multiple posts in a row, it's against the rules. Use the edit button instead.

Anders M.

Wolfram, Fri Jun 11 2010, 07:23AM

Your tube is pretty typical as far as dental tubes go, and the glass will mabe block everything under 25-30kV.

I don't think you need to worry very much about cooling. Dental X-ray heads often run the tube at close to a kilowatt without any means to circulate the oil except for convection, so I don't think your design will need any artificial way to get oil circulation either. Not even the largest medical tubes running much higher powers need fans to circulate the oil. Convection does a very good job.

Also, stop posting multiple posts in a row, it's against the rules. Use the edit button instead.

Anders M.

Re: Grenadier's big thread of Röntgen related shenanigans

Adam Munich, Fri Jun 11 2010, 01:59PM

Sorry.

However my tube is rated at only 75kvp@2mA. That's only 75Watts. I just don't want to break it.

Anyway, i'm livid. I got some lcd's in the mail, one for the ray, one for my geiger counter, and they're junk. The guy wants me to mail them back to china, but i'm not paying $20. I hope paypal can get me a refund.

Adam Munich, Fri Jun 11 2010, 01:59PM

Sorry.

However my tube is rated at only 75kvp@2mA. That's only 75Watts. I just don't want to break it.

Anyway, i'm livid. I got some lcd's in the mail, one for the ray, one for my geiger counter, and they're junk. The guy wants me to mail them back to china, but i'm not paying $20. I hope paypal can get me a refund.

Re: Grenadier's big thread of Röntgen related shenanigans

Wolfram, Fri Jun 11 2010, 04:48PM

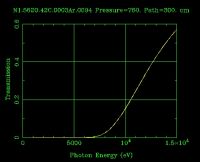

That's 150 watts, and that's the continous rating. These tubes are usually used at several times the continous power rating, as they are used for short durations. A dental exposure is usually under two seconds, unless it is a pantomographic unit, with those the exposure times can be as long as 20 seconds. The datasheets for the tubes usually give curves for maximum allowable power, but datasheets are usually very hard to find for most tubes, so I usually just find the datasheet for a tube with similar ratings and size, to get a general idea. This should be somewhere in the same area, and should give you a general idea.

should be somewhere in the same area, and should give you a general idea.

In any case, running it at 75W like you plan on doing will allow you to run it indefinitely. Taking x-ray pictures with intensifying cassettes should not require too much energy (unless you are running the tube on such a low voltage that almost all of the radiation is stopped by the glass), so I doubt you'll even be able to measure temperature rise in the oil after an exposure. This is why I think a fan to circulate the oil is largely uneccessary.

Anders M.

Wolfram, Fri Jun 11 2010, 04:48PM

That's 150 watts, and that's the continous rating. These tubes are usually used at several times the continous power rating, as they are used for short durations. A dental exposure is usually under two seconds, unless it is a pantomographic unit, with those the exposure times can be as long as 20 seconds. The datasheets for the tubes usually give curves for maximum allowable power, but datasheets are usually very hard to find for most tubes, so I usually just find the datasheet for a tube with similar ratings and size, to get a general idea. This

should be somewhere in the same area, and should give you a general idea.

should be somewhere in the same area, and should give you a general idea.In any case, running it at 75W like you plan on doing will allow you to run it indefinitely. Taking x-ray pictures with intensifying cassettes should not require too much energy (unless you are running the tube on such a low voltage that almost all of the radiation is stopped by the glass), so I doubt you'll even be able to measure temperature rise in the oil after an exposure. This is why I think a fan to circulate the oil is largely uneccessary.

Anders M.

Re: Grenadier's big thread of Röntgen related shenanigans

Proud Mary, Fri Jun 11 2010, 06:15PM

At a distance of 1 metre in the beam from a 75kV/2mA X-ray tube, the dose rate will be 32 Sv/hr.

We'll call this 0.5 Sv/minute to make life easy, since there is nothing very exact about the acute effects of radiation poisoning.

After 4 minutes, you will suffer 'mild' radiation poisoning, featuring nausea and vomiting within 24 hrs.

After 6 minutes, you can add general malaise, bloody stools, bloody vomit, and subsequent hair loss.

After 12 to 16 minutes, you will suffer all the previous within 30 minutes, plus high fever, vertigo, mental confusion, organ failure, collapse of blood pressure, and death in 50% of cases.

Long term consequences are to be expected among survivors of acute exposure, though some of these may take years to develop.

Repeated exposure to even very low doses is linked to various sorts of cancer in dental workers, despite their using all recommended screens, shields and aprons.

You may harm not just yourself, but innocent people and animals living above, below, and on either side of you.

And that's all I have to say on the matter.

Proud Mary, Fri Jun 11 2010, 06:15PM

At a distance of 1 metre in the beam from a 75kV/2mA X-ray tube, the dose rate will be 32 Sv/hr.

We'll call this 0.5 Sv/minute to make life easy, since there is nothing very exact about the acute effects of radiation poisoning.

After 4 minutes, you will suffer 'mild' radiation poisoning, featuring nausea and vomiting within 24 hrs.

After 6 minutes, you can add general malaise, bloody stools, bloody vomit, and subsequent hair loss.

After 12 to 16 minutes, you will suffer all the previous within 30 minutes, plus high fever, vertigo, mental confusion, organ failure, collapse of blood pressure, and death in 50% of cases.

Long term consequences are to be expected among survivors of acute exposure, though some of these may take years to develop.

Repeated exposure to even very low doses is linked to various sorts of cancer in dental workers, despite their using all recommended screens, shields and aprons.

You may harm not just yourself, but innocent people and animals living above, below, and on either side of you.

And that's all I have to say on the matter.

Re: Grenadier's big thread of Röntgen related shenanigans

Wolfram, Sat Jun 12 2010, 01:50AM

I don't think scare numbers are neccessary here, as Grenadier has already shown in the other thread that he respects the dangers of x-rays and that he has built a 4mm thick lead box to contain the whole experiment in. He is also planning on being several hundred feet away when the tube is powered, so I think any radiation exposure he will get from this will be immeasurable compared to background radiation.

Of course it's important to respect the dangers of x-rays, though most of the hobbies discussed here have very real dangers, and when the dangers are understood and safety precautions are taken, working with x-rays can be as safe as any other hobby.

Anders M.

Wolfram, Sat Jun 12 2010, 01:50AM

I don't think scare numbers are neccessary here, as Grenadier has already shown in the other thread that he respects the dangers of x-rays and that he has built a 4mm thick lead box to contain the whole experiment in. He is also planning on being several hundred feet away when the tube is powered, so I think any radiation exposure he will get from this will be immeasurable compared to background radiation.

Of course it's important to respect the dangers of x-rays, though most of the hobbies discussed here have very real dangers, and when the dangers are understood and safety precautions are taken, working with x-rays can be as safe as any other hobby.

Anders M.

Re: Grenadier's big thread of Röntgen related shenanigans

Adam Munich, Sat Jun 12 2010, 02:11AM

@Anders

Good to know. Sorry for the silly calc mistake. I'm going to take pictures 3 ways;

1) with kodak paper and intensifying screen pressed to it.

2) Using a europium glow in the dark screen. The long lasting phosphor should "build up enough light" let a camera inside take a picture.

@Proud Mary

I'm sorry for the big pic. Idk how to shrink it.

@Anders again

Thanks for the support.

[Edit: Now click the edit button and learn how to do it]

Adam Munich, Sat Jun 12 2010, 02:11AM

@Anders

Good to know. Sorry for the silly calc mistake. I'm going to take pictures 3 ways;

1) with kodak paper and intensifying screen pressed to it.

2) Using a europium glow in the dark screen. The long lasting phosphor should "build up enough light" let a camera inside take a picture.

@Proud Mary

I'm sorry for the big pic. Idk how to shrink it.

@Anders again

Thanks for the support.

[Edit: Now click the edit button and learn how to do it]

Re: Grenadier's big thread of Röntgen related shenanigans

Adam Munich, Sat Jun 12 2010, 05:47PM

I built an isolation relay. However, i'm starting to wonder if it's safe to turn on the hv before warming up the tube. I won't need this relay if my hot-bulb design works though. However i can't build it yet; my relay and other parts from bgmicro are still in the mail.

Adam Munich, Sat Jun 12 2010, 05:47PM

I built an isolation relay. However, i'm starting to wonder if it's safe to turn on the hv before warming up the tube. I won't need this relay if my hot-bulb design works though. However i can't build it yet; my relay and other parts from bgmicro are still in the mail.

Re: Grenadier's big thread of Röntgen related shenanigans

Proud Mary, Sat Jun 12 2010, 09:22PM

You may damage the tube by so-called 'cathode stripping' or internal flash-over if you apply anode voltage before the filament or cathode is thoroughly warmed. Further, if you are using a self-rectified circuit, damaging reverse conduction may occur.

Moreover, a tube which is either brand new, or has been out of service for some time, must be 'seasoned' before the full anode voltage is applied. The point of 'seasoning' is to re-absorb gas molecules which have cast adrift whilst the tube has been out of service. 'Seasoning' consists of the application of HT in a graduated sequence of increments over a period of time. By way of illustration only, and not recommendation, (since I know nothing of your tube, or its history) three one minute applications of 10kV with one minute between each, three applications of 15kV for a minute each with one minute intervals, three applications of 20kV, and so on in steps until you reach the full working voltage.

Different manufacturers have differing 'seasoning' recommendations, but all share the common principle of a graduated series of rising voltage steps before the full anode voltage is applied. The longer a tube has been out of service, the more thoroughly must the 'seasoning' procedure be performed. Light seasoning should be performed if a tube has been out of service for 3 - 6 months, with a longer, slower and more gradual procedure for 6 - 12 months, and so on.

Proud Mary, Sat Jun 12 2010, 09:22PM

Grenadier wrote ...

i'm starting to wonder if it's safe to turn on the hv before warming up the tube.

i'm starting to wonder if it's safe to turn on the hv before warming up the tube.

You may damage the tube by so-called 'cathode stripping' or internal flash-over if you apply anode voltage before the filament or cathode is thoroughly warmed. Further, if you are using a self-rectified circuit, damaging reverse conduction may occur.

Moreover, a tube which is either brand new, or has been out of service for some time, must be 'seasoned' before the full anode voltage is applied. The point of 'seasoning' is to re-absorb gas molecules which have cast adrift whilst the tube has been out of service. 'Seasoning' consists of the application of HT in a graduated sequence of increments over a period of time. By way of illustration only, and not recommendation, (since I know nothing of your tube, or its history) three one minute applications of 10kV with one minute between each, three applications of 15kV for a minute each with one minute intervals, three applications of 20kV, and so on in steps until you reach the full working voltage.

Different manufacturers have differing 'seasoning' recommendations, but all share the common principle of a graduated series of rising voltage steps before the full anode voltage is applied. The longer a tube has been out of service, the more thoroughly must the 'seasoning' procedure be performed. Light seasoning should be performed if a tube has been out of service for 3 - 6 months, with a longer, slower and more gradual procedure for 6 - 12 months, and so on.

Re: Grenadier's big thread of Röntgen related shenanigans

Adam Munich, Sat Jun 12 2010, 10:28PM

A) Wow, i really hope my keep-lightbulb-warm circuit will work now.

B) I read about seasoning and thought it would "cover itself", because i was going to start using the tube at a low voltage, and gradually build up my courage to bring it up. :) Now i know to start even lower. This could take a long time, and it should, because this tube hasn't been used in 10 years. I know it's vacuum is good though, because i tested it at 24v, 20ma as a thermionic diode.

More tube info;

Dunlee mfct 197?

Seems to be brosilicate glass.

Very minor browning.

Very tiny pits on anode, with a minor crack in an H shape.

75kVp max

2mA max

Heater white hot at 3.5v

Also... does filament polarity matter? I'm not sure if the electrostatic lens is hooked up to a wire, and if it is which one.

Adam Munich, Sat Jun 12 2010, 10:28PM

A) Wow, i really hope my keep-lightbulb-warm circuit will work now.

B) I read about seasoning and thought it would "cover itself", because i was going to start using the tube at a low voltage, and gradually build up my courage to bring it up. :) Now i know to start even lower. This could take a long time, and it should, because this tube hasn't been used in 10 years. I know it's vacuum is good though, because i tested it at 24v, 20ma as a thermionic diode.

More tube info;

Dunlee mfct 197?

Seems to be brosilicate glass.

Very minor browning.

Very tiny pits on anode, with a minor crack in an H shape.

75kVp max

2mA max

Heater white hot at 3.5v

Also... does filament polarity matter? I'm not sure if the electrostatic lens is hooked up to a wire, and if it is which one.

Re: Grenadier's big thread of Röntgen related shenanigans

Adam Munich, Sun Jun 13 2010, 12:14AM

New schematic. I had to shorten the length of wire because the longest cord i have is 250ft. So now, a lead apron is not a must, but i'm going to wear one. As i said before, "real" lead aprons are pathetic, they only give .5mm protection. I'm going to make my own from some 1mm sheet. I'll see if i can get some from local roofing companies. I really don't want to pay $80 for 6sqft. online.

Adam Munich, Sun Jun 13 2010, 12:14AM

New schematic. I had to shorten the length of wire because the longest cord i have is 250ft. So now, a lead apron is not a must, but i'm going to wear one. As i said before, "real" lead aprons are pathetic, they only give .5mm protection. I'm going to make my own from some 1mm sheet. I'll see if i can get some from local roofing companies. I really don't want to pay $80 for 6sqft. online.

Re: Grenadier's big thread of Röntgen related shenanigans

IntraWinding, Sun Jun 13 2010, 12:21AM

Could you dig a hole in the ground for your experiments so you get hundreds of feet of earth protecting you, and avoid lead poisoning too?

IntraWinding, Sun Jun 13 2010, 12:21AM

Could you dig a hole in the ground for your experiments so you get hundreds of feet of earth protecting you, and avoid lead poisoning too?

Re: Grenadier's big thread of Röntgen related shenanigans

Proud Mary, Sun Jun 13 2010, 12:36AM

You should plan to control the anode current by adjusting the heater voltage, for which you need a fairly 'stiff' EHT supply. It's no good if the anode voltage begins to fall when you increase the current due to an inadequate supply. I would suggest you start at 1.5V on the heater or filament , and gradually increase it until the tube's 2mA max is reached. Excess heater voltage is probably the quickest way of destroying a tube. I use a single Hawker Cyclon 2V 8AH lead acid cell (which has the same proportions as a standard "D" cell, but is rather larger) which is easy to 'float' at -20kv to -40kV in grounded anode configurations, compared with the problems of having a transformer which can hold of such voltages on its LT windings. Other advantages of using a single 2V cell is that the heater voltage cannot rise no matter what happens elsewhere in the circuit, and that no matter what may happen the production of X-rays will shut down in a few hours when the battery is discharged.

Once you have the apparatus running, you should make an X-ray pinhole camera in order to visualize the anode focal spot to see that all is right with the focusing cup potential.

Making all these adjustments and preliminary tests without compromising the shielding is time consuming.

Proud Mary, Sun Jun 13 2010, 12:36AM

Grenadier wrote ...

Heater white hot at 3.5v

Heater white hot at 3.5v

You should plan to control the anode current by adjusting the heater voltage, for which you need a fairly 'stiff' EHT supply. It's no good if the anode voltage begins to fall when you increase the current due to an inadequate supply. I would suggest you start at 1.5V on the heater or filament , and gradually increase it until the tube's 2mA max is reached. Excess heater voltage is probably the quickest way of destroying a tube. I use a single Hawker Cyclon 2V 8AH lead acid cell (which has the same proportions as a standard "D" cell, but is rather larger) which is easy to 'float' at -20kv to -40kV in grounded anode configurations, compared with the problems of having a transformer which can hold of such voltages on its LT windings. Other advantages of using a single 2V cell is that the heater voltage cannot rise no matter what happens elsewhere in the circuit, and that no matter what may happen the production of X-rays will shut down in a few hours when the battery is discharged.

Once you have the apparatus running, you should make an X-ray pinhole camera in order to visualize the anode focal spot to see that all is right with the focusing cup potential.

Making all these adjustments and preliminary tests without compromising the shielding is time consuming.

Re: Grenadier's big thread of Röntgen related shenanigans

Adam Munich, Sun Jun 13 2010, 01:30AM

@ IntraWinding

No. I could, but this box weighs 100lbs. If i put it in a hole, it's never coming out. Besides, i'll put my house in between me and the box too. Even though it's not, Sheetrock is better than nothing.

@ proudmary

I'm using a 3.7v lithium cell with a rheostat to control the heater current/temperature. I planned on adjusting that by a dial on the machine which i'll put a calibrated label on. Then i get well out of the way and the 0-120v is fed into the machine. This will warm up the lightbulb for a second, then a relay will switch feeding the current through the lightbulb through the transformer. By this method, the transformer is incapable of supplying more than .8ma, even when shorted. This way, i cant overheat the tube by accident. A longer exposure is better anyway; it gives more photographic control. After the exposure, i'll flip a switch or maybe two cutting off the mains and another turning off the arduino/12v supply, making sure it can't possibly expose while i'm adjusting it.

I'm building this thing with safety in mind, not accuracy. If the kVp drops with higher currents, so be it. I'll develop the photo and if it looks like crap, i'll turn up the variac.

X-ray pinhole camera? Explain please. I was just going to make images directly, just by placing an object in front of the intensifying screen. If it was blurry, then i probably have the heater wires backward and reverse them. I'm well aware how x-rays are produced/scattered/absorbed with the bremsstrahlung and compton scattering etc. However i'm still not too clear on how the focusing cup works. Does it lose focus at lower than intended kVps? My tube is of the 3 wire type.

FYI, it's going to be a self-rectifying circuit.

Adam Munich, Sun Jun 13 2010, 01:30AM

@ IntraWinding

No. I could, but this box weighs 100lbs. If i put it in a hole, it's never coming out. Besides, i'll put my house in between me and the box too. Even though it's not, Sheetrock is better than nothing.

@ proudmary

I'm using a 3.7v lithium cell with a rheostat to control the heater current/temperature. I planned on adjusting that by a dial on the machine which i'll put a calibrated label on. Then i get well out of the way and the 0-120v is fed into the machine. This will warm up the lightbulb for a second, then a relay will switch feeding the current through the lightbulb through the transformer. By this method, the transformer is incapable of supplying more than .8ma, even when shorted. This way, i cant overheat the tube by accident. A longer exposure is better anyway; it gives more photographic control. After the exposure, i'll flip a switch or maybe two cutting off the mains and another turning off the arduino/12v supply, making sure it can't possibly expose while i'm adjusting it.

I'm building this thing with safety in mind, not accuracy. If the kVp drops with higher currents, so be it. I'll develop the photo and if it looks like crap, i'll turn up the variac.

X-ray pinhole camera? Explain please. I was just going to make images directly, just by placing an object in front of the intensifying screen. If it was blurry, then i probably have the heater wires backward and reverse them. I'm well aware how x-rays are produced/scattered/absorbed with the bremsstrahlung and compton scattering etc. However i'm still not too clear on how the focusing cup works. Does it lose focus at lower than intended kVps? My tube is of the 3 wire type.

FYI, it's going to be a self-rectifying circuit.

Re: Grenadier's big thread of Röntgen related shenanigans

Proud Mary, Sun Jun 13 2010, 08:26AM

X-rays behave like visible light when they transit a pinhole.

If you make the smallest, most accurate pinhole you can in a lead or tungsten sheet, centre it in the beam half way between the anode and your film, and ensure that it is exactly at right angles to the beam with a plumb bob and triangle, then an image of the focal spot on the anode will be obtained, whose width can be measured directly.

You will also see directly what effect, if any, the pitting and cracking of the target has had.

Pinhole cameras are one of the key tools in X-ray astronomy. Arrays of pinhole cameras have been fitted to space craft to produce X-ray images of the universe.

Proud Mary, Sun Jun 13 2010, 08:26AM

Grenadier wrote ...

X-ray pinhole camera? Explain please.

X-ray pinhole camera? Explain please.

X-rays behave like visible light when they transit a pinhole.

If you make the smallest, most accurate pinhole you can in a lead or tungsten sheet, centre it in the beam half way between the anode and your film, and ensure that it is exactly at right angles to the beam with a plumb bob and triangle, then an image of the focal spot on the anode will be obtained, whose width can be measured directly.

You will also see directly what effect, if any, the pitting and cracking of the target has had.

Pinhole cameras are one of the key tools in X-ray astronomy. Arrays of pinhole cameras have been fitted to space craft to produce X-ray images of the universe.

Re: Grenadier's big thread of Röntgen related shenanigans

Adam Munich, Sun Jun 13 2010, 01:34PM

I'll have to try it. It probably requires a long exposure.

Adam Munich, Sun Jun 13 2010, 01:34PM

I'll have to try it. It probably requires a long exposure.

Re: Grenadier's big thread of Röntgen related shenanigans

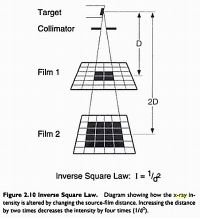

Adam Munich, Mon Jun 14 2010, 01:58AM

Assuming worst case scenario of 100kv...

HVL of Pb for 100kv is .27mm

Thinnest part of box is 3.6mm

3.6/.27 = 13.3333...

so;

100% penetration, halved 13 times = 0.00162760417%

.0016% ...That gives me some confidence :)

So, with a value of...

1sievert/min inside box * .0016 = 160mrem/min directly in front of the thing. Not safe, but manageable.

So if i'm 200ft away, w/o shielding, inverse square law dictates that it'll be .004millirem/min. or .24mr/hr. That's not negligable, but it's safe because this thing will only be on for fractions of a minute once every 20 minutes or so.

.004mr/m = 0.00006 mr/s

0.00006 mr/s * 10s = 0.0006 mr/longexposure without apron.

so 20 exposures = 0.012millirem

Hmm, lets add the 1mm lead apron, or roughly 3 halving thicknesses.

.0006mr/exp /3 = 0.0002mrem/exposure with apron

If i make 20 exposures every day for an entire year (ridiculous) that would work out to be 1.46 millirem a year + background. Since a smoker gets roughly 270mrem a year, i think i designed a pretty damn safe machine.

This is all in the beam path. I'll be behind the tube, so values should be even lower.

Please correct me if i screwed up somewhere. That's alot of math at 10pm.

Adam Munich, Mon Jun 14 2010, 01:58AM

Assuming worst case scenario of 100kv...

HVL of Pb for 100kv is .27mm

Thinnest part of box is 3.6mm

3.6/.27 = 13.3333...

so;

100% penetration, halved 13 times = 0.00162760417%

.0016% ...That gives me some confidence :)

So, with a value of...

1sievert/min inside box * .0016 = 160mrem/min directly in front of the thing. Not safe, but manageable.

So if i'm 200ft away, w/o shielding, inverse square law dictates that it'll be .004millirem/min. or .24mr/hr. That's not negligable, but it's safe because this thing will only be on for fractions of a minute once every 20 minutes or so.

.004mr/m = 0.00006 mr/s

0.00006 mr/s * 10s = 0.0006 mr/longexposure without apron.

so 20 exposures = 0.012millirem

Hmm, lets add the 1mm lead apron, or roughly 3 halving thicknesses.

.0006mr/exp /3 = 0.0002mrem/exposure with apron

If i make 20 exposures every day for an entire year (ridiculous) that would work out to be 1.46 millirem a year + background. Since a smoker gets roughly 270mrem a year, i think i designed a pretty damn safe machine.

This is all in the beam path. I'll be behind the tube, so values should be even lower.

Please correct me if i screwed up somewhere. That's alot of math at 10pm.

Re: Grenadier's big thread of Röntgen related shenanigans

Wolfram, Mon Jun 14 2010, 06:06AM

And even that is assuming all of the energy is at 100keV, when in reality, very little energy will be at the peak voltage. I think the average photon energy will be around a third of the peak photon energy, but to actually calculate the amount of radiation that gets through the shielding is not as simple. You can always do like you did and assume all of the photons are at the peak voltage, then you'll know that you get a very conservative rating. This is the way RadPro does it too.

Where did you get the 1Sv/min figure from?

Anders M.

Wolfram, Mon Jun 14 2010, 06:06AM

And even that is assuming all of the energy is at 100keV, when in reality, very little energy will be at the peak voltage. I think the average photon energy will be around a third of the peak photon energy, but to actually calculate the amount of radiation that gets through the shielding is not as simple. You can always do like you did and assume all of the photons are at the peak voltage, then you'll know that you get a very conservative rating. This is the way RadPro does it too.

Where did you get the 1Sv/min figure from?

Anders M.

Re: Grenadier's big thread of Röntgen related shenanigans

Adam Munich, Mon Jun 14 2010, 02:52PM