3 Stage Coilgun...advice on current and design?

Flochi, Thu Apr 01 2010, 06:43PMHey,

So I'm building a three stage optically triggered coilgun. I have 100 x 50 V, 18000uF capacitors, 54 feet of 12 Gauge magnet wire for the coils and a brass barrel 1/4" ID and 0.03" thickness (Intending on slotting to reduce eddy currents).

Basically my questions are as follows:

What will the current be though each coil (there'll be three) assuming I make three banks of 33 caps each?

Some specific info:

Coil length 80mm, ID 7mm, OD 20mm, 12 gauge. Three coils.

Barrel: 1/4" ID, 0.03" thickness, Brass

Projectile: Low carbon steel (probably, although up for whatever works best)

I'll be switching the coils with 880nm optical sensors connected to SCRs?IGBTs?Power MOSFETS?

Basically I'm trying to figure out what kind of switch I need to buy, and what rating it needs to have...

ANY ADVICE would be really appreciated!

Thanks!

Michael

Re: 3 Stage Coilgun...advice on current and design?

radiotech, Thu Apr 01 2010, 11:43PM

Current per coil

54 feet #12 Cu= .00162 * 54 = .087 ohms 50 V/.087 ohm=574 Amps

33 * 18,000 = .59 F .59 F * .087 ohms = .05 seconds at .05 seconds current will be.63 * 574 amps = 379 amps

radiotech, Thu Apr 01 2010, 11:43PM

Current per coil

54 feet #12 Cu= .00162 * 54 = .087 ohms 50 V/.087 ohm=574 Amps

33 * 18,000 = .59 F .59 F * .087 ohms = .05 seconds at .05 seconds current will be.63 * 574 amps = 379 amps

Re: 3 Stage Coilgun...advice on current and design?

klugesmith, Fri Apr 02 2010, 01:41AM

Michael,

My main advice is that you need to do more homework, and not waste our time re-asking noob questions that are answered here frequently (if you would bother to look).

And read the HvWiki, and sites with coilgun advice and simulators like

Suppose you want to skip learning any passive electrical circuit theory.

Apparently you have already designed your capacitor banks and coils (with, correctly, 18 feet of wire for each).

Online formulas and calculators will give you the coil inductance (hint: between 10 and 100 uH).

Radiotech showed you how to figure the resistance.

Barry's simulator will show you the current pulse height and width (heavily overdamped in your design. So you won't need to worry about voltage reversal or high efficiency, and can get away with simple RC analysis as in Radiotech's example).

Have you ever made and/or analyzed a single stage coilgun?

How far does the projectile move during the current pulse?

Will your three stages be identical in length and current pulse duration? Why?

You can't change the projectile on the fly. But you have plenty of freedom to tune the magnetic

impulse durations and (independently) trade off voltage vs. current,

by how you configure the capacitors (series/parallel) and wind the coils (wire size vs turns count).

As for semiconductor switches, I think you made things hard by choosing such

a low voltage and high current for the given amount of stored energy.

Good luck!

klugesmith, Fri Apr 02 2010, 01:41AM

Michael,

My main advice is that you need to do more homework, and not waste our time re-asking noob questions that are answered here frequently (if you would bother to look).

And read the HvWiki, and sites with coilgun advice and simulators like

Suppose you want to skip learning any passive electrical circuit theory.

Apparently you have already designed your capacitor banks and coils (with, correctly, 18 feet of wire for each).

Online formulas and calculators will give you the coil inductance (hint: between 10 and 100 uH).

Radiotech showed you how to figure the resistance.

Barry's simulator will show you the current pulse height and width (heavily overdamped in your design. So you won't need to worry about voltage reversal or high efficiency, and can get away with simple RC analysis as in Radiotech's example).

Have you ever made and/or analyzed a single stage coilgun?

How far does the projectile move during the current pulse?

Will your three stages be identical in length and current pulse duration? Why?

You can't change the projectile on the fly. But you have plenty of freedom to tune the magnetic

impulse durations and (independently) trade off voltage vs. current,

by how you configure the capacitors (series/parallel) and wind the coils (wire size vs turns count).

As for semiconductor switches, I think you made things hard by choosing such

a low voltage and high current for the given amount of stored energy.

Good luck!

Re: 3 Stage Coilgun...advice on current and design?

Barry, Fri Apr 02 2010, 04:13PM

In multi-stage coilguns I suggest dividing the capacitors evenly among stages, but not the wire. You need a longer firing pulse in the first stage, and progressively shorter pulses as the projectile moves faster. This is usually accomplished by choosing progressively lower inductance in each coil, and therefore progressively smaller coils.

Your question was about peak current, which will be higher in the 3rd coil than the other two, if it's the one with the lowest inductance and dc resistance. So you'll need to design this coil before you can answer the peak-current question.

I suggest a designing the coils in sequence, as the estimated projectile entrance velocity is needed in each stage to design the firing time. Indeed, you could design AND build one stage at a time, so you can just measure the velocity at each step.

The general approach at each stage is to estimate the pulse time required, and then design the LC time constant to match. The LC Time Simulation may help. Use the setting for "time for zero crossing pulse" since coilguns need to use the first half of a sinusoidal pulse. You may also find helpful the RLC Simulation and then design the coil with assistance from the Inductor Simulation. Play with these for awhile and then ask more questions.

Your other question was about SCR v IGBT v MOSFET. Most people begin with SCRs as being the most inexpensive and high-current devices, and also the easiest (by far!) to trigger. The IGBTs have a wide reputation as being both expensive and easy to damage. The MOSFETs are extremely expensive if you want a device that can handle thousands of amps.

I think you'll be fine if you start with any random hefty stud-mounted SCR from eBay. Find something with a high current rating and a voltage rating of 200v or higher. (I suggest you don't ever connect more than 4 capacitors in series, to reduce ESR and possible problems with voltage-sharing.) Note that SCR continuous-duty ratings can be used in 10x pulse-firing conditions. For example, an SCR rated for 100A should work reliably in a coilgun of 1,000A peak current.

I see nothing wrong with a low voltage coilgun, even at 50v. My little 12v coilgun works just fine, tyvm.

The important thing is to have the correct firing time and to minimize total series resistance.

Never mind Kludges harsh comments, he must be having a bad day; everyone was a newb once.

Cheers, Barry

Can a hearse carrying a dead body drive in the carpool lane?

Barry, Fri Apr 02 2010, 04:13PM

In multi-stage coilguns I suggest dividing the capacitors evenly among stages, but not the wire. You need a longer firing pulse in the first stage, and progressively shorter pulses as the projectile moves faster. This is usually accomplished by choosing progressively lower inductance in each coil, and therefore progressively smaller coils.

Your question was about peak current, which will be higher in the 3rd coil than the other two, if it's the one with the lowest inductance and dc resistance. So you'll need to design this coil before you can answer the peak-current question.

I suggest a designing the coils in sequence, as the estimated projectile entrance velocity is needed in each stage to design the firing time. Indeed, you could design AND build one stage at a time, so you can just measure the velocity at each step.

The general approach at each stage is to estimate the pulse time required, and then design the LC time constant to match. The LC Time Simulation may help. Use the setting for "time for zero crossing pulse" since coilguns need to use the first half of a sinusoidal pulse. You may also find helpful the RLC Simulation and then design the coil with assistance from the Inductor Simulation. Play with these for awhile and then ask more questions.

Your other question was about SCR v IGBT v MOSFET. Most people begin with SCRs as being the most inexpensive and high-current devices, and also the easiest (by far!) to trigger. The IGBTs have a wide reputation as being both expensive and easy to damage. The MOSFETs are extremely expensive if you want a device that can handle thousands of amps.

I think you'll be fine if you start with any random hefty stud-mounted SCR from eBay. Find something with a high current rating and a voltage rating of 200v or higher. (I suggest you don't ever connect more than 4 capacitors in series, to reduce ESR and possible problems with voltage-sharing.) Note that SCR continuous-duty ratings can be used in 10x pulse-firing conditions. For example, an SCR rated for 100A should work reliably in a coilgun of 1,000A peak current.

I see nothing wrong with a low voltage coilgun, even at 50v. My little 12v coilgun works just fine, tyvm.

The important thing is to have the correct firing time and to minimize total series resistance.

Never mind Kludges harsh comments, he must be having a bad day; everyone was a newb once.

Cheers, Barry

Can a hearse carrying a dead body drive in the carpool lane?

Re: 3 Stage Coilgun...advice on current and design?

Flochi, Mon Apr 05 2010, 12:21PM

Thanks for the advice everyone.

So I've put some more thought into all of this and my concerns are as follows.

For the moment, assuming the same coil thickness per stage (which will decrease in reality) I'm calculating inductance of 23uH. If the 33 capacitors per bank are connected in parallel then each bank will output 50v at 0.594F. When I plug these vales into I am finding that the current ranges between a manageable couple hundred amps to 4000 if I make the resistance almost zero.

I am finding that the current ranges between a manageable couple hundred amps to 4000 if I make the resistance almost zero.

My problem is that assuming the coil resistance to e the ONLY resistance in the circuit, and with all those other values, it appears to take over 100ms for the inductor current to drop to zero and the capacitor to discharge. I was under the impression that I really want the capacitor discharge to occur within 2-7 ms for decent projectile speeds...is this the case. If so how can I redesign the coil to achieve this given my specs as described above?

As for my switches I managed to find three SCRs with a surge current rating of 3.5kA @400V for $36 so hopefully those will handle almost anything I can throw at them.

Flochi, Mon Apr 05 2010, 12:21PM

Thanks for the advice everyone.

So I've put some more thought into all of this and my concerns are as follows.

For the moment, assuming the same coil thickness per stage (which will decrease in reality) I'm calculating inductance of 23uH. If the 33 capacitors per bank are connected in parallel then each bank will output 50v at 0.594F. When I plug these vales into

I am finding that the current ranges between a manageable couple hundred amps to 4000 if I make the resistance almost zero.

I am finding that the current ranges between a manageable couple hundred amps to 4000 if I make the resistance almost zero.My problem is that assuming the coil resistance to e the ONLY resistance in the circuit, and with all those other values, it appears to take over 100ms for the inductor current to drop to zero and the capacitor to discharge. I was under the impression that I really want the capacitor discharge to occur within 2-7 ms for decent projectile speeds...is this the case. If so how can I redesign the coil to achieve this given my specs as described above?

As for my switches I managed to find three SCRs with a surge current rating of 3.5kA @400V for $36 so hopefully those will handle almost anything I can throw at them.

Re: 3 Stage Coilgun...advice on current and design?

klugesmith, Mon Apr 05 2010, 04:54PM

Your problem is basically an inordinately high capacitance value.

One remedy is to reduce the inductance by winding fewer turns (magnetic effect = amperes x turns), but then the resistance and inductance of capacitors, interconnections, and switch become even more significant, and the current gets extreme. You need enough copper mass to absorb the pulse energy without excessive temperature rise.

Another is to reduce the capacitance by changing the configuration.

For example, try 32 caps in a 4-series 8-parallel bank. Warning: now you are talking about hundreds of volts and run the risk of serious electrical shocks.

-Rich

[edit] It might be enlightening to consider the energy stored in the coil at the moment of maximum current: E = L * I^2 / 2.

If you hit 4000 amperes in your 23 uH coil, that's 184 joules -- about 1/4 of the original energy in your 33 capacitors. The ratio is 100% in a LC tank with -no- resistance -- you'd reach 8000 amperes, the theoretical maximum. What would it be in the critically damped case?

klugesmith, Mon Apr 05 2010, 04:54PM

Flochi wrote ...

My problem is that assuming the coil resistance to e the ONLY resistance in the circuit, and with all those other values, it appears to take over 100ms for the inductor current to drop to zero and the capacitor to discharge. I was under the impression that I really want the capacitor discharge to occur within 2-7 ms for decent projectile speeds...is this the case. If so how can I redesign the coil to achieve this given my specs as described above?

Good progress, Michael!My problem is that assuming the coil resistance to e the ONLY resistance in the circuit, and with all those other values, it appears to take over 100ms for the inductor current to drop to zero and the capacitor to discharge. I was under the impression that I really want the capacitor discharge to occur within 2-7 ms for decent projectile speeds...is this the case. If so how can I redesign the coil to achieve this given my specs as described above?

Your problem is basically an inordinately high capacitance value.

One remedy is to reduce the inductance by winding fewer turns (magnetic effect = amperes x turns), but then the resistance and inductance of capacitors, interconnections, and switch become even more significant, and the current gets extreme. You need enough copper mass to absorb the pulse energy without excessive temperature rise.

Another is to reduce the capacitance by changing the configuration.

For example, try 32 caps in a 4-series 8-parallel bank. Warning: now you are talking about hundreds of volts and run the risk of serious electrical shocks.

-Rich

[edit] It might be enlightening to consider the energy stored in the coil at the moment of maximum current: E = L * I^2 / 2.

If you hit 4000 amperes in your 23 uH coil, that's 184 joules -- about 1/4 of the original energy in your 33 capacitors. The ratio is 100% in a LC tank with -no- resistance -- you'd reach 8000 amperes, the theoretical maximum. What would it be in the critically damped case?

Re: 3 Stage Coilgun...advice on current and design?

Flochi, Mon Apr 05 2010, 06:27PM

Thanks for the response...

Unfortunately both options cause some unsurmountable problems. I'm limited to 50V working due to safety reasons and charging to 300V is problematic. As for the coil option, I think an option might be to wind two layers of 59 turns 12 gauge and then switch that with a mechanical switch and then use three coils with only one layer for progressive acceleration, switched by 3 3.5k surge SCRs.

Sound reasonable?

Flochi, Mon Apr 05 2010, 06:27PM

Thanks for the response...

Unfortunately both options cause some unsurmountable problems. I'm limited to 50V working due to safety reasons and charging to 300V is problematic. As for the coil option, I think an option might be to wind two layers of 59 turns 12 gauge and then switch that with a mechanical switch and then use three coils with only one layer for progressive acceleration, switched by 3 3.5k surge SCRs.

Sound reasonable?

Re: 3 Stage Coilgun...advice on current and design?

klugesmith, Mon Apr 05 2010, 08:51PM

say, 70 or 80 volts?

a) Demonstrates prudent derating of nameplate values for extreme service.

b) Might actually give better ultimate performance, in spite of less energy per capacitor. As you are learning, it's hard to efficiently apply your 700 joules per bank using practical coils and 50 volts.

As for lower inductance with fewer turns, you can further reduce the resistannce

by using thicker wire, or several lengths of AWG12 wound as one & connected in parallel.

klugesmith, Mon Apr 05 2010, 08:51PM

Flochi wrote ...

I'm limited to 50V working due to safety reasons and charging to 300V is problematic.

Can you talk the authority into a 2-series configuration (100V rating), with a negotiable maximum charge voltage of,I'm limited to 50V working due to safety reasons and charging to 300V is problematic.

say, 70 or 80 volts?

a) Demonstrates prudent derating of nameplate values for extreme service.

b) Might actually give better ultimate performance, in spite of less energy per capacitor. As you are learning, it's hard to efficiently apply your 700 joules per bank using practical coils and 50 volts.

As for lower inductance with fewer turns, you can further reduce the resistannce

by using thicker wire, or several lengths of AWG12 wound as one & connected in parallel.

Re: 3 Stage Coilgun...advice on current and design?

Flochi, Wed Apr 07 2010, 12:02AM

Alright! So I spoke with the higher up, who has allowed me to go so far as 150V, although he would rather I stay less than 100V.

Regarding the coiling, if you're suggesting having more than one single layer coil, one inside the other, that has a lot of merit but seems like an air core transformer to me where the powered coil sets up a back EMF which could be detrimental. On the other hand, since I would just be setting up a single pulse the back EMF may not matter or could even be beneficial.

How would I model that? Or how do I determine the combined inductance through that system then? Same for current? Could you advise me on the inductance and current expected for a 2 series 15 parallel config with two layers of AWG12 at 61mm long (? length still 61 or longer/shorter?)

Flochi, Wed Apr 07 2010, 12:02AM

Alright! So I spoke with the higher up, who has allowed me to go so far as 150V, although he would rather I stay less than 100V.

Regarding the coiling, if you're suggesting having more than one single layer coil, one inside the other, that has a lot of merit but seems like an air core transformer to me where the powered coil sets up a back EMF which could be detrimental. On the other hand, since I would just be setting up a single pulse the back EMF may not matter or could even be beneficial.

How would I model that? Or how do I determine the combined inductance through that system then? Same for current? Could you advise me on the inductance and current expected for a 2 series 15 parallel config with two layers of AWG12 at 61mm long (? length still 61 or longer/shorter?)

Re: 3 Stage Coilgun...advice on current and design?

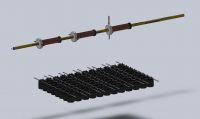

Flochi, Thu Apr 08 2010, 07:12PM

Pic of the CAD as it currently stands. Lot of work still to do...but I'm getting there.

Any advice on those last questions i asked? Current and inductance through two parallel coil?

Flochi, Thu Apr 08 2010, 07:12PM

Pic of the CAD as it currently stands. Lot of work still to do...but I'm getting there.

Any advice on those last questions i asked? Current and inductance through two parallel coil?

Re: 3 Stage Coilgun...advice on current and design?

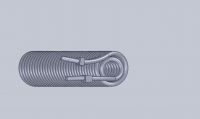

Flochi, Fri Apr 09 2010, 02:13AM

So update on the coils...Klugesmith PMd me (which was really nice since I'm rushing now) and suggested I try a bifilar coil...the reason makes a lot of sense to me...so I've given it a quick CAD to confirm if this is indeed what was suggested and that it will be valid.

Flochi, Fri Apr 09 2010, 02:13AM

So update on the coils...Klugesmith PMd me (which was really nice since I'm rushing now) and suggested I try a bifilar coil...the reason makes a lot of sense to me...so I've given it a quick CAD to confirm if this is indeed what was suggested and that it will be valid.

Re: 3 Stage Coilgun...advice on current and design?

klugesmith, Fri Apr 09 2010, 02:53PM

Do you know how to compute the capacitance and stored energy of a series-parallel bank?

Do you know how to compute the stored energy in a coil, given L and I?

Then here's a two step design process where you don't need to do any more math.

First: use interactive RLC simulator to -quickly- explore the design space with 3500 ampere limit and no attention to physical coil design. You will get an idea of target L and R values, and how close is good enough. Second: use the inductor simulator to find how to wind your 61mm bobbins to get those L and R values -- you may be pleasantly surprised.

Your tour guide suggests that you compare three different 30-capacitor bank configurations: 30P at 50V, 2S15P at 100V, and 3S10P at 150V. (S,P nomenclature borrowed from model airplane battery-pack jargon).

In the RLC simulator, set resistance to zero (undamped oscillation) and see what inductance value will limit the current to 3500 A. Check: should be around 110 uH for any of the three C,V combinations (it's the L value that holds 100% of capacitor bank energy at 3500 A). But you see the frequencies are different in 1:2:3 ratio.

Of course resistance is real, in more ways than one. You want enough to make the current die out before your projectile gets too far past middle of coil. And you want enough to prevent the capacitor voltage from reversing. The simulator has a check box to show voltage on the graph. People with actual coilgun experience may have advice about how much overshoot is OK. Dial in some R, then back off on L to bring the peak current back to 3500 A. Find the R,L point where the current decays from 3500 A and barely does not overshoot. This is "critically damped" and gives the fastest stoppage.

With the dual targets of 3500 A and critical damping, all three capacitor configs will want the same inductance. It's the value which, at 3500 A, holds a secret fraction of initial capacitor energy. But as you progress from 1S to 2S to 3S banks, the critical resistance goes up and the pulse width goes down (by ratio 1 : 1/2 : 1/3).

But as you progress from 1S to 2S to 3S banks, the critical resistance goes up and the pulse width goes down (by ratio 1 : 1/2 : 1/3).

At this point, make some choices about C, V, L, and R.

Now go to the inductor simulator and work out the winding details.

Please tell us about it. Good luck!

I have to tune out for a couple days.

Hope there are other readers who can step in for next round.

klugesmith, Fri Apr 09 2010, 02:53PM

Flochi wrote ...

Alright! So I spoke with the higher up, who has allowed me to go so far as 150V, although he would rather I stay less than 100V.

That's great. You will see that series connections allow shorter pulses with the same energy, same peak current, and same coil.Alright! So I spoke with the higher up, who has allowed me to go so far as 150V, although he would rather I stay less than 100V.

Flochi wrote ...

Regarding the coiling, if you're suggesting having more than one single layer coil, one inside the other ...

Nothing that complicated. Looks like you got it. (Great CAD pictures!) It only makes sense if you want fewer turns than a simple winding that fills the volume.Regarding the coiling, if you're suggesting having more than one single layer coil, one inside the other ...

Flochi wrote ...

Could you advise me on the inductance and current expected for a 2 series 15 parallel config with two layers of AWG12 at 61mm long (? length still 61 or longer/shorter?)

Are you having any trouble using Barry's inductor simulator and RLC simulator?Could you advise me on the inductance and current expected for a 2 series 15 parallel config with two layers of AWG12 at 61mm long (? length still 61 or longer/shorter?)

Do you know how to compute the capacitance and stored energy of a series-parallel bank?

Do you know how to compute the stored energy in a coil, given L and I?

Then here's a two step design process where you don't need to do any more math.

First: use interactive RLC simulator to -quickly- explore the design space with 3500 ampere limit and no attention to physical coil design. You will get an idea of target L and R values, and how close is good enough. Second: use the inductor simulator to find how to wind your 61mm bobbins to get those L and R values -- you may be pleasantly surprised.

Your tour guide suggests that you compare three different 30-capacitor bank configurations: 30P at 50V, 2S15P at 100V, and 3S10P at 150V. (S,P nomenclature borrowed from model airplane battery-pack jargon).

In the RLC simulator, set resistance to zero (undamped oscillation) and see what inductance value will limit the current to 3500 A. Check: should be around 110 uH for any of the three C,V combinations (it's the L value that holds 100% of capacitor bank energy at 3500 A). But you see the frequencies are different in 1:2:3 ratio.

Of course resistance is real, in more ways than one. You want enough to make the current die out before your projectile gets too far past middle of coil. And you want enough to prevent the capacitor voltage from reversing. The simulator has a check box to show voltage on the graph. People with actual coilgun experience may have advice about how much overshoot is OK. Dial in some R, then back off on L to bring the peak current back to 3500 A. Find the R,L point where the current decays from 3500 A and barely does not overshoot. This is "critically damped" and gives the fastest stoppage.

With the dual targets of 3500 A and critical damping, all three capacitor configs will want the same inductance. It's the value which, at 3500 A, holds a secret fraction of initial capacitor energy.

But as you progress from 1S to 2S to 3S banks, the critical resistance goes up and the pulse width goes down (by ratio 1 : 1/2 : 1/3).

But as you progress from 1S to 2S to 3S banks, the critical resistance goes up and the pulse width goes down (by ratio 1 : 1/2 : 1/3).At this point, make some choices about C, V, L, and R.

Now go to the inductor simulator and work out the winding details.

Please tell us about it. Good luck!

I have to tune out for a couple days.

Hope there are other readers who can step in for next round.

Print this page