Induction heater, what frequency to use for heating copper to brazing temperatures?

Henry, Tue Dec 01 2009, 10:15PMWhat would be a good frequency to use to be able to heat up a 10 mm copper tube to brazing temperatures, what i guess would be maybe around 800 centigrade or so?

Have wanted to do an induction heater quite some time now and finally got my thumb out and made one. Its a smaller induction heater based on the ZVS schematic that the first time i connected it worked just as it should and as a test i heated up at hacksaw blade to its curie temperature in about 2 - 3 seconds. Now, which initially was the reason for this heater, i want to heat up a copper tube so i can braze it since i dont have access to a oxy-acetylene torch and i have started to increase the frequency so it can induce eddycurrents in the tube. And sure the coppertube started to get slowly hotter the more capacitors i removed but also with some destroyed mosfets along the way but it has been my own fault.

Before i did this so did it draw 2 Amps at 45V at idle which increased to 11A just in the beginning of heating of iron, it did not change at all with copper. After i had increased the frequency twice as much so did the copper get quite hot after about 15 seconds but you could still touch it. I then wanted to try with iron to se if it would melt and 1 mm into the coil so was the current 13A so i thought it was ok. I then put it in 3 mm more but this time the current hit the roof with 118A which instant fried one of the mosfets and draw the zener and diod down the drain with it. Think i have to make a current limit for it all because it a little work involved to change a mosfet every time.

I have experiment some with capacitors and coils but anybody know what frequency i should aim at? So would it go faster to hit the right point. The transformer are good for about 20A+ continuously at about 40 - 45V so i have around 1KW+ to play with but dont know if i might need to have a higher voltage or so or this might be enough? I rather dont wan to connect me to the main. The mosfets are irfp260 and the coil right now is 7 turns bifilar winded that get hot as hell so i have to have a fan on it. Have seriously thoughts on water-cooling.

Re: Induction heater, what frequency to use for heating copper to brazing temperatures?

Tonskulus, Wed Dec 02 2009, 04:05PM

Copper requires much more workcoil current/reactive power because copper has no hysteresis losses while iron does have. So all we have here is eddy current losses to be play with. And copper is good conductor so we must induce very high eddy currents for copper workpiece to heat it up to a required brazing temperature.

We need specific amount of inverter power there, something like 600W or even more. Workcoil current should be hundreds of amperes (depending on turns and frequency, they all are depending on each other).

Tonskulus, Wed Dec 02 2009, 04:05PM

Copper requires much more workcoil current/reactive power because copper has no hysteresis losses while iron does have. So all we have here is eddy current losses to be play with. And copper is good conductor so we must induce very high eddy currents for copper workpiece to heat it up to a required brazing temperature.

We need specific amount of inverter power there, something like 600W or even more. Workcoil current should be hundreds of amperes (depending on turns and frequency, they all are depending on each other).

Re: Induction heater, what frequency to use for heating copper to brazing temperatures?

Henry, Fri Jan 22 2010, 02:25PM

Yes eddy currents is the only way to go no doubt but as i see it so is the problem that copper cant conduct a magnetic field unless you go, as i guess, up quite high in frequency so it start to be magnetic conductive, just as iron but at much higher frequency. Only then can the power in the coil be transferred to the copper tube and heat it up, not otherwise. If i need to get more power into the coil so would that be equal to more capacitance but by doing that would lower the frequency and make the copper less magnetic conductive so that shouldnt work? So im a little lost right now..

The frequency is at about 130kHz and a copper tube would just get slightly warm after 20 seconds but not more then that. A hacksaw blade however will glow bright red after under 3 seconds so something is missing but i dont understand what.

Henry, Fri Jan 22 2010, 02:25PM

Yes eddy currents is the only way to go no doubt but as i see it so is the problem that copper cant conduct a magnetic field unless you go, as i guess, up quite high in frequency so it start to be magnetic conductive, just as iron but at much higher frequency. Only then can the power in the coil be transferred to the copper tube and heat it up, not otherwise. If i need to get more power into the coil so would that be equal to more capacitance but by doing that would lower the frequency and make the copper less magnetic conductive so that shouldnt work? So im a little lost right now..

The frequency is at about 130kHz and a copper tube would just get slightly warm after 20 seconds but not more then that. A hacksaw blade however will glow bright red after under 3 seconds so something is missing but i dont understand what.

Re: Induction heater, what frequency to use for heating copper to brazing temperatures?

Tonskulus, Fri Jan 22 2010, 02:38PM

Well I have melted coppersheets @ 5kHz. I used multi turn work coil and flux concentrator (one half of big E core ferrite).

So it is possible using low frequency for brazing purpose. There just has to be strong alternating magnetic flux density for inducing enough circulating current for copper work piece.

Also very high frequency is useful for copper brazing, like 1..3MHz. This high frequency will make considerable skin effect losses on surface of the workpiece. However, it will be difficult task making >3MHz high power mosfet inverter. Vacuum tube oscillator would be good idea there if anything.

Afterall conculsion is that almost any "high" frequency CAN BE used for copper brazing. The only thing we need is enough reactive work coil power and flux density.

Tonskulus, Fri Jan 22 2010, 02:38PM

Well I have melted coppersheets @ 5kHz. I used multi turn work coil and flux concentrator (one half of big E core ferrite).

So it is possible using low frequency for brazing purpose. There just has to be strong alternating magnetic flux density for inducing enough circulating current for copper work piece.

Also very high frequency is useful for copper brazing, like 1..3MHz. This high frequency will make considerable skin effect losses on surface of the workpiece. However, it will be difficult task making >3MHz high power mosfet inverter. Vacuum tube oscillator would be good idea there if anything.

Afterall conculsion is that almost any "high" frequency CAN BE used for copper brazing. The only thing we need is enough reactive work coil power and flux density.

Re: Induction heater, what frequency to use for heating copper to brazing temperatures?

IamSmooth, Fri Jan 22 2010, 02:57PM

I gotten thick and thin pieces of copper to melt and boil without a problem. My problem is containing the melt. I am going to try and make some crucibles using furnace cement. I am using about 80khz. I have fount that a tightly packed coil (little spacing between turns) and 1.5 to 2" ID worked well for me.

IamSmooth, Fri Jan 22 2010, 02:57PM

I gotten thick and thin pieces of copper to melt and boil without a problem. My problem is containing the melt. I am going to try and make some crucibles using furnace cement. I am using about 80khz. I have fount that a tightly packed coil (little spacing between turns) and 1.5 to 2" ID worked well for me.

Re: Induction heater, what frequency to use for heating copper to brazing temperatures?

Henry, Fri Jan 22 2010, 05:23PM

Had no idea that even a low frequency could melt copper no matter what, was absolutely sure that high frequency was the only way to go for that to make the copper magnetic so it would take the current from the coil. Cant really understand how a high current in the coil at a low frequency anyway could get into the copper without any flux concentrator or similar, dont get it the copper had to be magnetic?

As mention i use the ZVS schematic and the coil used is 1.8" ID and about 2" OD so the wire are quit thin its about 0.1" maybe i should use bigger tube? The coil i use are 7 turns bifilar winded but maybe 5 turns would be better and smaller ID? The wire, or actually tube to water cooling soon, are as it could and the coil is about 8µH. The capacitor bank are right now 6 x 0.22µ capacitors with high frequency, high current and pulse capability and they wont get warm at all.

But maybe then put more power into the coil by increase the capacitance and make the frequency higher by making the coil little smaller and take of a rev or two to compensate the lower frequency due to the higher capacitance or this might not matter to heat the copper as far as the capacitance is high?

Henry, Fri Jan 22 2010, 05:23PM

Had no idea that even a low frequency could melt copper no matter what, was absolutely sure that high frequency was the only way to go for that to make the copper magnetic so it would take the current from the coil. Cant really understand how a high current in the coil at a low frequency anyway could get into the copper without any flux concentrator or similar, dont get it the copper had to be magnetic?

As mention i use the ZVS schematic and the coil used is 1.8" ID and about 2" OD so the wire are quit thin its about 0.1" maybe i should use bigger tube? The coil i use are 7 turns bifilar winded but maybe 5 turns would be better and smaller ID? The wire, or actually tube to water cooling soon, are as it could and the coil is about 8µH. The capacitor bank are right now 6 x 0.22µ capacitors with high frequency, high current and pulse capability and they wont get warm at all.

But maybe then put more power into the coil by increase the capacitance and make the frequency higher by making the coil little smaller and take of a rev or two to compensate the lower frequency due to the higher capacitance or this might not matter to heat the copper as far as the capacitance is high?

Re: Induction heater, what frequency to use for heating copper to brazing temperatures?

IamSmooth, Fri Jan 22 2010, 06:01PM

Give me a day or two, and I will put a video on youtube showing me taking some thick chunks and converting it into a bubbling red liquid. This will be my stationary coil, and not the levitation coil. I have been able to melt copper with 1/4" tubing, but the 3/8" works better. You need tubing so you can run a coolant like ice water through it. I tried turning up the power without cooling the coil and it started to smoke before I was able to accomplish much on the workpiece.

My coil is 3/8" tubing, about 1.75" ID, 4-6 turns. I will double-check the frequency. Input Power about 1.5-2.5kw. Resonance lock is with a PLL/integrator feedback.

I will put some pictures of the coil on there tonight or tomorrow.

IamSmooth, Fri Jan 22 2010, 06:01PM

Give me a day or two, and I will put a video on youtube showing me taking some thick chunks and converting it into a bubbling red liquid. This will be my stationary coil, and not the levitation coil. I have been able to melt copper with 1/4" tubing, but the 3/8" works better. You need tubing so you can run a coolant like ice water through it. I tried turning up the power without cooling the coil and it started to smoke before I was able to accomplish much on the workpiece.

My coil is 3/8" tubing, about 1.75" ID, 4-6 turns. I will double-check the frequency. Input Power about 1.5-2.5kw. Resonance lock is with a PLL/integrator feedback.

I will put some pictures of the coil on there tonight or tomorrow.

Re: Induction heater, what frequency to use for heating copper to brazing temperatures?

Henry, Fri Jan 22 2010, 07:24PM

That would be very interesting! Aha so you using that thick tubing good to know.

Im using the Mazzilli ZVP schematic due to its simlicity just so i dont have to build and test out a PLL control. And if its possible to get such high temperature anyway with the ZPV instead without having to crank up the powerlever insanly much so would that be just perfect.

Yes i had it going before without any cooling of the coil only a fan att full speed and that worked, but after i removed some capacitors so did the idle current go up to about double and then the fan wasnt enough and the coil started to smoke, so bigger tubes and watercooling is what im aiming for. I think i will go and buy coppertubes already tomorrow.

Henry, Fri Jan 22 2010, 07:24PM

That would be very interesting! Aha so you using that thick tubing good to know.

Im using the Mazzilli ZVP schematic due to its simlicity just so i dont have to build and test out a PLL control. And if its possible to get such high temperature anyway with the ZPV instead without having to crank up the powerlever insanly much so would that be just perfect.

Yes i had it going before without any cooling of the coil only a fan att full speed and that worked, but after i removed some capacitors so did the idle current go up to about double and then the fan wasnt enough and the coil started to smoke, so bigger tubes and watercooling is what im aiming for. I think i will go and buy coppertubes already tomorrow.

Re: Induction heater, what frequency to use for heating copper to brazing temperatures?

Tonskulus, Fri Jan 22 2010, 08:47PM

Basic mazzilli ZVS is way too low power for melting copper, there is just not enough tank voltage and thus, not enough work coil current. We want to see some hundreds of volts there (not just some tens of volts as mazzilli ZVS) to get reasonable heating results.

btw, it should be noted that heating iron above curie point (up to yellow-bright white glow), is much easier and requires less power than melting copper.

Flux concentrator is good idea for low freq. systems if smallish workpieces are being heated.

Tonskulus, Fri Jan 22 2010, 08:47PM

Basic mazzilli ZVS is way too low power for melting copper, there is just not enough tank voltage and thus, not enough work coil current. We want to see some hundreds of volts there (not just some tens of volts as mazzilli ZVS) to get reasonable heating results.

btw, it should be noted that heating iron above curie point (up to yellow-bright white glow), is much easier and requires less power than melting copper.

Flux concentrator is good idea for low freq. systems if smallish workpieces are being heated.

Re: Induction heater, what frequency to use for heating copper to brazing temperatures?

IamSmooth, Fri Jan 22 2010, 10:00PM

You are right about that. The resistance of steel is higher that the RI^2 losses generate much more heat.

I am not familiar with the mazzilli, but the series tank I have has a Vcap voltage between 150-200v when I'm melting the copper. I've calculated the current to be in the hundreds of amps just like you mentioned.

Henry, you should check out the tutorial to see the circuit and tank I used, as you can do this off of MAINS voltage.

IamSmooth, Fri Jan 22 2010, 10:00PM

Tonskulus wrote ...

.btw, it should be noted that heating iron above curie point (up to yellow-bright white glow), is much easier and requires less power than melting copper.

.btw, it should be noted that heating iron above curie point (up to yellow-bright white glow), is much easier and requires less power than melting copper.

You are right about that. The resistance of steel is higher that the RI^2 losses generate much more heat.

I am not familiar with the mazzilli, but the series tank I have has a Vcap voltage between 150-200v when I'm melting the copper. I've calculated the current to be in the hundreds of amps just like you mentioned.

Henry, you should check out the tutorial to see the circuit and tank I used, as you can do this off of MAINS voltage.

Re: Induction heater, what frequency to use for heating copper to brazing temperatures?

Henry, Sat Jan 23 2010, 06:13AM

We want to see some hundreds of volts there

--

not just some tens of volts as mazzilli ZVS

I dont really know if it is the input voltage to the schematic that is meant or induced voltage in the coil but i have a voltage around 160Vp at the coil. Its a little strange looking sinewave i get its like it has been rectified but i havent done that. But i remember once with a smaller coil i tried once so would it be a perfect sinewave bvut that coil more or less went up in smoke right away. But the waves are 160V top and the schematic draws about 20A+ if heating up a bigger nut for example. Although i havent calculated the coil current yet mainly since i dont remember how right now but i guess it could be a little higher then i might think. The coil is around 7 - 8µH

The input voltage is around 50V but if i go any higher the mosfets max 200V will be exceeded since the coil is at 160V+ and blow them up which have happened 2 times already. Based on this so should the voltage in the coil be quite all right even if ofcourse higher is better. Then its only the current left which i doubt are enough due to, as i guess, the small wire in the coil i use right now so enopugh power cant be transferred and the maybe small capacitance in the bank or in worst case, which i dont hope, the schematic it self.

Yes steel is really easy to get hot no doubt about that but maybe a little challenge though if you want to melt it.

About running directly on mains; i would like to avoid this as far as possible and instead as far as it could go try with an non dangerous voltage first since we use 230V where i live. And higher the voltage bigger the bang if something would break and i would be almost afraid on just thinking about a mosfet that had been shorted and at the same feeded with 230V directly connected to mains.

Henry, Sat Jan 23 2010, 06:13AM

We want to see some hundreds of volts there

--

not just some tens of volts as mazzilli ZVS

I dont really know if it is the input voltage to the schematic that is meant or induced voltage in the coil but i have a voltage around 160Vp at the coil. Its a little strange looking sinewave i get its like it has been rectified but i havent done that. But i remember once with a smaller coil i tried once so would it be a perfect sinewave bvut that coil more or less went up in smoke right away. But the waves are 160V top and the schematic draws about 20A+ if heating up a bigger nut for example. Although i havent calculated the coil current yet mainly since i dont remember how right now but i guess it could be a little higher then i might think. The coil is around 7 - 8µH

The input voltage is around 50V but if i go any higher the mosfets max 200V will be exceeded since the coil is at 160V+ and blow them up which have happened 2 times already. Based on this so should the voltage in the coil be quite all right even if ofcourse higher is better. Then its only the current left which i doubt are enough due to, as i guess, the small wire in the coil i use right now so enopugh power cant be transferred and the maybe small capacitance in the bank or in worst case, which i dont hope, the schematic it self.

Yes steel is really easy to get hot no doubt about that but maybe a little challenge though if you want to melt it.

About running directly on mains; i would like to avoid this as far as possible and instead as far as it could go try with an non dangerous voltage first since we use 230V where i live. And higher the voltage bigger the bang if something would break and i would be almost afraid on just thinking about a mosfet that had been shorted and at the same feeded with 230V directly connected to mains.

Re: Induction heater, what frequency to use for heating copper to brazing temperatures?

Tonskulus, Sat Jan 23 2010, 09:30AM

I think you all know that:

200Amps through 3 turn work coil makes almost no difference compared to 6 turn work coil running at 100Amps. Flux density keeps the same IF both coils are about the same size. If single turn (low inductance/impedance) work coil is used, very high current is required. OR very high frequency.

Maybe i should make ZVS mazzilli to see what it really can do as induction heater. I think it is possible to run it >100volts using separate low voltage bias supply? Anyone tested this method?

Tonskulus, Sat Jan 23 2010, 09:30AM

I think you all know that:

200Amps through 3 turn work coil makes almost no difference compared to 6 turn work coil running at 100Amps. Flux density keeps the same IF both coils are about the same size. If single turn (low inductance/impedance) work coil is used, very high current is required. OR very high frequency.

Maybe i should make ZVS mazzilli to see what it really can do as induction heater. I think it is possible to run it >100volts using separate low voltage bias supply? Anyone tested this method?

Re: Induction heater, what frequency to use for heating copper to brazing temperatures?

Steve Conner, Sat Jan 23 2010, 02:24PM

Tonskulus, I tried to build the biggest ZVS I could (see the old OMG Induction Heater thread for more details) and it suffered from parasitic oscillations above a few hundred watts.

Maybe the parasitic oscillations can be fixed somehow, but I couldn't be bothered trying. I changed to an IGBT halfbridge driven by one of my old PLL drivers, and it would happily run straight off the mains at over 1kW and melt steel bolts. The ZVS with the same tank capacitor could only get the bolt red hot, before the parasitics got bad enough to blow the MOSFETs.

Steve Conner, Sat Jan 23 2010, 02:24PM

Tonskulus, I tried to build the biggest ZVS I could (see the old OMG Induction Heater thread for more details) and it suffered from parasitic oscillations above a few hundred watts.

Maybe the parasitic oscillations can be fixed somehow, but I couldn't be bothered trying. I changed to an IGBT halfbridge driven by one of my old PLL drivers, and it would happily run straight off the mains at over 1kW and melt steel bolts. The ZVS with the same tank capacitor could only get the bolt red hot, before the parasitics got bad enough to blow the MOSFETs.

Re: Induction heater, what frequency to use for heating copper to brazing temperatures?

Henry, Sat Jan 23 2010, 05:39PM

About the ZVS mazzilli topology i would say if you want an inductive heater for steel to heat it up to its curiepoint and you want a quite easy build without much electronics then go with this topology. PLL; much more work with and a lot of electronics but you can melt steel and pretty much everything else with it.

As much power this schematic has drawn for me is 24A at 50V (althought maybe down to 40V or so at this current) when putting in a big fat bolt just to se. But at this level so was there only a small very short distortion after the sinwaves of about 3 volt, thats all distorsion there was but it doesent disturb anything as far as i have seen on the scope.

Henry, Sat Jan 23 2010, 05:39PM

About the ZVS mazzilli topology i would say if you want an inductive heater for steel to heat it up to its curiepoint and you want a quite easy build without much electronics then go with this topology. PLL; much more work with and a lot of electronics but you can melt steel and pretty much everything else with it.

As much power this schematic has drawn for me is 24A at 50V (althought maybe down to 40V or so at this current) when putting in a big fat bolt just to se. But at this level so was there only a small very short distortion after the sinwaves of about 3 volt, thats all distorsion there was but it doesent disturb anything as far as i have seen on the scope.

Re: Induction heater, what frequency to use for heating copper to brazing temperatures?

Henry, Sun Jan 24 2010, 03:06PM

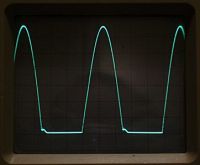

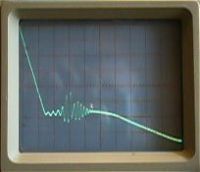

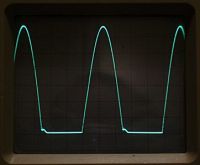

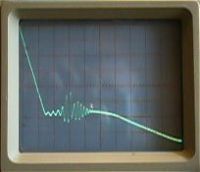

The distortion in the end is the only one and the other picture is a zoom in. The top is 2V/div the other is i think 0.1V/div probe at x10 on both.

As soon as i put a load in the coil it disappear the dip is still there though what that now is. This distortion absolutely seem to be resonance somewhere and its in the MHz range but it doesnt cause any problems as i can see.

The signal is taken from one side of the coil and it seems that the sine had been rectified, there should be a full sinewave if im not wrong no matter what buttons is pushed on the scope but there isnt. But once when i tested a smaller coil then there was a full perfect sinewave but distorted with a heavy load, but i cant understand why there isnt a full sinewave now with the little bigger coil i have? I strongly guess that i also only have half the power or so due to this.

BTW i put a little more capacitance in it and steel started to warm up a little bit quicker now and went a little hotter as it seemed but copper no real change. I guess a more or less quite big capacitor bank could do something at least to iron maybe but copper i dont know but one could hope but the caps i use are a little expensive.

Henry, Sun Jan 24 2010, 03:06PM

The distortion in the end is the only one and the other picture is a zoom in. The top is 2V/div the other is i think 0.1V/div probe at x10 on both.

As soon as i put a load in the coil it disappear the dip is still there though what that now is. This distortion absolutely seem to be resonance somewhere and its in the MHz range but it doesnt cause any problems as i can see.

The signal is taken from one side of the coil and it seems that the sine had been rectified, there should be a full sinewave if im not wrong no matter what buttons is pushed on the scope but there isnt. But once when i tested a smaller coil then there was a full perfect sinewave but distorted with a heavy load, but i cant understand why there isnt a full sinewave now with the little bigger coil i have? I strongly guess that i also only have half the power or so due to this.

BTW i put a little more capacitance in it and steel started to warm up a little bit quicker now and went a little hotter as it seemed but copper no real change. I guess a more or less quite big capacitor bank could do something at least to iron maybe but copper i dont know but one could hope but the caps i use are a little expensive.

Re: Induction heater, what frequency to use for heating copper to brazing temperatures?

IamSmooth, Sun Jan 24 2010, 06:20PM

As promised:

boiling copper

Frequency 62.5khz

Input power 2.5-2.8kw

Result: boiling crucible of copper. Very hot.

Now, what can I do with this?

I have found that the furnace cement is a very cheap way to make crucibles and stirring sticks. I have also found that by coating the inside of my levitating coil with it I have eliminated any shorting of the coils before I get it airborne.

IamSmooth, Sun Jan 24 2010, 06:20PM

As promised:

boiling copper

Frequency 62.5khz

Input power 2.5-2.8kw

Result: boiling crucible of copper. Very hot.

Now, what can I do with this?

I have found that the furnace cement is a very cheap way to make crucibles and stirring sticks. I have also found that by coating the inside of my levitating coil with it I have eliminated any shorting of the coils before I get it airborne.

Re: Induction heater, what frequency to use for heating copper to brazing temperatures?

Henry, Tue Jan 26 2010, 05:30PM

Nice one! That is exactly what i want and probably need to build, altough that high power level is to much for what i neeed i guess and maybe a little hard to control.

I have now read a little more about this and your tutorial as well, great one!

Am i right about this: to heat iron beyond its cure point and to generally heat non ferrous materials like copper so do the resonance frequency need to be changed so neither of current and voltage lags but follow each other pretty much exactly so maximum power would be transferred. Only then can non-ferrous material be heated as much as you want and also beyond the cure point for iron? The Mazzilli topology doesnt do this only resonance at the coil and capacitor frequency which isnt enough since it should resonate at the heated materials point and therefore cant heat non ferrous materials but ferrous material but only to its curie point?

I havent really understand before why the Mazzilli topology couldnt heat copper and so on but i think my theory above might be the reason. If this is what its all about so doesnt it matter how much time i put into the Mazzilli topology it will never been able to heat copper or any non ferrous material more than maybe a little if you lucky by some reason. But i have seen one here that had built a Mazzilli with pretty much exactly the same components then i and he could heat aluminum quite much as it seemed, but i cant understand how that could be done.

Henry, Tue Jan 26 2010, 05:30PM

Nice one! That is exactly what i want and probably need to build, altough that high power level is to much for what i neeed i guess and maybe a little hard to control.

I have now read a little more about this and your tutorial as well, great one!

Am i right about this: to heat iron beyond its cure point and to generally heat non ferrous materials like copper so do the resonance frequency need to be changed so neither of current and voltage lags but follow each other pretty much exactly so maximum power would be transferred. Only then can non-ferrous material be heated as much as you want and also beyond the cure point for iron? The Mazzilli topology doesnt do this only resonance at the coil and capacitor frequency which isnt enough since it should resonate at the heated materials point and therefore cant heat non ferrous materials but ferrous material but only to its curie point?

I havent really understand before why the Mazzilli topology couldnt heat copper and so on but i think my theory above might be the reason. If this is what its all about so doesnt it matter how much time i put into the Mazzilli topology it will never been able to heat copper or any non ferrous material more than maybe a little if you lucky by some reason. But i have seen one here that had built a Mazzilli with pretty much exactly the same components then i and he could heat aluminum quite much as it seemed, but i cant understand how that could be done.

Print this page