Diffusion pump project

plazmatron, Sat Oct 10 2009, 07:46PMI have wanted to get into high vacuum for some time, so I can make homemade x-ray tubes etc. However I was always under the impression it was expensive.

I picked up this small vintage Edwards EO1 diffusion pump about a month or so off of eBay, for just £5.50!

It is a water cooled affair, and had to have manifolds made for it, plus I wanted a closed loop cooling system for it, since I didn't want to be tied to the sink.

I made all the manifolds out of soldered copper and brass, and built a cooling system based around a 120mm PC radiator, the kind enjoyed by the watercoled PC crowd. Water is pumped round the system by a small 12v window washer pump, and the whole lot is mounted on a 5mm thick Aluminium plate

Front view.

Rear view.

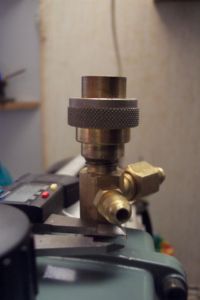

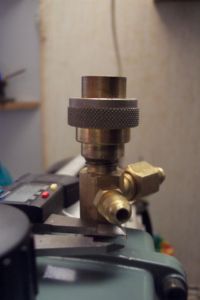

Hooked up to the Javac.

The backing pump is a Javac CC-141 rotary vane pump, that by itself, is quoted as pumping down to 15 microns, though I estimate 20µ.

In the above photo, note there are two vacuum lines to the backing connection. The reason is that the diffusion pump requires a backing pump speed of at least 30 l/min, and whilst the Javac is rated for 140 l/min, the small diameter of the provided inlets chokes the pump somewhat, so two of the three inlets were used, so I would have reasonable pumping speed.

A discharge tube (made from a Pyrex rolling pin!) was hooked up to the assembly, to which 30kV DC was applied The cathode is the filament from a 12v lamp, and the anode is a copper rod. The above picture was taken with just the Javac running, and shows the striated positive column.

Once the Javac has reached its base pressure, the positive column is much shorter, and the luminous disks, have become thicker, and more diffuse.

Once the Diffusion pump gets upto operating temperature, the column fluctuates in length, then shrinks until.......

.....we get into the soft x-ray region shown above. The walls fluoresce a pale blue from the impact of electrons. Note the luminous vertical mark. This is some diffusion pump oil that ran down the inside of the tube, after I applied too much to the top bung, it is brilliantly fluorescent under the impact of electrons.

Seconds after this photo was taken, the vacuum had become so hard, that the tube became dark, and ceased x-ray emission. So now a hot cathode is needed.

Once again HV is applied, except the filament is now lit. You can't tell in the photo as the light from the filament has washed it out, but the glass surface of the tube is glowing pale blue again, and the tube is once again emitting x-rays.

I spent a lot of time and effort before finally acquiring a diffusion pump, trying to squeeze an extra micron out of the Javac, by using molecular sieves and cold traps, and can honestly say that this project was much easier, in terms of cost time and effort, in reaching a repeatable high vacuum.

I highly recommend that anyone wanting to build a high vacuum system should go down this route, its not that expensive.

The Javac as I recall cost £120 new, the Diffusion pump was £5.50, and the Radiator was about £6 new (in a "brown box") everything else was out of the junk pile.

The diffusion pump is tiny (only 1 inch inside diameter) I also have a 3 inch pump (these show up on eBay all the time, out of Spectron leak detectors), and this will be radiator cooled as well. This pump was also cheap at just 50p!

Les

Re: Diffusion pump project

Proud Mary, Sat Oct 10 2009, 08:04PM

A marvellous effort!

Proud Mary, Sat Oct 10 2009, 08:04PM

A marvellous effort!

Re: Diffusion pump project

Scott Fusare, Sat Oct 10 2009, 08:04PM

Lovely work Plazmatron! The venerable diff pump lacks the convenience of a turbo but more than makes up for it when it comes to price and durability. Out of curiosity, what are you using for pumping fluid?

Scott

Scott Fusare, Sat Oct 10 2009, 08:04PM

Lovely work Plazmatron! The venerable diff pump lacks the convenience of a turbo but more than makes up for it when it comes to price and durability. Out of curiosity, what are you using for pumping fluid?

Scott

Re: Diffusion pump project

plazmatron, Sat Oct 10 2009, 08:15PM

Thanks everyone ! I'm using Dow corning DC-704 as the pump fluid. The manual specifies DC-702, DC-704 is a superior oil, but requires a lower backing pressure. DC-704 is claimed to be a hardier oil too, being able to resist the pump being opened up to atmosphere whilst boiling, and other accidents!

The pump isn't to inconvenient to run either. This one warms up in around 10 minutes, and cools down in around the same amount of time. Plus if I had a turbopump I would always be worrying about a washer falling in there!

Les

plazmatron, Sat Oct 10 2009, 08:15PM

scott fusare wrote ...

Lovely work Plazmatron! The venerable diff pump lacks the convenience of a turbo but more than makes up for it when it comes to price and durability. Out of curiosity, what are you using for pumping fluid?

Lovely work Plazmatron! The venerable diff pump lacks the convenience of a turbo but more than makes up for it when it comes to price and durability. Out of curiosity, what are you using for pumping fluid?

Thanks everyone ! I'm using Dow corning DC-704 as the pump fluid. The manual specifies DC-702, DC-704 is a superior oil, but requires a lower backing pressure. DC-704 is claimed to be a hardier oil too, being able to resist the pump being opened up to atmosphere whilst boiling, and other accidents!

The pump isn't to inconvenient to run either. This one warms up in around 10 minutes, and cools down in around the same amount of time. Plus if I had a turbopump I would always be worrying about a washer falling in there!

Les

Re: Diffusion pump project

Scott Fusare, Sat Oct 10 2009, 08:23PM

DC-704 is still around, wonderful. I have not used it since the 1980s but it was a great improvement over the easily cracked hydrocarbon based oils. It used to be horribly expensive, has that changed?

I suppose my "inconvenient" statement is an old bias that stems from working with large, water cooled diff pumps. The little guys like you have are indeed much friendlier!

Again, great work!

Scott

Scott Fusare, Sat Oct 10 2009, 08:23PM

DC-704 is still around, wonderful. I have not used it since the 1980s but it was a great improvement over the easily cracked hydrocarbon based oils. It used to be horribly expensive, has that changed?

I suppose my "inconvenient" statement is an old bias that stems from working with large, water cooled diff pumps. The little guys like you have are indeed much friendlier!

Again, great work!

Scott

Re: Diffusion pump project

plazmatron, Sat Oct 10 2009, 08:39PM

In the US, svp-neon does 50ml of DC-704 for around $30 USD. (just search eBay for DC-704)

They wouldn't ship abroad. so in the UK, I found a neon supplier that would do 25ml for £9 UKP

Its still horribly expensive, but this tiny pump only needs 11ml, and my 3 inch pump only needs 50ml,so its not a fortune to charge a pump.

Oddly it turns out that the old oils like DC-702 are still available, but are now more expensive than DC-704, and approaching the price bracket of Santovac-5!

Les

plazmatron, Sat Oct 10 2009, 08:39PM

scott fusare wrote ...

DC-704 is still around, wonderful. I have not used it since the 1980s but it was a great improvement over the easily cracked hydrocarbon based oils. It used to be horribly expensive, has that changed?

I suppose my "inconvenient" statement is an old bias that stems from working with large, water cooled diff pumps. The little guys like you have are indeed much friendlier!

Again, great work!

Scott

DC-704 is still around, wonderful. I have not used it since the 1980s but it was a great improvement over the easily cracked hydrocarbon based oils. It used to be horribly expensive, has that changed?

I suppose my "inconvenient" statement is an old bias that stems from working with large, water cooled diff pumps. The little guys like you have are indeed much friendlier!

Again, great work!

Scott

In the US, svp-neon does 50ml of DC-704 for around $30 USD. (just search eBay for DC-704)

They wouldn't ship abroad. so in the UK, I found a neon supplier that would do 25ml for £9 UKP

Its still horribly expensive, but this tiny pump only needs 11ml, and my 3 inch pump only needs 50ml,so its not a fortune to charge a pump.

Oddly it turns out that the old oils like DC-702 are still available, but are now more expensive than DC-704, and approaching the price bracket of Santovac-5!

Les

Re: Diffusion pump project

Hazmatt_(The Underdog), Sat Oct 10 2009, 10:20PM

Lemme know when you need a bigger pump

Hazmatt_(The Underdog), Sat Oct 10 2009, 10:20PM

Lemme know when you need a bigger pump

Re: Diffusion pump project

thedatastream, Mon Oct 12 2009, 07:16AM

How good is soldered copper pipe with a vacuum? I had considered it for a vacuum project (that never went anywhere)

thedatastream, Mon Oct 12 2009, 07:16AM

How good is soldered copper pipe with a vacuum? I had considered it for a vacuum project (that never went anywhere)

Re: Diffusion pump project

plazmatron, Mon Oct 12 2009, 04:02PM

Personally I find it OK, there seem to be a consensus that the vapor pressure of lead in a concern, however the vapor pressure is quoted as 10E-4mm Hg at 548 C, so as long as the parts are cool, it poses no problem.

Ideally one would use silver solder, to join copper, but I have found ordinary solder to be quite alright. You must flush all the pipework with acetone, to wash out the fluxes used in soldering, and I try to keep the exposed solder on the inside of the joins to a minimum, and also the number of joints to a minimum.

There are only two soldered joints on the high vacuum side of this pump.

Les

plazmatron, Mon Oct 12 2009, 04:02PM

thedatastream wrote ...

How good is soldered copper pipe with a vacuum? I had considered it for a vacuum project (that never went anywhere)

How good is soldered copper pipe with a vacuum? I had considered it for a vacuum project (that never went anywhere)

Personally I find it OK, there seem to be a consensus that the vapor pressure of lead in a concern, however the vapor pressure is quoted as 10E-4mm Hg at 548 C, so as long as the parts are cool, it poses no problem.

Ideally one would use silver solder, to join copper, but I have found ordinary solder to be quite alright. You must flush all the pipework with acetone, to wash out the fluxes used in soldering, and I try to keep the exposed solder on the inside of the joins to a minimum, and also the number of joints to a minimum.

There are only two soldered joints on the high vacuum side of this pump.

Les

Re: Diffusion pump project

Steve Conner, Mon Oct 12 2009, 05:22PM

I recently found an Edwards vacuum coating machine in the uni's junk pile, and it looked to me as if it just used a length of plastic hose between the diffusion pump and the backing pump. The clear stuff with the reinforcing braid.

I never figured out a way to dismantle it or get it off campus without getting in trouble, and it's now been rained on.

Steve Conner, Mon Oct 12 2009, 05:22PM

I recently found an Edwards vacuum coating machine in the uni's junk pile, and it looked to me as if it just used a length of plastic hose between the diffusion pump and the backing pump. The clear stuff with the reinforcing braid.

I never figured out a way to dismantle it or get it off campus without getting in trouble, and it's now been rained on.

Re: Diffusion pump project

plazmatron, Mon Oct 12 2009, 05:42PM

Thats a shame! They are very cool toys! I manage to get two off of evilBay for just a few pounds, so I`m all set up.

Yes reinforced PVC is often used for the backing connection, since outgassing on the low side is minimal, and the rotary should be able to handle it. Often a spring is pushed up the pipe to stop it collapsing under vacuum.

I will be modifying the rotary pump connections again, by having two 10mm pipes going into a 15mm. Microbore is still much too thin for my liking, plus I want to get the 3inch pump up and running too, which will require the backing bump to pull at least 85l/min, so I need much larger diameter tube, and shorter connections.

Les

plazmatron, Mon Oct 12 2009, 05:42PM

Steve McConner wrote ...

I recently found an Edwards vacuum coating machine in the uni's junk pile, and it looked to me as if it just used a length of plastic hose between the diffusion pump and the backing pump. The clear stuff with the reinforcing braid.

I never figured out a way to dismantle it or get it off campus without getting in trouble, and it's now been rained on.

I recently found an Edwards vacuum coating machine in the uni's junk pile, and it looked to me as if it just used a length of plastic hose between the diffusion pump and the backing pump. The clear stuff with the reinforcing braid.

I never figured out a way to dismantle it or get it off campus without getting in trouble, and it's now been rained on.

Thats a shame! They are very cool toys! I manage to get two off of evilBay for just a few pounds, so I`m all set up.

Yes reinforced PVC is often used for the backing connection, since outgassing on the low side is minimal, and the rotary should be able to handle it. Often a spring is pushed up the pipe to stop it collapsing under vacuum.

I will be modifying the rotary pump connections again, by having two 10mm pipes going into a 15mm. Microbore is still much too thin for my liking, plus I want to get the 3inch pump up and running too, which will require the backing bump to pull at least 85l/min, so I need much larger diameter tube, and shorter connections.

Les

Re: Diffusion pump project

uzzors2k, Wed Oct 14 2009, 02:31PM

Awesome! Your project is truly inspiring. I had no idea diffusion pumps could be found so cheap, I'll have to keep an eye out for one. Are you going to try glass-blowing with this setup?

uzzors2k, Wed Oct 14 2009, 02:31PM

Awesome! Your project is truly inspiring. I had no idea diffusion pumps could be found so cheap, I'll have to keep an eye out for one. Are you going to try glass-blowing with this setup?

Re: Diffusion pump project

plazmatron, Wed Oct 14 2009, 06:58PM

Yes, I am, I have been playing with soda glass tubing, however I still need more practice to get up to a reasonable standard.

I also need a better heat source too. I have just got a Neon sign catalogue, and their prices for neon sign electrodes seem reasonable, and also come with sealing stems too, however I will practice some more with scrap glass, before purchasing some.

For the time being, most of my experiments will be done in demountable chambers. This is dead easy, since there are hundreds of candidate chambers kicking about, for example the glass rolling pin shown in the previous posts, and just today, I was using a small Salmon paste jar! These little jars are great, as they are very thick (4mm), and easy to drill holes in. I built an experimental Lenard tube today with one. It worked for a short while, until the electron beam punctured the Aluminium foil window More voltage, and less current next time I think!

More voltage, and less current next time I think!

Les

plazmatron, Wed Oct 14 2009, 06:58PM

Uzzors wrote ...

Are you going to try glass-blowing with this setup?

Are you going to try glass-blowing with this setup?

Yes, I am, I have been playing with soda glass tubing, however I still need more practice to get up to a reasonable standard.

I also need a better heat source too. I have just got a Neon sign catalogue, and their prices for neon sign electrodes seem reasonable, and also come with sealing stems too, however I will practice some more with scrap glass, before purchasing some.

For the time being, most of my experiments will be done in demountable chambers. This is dead easy, since there are hundreds of candidate chambers kicking about, for example the glass rolling pin shown in the previous posts, and just today, I was using a small Salmon paste jar! These little jars are great, as they are very thick (4mm), and easy to drill holes in. I built an experimental Lenard tube today with one. It worked for a short while, until the electron beam punctured the Aluminium foil window

More voltage, and less current next time I think!

More voltage, and less current next time I think!Les

Re: Diffusion pump project

uzzors2k, Wed Oct 14 2009, 09:16PM

Great stuff, can you post some pictures of your Lenard tube?

I've found a source for both a little shop vac like the Javac you have, and borosilicate glass here in Norway. I'm debating whether I should get into this now or wait until I'm done my studies at the moment. Seeing you doing this is really tempting me!

uzzors2k, Wed Oct 14 2009, 09:16PM

Great stuff, can you post some pictures of your Lenard tube?

I've found a source for both a little shop vac like the Javac you have, and borosilicate glass here in Norway. I'm debating whether I should get into this now or wait until I'm done my studies at the moment. Seeing you doing this is really tempting me!

Re: Diffusion pump project

Proud Mary, Thu Oct 15 2009, 12:32AM

Eirik, finish your degree or you'll end up hanging out on corners in downtown Oslo!

BUT - since the true enthusiast can never really be deterred - you may not know that you can produce all kinds of interesting soft X-rays at the pressures obtainable by the Javac alone by plasma discharge.

The problem for most folk is that unless you have a pal in Brighton who will send you a Ne-CH4 proportional counter tube with opposing Be windows,* it's pretty much impossible to measure X-rays much less than 10keV, as I'm sure you know.

So, with the Javac, or whatever pump will get you down to 20 millitorr you could make plasma discharge X-ray tubes with Kapton exit windows for not very much money.

Plazmatron has the Devil's Luck, and you could watch and wait in ebay till the Crack of Doom and never find another diffusion pump for NOK 135.

As for these very soft rays: as well you know, the softer the nastier. I think you'd absorb about 99% of a 5keV

'mistake.' Just because they're 'soft' doesn't mean that there aren't plenty of them either. The plus side is that shielding costs are very low indeed.

The plus side is that shielding costs are very low indeed.

Did I send you a BPX-65? If you take the lens out, it will go down to about 2keV, and detect individual X-photon strikes with nearly 100% percent quantum efficiency, the attenuation of the rays by any intervening air being a limiting factor.

Imaging, however, becomes increasingly problematic as we descend from 10keV.

* Generally valued at a good piece of reindeer sausage or dried reindeer meat....

Proud Mary, Thu Oct 15 2009, 12:32AM

Eirik, finish your degree or you'll end up hanging out on corners in downtown Oslo!

BUT - since the true enthusiast can never really be deterred - you may not know that you can produce all kinds of interesting soft X-rays at the pressures obtainable by the Javac alone by plasma discharge.

The problem for most folk is that unless you have a pal in Brighton who will send you a Ne-CH4 proportional counter tube with opposing Be windows,* it's pretty much impossible to measure X-rays much less than 10keV, as I'm sure you know.

So, with the Javac, or whatever pump will get you down to 20 millitorr you could make plasma discharge X-ray tubes with Kapton exit windows for not very much money.

Plazmatron has the Devil's Luck, and you could watch and wait in ebay till the Crack of Doom and never find another diffusion pump for NOK 135.

As for these very soft rays: as well you know, the softer the nastier. I think you'd absorb about 99% of a 5keV

'mistake.' Just because they're 'soft' doesn't mean that there aren't plenty of them either.

The plus side is that shielding costs are very low indeed.

The plus side is that shielding costs are very low indeed. Did I send you a BPX-65? If you take the lens out, it will go down to about 2keV, and detect individual X-photon strikes with nearly 100% percent quantum efficiency, the attenuation of the rays by any intervening air being a limiting factor.

Imaging, however, becomes increasingly problematic as we descend from 10keV.

* Generally valued at a good piece of reindeer sausage or dried reindeer meat....

Re: Diffusion pump project

plazmatron, Fri Oct 16 2009, 04:03PM

Hi Uzzors,

yep, check these out:

This is a view of the foil Anode. A 5mm hole is drilled into the base of the jar, and the foil, is imply superglued over it!

This is ordinary household foil, and the 5mm window can easily support the high vacuum.

This is a view of the tube running. The blue glow, is a result of a thin layer of electron sensitive phosphor sprinkled on the window.

I made a shorter tube today, and finally observed the emerging electron beam first hand!

This tube was sprayed black, as the light from the filament easily washes out the dim glow.

The dim blue "jet" exiting from the centre of the tube looked to be about 10mm long, at 80kV, however there was significant light in the room.

Shortly after taking this photo, the Aluminium window punctured again, I think its time to invest in some Titanium foil, and give that a shot.

I`m with Harry on this one, do complete your studies, but, at the same time, always keep an eye out for cheap bits and pieces as they show up, I'm not that lucky!

plazmatron, Fri Oct 16 2009, 04:03PM

Uzzors wrote ...

Great stuff, can you post some pictures of your Lenard tube?

I've found a source for both a little shop vac like the Javac you have, and borosilicate glass here in Norway. I'm debating whether I should get into this now or wait until I'm done my studies at the moment. Seeing you doing this is really tempting me!

Great stuff, can you post some pictures of your Lenard tube?

I've found a source for both a little shop vac like the Javac you have, and borosilicate glass here in Norway. I'm debating whether I should get into this now or wait until I'm done my studies at the moment. Seeing you doing this is really tempting me!

Hi Uzzors,

yep, check these out:

This is a view of the foil Anode. A 5mm hole is drilled into the base of the jar, and the foil, is imply superglued over it!

This is ordinary household foil, and the 5mm window can easily support the high vacuum.

This is a view of the tube running. The blue glow, is a result of a thin layer of electron sensitive phosphor sprinkled on the window.

I made a shorter tube today, and finally observed the emerging electron beam first hand!

This tube was sprayed black, as the light from the filament easily washes out the dim glow.

The dim blue "jet" exiting from the centre of the tube looked to be about 10mm long, at 80kV, however there was significant light in the room.

Shortly after taking this photo, the Aluminium window punctured again, I think its time to invest in some Titanium foil, and give that a shot.

I`m with Harry on this one, do complete your studies, but, at the same time, always keep an eye out for cheap bits and pieces as they show up, I'm not that lucky!

Re: Diffusion pump project

..., Fri Oct 16 2009, 05:43PM

That is amazing :-o

A little ebay searching turned up some 9um (.3mil!) thick Ti foil, I wonder if it would hold to 15psi or not

Otherwise you can get the 3 mill stuff

What are you planning to do with this new toy?

..., Fri Oct 16 2009, 05:43PM

That is amazing :-o

A little ebay searching turned up some 9um (.3mil!) thick Ti foil, I wonder if it would hold to 15psi or not

Otherwise you can get the 3 mill stuff

What are you planning to do with this new toy?

Re: Diffusion pump project

plazmatron, Fri Oct 16 2009, 06:20PM

Thanks for the link, I was just having a dig myself!

9µ should be easily able to handle the the pressure, the window is only 5mm diameter after all.

I hear that ordinary kitchen foil is around 16µ so 9µ in Ti should be ideal.

Well the diff pump will be used for allsorts of vacuum work, the Lenard tube was something of a diversion

But, since it is a very interesting diversion, it will have to be scaled up a little. I figure a 250kV tube would satisfy my curiosity!

Les

plazmatron, Fri Oct 16 2009, 06:20PM

... wrote ...

That is amazing :-o

A little ebay searching turned up some 9um (.3mil!) thick Ti foil, I wonder if it would hold to 15psi or not

What are you planning to do with this new toy?

That is amazing :-o

A little ebay searching turned up some 9um (.3mil!) thick Ti foil, I wonder if it would hold to 15psi or not

What are you planning to do with this new toy?

Thanks for the link, I was just having a dig myself!

9µ should be easily able to handle the the pressure, the window is only 5mm diameter after all.

I hear that ordinary kitchen foil is around 16µ so 9µ in Ti should be ideal.

Well the diff pump will be used for allsorts of vacuum work, the Lenard tube was something of a diversion

But, since it is a very interesting diversion, it will have to be scaled up a little. I figure a 250kV tube would satisfy my curiosity!

Les

Re: Diffusion pump project

uzzors2k, Wed Oct 21 2009, 06:57PM

Hi Harry, you did indeed send a BPX-65 over, along with some organic gas Geiger tubes for lower energy X-rays. I just need a gigaohm resistor and some time off for Christmas before I make a counter with them. It'll be fun/scary to see how much radiation leaks from my X-ray setup. Those Javacs go for the same price as a cell-phone, so they won't set me back too far. After seeing this it's hard not to jump into it, but I'll stick to my studies for now, if for no other reason than that darned polyprojectilitus which has me still doing projects I planned years ago!

That's too neat Leslie! Have you considered irritating plexiglass to see whether you can make Lichtenberg Figures? Maybe not near the same scale as Bert, but shouldn't it be possible granted you use a thin sheet and lot's of irritation time?

uzzors2k, Wed Oct 21 2009, 06:57PM

Hi Harry, you did indeed send a BPX-65 over, along with some organic gas Geiger tubes for lower energy X-rays. I just need a gigaohm resistor and some time off for Christmas before I make a counter with them. It'll be fun/scary to see how much radiation leaks from my X-ray setup. Those Javacs go for the same price as a cell-phone, so they won't set me back too far. After seeing this it's hard not to jump into it, but I'll stick to my studies for now, if for no other reason than that darned polyprojectilitus which has me still doing projects I planned years ago!

That's too neat Leslie! Have you considered irritating plexiglass to see whether you can make Lichtenberg Figures? Maybe not near the same scale as Bert, but shouldn't it be possible granted you use a thin sheet and lot's of irritation time?

Re: Diffusion pump project

klugesmith, Thu Oct 22 2009, 01:46AM

So, though this is probably preaching to the choir:

A foil too thin to span a 5mm hole, may be able to span a dense array of smaller holes.

Here is one patent about supporting and heat-sinking a large foil window for electron beams, using finely spaced parallel fins on the vacuum side. Check out the figures:

These guys spanned a 38mm window with 0.002" (51 µm) Al foil, by making a simple but very strong attachment between the foil and its supporting rim.

klugesmith, Thu Oct 22 2009, 01:46AM

plazmatron wrote ...

9µ should be easily able to handle the the pressure, the window is only 5mm diameter after all.

I hear that ordinary kitchen foil is around 16µ so 9µ in Ti should be ideal.

Nice work. I guess the thread is drifting from diffusion pumps to Lenard tubes.9µ should be easily able to handle the the pressure, the window is only 5mm diameter after all.

I hear that ordinary kitchen foil is around 16µ so 9µ in Ti should be ideal.

So, though this is probably preaching to the choir:

A foil too thin to span a 5mm hole, may be able to span a dense array of smaller holes.

Here is one patent about supporting and heat-sinking a large foil window for electron beams, using finely spaced parallel fins on the vacuum side. Check out the figures:

These guys spanned a 38mm window with 0.002" (51 µm) Al foil, by making a simple but very strong attachment between the foil and its supporting rim.

Re: Diffusion pump project

Fabio, Fri Nov 06 2009, 11:29PM

Hi Guys!

This theread is simply inspiring for me, for this reason, i searched something similar on ebay with no luck...... after 2 tries i finally bought this:

it came from italy so shipping is faster and cheaper for me, the final price was 130€ including shipping, handling and insurance, now i need 60ml of diffusion fluid and some spare time to make my vacuum setup!

Fabio, Fri Nov 06 2009, 11:29PM

Hi Guys!

This theread is simply inspiring for me, for this reason, i searched something similar on ebay with no luck...... after 2 tries i finally bought this:

it came from italy so shipping is faster and cheaper for me, the final price was 130€ including shipping, handling and insurance, now i need 60ml of diffusion fluid and some spare time to make my vacuum setup!

Re: Diffusion pump project

Proud Mary, Sat Nov 07 2009, 01:19AM

I feel a little sad to say nothing more than Grosse Gluck, but I have a few hundred gammes of Ca - an old fashioned getter I know - but I'll be more than happy to help out with any genuine vacuum ethusiasts in need of old fashioned getters.

Proud Mary, Sat Nov 07 2009, 01:19AM

I feel a little sad to say nothing more than Grosse Gluck, but I have a few hundred gammes of Ca - an old fashioned getter I know - but I'll be more than happy to help out with any genuine vacuum ethusiasts in need of old fashioned getters.

Re: Diffusion pump project

plazmatron, Sat Nov 07 2009, 01:28AM

Ah! You're the guy that managed to build a gas x-ray tube using a air conditioning pump, and some getters right?

Nice pump! Told you these things were cheap!

The spec for the diffstak 63, says it requires Santovac 5 as the pump fluid. In the event you cant get hold of it in the small quantities required, you could always use DC-704 or DC-705. A neon sign shop is your best bet for getting fluid, since the main manufacturers have minimum orders of 500ml (which is around 650 Euro!)

I bought my fluid from http://www.sign-tec.co.uk/ they were quite helpful, and sell in multiples of 50ml. If you ask nicely, they will probably ship internationally.

The Lenard tube is on hold until my titanium foil arrives, at which point it will get its own thread, since I have been busy building a much better tube

Once you have this thing up and running, you will love it!

Les

plazmatron, Sat Nov 07 2009, 01:28AM

Ah! You're the guy that managed to build a gas x-ray tube using a air conditioning pump, and some getters right?

Nice pump! Told you these things were cheap!

The spec for the diffstak 63, says it requires Santovac 5 as the pump fluid. In the event you cant get hold of it in the small quantities required, you could always use DC-704 or DC-705. A neon sign shop is your best bet for getting fluid, since the main manufacturers have minimum orders of 500ml (which is around 650 Euro!)

I bought my fluid from http://www.sign-tec.co.uk/ they were quite helpful, and sell in multiples of 50ml. If you ask nicely, they will probably ship internationally.

The Lenard tube is on hold until my titanium foil arrives, at which point it will get its own thread, since I have been busy building a much better tube

Once you have this thing up and running, you will love it!

Les

Re: Diffusion pump project

Fabio, Sat Nov 07 2009, 11:29PM

Yes i am!

I also build the Xray camera and the demo fusor and many other strange equipments

I have a friend who works for a company that installs and makes maintenance for the vacuum systems, finding the right fluid isn't a problem, i also haven't any problem in finding some getters, nickel, kovar, berillium windows and glass; finally, if i need a titanium foil, i can simply search it on ebay!

Fabio, Sat Nov 07 2009, 11:29PM

Ah! You're the guy that managed to build a gas x-ray tube using a air conditioning pump, and some getters right?

Yes i am!

I also build the Xray camera and the demo fusor and many other strange equipments

The spec for the diffstak 63, says it requires Santovac 5 as the pump fluid. In the event you cant get

I have a friend who works for a company that installs and makes maintenance for the vacuum systems, finding the right fluid isn't a problem, i also haven't any problem in finding some getters, nickel, kovar, berillium windows and glass; finally, if i need a titanium foil, i can simply search it on ebay!

Re: Diffusion pump project

rp181, Sat Nov 07 2009, 11:48PM

Did the fusor actually achieve fusion? All of the ones I have seen used the lab type vacuum chambers, to support the high vacuum.

rp181, Sat Nov 07 2009, 11:48PM

Did the fusor actually achieve fusion? All of the ones I have seen used the lab type vacuum chambers, to support the high vacuum.

Re: Diffusion pump project

Fabio, Wed Nov 11 2009, 09:37AM

Where is my previous post????

anyway, i have a backup!

*********************************************

i never tried a real fusion yet because so far i don't have a decent vacuum pump.

anyhow, a glass chamber can easily support the required vacuum if all seals are OK, the main problem is relative to ion bombardment, the glass will be easily overheated in some spots while remains cold in the other, this phenomenon will lead in cracks, and finally an implosion if the fusion will be continued for too much time!

Now i have this chamber, but after i will reach my first fusion, i will probably switch to a better chamber.

Ciao!

Fabio.

Fabio, Wed Nov 11 2009, 09:37AM

Where is my previous post????

anyway, i have a backup!

*********************************************

i never tried a real fusion yet because so far i don't have a decent vacuum pump.

anyhow, a glass chamber can easily support the required vacuum if all seals are OK, the main problem is relative to ion bombardment, the glass will be easily overheated in some spots while remains cold in the other, this phenomenon will lead in cracks, and finally an implosion if the fusion will be continued for too much time!

Now i have this chamber, but after i will reach my first fusion, i will probably switch to a better chamber.

Ciao!

Fabio.

Re: Diffusion pump project

Nicko, Thu Nov 12 2009, 08:53AM

Usefully, they are also adjacent to the local recycling centre - very convenient for nice MOT/MOCs etc.

Nicko, Thu Nov 12 2009, 08:53AM

plazmatron wrote ...

...I bought my fluid from http://www.sign-tec.co.uk/ they were quite helpful, and sell in multiples of 50ml. If you ask nicely, they will probably ship internationally.

...

Sign-Tec are just down the road from me (next village where my in-laws have a farm). I paid them a visit a couple of months ago - very helpful people. They do accept personal callers (I always phoned in advance), but are mostly mail-order - bought an NST and some HV cable. As the neon business is in general decline world-wide, they are also doing a lot of LED & other stuff - their new web site is vastly better than their old one, but its always worth phoning as not everything is online....I bought my fluid from http://www.sign-tec.co.uk/ they were quite helpful, and sell in multiples of 50ml. If you ask nicely, they will probably ship internationally.

...

Usefully, they are also adjacent to the local recycling centre - very convenient for nice MOT/MOCs etc.

Re: Diffusion pump project

Fabio, Sun Jan 17 2010, 09:12PM

Hi All!

Weeeeeeee, i finally have a real vacuum vessel!!!!!!!!!

Unfortunately, i found a big leak (and eventually there are some other smaller leaks) so the system

cannot be pumped down yet, but i have a limited mechanical skills and this is only my first attempt with the diffusion pump.

WORK IN PROGRESS!!!!

Fabio, Sun Jan 17 2010, 09:12PM

Hi All!

Weeeeeeee, i finally have a real vacuum vessel!!!!!!!!!

Unfortunately, i found a big leak (and eventually there are some other smaller leaks) so the system

cannot be pumped down yet, but i have a limited mechanical skills and this is only my first attempt with the diffusion pump.

WORK IN PROGRESS!!!!

Re: Diffusion pump project

Fabio, Sun Feb 07 2010, 11:58PM

New update: Now i have a welded frame, is not exactly a small vacuum system but..... who cares???

Ciao!

Fabio.

Fabio, Sun Feb 07 2010, 11:58PM

New update: Now i have a welded frame, is not exactly a small vacuum system but..... who cares???

Ciao!

Fabio.

Re: Diffusion pump project

plazmatron, Sun Feb 14 2010, 04:31PM

Very cool!

You will likely need a larger diameter, and shorter vacuum line to pump down the Diffusion pump.

A few posts back I had said that I was using copper brake line on the low side, and that the fittings on the pump manifold (1/4" SAE) were much too small, and were doing a marvelous job of choking what could be a good pump!

For this reason I was using two of the available ports, however I wasn't really happy with using such narrow diameter tubes, so last night I disassembled the pump manifold, and modified it a little.

There are three fittings on the javac inlet, a 1/4" SAE, a 3/8" SAE, and 1/2" acme. The acme is on top of the inlet, providing the path of least resistance for the pumped gases, and is also has the largest internal diameter, so I modified this port.

The internal diameter of the 1/2" acme is just over 6mm, and it turns out after removing it from the pump body, that the internal diameter of the inlet manifold is 10mm, so I bored out the center of the acme to 10mm for maximum possible flow rate.

I soldered on a 1/2" speedivac coupling I had in my box of junk. A more modern flange might have been better, but this is quite satisfactory for now.

Above: The complete coupling on the manifold.

The results:

To the other half of the coupling I soldered a 6" length of standard 15mm copper plumbing pipe, that just happened to fit quite snugly in the 1/2" speedivac fitting.

To this I attached one of my glass discharge tubes, shown further up the post, connected up the EHT supply, and fired up the pump.

The flow rate and base pressure now is simply amazing! It will pump down to a "soft x-ray" vacuum (i.e. the luminous discharge in the tube will cease, and the tube will produce x-rays) in about 5 seconds, all by itself!

Before, it would take around 15minutes to reach base pressure, and this was quite a way away from the vacuum it pulls now.

There is no doubt now, that the pump will be capable of forepumping quite large diffusion pumps, and once I hook it up to my small diffusion pump, I expect the ultimate vacuum of the system to be much much deeper.

Les

plazmatron, Sun Feb 14 2010, 04:31PM

Very cool!

You will likely need a larger diameter, and shorter vacuum line to pump down the Diffusion pump.

A few posts back I had said that I was using copper brake line on the low side, and that the fittings on the pump manifold (1/4" SAE) were much too small, and were doing a marvelous job of choking what could be a good pump!

For this reason I was using two of the available ports, however I wasn't really happy with using such narrow diameter tubes, so last night I disassembled the pump manifold, and modified it a little.

There are three fittings on the javac inlet, a 1/4" SAE, a 3/8" SAE, and 1/2" acme. The acme is on top of the inlet, providing the path of least resistance for the pumped gases, and is also has the largest internal diameter, so I modified this port.

The internal diameter of the 1/2" acme is just over 6mm, and it turns out after removing it from the pump body, that the internal diameter of the inlet manifold is 10mm, so I bored out the center of the acme to 10mm for maximum possible flow rate.

I soldered on a 1/2" speedivac coupling I had in my box of junk. A more modern flange might have been better, but this is quite satisfactory for now.

Above: The complete coupling on the manifold.

The results:

To the other half of the coupling I soldered a 6" length of standard 15mm copper plumbing pipe, that just happened to fit quite snugly in the 1/2" speedivac fitting.

To this I attached one of my glass discharge tubes, shown further up the post, connected up the EHT supply, and fired up the pump.

The flow rate and base pressure now is simply amazing! It will pump down to a "soft x-ray" vacuum (i.e. the luminous discharge in the tube will cease, and the tube will produce x-rays) in about 5 seconds, all by itself!

Before, it would take around 15minutes to reach base pressure, and this was quite a way away from the vacuum it pulls now.

There is no doubt now, that the pump will be capable of forepumping quite large diffusion pumps, and once I hook it up to my small diffusion pump, I expect the ultimate vacuum of the system to be much much deeper.

Les

Re: Diffusion pump project

Proud Mary, Sun Feb 14 2010, 06:13PM

Coo that's good, Les!

I very recently bought a lot of seven Mini-Instruments Mini-Monitors, together with ten Alrad Gammatell II, and three branded only "Harwell Dose Meter" in an ex-Harwell auction, £23 the lot.

The Gammatell IIs use tin foil compensated ZP1313 mini GM tubes and have a cute little 500V supply the size of a double sugar cube.

I'll re-calibrate these instruments with a function generator when I've finished refurbishing them.

The Alrad Gammatells run from a standard PP3 9V battery and have a red LED display in total uSv (push button to view), and a dose-rate alarm with five levels (uSv/hr) which can be selected by moving an agreeably simple internal jumper. The three yellow "Harwell Dose Meter" also have a programmable alarm but use a 3V battery and have an LCD display

I'll send you a Gammatell II when I've rigourously tested them over one month's continuous operation.

Proud Mary, Sun Feb 14 2010, 06:13PM

Coo that's good, Les!

I very recently bought a lot of seven Mini-Instruments Mini-Monitors, together with ten Alrad Gammatell II, and three branded only "Harwell Dose Meter" in an ex-Harwell auction, £23 the lot.

The Gammatell IIs use tin foil compensated ZP1313 mini GM tubes and have a cute little 500V supply the size of a double sugar cube.

I'll re-calibrate these instruments with a function generator when I've finished refurbishing them.

The Alrad Gammatells run from a standard PP3 9V battery and have a red LED display in total uSv (push button to view), and a dose-rate alarm with five levels (uSv/hr) which can be selected by moving an agreeably simple internal jumper. The three yellow "Harwell Dose Meter" also have a programmable alarm but use a 3V battery and have an LCD display

I'll send you a Gammatell II when I've rigourously tested them over one month's continuous operation.

Re: Diffusion pump project

plazmatron, Tue Feb 16 2010, 10:51PM

Thanks! Thats jolly decent of you!

My 1/2" "vacuum hose", turned up today. I was looking for wire reinforced PVC pipe for the low side. I scoured the 'net for the boomin' stuff, and it was only when I was looking on evilBay for a reaction vessel, that I found some being sold by the biodiesel crowd as suction hose.

In case anyone was wondering, wire reinforced PVC is ideal for medium vacuum use, i.e. connecting your forepumps to your diff pumps, for the high vacuum side, you really do need metal.

I will fire up a pic of the new setup once my valves turn up, and are fitted

Les

plazmatron, Tue Feb 16 2010, 10:51PM

Proud Mary wrote ...

I'll send you a Gammatell II when I've rigourously tested them over one month's continuous operation.

I'll send you a Gammatell II when I've rigourously tested them over one month's continuous operation.

Thanks! Thats jolly decent of you!

My 1/2" "vacuum hose", turned up today. I was looking for wire reinforced PVC pipe for the low side. I scoured the 'net for the boomin' stuff, and it was only when I was looking on evilBay for a reaction vessel, that I found some being sold by the biodiesel crowd as suction hose.

In case anyone was wondering, wire reinforced PVC is ideal for medium vacuum use, i.e. connecting your forepumps to your diff pumps, for the high vacuum side, you really do need metal.

I will fire up a pic of the new setup once my valves turn up, and are fitted

Les

Re: Diffusion pump project

plazmatron, Fri Feb 19 2010, 07:32PM

Here is the diffusion pump with 1/2" reinforced hose, attached to the modified manifold.

Some of the more observant among you, might also notice I removed the fitting on the Diffusion pump, that necked the pipe down to 8mm. Now the high vacuum side is 15mm diameter, with only one solder joint.

Every little helps with these things! I am happy with it now as it stands.

Les

plazmatron, Fri Feb 19 2010, 07:32PM

Here is the diffusion pump with 1/2" reinforced hose, attached to the modified manifold.

Some of the more observant among you, might also notice I removed the fitting on the Diffusion pump, that necked the pipe down to 8mm. Now the high vacuum side is 15mm diameter, with only one solder joint.

Every little helps with these things! I am happy with it now as it stands.

Les

Re: Diffusion pump project

Fabio, Mon Nov 22 2010, 12:18PM

Hi guys!

After some time, i found the other parts necessary for the cooling system; now i'm fixing them on the frame.

Ciao!

Fabio.

Fabio, Mon Nov 22 2010, 12:18PM

Hi guys!

After some time, i found the other parts necessary for the cooling system; now i'm fixing them on the frame.

Ciao!

Fabio.

Re: Diffusion pump project

Proud Mary, Mon Nov 22 2010, 12:26PM

My Goodness, Fabio! What a splendid piece of work! And your great metal beehive makes my diffusion pumps look tiny. But size isn't everything, you know!

Proud Mary, Mon Nov 22 2010, 12:26PM

My Goodness, Fabio! What a splendid piece of work! And your great metal beehive makes my diffusion pumps look tiny. But size isn't everything, you know!

Re: Diffusion pump project

Fabio, Fri Dec 10 2010, 10:04PM

i fixed and connected everything on the cooling system last week but, unfortunately, the diaphragm pump i used for liquid circulation is too violent, it acts as hidraulic ram and force the internal baffle of the diffusion pump to vibrate vigorously.

to avoid any risk of damages, i must add something to smooth the hidraulic flux coming from the pump, a water reservoir with an huge air bubble inside should work fine.

This is my solution of the problem, i made a transparent reservoir with a water fountain inside for both aestethical and pratical purposes (i can clearly see if i have a liquid flux or i have occlusion problems)

Ciao!

Fabio.

Fabio, Fri Dec 10 2010, 10:04PM

i fixed and connected everything on the cooling system last week but, unfortunately, the diaphragm pump i used for liquid circulation is too violent, it acts as hidraulic ram and force the internal baffle of the diffusion pump to vibrate vigorously.

to avoid any risk of damages, i must add something to smooth the hidraulic flux coming from the pump, a water reservoir with an huge air bubble inside should work fine.

This is my solution of the problem, i made a transparent reservoir with a water fountain inside for both aestethical and pratical purposes (i can clearly see if i have a liquid flux or i have occlusion problems)

Ciao!

Fabio.

Re: Diffusion pump project

hboy007, Sun Aug 19 2012, 10:42AM

forgive me for disturbing the dead (threads), I just found an interesting publication on the electron beam induced radiolysis of organic pollutants:

"Boron Nitride Electron Permeable Windows Used In Electron Beam Water Treatment"

Basically, you'd break up organic compounds by direct radiolysis and by introducing free radicals. The radiation dose in the kGy range however seems to be intimidating. Maybe there is something to be learnt in the context of food irradiation, too.

Aromatic compounds can be qualitatively analyzed with aluminium chloride. I'm not asking plazmatron to do the experiment, just wanted to hint to its existence

ps.

At higher energies in conjunction with oxide surfaces, even more intriguing reactions happen, leading to the production of molecular hydrogen:

"Zirconia is thus found to produce high amounts of H2 (Figure 1) [60],

which is due to the scavenging of excitons by adsorbed water molecules, as also shown by

thermostimulated luminescence experiments."

hboy007, Sun Aug 19 2012, 10:42AM

forgive me for disturbing the dead (threads), I just found an interesting publication on the electron beam induced radiolysis of organic pollutants:

"Boron Nitride Electron Permeable Windows Used In Electron Beam Water Treatment"

Basically, you'd break up organic compounds by direct radiolysis and by introducing free radicals. The radiation dose in the kGy range however seems to be intimidating. Maybe there is something to be learnt in the context of food irradiation, too.

Aromatic compounds can be qualitatively analyzed with aluminium chloride. I'm not asking plazmatron to do the experiment, just wanted to hint to its existence

plazmatron wrote ...

Thanks for the link, I was just having a dig myself!

9µ should be easily able to handle the the pressure, the window is only 5mm diameter after all.

I hear that ordinary kitchen foil is around 16µ so 9µ in Ti should be ideal.

Well the diff pump will be used for allsorts of vacuum work, the Lenard tube was something of a diversion

But, since it is a very interesting diversion, it will have to be scaled up a little. I figure a 250kV tube would satisfy my curiosity!

Les

... wrote ...

That is amazing :-o

A little ebay searching turned up some 9um (.3mil!) thick Ti foil, I wonder if it would hold to 15psi or not

What are you planning to do with this new toy?

That is amazing :-o

A little ebay searching turned up some 9um (.3mil!) thick Ti foil, I wonder if it would hold to 15psi or not

What are you planning to do with this new toy?

Thanks for the link, I was just having a dig myself!

9µ should be easily able to handle the the pressure, the window is only 5mm diameter after all.

I hear that ordinary kitchen foil is around 16µ so 9µ in Ti should be ideal.

Well the diff pump will be used for allsorts of vacuum work, the Lenard tube was something of a diversion

But, since it is a very interesting diversion, it will have to be scaled up a little. I figure a 250kV tube would satisfy my curiosity!

Les

ps.

At higher energies in conjunction with oxide surfaces, even more intriguing reactions happen, leading to the production of molecular hydrogen:

"Zirconia is thus found to produce high amounts of H2 (Figure 1) [60],

which is due to the scavenging of excitons by adsorbed water molecules, as also shown by

thermostimulated luminescence experiments."

Re: Diffusion pump project

plazmatron, Sun Aug 19 2012, 02:39PM

Not dead, just slumbering!

Stella mentioned Boron Nitride windows some time back, as possible x-ray windows, since they are very transparent to low energy x-rays, which is one of our interests.

It is expensive stuff though! It is possible for x-rays to use polyethylene, and any number of other light polymers, on a continuously pumped system. Although the electrons and x-rays will destroy the window, they will last long enough to perform a variety of experiments, and are inexpensive enough to be considered consumables.

For electrons, obviously a polymer would be destroyed almost instantly.

Incidentally, the Titanium window I made was much too thin, and ignited from the electron impact in my Lenard tube!

I did however, manage to use ordinary aluminium foil effectively, once I redesigned the tube:

This tube used a carbon fibre cold cathode, and worked extremely well. The camera did not pick up the blue glow as well as the dark adapted eye can, and it extended some 3 cm out from the window at 60kV or so.

These are particularly dangerous devices, and whilst I am happy that I built it, it isn't something I would want to work around to investigate radiochemistry. Low energy x-rays are much, much safer!

Les

plazmatron, Sun Aug 19 2012, 02:39PM

hboy007 wrote ...

forgive me for disturbing the dead (threads), I just found an interesting publication on the electron beam induced radiolysis of organic pollutants:

"Boron Nitride Electron Permeable Windows Used In Electron Beam Water Treatment"

Basically, you'd break up organic compounds by direct radiolysis and by introducing free radicals. The radiation dose in the kGy range however seems to be intimidating. Maybe there is something to be learnt in the context of food irradiation, too.

Aromatic compounds can be qualitatively analyzed with aluminium chloride. I'm not asking plazmatron to do the experiment, just wanted to hint to its existence

forgive me for disturbing the dead (threads), I just found an interesting publication on the electron beam induced radiolysis of organic pollutants:

"Boron Nitride Electron Permeable Windows Used In Electron Beam Water Treatment"

Basically, you'd break up organic compounds by direct radiolysis and by introducing free radicals. The radiation dose in the kGy range however seems to be intimidating. Maybe there is something to be learnt in the context of food irradiation, too.

Aromatic compounds can be qualitatively analyzed with aluminium chloride. I'm not asking plazmatron to do the experiment, just wanted to hint to its existence

Not dead, just slumbering!

Stella mentioned Boron Nitride windows some time back, as possible x-ray windows, since they are very transparent to low energy x-rays, which is one of our interests.

It is expensive stuff though! It is possible for x-rays to use polyethylene, and any number of other light polymers, on a continuously pumped system. Although the electrons and x-rays will destroy the window, they will last long enough to perform a variety of experiments, and are inexpensive enough to be considered consumables.

For electrons, obviously a polymer would be destroyed almost instantly.

Incidentally, the Titanium window I made was much too thin, and ignited from the electron impact in my Lenard tube!

I did however, manage to use ordinary aluminium foil effectively, once I redesigned the tube:

This tube used a carbon fibre cold cathode, and worked extremely well. The camera did not pick up the blue glow as well as the dark adapted eye can, and it extended some 3 cm out from the window at 60kV or so.

These are particularly dangerous devices, and whilst I am happy that I built it, it isn't something I would want to work around to investigate radiochemistry. Low energy x-rays are much, much safer!

Les

Print this page