ETG Development

DYI, Wed Feb 11 2009, 02:15AMThis is going to be an ongoing log of my research involving electrothermal guns. For those who prefer to skip the big words and go right to the pretty pictures, they're at the bottom of the post.

I'll start off here with a little background: I've been interested in ETGs since before Larda posted his 29kJ monster on Spudfiles. My interests have always been directed toward propelling things at the highest speeds I can, and ETGs offer an interesting opportunity in that field: other than the mechanical properties of the chamber, projectile, and barrel, there is really very little limiting the speeds that can be achieved with them, unlike railguns, coilguns, or any chemical propellant systems - when you input more energy, you get more out. My first attempt at an ETG used a mechanical switch and a few camera flash capacitors connected in parallel and couldn't even push the wadding out the barrel. I later obtained a 450V 4900uF electrolytic capacitor and a 1.2kV 7.2kA SCR, and this allowed the old gun to shoot 0.12g airsoft rounds at around 180m/s after tweaking. At this point, my interests and money were directed elsewhere, and when the SCR fried, I put away the ETG.

In December, I regained my interest in the project, and came armed with slightly more knowledge than before. I ballasted a MOT with a 300W lightbulb as a power supply, found four old 400V 3900uF 'lytics, and put together a new airsoft ETG with a more solid design (1/4" machined yellow brass nipples and coupling, 0.257" ID seamless SS tube for a barrel, 1/4" SS rod for the electrode with copper busbar and 4AWG conductors). After the pain and suffering of getting the trigatron switch to trigger at such low voltage, I tested at 400V for a while before I got my 20kOhm 12W bleeder resistors. This produced interesting, but not altogether impressive results. With some work, the gun could just barely pierce 3/16" plywood with one of the 0.12g spheres. After getting the resistors, I rearranged the bank so that all four caps were in series, and tweaked the design extensively. I've tested salt water, tap water, Al, Cu, and steel as "propellants" (I only have 1.6kV right now, not enough to bridge the 3mm gap between the electrode and the chamber wall, so I need something to start up the arc) as well as various wadding methods. Aluminum seems most effective at the moment, as well as being much less messy to work with than salt water. On the better shots (performance degrades quickly via the deposition of oxide layers on the electrode and chamber and the ablation of the spark gap electrodes, and the whole thing needs to be cleaned regularly) the 6mm diameter projectiles will punch 15mm diameter entry holes into plasticine targets, which they can travel about 16mm through at the maximum.

Although this project is still in its infancy, I've gleaned quite a bit of potentially useful information already:

-Plasticine is a VERY GOOD target choice for SMALL guns (the 100kJ muzzle energy gas gun I built in the summer would have gone through a lot of plasticine...). The impact marks on the targets can tell a lot about what happened during the impact. Some pellets will shatter on impact and leave very wide but shallow holes, others will penetrate almost three times their own length and remain somewhat intact (although they do expand by about 1mm around their diameter and flatten into disks). As I lack a chrony, or any other way of accurately measuring speeds at the moment, I can tell which loading parameters extract the most efficiency by observation of the crater size. It's relative measurement, but that is better than no measurement at all.

- El Cheapo 0.12g "Airsoft" rounds are not particularly consistent in their manufacture and not effective as high speed projectiles. 0.25" Delrin rod or spheres would be more suited to the purpose, and I intend to acquire some as soon as is possible (Delrin has extremely high impact resistance and shape retention, and was the choice of insulator in the "sparkplug" for my HE gun project).

-Low voltage ETGs are very finnicky things - while a variation of 1% in the ratio of the fuel:oxidiser mix injected into a combustion gas gun makes no significant difference, small changes in ETG loading can affect muzzle energy by a factor of more than 2. Oxide buildup after a few tens of shots on the center electrode in this test device dropped its performance to the point that it was barely more powerful than a high-end commercial airsoft gun.

-Electrolytic caps should be avoided in favour of pulse capacitors for ETG use. There's no way that any shot I have taken yet has topped 5% overall efficiency (60J). That would equate to 1000m/s. Conveniently enough, I still have a target from the summer that was hit by an airsoft pellet that was measured to be traveling at roughly 1000m/s, so the comparison can be made directly, simply by firing at that target and comparing the effects.

-The "propellant", while important, is really only there for the purpose of starting up the plasma production. After the plasma is established, the remainder of the energy probably goes toward making it hotter. I obviously can't determine this for certain, but a very small (2mm x 15mm) strip of foil (the smallest that I can get to "stick" in the chamber and make solid contact with the electrode) is sufficient for full performance, and performance decreases noticeably with large amounts of conductor present in the chamber.

-For some reason, a slightly damp chamber and electrode is superior to a completely dry chamber or a very wet/completely full of water chamber, assuming that a constant amount of foil is used. Theories in regards to this phenomenon would be appreciated.

-Slight leaks in the chamber cut muzzle energy dramatically. The pressure isn't there for very long, but it's also very hot in the chamber, meaning that the plasma can escape through places that it isn't supposed to very easily.

-While there is probably ringing (I don't have the instrumentation to tell), there is no voltage reversal to speak of in this design. Caps always end up charged to between 200V and 300V after firing. So it would seem that I'm discharging at least 96% of the stored energy through the circuit. How much is being dissipated in the switch? I've no idea. There seem to be a lot of ~50% efficiency figures for trigatrons floating around, so perhaps I'm actually putting about 600J into the chamber of the gun. If these numbers are correct, then 1000m/s would be more like 10% efficient conversion of electricity to kinetic energy.

This brings me to where I am now. I hope to acquire a Chrony in a few weeks for measurement purposes. Pulse caps are definitely in the works, and I'd like to try some non-conductive propellants as well as play with the barrel lengths after I get some real speed data. One interesting idea I've come up with is to use a chamber pressurised with helium, with an insulated electrode in the middle. The pressure puts the breakdown voltage of the gas just above the length of the gap, and to fire the gun, the pressure is dropped via a crazy-fast burst disc valve into the barrel. This would have the beneficial effects of eliminating the switch (and by extension, the switching losses) altogether, as well as pre-accelerating the projectile to some extent before the effects of the pulse hit it, hopefully helping to keep it relatively intact. I am aware that this will require a long barrel, and a LOT more power than I currently have at my disposal to work properly.

And now for the pretty pictures (which should be pretty self-explanatory). No vids as of yet, because without a high speed camera or a massive muzzle blast, there's really not that much to see. All of the impacts shown were done with 0.12g airsoft rounds.

Re: ETG Development

rp181, Wed Feb 11 2009, 02:54AM

As far as electrolytic capacitor's being "slow", i do not think that is your main problem. The main goal right now should be to get a high density LOW temperature plasma in order to conduct the power more effectively. It would probably help if the explosive was enclosed in a low thermal conductivity capsule, but weak enough that the force of the bank will break it. Carbonization of the propellant is bad, it lowers its yield. Look for some research paper's, they are very helpful.

As for a damp chamber making it much more power full ( I have found that the best is to wash it with water, dry the outside, and shake it to get the interior water out. Water in the barrel helps too), It may have something to do with hydrogen oxygen production from the temperature. It also may efficiently convert thermal energy to pressure.

When you use SCR's, beware of the di/dt. I suggest making a rogowski coil.

You need to add some small diodes on there (not to refer to anything). Ring back sometimes happens. I have had a 50v reverse voltage with 6 of those capacitor's. when you move on to higher power version's, clamp the wire's securely.

On another note, This has nothing to do with electromagnetic stuff =p

rp181, Wed Feb 11 2009, 02:54AM

As far as electrolytic capacitor's being "slow", i do not think that is your main problem. The main goal right now should be to get a high density LOW temperature plasma in order to conduct the power more effectively. It would probably help if the explosive was enclosed in a low thermal conductivity capsule, but weak enough that the force of the bank will break it. Carbonization of the propellant is bad, it lowers its yield. Look for some research paper's, they are very helpful.

As for a damp chamber making it much more power full ( I have found that the best is to wash it with water, dry the outside, and shake it to get the interior water out. Water in the barrel helps too), It may have something to do with hydrogen oxygen production from the temperature. It also may efficiently convert thermal energy to pressure.

When you use SCR's, beware of the di/dt. I suggest making a rogowski coil.

You need to add some small diodes on there (not to refer to anything). Ring back sometimes happens. I have had a 50v reverse voltage with 6 of those capacitor's. when you move on to higher power version's, clamp the wire's securely.

On another note, This has nothing to do with electromagnetic stuff =p

Re: ETG Development

DYI, Wed Feb 11 2009, 04:02AM

You don't seem to have read the post very well

There are no explosives involved here.

I have found the exact same that you did in regards to the water - wash chamber interior (removing oxide buildup and assorted other crap), then shake out the chamber to remove any water lying around, then insert Al. foil strip.

As to reverse voltage: I don't intend on going any bigger than this with electrolytics. The only way that I see reverse charging happening with such low voltage caps is using a conductor in the chamber so large that it doesn't even vaporize. Larda hasn't had reverse charging problems, and he's running about as much energy as both of our designs added together and multiplied by ten. I also don't intend on messing about with semiconductor switches - a design like this should concentrate on internal ballistics, and eliminate as many other potential problems as possible. In my book, when compared to solidly built mechanical things, semiconductors count as "potential problems". The pulse capacitors I intend on using for the next stage of the design are rated for enough voltage reversal and a long enough life that I won't be investing in monstrous diodes unless I find some really good deals.

I have to disagree on the pulse length thing considering that, even now, with relatively low muzzle speeds, the projectile is only in the barrel for about 1ms. Electrolytic caps usually have discharge times in the millisecond range. Now what happens if you want, say, 2km/s? A quarter millisecond. I don't know enough about electricity to know for sure, but I'd be willing to place money on the fact that this gun will be more efficient with a 7.5kV pulse cap than it is right now.

And finally, the section this is placed in: I know it isn't strictly electromagnetic, but it is a projectile accelerator, and there have been numerous other ETG threads in this section.

DYI, Wed Feb 11 2009, 04:02AM

You don't seem to have read the post very well

There are no explosives involved here.

I have found the exact same that you did in regards to the water - wash chamber interior (removing oxide buildup and assorted other crap), then shake out the chamber to remove any water lying around, then insert Al. foil strip.

As to reverse voltage: I don't intend on going any bigger than this with electrolytics. The only way that I see reverse charging happening with such low voltage caps is using a conductor in the chamber so large that it doesn't even vaporize. Larda hasn't had reverse charging problems, and he's running about as much energy as both of our designs added together and multiplied by ten. I also don't intend on messing about with semiconductor switches - a design like this should concentrate on internal ballistics, and eliminate as many other potential problems as possible. In my book, when compared to solidly built mechanical things, semiconductors count as "potential problems". The pulse capacitors I intend on using for the next stage of the design are rated for enough voltage reversal and a long enough life that I won't be investing in monstrous diodes unless I find some really good deals.

I have to disagree on the pulse length thing considering that, even now, with relatively low muzzle speeds, the projectile is only in the barrel for about 1ms. Electrolytic caps usually have discharge times in the millisecond range. Now what happens if you want, say, 2km/s? A quarter millisecond. I don't know enough about electricity to know for sure, but I'd be willing to place money on the fact that this gun will be more efficient with a 7.5kV pulse cap than it is right now.

And finally, the section this is placed in: I know it isn't strictly electromagnetic, but it is a projectile accelerator, and there have been numerous other ETG threads in this section.

Re: ETG Development

rp181, Wed Feb 11 2009, 04:10AM

Its just soooo long =p

My excuse will be i was giving suggestion's for your future ETC =p

As for power, look at what i got:

So lardas is only 6 times as powerful =p

If you are interested in pulse caps, check out general atomics energy products. Very good quality, and price is not that bad contrary to what people think (where else can you get a 201kJ pulse capacitor for 20,000$ and 500$ for shipping in the US?)

rp181, Wed Feb 11 2009, 04:10AM

Its just soooo long =p

My excuse will be i was giving suggestion's for your future ETC =p

As for power, look at what i got:

So lardas is only 6 times as powerful =p

If you are interested in pulse caps, check out general atomics energy products. Very good quality, and price is not that bad contrary to what people think (where else can you get a 201kJ pulse capacitor for 20,000$ and 500$ for shipping in the US?)

Re: ETG Development

Electroholic, Wed Feb 11 2009, 06:48AM

if you think they are slow, why dont' you put them in parallel?

Electroholic, Wed Feb 11 2009, 06:48AM

if you think they are slow, why dont' you put them in parallel?

Re: ETG Development

DYI, Wed Feb 11 2009, 10:06PM

GAEP's prices do get quite reasonable at higher power, but have you ever asked them how much a 2kJ capacitor costs? The per-joule cost goes up by a factor of ten. And I really hope that you try that 5.6kJ bank in an ETG too - considering that you now have 4.5 times as many caps as I do, you might be able to get an airsoft round over 1km/s

And to answer Electroholic: while it would seem as though the reduced ESR at 400V would allow for better performance, this is not the case. All four in series is noticeably superior. Perhaps when they're all in parallel the arc doesn't conduct as well? I really don't know the reason behind it.

DYI, Wed Feb 11 2009, 10:06PM

GAEP's prices do get quite reasonable at higher power, but have you ever asked them how much a 2kJ capacitor costs? The per-joule cost goes up by a factor of ten. And I really hope that you try that 5.6kJ bank in an ETG too - considering that you now have 4.5 times as many caps as I do, you might be able to get an airsoft round over 1km/s

And to answer Electroholic: while it would seem as though the reduced ESR at 400V would allow for better performance, this is not the case. All four in series is noticeably superior. Perhaps when they're all in parallel the arc doesn't conduct as well? I really don't know the reason behind it.

Re: ETG Development

mnr, Wed Feb 11 2009, 11:04PM

Your circuit can be modeled as a simple RC discharge circuit (stray L will not have a very pronounced effect on your current setup). When the capacitors are in parallel, this will increase the total capacitance, resulting in a longer discharge time constant. With capacitors in series this will give a higher peak power by allowing for a shorter discharge time (assuming the capacitor ESR is much less than the rest of the loop resistance). It can be inferred from your experimental data that the resistance of your connections, bus bars, chamber, and propellant is much greater than all of your capacitors ESR's added in series.

mnr, Wed Feb 11 2009, 11:04PM

DYI wrote ...

And to answer Electroholic: while it would seem as though the reduced ESR at 400V would allow for better performance, this is not the case. All four in series is noticeably superior. Perhaps when they're all in parallel the arc doesn't conduct as well? I really don't know the reason behind it.

And to answer Electroholic: while it would seem as though the reduced ESR at 400V would allow for better performance, this is not the case. All four in series is noticeably superior. Perhaps when they're all in parallel the arc doesn't conduct as well? I really don't know the reason behind it.

Your circuit can be modeled as a simple RC discharge circuit (stray L will not have a very pronounced effect on your current setup). When the capacitors are in parallel, this will increase the total capacitance, resulting in a longer discharge time constant. With capacitors in series this will give a higher peak power by allowing for a shorter discharge time (assuming the capacitor ESR is much less than the rest of the loop resistance). It can be inferred from your experimental data that the resistance of your connections, bus bars, chamber, and propellant is much greater than all of your capacitors ESR's added in series.

Re: ETG Development

rp181, Wed Feb 11 2009, 11:46PM

All the parts for a railgun arrived (garolite enclosure!) so that will occupy my time. Ile try it when i get tired of sanding though.

EDIT: I tried it with my setup i told you about earlier, at 330 volts. My camera died right before doing it, so no video. This was LOUD. After the shot, the vent pipe's where audibly shaking. The 12 AWG copper electrode completely vaporised, and before one electrode could be used for a long time with sanding.

rp181, Wed Feb 11 2009, 11:46PM

All the parts for a railgun arrived (garolite enclosure!) so that will occupy my time. Ile try it when i get tired of sanding though.

EDIT: I tried it with my setup i told you about earlier, at 330 volts. My camera died right before doing it, so no video. This was LOUD. After the shot, the vent pipe's where audibly shaking. The 12 AWG copper electrode completely vaporised, and before one electrode could be used for a long time with sanding.

Re: ETG Development

DYI, Thu Feb 12 2009, 01:16AM

Excellent!I hope you do it again, and get a video of it. What were the target and projectile for that test, and how did they fare? Would that be 3.8kJ of energy you discharged there?

I'm surprised that my caps have lasted so long, considering the fast discharges and use at 430V... I suppose that the infrequent use and lack of voltage reversal probably contribute to their continued survival.

DYI, Thu Feb 12 2009, 01:16AM

Excellent!I hope you do it again, and get a video of it. What were the target and projectile for that test, and how did they fare? Would that be 3.8kJ of energy you discharged there?

I'm surprised that my caps have lasted so long, considering the fast discharges and use at 430V... I suppose that the infrequent use and lack of voltage reversal probably contribute to their continued survival.

Re: ETG Development

rp181, Thu Feb 12 2009, 01:24AM

Dry shot, just foil dropping into the electrode, And yes, 3.8kJ. After the shot, there was 73v left in the bank. Camera is charging right now.

Your capacitor's will last quite awhile, The fact that there not being rapid pulsed helps alot.

On a offtopic note, certain people have been wondering where you where, so if anyone asks, your in narnia =)

rp181, Thu Feb 12 2009, 01:24AM

Dry shot, just foil dropping into the electrode, And yes, 3.8kJ. After the shot, there was 73v left in the bank. Camera is charging right now.

Your capacitor's will last quite awhile, The fact that there not being rapid pulsed helps alot.

On a offtopic note, certain people have been wondering where you where, so if anyone asks, your in narnia =)

Re: ETG Development

DYI, Thu Feb 12 2009, 02:39AM

Ah, dropping foil. I'm really hoping that you used something more remote than needlenose pliers for that...

73V left is almost exactly in line with what I'm getting: 96% discharge of the caps. I just tried wetting the barrel interior as well as the chamber, and while the crater in the target was excavated to roughly the same depth that it usually is, it was only 11mm wide. After that, I took one more shot with regular loading parameters, and results were in line with what was recorded yesterday. Maybe the discrepancy between our results lies in the voltage used? I still haven't heard any great explanation of why the damp chamber walls improve performance.

On the off-topic note you brought up, certain people could have figured out how to contact me if they really wanted to. I've heard that Spudfiles is degrading, but I don't have anything to contribute there right now.

DYI, Thu Feb 12 2009, 02:39AM

Ah, dropping foil. I'm really hoping that you used something more remote than needlenose pliers for that...

73V left is almost exactly in line with what I'm getting: 96% discharge of the caps. I just tried wetting the barrel interior as well as the chamber, and while the crater in the target was excavated to roughly the same depth that it usually is, it was only 11mm wide. After that, I took one more shot with regular loading parameters, and results were in line with what was recorded yesterday. Maybe the discrepancy between our results lies in the voltage used? I still haven't heard any great explanation of why the damp chamber walls improve performance.

On the off-topic note you brought up, certain people could have figured out how to contact me if they really wanted to. I've heard that Spudfiles is degrading, but I don't have anything to contribute there right now.

Re: ETG Development

rp181, Thu Feb 12 2009, 02:49AM

I drilled a hole in the side of the barrel, and stick in a piece of 12AWG wire. I attached a string to it, and the foil rests on top. Pull the string, and BOOM! The disadvantage of this is that the barrel has to be at a steep angle, even more if the barrel is wet. I also setup a pneumatic piston to drop it in, but that was way more complicated then it needed to be. My only complaint about my current method is that some plasma escapes from it. Look at [ETG 2, ETG] on my site, you can see it in some of the stills.

My power was also limited by the fact my connection's where steel. I did not want to ruin the 1/0 AWG cable, so i put a steel bolt on, and hose clamped that to the (steel) barrel.

I think the voltage left in the bank could be two things:

1) ringback. I am going to install a diode and see what happens.

2) Plasma exit velocity. Our design looks very similar in size. Maybe having a flow choke will allow all the power to empty.

I will try to get a shot in tomorrow, but i have to limit myself to 2 shots a day. My mom yells at the noise (even if its JUST my injection system). I will record that. I have had problems with the video washing out even at lower powers. How would a polarized screen (for laptops) placed in front of it affect it?

OT: agreed =) oddly enough, a topic like that appeared here.

rp181, Thu Feb 12 2009, 02:49AM

I drilled a hole in the side of the barrel, and stick in a piece of 12AWG wire. I attached a string to it, and the foil rests on top. Pull the string, and BOOM! The disadvantage of this is that the barrel has to be at a steep angle, even more if the barrel is wet. I also setup a pneumatic piston to drop it in, but that was way more complicated then it needed to be. My only complaint about my current method is that some plasma escapes from it. Look at [ETG 2, ETG] on my site, you can see it in some of the stills.

My power was also limited by the fact my connection's where steel. I did not want to ruin the 1/0 AWG cable, so i put a steel bolt on, and hose clamped that to the (steel) barrel.

I think the voltage left in the bank could be two things:

1) ringback. I am going to install a diode and see what happens.

2) Plasma exit velocity. Our design looks very similar in size. Maybe having a flow choke will allow all the power to empty.

I will try to get a shot in tomorrow, but i have to limit myself to 2 shots a day. My mom yells at the noise (even if its JUST my injection system). I will record that. I have had problems with the video washing out even at lower powers. How would a polarized screen (for laptops) placed in front of it affect it?

OT: agreed =) oddly enough, a topic like that appeared here.

Re: ETG Development

DYI, Thu Feb 12 2009, 03:37AM

How much damage do you really think that steel connections will do to energy transfer? I don't have accurate enough instrumentation to detect the differences in resistance between steel bolts, copper wires, and copper busbar (which are all alarmingly high, if my $20 multimeter is to be believed...).

About the ringback: why would the remaining charge always be in the correct polarity if ringback was the culprit? I'm more inclined toward believing #2, but I'm going to work on reducing the massive losses from my switch before I go worrying about 4% losses from something like plasma exit speed.

The washed out video could be difficult to fix, especially if it is caused by muzzle flash (and not the trigatron, which is what's causing it in my case). Taking the setup outside could reduce the problem, or using bright lighting. Theres not really much to see on the first frame anyway, unless you're using a Casio Exilim or something better for recording it.

That's too bad about the noise. It isn't much of an issue here - as long as the neighbours don't call asking about it, my parents are happy.

DYI, Thu Feb 12 2009, 03:37AM

How much damage do you really think that steel connections will do to energy transfer? I don't have accurate enough instrumentation to detect the differences in resistance between steel bolts, copper wires, and copper busbar (which are all alarmingly high, if my $20 multimeter is to be believed...).

About the ringback: why would the remaining charge always be in the correct polarity if ringback was the culprit? I'm more inclined toward believing #2, but I'm going to work on reducing the massive losses from my switch before I go worrying about 4% losses from something like plasma exit speed.

The washed out video could be difficult to fix, especially if it is caused by muzzle flash (and not the trigatron, which is what's causing it in my case). Taking the setup outside could reduce the problem, or using bright lighting. Theres not really much to see on the first frame anyway, unless you're using a Casio Exilim or something better for recording it.

That's too bad about the noise. It isn't much of an issue here - as long as the neighbours don't call asking about it, my parents are happy.

Re: ETG Development

rp181, Thu Feb 12 2009, 04:15AM

Its not just the fact that is was steel, but also it is a threaded rod connecting to round object. That means very low contact area. My neighbor's are not the problem (they didn't say anything when there backyard was filled with smoke), My mom just thinks im destroying the house.

I can't say much about the resistance, my multimeter is a 10$ one with the resistance function not working =)

Tomorrow i will try a bit of steel rod as a projectile aiming at 1/4" particle board after i machine some stuff for the railgun at school.

rp181, Thu Feb 12 2009, 04:15AM

Its not just the fact that is was steel, but also it is a threaded rod connecting to round object. That means very low contact area. My neighbor's are not the problem (they didn't say anything when there backyard was filled with smoke), My mom just thinks im destroying the house.

I can't say much about the resistance, my multimeter is a 10$ one with the resistance function not working =)

Tomorrow i will try a bit of steel rod as a projectile aiming at 1/4" particle board after i machine some stuff for the railgun at school.

Re: ETG Development

rp181, Thu Feb 12 2009, 10:35PM

So i just did another ETG shot, and recorded. This shot was alot worse, and ended up with 110v at the end, as the connection werent secure enough. This shot had alot more smoke than usualy, but not as much plasma.

Video:

oops, double post. merge unless no one really cares.

rp181, Thu Feb 12 2009, 10:35PM

So i just did another ETG shot, and recorded. This shot was alot worse, and ended up with 110v at the end, as the connection werent secure enough. This shot had alot more smoke than usualy, but not as much plasma.

Video:

oops, double post. merge unless no one really cares.

Re: ETG Development

DYI, Sat Feb 14 2009, 03:00AM

Rp181, if you could get a DECENT video of a shot at a TARGET with a PROJECTILE, it would be much appreciated . One needs a very big gun indeed before watching it fire is even remotely as entertaining as seeing what happened to the target.

. One needs a very big gun indeed before watching it fire is even remotely as entertaining as seeing what happened to the target.

There's not a whole lot more I can do until I get a new chrony, or miraculously find a high voltage energy discharge capacitor around here somewhere (that doesn't cost thousands of dollars).

Also, I've noticed that this thread has become more of a dialogue than a multi-party discussion. Does anyone else here have some experience in this field?

DYI, Sat Feb 14 2009, 03:00AM

Rp181, if you could get a DECENT video of a shot at a TARGET with a PROJECTILE, it would be much appreciated

. One needs a very big gun indeed before watching it fire is even remotely as entertaining as seeing what happened to the target.

. One needs a very big gun indeed before watching it fire is even remotely as entertaining as seeing what happened to the target.There's not a whole lot more I can do until I get a new chrony, or miraculously find a high voltage energy discharge capacitor around here somewhere (that doesn't cost thousands of dollars).

Also, I've noticed that this thread has become more of a dialogue than a multi-party discussion. Does anyone else here have some experience in this field?

Re: ETG Development

rp181, Sat Feb 14 2009, 03:29AM

Not to continue the dialog, but here it is:

I am currently sitting in the basement, with the rogowski coil connected to the laptop. I fired off a shot (very suckish), and the Coil peaked up AND down. There ther was a up peak, down peak, goes midway from top and mid, back up to the top, and down to zero. That means massive ringing, or a issue with the coil (worked fine for 1 capacitor). Does it affect the coil if the cable goe through the center, and the cathode is right outside of the coil?

I am doing another shot now.

rp181, Sat Feb 14 2009, 03:29AM

Not to continue the dialog, but here it is:

I am currently sitting in the basement, with the rogowski coil connected to the laptop. I fired off a shot (very suckish), and the Coil peaked up AND down. There ther was a up peak, down peak, goes midway from top and mid, back up to the top, and down to zero. That means massive ringing, or a issue with the coil (worked fine for 1 capacitor). Does it affect the coil if the cable goe through the center, and the cathode is right outside of the coil?

I am doing another shot now.

Re: ETG Development

j.azz, Sat Feb 14 2009, 06:19PM

Well, some years ago I built an ETG but it was too small to say that I really gained experience that could be useful for high power devices.

I discharged some paralled caps of an electric fence device (about 30J @ 1200V iirc) into a small 1Ohm resistor placed inside a plastic tube of a pen.

It could launch wet paper balls about 10 meters, so not very spectacular.

But I found out that at higher power with lower voltage (200J @ 360V, electrolytics), the discharge, though exploding the whole pen, seemed too long to transfer more power to the projectile.

When the hot phase in university has cooled down, I would be eager to do some more research with more power...

greetz, j.azz

j.azz, Sat Feb 14 2009, 06:19PM

DYI wrote ...

Also, I've noticed that this thread has become more of a dialogue than a multi-party discussion. Does anyone else here have some experience in this field?

Also, I've noticed that this thread has become more of a dialogue than a multi-party discussion. Does anyone else here have some experience in this field?

Well, some years ago I built an ETG but it was too small to say that I really gained experience that could be useful for high power devices.

I discharged some paralled caps of an electric fence device (about 30J @ 1200V iirc) into a small 1Ohm resistor placed inside a plastic tube of a pen.

It could launch wet paper balls about 10 meters, so not very spectacular.

But I found out that at higher power with lower voltage (200J @ 360V, electrolytics), the discharge, though exploding the whole pen, seemed too long to transfer more power to the projectile.

When the hot phase in university has cooled down, I would be eager to do some more research with more power...

greetz, j.azz

Re: ETG Development

DYI, Sun Feb 15 2009, 04:43AM

I tried a longer barrel today: 60" long, instead of the 10" one I'd been using before. While there would be sufficient pressure in the chamber to allow for a barrel this long at room temperature, it seems as though enough heat is lost through the barrel walls to ruin the muzzle energy. It would be interesting to see which barrel length optimizes muzzle energy for a given projectile here, but in my case that just isn't possible (such small bores necessitate the shipping of tubes across the border, and that just isn't fun at all). If someone could throw together a multi-kilojoule system, commonly available copper pipes could be used for barrels, and the barrel lengths adjusted easily. This much energy is not currently within my grasp.

Assuming that I'm right in the middle of my "plausible muzzle speed range", I'm guesstimating the chamber pressure at around 100bar, although it would depend to some extent on how hot it is in there.

DYI, Sun Feb 15 2009, 04:43AM

I tried a longer barrel today: 60" long, instead of the 10" one I'd been using before. While there would be sufficient pressure in the chamber to allow for a barrel this long at room temperature, it seems as though enough heat is lost through the barrel walls to ruin the muzzle energy. It would be interesting to see which barrel length optimizes muzzle energy for a given projectile here, but in my case that just isn't possible (such small bores necessitate the shipping of tubes across the border, and that just isn't fun at all). If someone could throw together a multi-kilojoule system, commonly available copper pipes could be used for barrels, and the barrel lengths adjusted easily. This much energy is not currently within my grasp.

Assuming that I'm right in the middle of my "plausible muzzle speed range", I'm guesstimating the chamber pressure at around 100bar, although it would depend to some extent on how hot it is in there.

Re: ETG Development

rp181, Sun Feb 15 2009, 06:51PM

I did another shot, this time with a target. No video this time, battery died again =( This shot was the weakest yet, with 120v remaining after fired. The projectile was a small screw, and the target a sheet of 1/8" acrylic. It did not penetrate, but gave a spider-web crack about 2" in diameter. Next to the main target crater, there was another small one, I am attributing this to the foil being launched out. That means it is not vaporizing all of the foil. I presume that the weak power is due to several reasons:

1) electrode vaporizing

2)Electrode shooting out, which leaves another hole for the exhaust

3) hole in the side of the barrel used for triggering

I did however get a interesting rogowski coil shot.

This was with the anti- parallel diode.It is good news that it maxed out though, With integration. With a single capacitor and passive integration, the peak was below the first vertical div. I was put off by the long pulse time (almost 2ms). How is your pulse time?

I just now got my railgun enclosure to fit together, so that will occupy my time. My dad also saw the video of the ETG, and thought it would catch the house on fire =/

rp181, Sun Feb 15 2009, 06:51PM

I did another shot, this time with a target. No video this time, battery died again =( This shot was the weakest yet, with 120v remaining after fired. The projectile was a small screw, and the target a sheet of 1/8" acrylic. It did not penetrate, but gave a spider-web crack about 2" in diameter. Next to the main target crater, there was another small one, I am attributing this to the foil being launched out. That means it is not vaporizing all of the foil. I presume that the weak power is due to several reasons:

1) electrode vaporizing

2)Electrode shooting out, which leaves another hole for the exhaust

3) hole in the side of the barrel used for triggering

I did however get a interesting rogowski coil shot.

This was with the anti- parallel diode.It is good news that it maxed out though, With integration. With a single capacitor and passive integration, the peak was below the first vertical div. I was put off by the long pulse time (almost 2ms). How is your pulse time?

I just now got my railgun enclosure to fit together, so that will occupy my time. My dad also saw the video of the ETG, and thought it would catch the house on fire =/

Re: ETG Development

DYI, Mon Feb 16 2009, 01:03AM

I'm guessing that the launcher is too leaky, and uses insufficient voltage. Although I haven't tried it, I'd be pretty confident in my ETG's ability to put a pointed steel projectile through 1/8" acrylic, or at least to come close (although, in fairness, I've done a LOT more tweaking than you've had the chance to).

I'm probably not reading this this right, but it looks on that readout like the reversal is larger than the initial pulse... What is that initial downward spike?

DYI, Mon Feb 16 2009, 01:03AM

I'm guessing that the launcher is too leaky, and uses insufficient voltage. Although I haven't tried it, I'd be pretty confident in my ETG's ability to put a pointed steel projectile through 1/8" acrylic, or at least to come close (although, in fairness, I've done a LOT more tweaking than you've had the chance to).

I'm probably not reading this this right, but it looks on that readout like the reversal is larger than the initial pulse... What is that initial downward spike?

Re: ETG Development

rp181, Mon Feb 16 2009, 01:09AM

just flip it on the X axis. The direction of the pulse spike depends on which way the current is traveling through the coil.

rp181, Mon Feb 16 2009, 01:09AM

just flip it on the X axis. The direction of the pulse spike depends on which way the current is traveling through the coil.

Re: ETG Development

DYI, Sat Feb 21 2009, 03:01AM

Flipping it on the x-axis doesn't fix any problem, the second spike is still bigger than the first.

In other news, I've obtained a small pulse capacitor (7.5kV, 16uF). While I don't have the equipment to charge it to full power or accurately monitor its charge level yet (I still need to build a voltage divider, get a new meter, and scavenge at least two more MOTs), the initial results at only 100J (or thereabouts, I can't tell right now ) are quite promising. While it is not as powerful as the 1.3kJ electrolytic version yet, I think that's to be expected.

) are quite promising. While it is not as powerful as the 1.3kJ electrolytic version yet, I think that's to be expected.

I'll try to update this thread after I get the equipment I need to test the new version properly.

DYI, Sat Feb 21 2009, 03:01AM

Flipping it on the x-axis doesn't fix any problem, the second spike is still bigger than the first.

In other news, I've obtained a small pulse capacitor (7.5kV, 16uF). While I don't have the equipment to charge it to full power or accurately monitor its charge level yet (I still need to build a voltage divider, get a new meter, and scavenge at least two more MOTs), the initial results at only 100J (or thereabouts, I can't tell right now

) are quite promising. While it is not as powerful as the 1.3kJ electrolytic version yet, I think that's to be expected.

) are quite promising. While it is not as powerful as the 1.3kJ electrolytic version yet, I think that's to be expected.I'll try to update this thread after I get the equipment I need to test the new version properly.

Re: ETG Development

rp181, Sat Feb 21 2009, 04:25AM

My theory on the rogowski coil is that the limits are different. So the upper limit is not equidistant from zero to the lower limit. The railgun will be fired tomorrow, so i will see how the coil readout comes.

rp181, Sat Feb 21 2009, 04:25AM

My theory on the rogowski coil is that the limits are different. So the upper limit is not equidistant from zero to the lower limit. The railgun will be fired tomorrow, so i will see how the coil readout comes.

Re: ETG Development

DYI, Fri Mar 06 2009, 11:40PM

As was mentioned on the "ETG theoretical efficiency" thread a few days ago, I rebuilt my ETG to have almost no chamber volume (20 cubic millimetres). Results of that reconfiguration, in terms of performance, were quite promising. At 300J, this design produced similar effects to what was done by the one shown at the top of the page at 1300J, with no other changes.

Unfortunately, the new design builds enough chamber pressure that my simple epoxied electrode designs are not holding together very well. Both attempts cracked severely and immediately. I won't be doing any more testing now until I can access a lathe and make a proper test chamber from brass and Teflon. This may happen as early as two weeks from now, depending on circumstances. At that point, I should also have my voltage divider and charging circuit built as well.

Actual muzzle speed measurements may be attempted within a month, but I won't be releasing them directly because of my fear that they could fall into the wrong hands.

DYI, Fri Mar 06 2009, 11:40PM

As was mentioned on the "ETG theoretical efficiency" thread a few days ago, I rebuilt my ETG to have almost no chamber volume (20 cubic millimetres). Results of that reconfiguration, in terms of performance, were quite promising. At 300J, this design produced similar effects to what was done by the one shown at the top of the page at 1300J, with no other changes.

Unfortunately, the new design builds enough chamber pressure that my simple epoxied electrode designs are not holding together very well. Both attempts cracked severely and immediately. I won't be doing any more testing now until I can access a lathe and make a proper test chamber from brass and Teflon. This may happen as early as two weeks from now, depending on circumstances. At that point, I should also have my voltage divider and charging circuit built as well.

Actual muzzle speed measurements may be attempted within a month, but I won't be releasing them directly because of my fear that they could fall into the wrong hands.

Re: ETG Development

DYI, Thu Jul 09 2009, 10:48PM

Well, I've finally got around to doing some proper research and spent some time building a sturdy, well designed chamber. I'm still using very low energy, in the 100 - 300J range, as I will be for quite a while yet, but I have made some tangible progress - efficiency has climbed to around 10% (although I still haven't managed to measure anything directly).

The reason that the wetted chamber walls increased efficiency was the contribution that steam made to the propelling gas (the hot aluminum plasma ablates the water clinging to the chamber walls), and the reason for decreased efficiency with a chamber full of water was heat loss to the un-vaporized water. Aluminum plasma alone loses heat too quickly to the chamber walls and barrel, and its molecular weight is too high to make it an effective propellant gas. Instead, the plasma should be used to heat something that will produce a gas with a low molecular weight and high speed of sound

Switching to a simple capillary tube plasma generator from the old "electrode in center of chamber" design, and reducing the chamber volume to something in the neighborhood of 200 cubic millimetres has made the efficiency increase possible. However, the fact that I need something on the order of 5mg of water in the chamber has made experimentation with other working fluids difficult. If anyone is interested, I'll post the chamber design for the 10% efficient version.

DYI, Thu Jul 09 2009, 10:48PM

Well, I've finally got around to doing some proper research and spent some time building a sturdy, well designed chamber. I'm still using very low energy, in the 100 - 300J range, as I will be for quite a while yet, but I have made some tangible progress - efficiency has climbed to around 10% (although I still haven't managed to measure anything directly).

The reason that the wetted chamber walls increased efficiency was the contribution that steam made to the propelling gas (the hot aluminum plasma ablates the water clinging to the chamber walls), and the reason for decreased efficiency with a chamber full of water was heat loss to the un-vaporized water. Aluminum plasma alone loses heat too quickly to the chamber walls and barrel, and its molecular weight is too high to make it an effective propellant gas. Instead, the plasma should be used to heat something that will produce a gas with a low molecular weight and high speed of sound

Switching to a simple capillary tube plasma generator from the old "electrode in center of chamber" design, and reducing the chamber volume to something in the neighborhood of 200 cubic millimetres has made the efficiency increase possible. However, the fact that I need something on the order of 5mg of water in the chamber has made experimentation with other working fluids difficult. If anyone is interested, I'll post the chamber design for the 10% efficient version.

Re: ETG Development

Gunner, Thu Jul 16 2009, 04:46PM

I would like to see you design :)

Gunner, Thu Jul 16 2009, 04:46PM

I would like to see you design :)

Re: ETG Development

DYI, Sun Jul 19 2009, 08:29PM

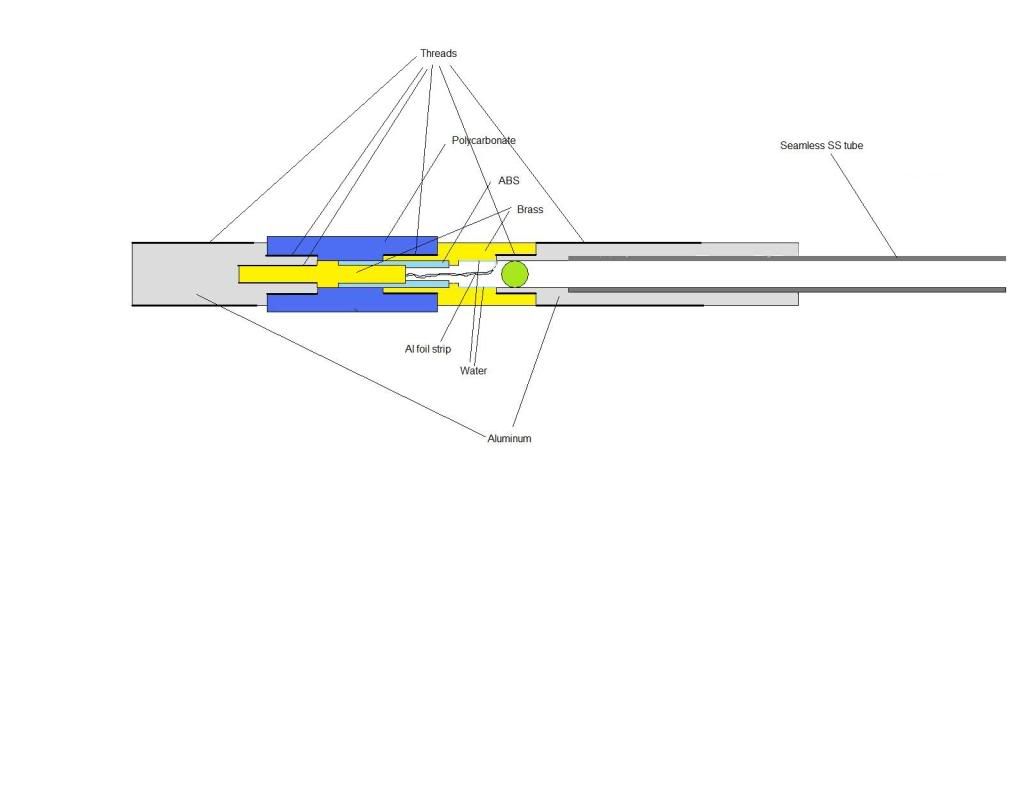

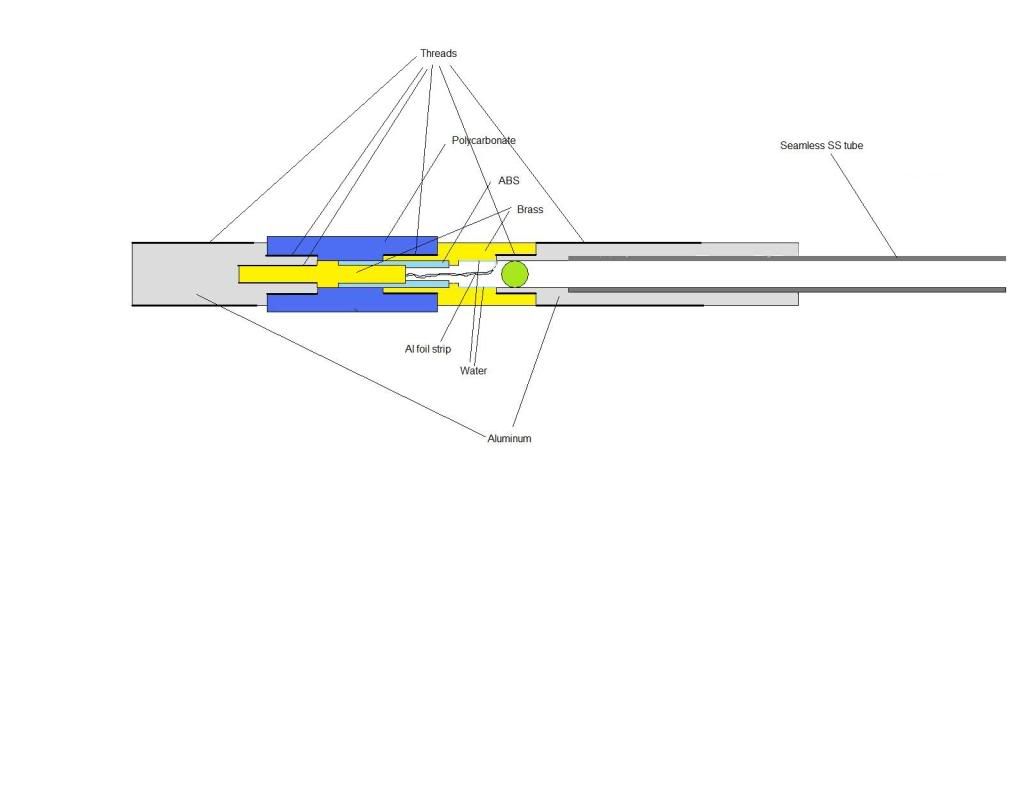

Here's the basic design:

The barrel is a slip fit connection. When I had problems with it detaching, I made a similar looking part out of 30mm diameter aluminum rod, and drilled and tapped holes which extend to the center hole. Bolts thread into these holes and are tightened, firmly holding the barrel in place.

And now a few impact marks with the new design. All were done using 0.12g airsoft rounds:

This next one has an unused round in the crater for comparison:

DYI, Sun Jul 19 2009, 08:29PM

Here's the basic design:

The barrel is a slip fit connection. When I had problems with it detaching, I made a similar looking part out of 30mm diameter aluminum rod, and drilled and tapped holes which extend to the center hole. Bolts thread into these holes and are tightened, firmly holding the barrel in place.

And now a few impact marks with the new design. All were done using 0.12g airsoft rounds:

This next one has an unused round in the crater for comparison:

Re: ETG Development

Gunner, Tue Jul 21 2009, 12:38PM

Do you have any ideas of output velocity?

Gunner, Tue Jul 21 2009, 12:38PM

Do you have any ideas of output velocity?

Re: ETG Development

rp181, Tue Jul 21 2009, 03:36PM

Thats what you mean by capilary plasma injection. I have seen that before, but it was reffered to with different names. I made a design for a high power version a while back. This one was not intended to fire a projectile, but study the plasma with a high speed camera. It has a replacable plastic linear, that requires minimal machining.

wires screw inbetween the two red pieces (copper), come out, and tighten beneath the aluminum casing and cap.

EDIT: forgot to mention, for size, the red pieces are .5" diameter, and the widest diameter is 1.5".

rp181, Tue Jul 21 2009, 03:36PM

Thats what you mean by capilary plasma injection. I have seen that before, but it was reffered to with different names. I made a design for a high power version a while back. This one was not intended to fire a projectile, but study the plasma with a high speed camera. It has a replacable plastic linear, that requires minimal machining.

wires screw inbetween the two red pieces (copper), come out, and tighten beneath the aluminum casing and cap.

EDIT: forgot to mention, for size, the red pieces are .5" diameter, and the widest diameter is 1.5".

Re: ETG Development

DYI, Wed Jul 22 2009, 04:11AM

With further research, I have gained further insight. The writers of one of the papers from the 13th EML symposium had a setup almost identical to mine, and it incorporated a few points I will likely test with the "ETAv2" (Electro-Thermal Accelerator - because it's really not a gun in all but the loosest sense of the word).

1. My capillary tubes are way too short - I've got 10mm, and this paper tests two tube lengths - 23mm, and 38mm. They used 600J maximum, so I think it would be safe to assume that increasing the length of the tubes I use by a factor of two would be unlikely to damage performance, and may in fact improve it.

2. Lower diameter is, as I assumed, better in capillary tubes. Their study indicated that ablated mass increased with decreasing capillary diameter for a given energy level. In this vein, I may try decreasing diameter to 2.5mm, or even 2mm (a trivial change in the case of my design, requiring no major modifications, and it only makes machining the things easier, as does an increase in length).

3. The cathode/nozzle. There's was 4mm in diameter (for testing 3mm and 4.5mm ID tubes), and made of a tantalum/tungsten alloy. I haven't checked the shop yet, but there's a good chance that I don't have any tantalum/tungsten bar stock left over from my previous projects (no dense metals at all, unless you count those M829A3 rounds in the storage bin...). I don't think this will be a problem at the moment, but I may have to upgrade to a tungsten alloy cathode later on, when I eventually get more energy to play around with. My wallet shudders at the thought...

4. The anode. They used a carbon disk to protect the brass anode from ablation. Apparently the carbon disk suffers almost no ablation at all, which also reduced the number of variables in their experiments. This is another factor which hasn't bothered me much yet, but which may become nasty at higher energies. However, I would likely use a copper or brass disk instead, simply to avoid having to machine complex parts every other shot - it's certainly cheaper than a tungsten anode. Carbon introduces very significant resistance, and it sounds a bit too explodey for my liking.

I feel that I can also make an improvement to the working fluid and its ablation. If anyone has ideas for turning the water or another suitable working fluid into a low density foam or similar, they would be greatly appreciated. The current setup simply wets the chamber walls and saturates the paper towel wadding with water. This works (the chamber and wadding remains are reasonably dry after a shot), but I feel that it could definitely be improved. Areas of further study will include optimizing barrel length, efficiency changes with different projectile masses, and what maximum speed I can obtain with this supply before I am forced to upgrade. An even smaller bore to allow ridiculous muzzle speeds with insignificant chunks of plastic (~50mg) is also being considered. This would, of course, happen after I come up with a way to actually measure the muzzle speed :p . 20% efficiency is my goal, and it is looking more reachable all the time.

DYI, Wed Jul 22 2009, 04:11AM

With further research, I have gained further insight. The writers of one of the papers from the 13th EML symposium had a setup almost identical to mine, and it incorporated a few points I will likely test with the "ETAv2" (Electro-Thermal Accelerator - because it's really not a gun in all but the loosest sense of the word).

1. My capillary tubes are way too short - I've got 10mm, and this paper tests two tube lengths - 23mm, and 38mm. They used 600J maximum, so I think it would be safe to assume that increasing the length of the tubes I use by a factor of two would be unlikely to damage performance, and may in fact improve it.

2. Lower diameter is, as I assumed, better in capillary tubes. Their study indicated that ablated mass increased with decreasing capillary diameter for a given energy level. In this vein, I may try decreasing diameter to 2.5mm, or even 2mm (a trivial change in the case of my design, requiring no major modifications, and it only makes machining the things easier, as does an increase in length).

3. The cathode/nozzle. There's was 4mm in diameter (for testing 3mm and 4.5mm ID tubes), and made of a tantalum/tungsten alloy. I haven't checked the shop yet, but there's a good chance that I don't have any tantalum/tungsten bar stock left over from my previous projects (no dense metals at all, unless you count those M829A3 rounds in the storage bin...). I don't think this will be a problem at the moment, but I may have to upgrade to a tungsten alloy cathode later on, when I eventually get more energy to play around with. My wallet shudders at the thought...

4. The anode. They used a carbon disk to protect the brass anode from ablation. Apparently the carbon disk suffers almost no ablation at all, which also reduced the number of variables in their experiments. This is another factor which hasn't bothered me much yet, but which may become nasty at higher energies. However, I would likely use a copper or brass disk instead, simply to avoid having to machine complex parts every other shot - it's certainly cheaper than a tungsten anode. Carbon introduces very significant resistance, and it sounds a bit too explodey for my liking.

I feel that I can also make an improvement to the working fluid and its ablation. If anyone has ideas for turning the water or another suitable working fluid into a low density foam or similar, they would be greatly appreciated. The current setup simply wets the chamber walls and saturates the paper towel wadding with water. This works (the chamber and wadding remains are reasonably dry after a shot), but I feel that it could definitely be improved. Areas of further study will include optimizing barrel length, efficiency changes with different projectile masses, and what maximum speed I can obtain with this supply before I am forced to upgrade. An even smaller bore to allow ridiculous muzzle speeds with insignificant chunks of plastic (~50mg) is also being considered. This would, of course, happen after I come up with a way to actually measure the muzzle speed :p . 20% efficiency is my goal, and it is looking more reachable all the time.

Re: ETG Development

Reid, Thu Jul 23 2009, 10:14PM

here's an idea for a DIY chrony, it'll need some modifications depending on the ammount on noise produced by the ETG firing and the projectile impact, bit it will give you a good idea of (downrange) speed.

disclaimer....

yes, I am the author of this 'ible, but it can definitely be made to work.

good luck and good work, I'll definitely be building an ETG next!

Reid, Thu Jul 23 2009, 10:14PM

here's an idea for a DIY chrony, it'll need some modifications depending on the ammount on noise produced by the ETG firing and the projectile impact, bit it will give you a good idea of (downrange) speed.

disclaimer....

yes, I am the author of this 'ible, but it can definitely be made to work.

good luck and good work, I'll definitely be building an ETG next!

Re: ETG Development

DYI, Mon Jul 27 2009, 11:18PM

Here's the problem with a sound-based system: airsoft rounds moving at this kind of speed will slow down at a very high rate. Measured over a large enough distance to separate the two noises, the result will be a reading lower than the actual muzzle speed. And I don't aim on getting into ballistics modeling to obtain results from the apparatus, so this option seems unlikely to be used.

My current idea is a ballistic pendulum. While it may not be accurate enough for fine-tuning, I will be able to get a reasonable idea of the speeds involved, and characterize the crater formation properties with increasing impact speed. If money and equipment allows, I will eventually build a very accurate wire break based system to do the fine-tuning. This will likely be necessary to reach my 20% efficiency goal (the current estimate of system efficiency lies around 10%, but it is only a guess at the moment).

DYI, Mon Jul 27 2009, 11:18PM

Here's the problem with a sound-based system: airsoft rounds moving at this kind of speed will slow down at a very high rate. Measured over a large enough distance to separate the two noises, the result will be a reading lower than the actual muzzle speed. And I don't aim on getting into ballistics modeling to obtain results from the apparatus, so this option seems unlikely to be used.

My current idea is a ballistic pendulum. While it may not be accurate enough for fine-tuning, I will be able to get a reasonable idea of the speeds involved, and characterize the crater formation properties with increasing impact speed. If money and equipment allows, I will eventually build a very accurate wire break based system to do the fine-tuning. This will likely be necessary to reach my 20% efficiency goal (the current estimate of system efficiency lies around 10%, but it is only a guess at the moment).

Re: ETG Development

rp181, Tue Jul 28 2009, 02:18AM

Wire break chrono still presented problems when trying to chrono the railgun. It seems the plasma is either conducting a little, or it is electromagnetic interfereance from the pulse. It may work for you, with the lower energy.

rp181, Tue Jul 28 2009, 02:18AM

Wire break chrono still presented problems when trying to chrono the railgun. It seems the plasma is either conducting a little, or it is electromagnetic interfereance from the pulse. It may work for you, with the lower energy.

Re: ETG Development

DYI, Wed Jul 29 2009, 01:54AM

EM interference from the pulse should be distinguishable from the wires actually breaking, unless the pulse is still going when the wires are broken. As the pulse in this design is likely complete long before the projectile leaves the barrel (including the ring-down time, the current flow lasts less than 400us, and projectile exit should occur somewhere in the neighborhood of 1000us after the beginning of the pulse), it should be easy to make the distinction. I doubt that there will be enough plasma in the muzzle flash to mess with the readings significantly. Any plasma there is will be very low density, and not nearly conductive enough for a few volts to flow through.

The main chamber parts have been replaced, and the design slightly modified, following a plasma blowby incident which damaged them sufficiently to prevent their continued use. If anyone wants the exact specifics, I can post them here.

DYI, Wed Jul 29 2009, 01:54AM

wrote ...

Wire break chrono still presented problems when trying to chrono the railgun. It seems the plasma is either conducting a little, or it is electromagnetic interfereance from the pulse. It may work for you, with the lower energy.

Wire break chrono still presented problems when trying to chrono the railgun. It seems the plasma is either conducting a little, or it is electromagnetic interfereance from the pulse. It may work for you, with the lower energy.

EM interference from the pulse should be distinguishable from the wires actually breaking, unless the pulse is still going when the wires are broken. As the pulse in this design is likely complete long before the projectile leaves the barrel (including the ring-down time, the current flow lasts less than 400us, and projectile exit should occur somewhere in the neighborhood of 1000us after the beginning of the pulse), it should be easy to make the distinction. I doubt that there will be enough plasma in the muzzle flash to mess with the readings significantly. Any plasma there is will be very low density, and not nearly conductive enough for a few volts to flow through.

The main chamber parts have been replaced, and the design slightly modified, following a plasma blowby incident which damaged them sufficiently to prevent their continued use. If anyone wants the exact specifics, I can post them here.

Re: ETG Development

DYI, Tue Aug 11 2009, 02:31AM

I recently constructed a simple ballistic pendulum and ran a single test. The result is likely anomalous, as it indicates efficiency in the neighbourhood of 20% (achievable, but difficult, especially without optimization). The camera was positioned wrong because of my expectation of ~10% efficiency, so the exact height reached by the 44g pendulum is unknown. Absolute minimum is 0.42m above initial position. You do the math

I'll be cutting out more capillary tubes, and testing a new material (UHMW polyethylene) to build them with. I will conduct several pendulum tests with an improved setup which will eliminate the possible anomalous results, and update with real efficiency figures in a week or so. On the off chance that the first test was accurate, well, I'd have to say that I've got a hell of a contraption here...

DYI, Tue Aug 11 2009, 02:31AM

I recently constructed a simple ballistic pendulum and ran a single test. The result is likely anomalous, as it indicates efficiency in the neighbourhood of 20% (achievable, but difficult, especially without optimization). The camera was positioned wrong because of my expectation of ~10% efficiency, so the exact height reached by the 44g pendulum is unknown. Absolute minimum is 0.42m above initial position. You do the math

I'll be cutting out more capillary tubes, and testing a new material (UHMW polyethylene) to build them with. I will conduct several pendulum tests with an improved setup which will eliminate the possible anomalous results, and update with real efficiency figures in a week or so. On the off chance that the first test was accurate, well, I'd have to say that I've got a hell of a contraption here...

Re: ETG Development

Gunner, Wed Aug 12 2009, 06:09PM

What was your cap bank and how much did the projectile weigh? I am very intrested of your project :)

Gunner, Wed Aug 12 2009, 06:09PM

What was your cap bank and how much did the projectile weigh? I am very intrested of your project :)

Re: ETG Development

DYI, Thu Aug 13 2009, 01:52AM

The capacitor is currently 7.5kV, 16uF, for 450J at full charge. The first shot with the pendulum was done at 300J. The projectile is still a 0.12g airsoft round, as it is the only commonly available thing that fits the barrel. Eventually I'll have to get a barrel with a more useful diameter like 6.4mm (instead of 6.1, which is the current size) so that I can simply cut off chunks of plastic bar or use steel/nylon spheres. I don't ever intend on using projectiles much in excess of 1g, as the aim is to produce a launcher which reaches higher speeds than can be achieved through "normal" means, for impact testing.

On another interesting note, I rebuilt the pendulum to weigh 96g instead of 44g, and did a test shot at full power (around 450J, the multimeter/voltage divider was giving screwy readings again, but the current draw through the divider equals the current through the charger at just under 8kV, a neat little safety feature which prevents me from accidentally making the cap go boom). At more than double the pendulum mass, with a different energy level, and at a distance where the minute muzzle blast would have no measurable effect on the momentum transferred to the pendulum, the previous efficiency level was maintained (the pendulum rose to 0.22m) - ~20% efficiency is seeming more and more likely. Even with the absolute most conservative assumptions, 21% of bank energy is converted to kinetic energy of the projectile (the wadding, which weighs 25% as much as the projectile carries some too, so the actual electric to kinetic conversion efficiency is higher).

I should be able to do three more pendulum tests, and obtain an average muzzle speed from the full power results. At the moment, based on results of these and previous tests, I'd feel safe in claiming a minimum of 10% efficient conversion from stored electrical energy to kinetic energy of the projectile. Does anyone know of other amateur ETGs reaching similar efficiency levels?

DYI, Thu Aug 13 2009, 01:52AM

wrote ...

What was your cap bank and how much did the projectile weigh? I am very intrested of your project

What was your cap bank and how much did the projectile weigh? I am very intrested of your project

The capacitor is currently 7.5kV, 16uF, for 450J at full charge. The first shot with the pendulum was done at 300J. The projectile is still a 0.12g airsoft round, as it is the only commonly available thing that fits the barrel. Eventually I'll have to get a barrel with a more useful diameter like 6.4mm (instead of 6.1, which is the current size) so that I can simply cut off chunks of plastic bar or use steel/nylon spheres. I don't ever intend on using projectiles much in excess of 1g, as the aim is to produce a launcher which reaches higher speeds than can be achieved through "normal" means, for impact testing.

On another interesting note, I rebuilt the pendulum to weigh 96g instead of 44g, and did a test shot at full power (around 450J, the multimeter/voltage divider was giving screwy readings again, but the current draw through the divider equals the current through the charger at just under 8kV, a neat little safety feature which prevents me from accidentally making the cap go boom). At more than double the pendulum mass, with a different energy level, and at a distance where the minute muzzle blast would have no measurable effect on the momentum transferred to the pendulum, the previous efficiency level was maintained (the pendulum rose to 0.22m) - ~20% efficiency is seeming more and more likely. Even with the absolute most conservative assumptions, 21% of bank energy is converted to kinetic energy of the projectile (the wadding, which weighs 25% as much as the projectile carries some too, so the actual electric to kinetic conversion efficiency is higher).

I should be able to do three more pendulum tests, and obtain an average muzzle speed from the full power results. At the moment, based on results of these and previous tests, I'd feel safe in claiming a minimum of 10% efficient conversion from stored electrical energy to kinetic energy of the projectile. Does anyone know of other amateur ETGs reaching similar efficiency levels?

Re: ETG Development

Gunner, Thu Aug 13 2009, 06:39AM

Huh...that`s crazy...if your effiency is 20% with 450Joules that makes 90 Joules to the bullet and when 0.12 gram bb has 90Joules, it has to go +1200m/s :)

E: And if you could it would be great to see few extra pics of your cannon :)

Gunner, Thu Aug 13 2009, 06:39AM

Huh...that`s crazy...if your effiency is 20% with 450Joules that makes 90 Joules to the bullet and when 0.12 gram bb has 90Joules, it has to go +1200m/s :)

E: And if you could it would be great to see few extra pics of your cannon :)

Re: ETG Development

DYI, Fri Aug 14 2009, 12:02AM

I conducted another pendulum test today, this time with a 99.5g pendulum. The mass of the round+wadding was measured at 140mg, +/-5mg. Height reached was 0.18m, consistent with 125J total kinetic energy, and 107J kinetic energy in the projectile. Unfortunately, the voltage reading system is broken, so I can say only that a minimum efficiency of 21% was reached. It is worth noting that the pendulum completed a half rotation before it reached maximum height, so the reading obtained will actually be slightly low. Once again, any assumptions made here were conservative - the pendulum probably reached more like 0.19m, and it was likely slightly heavier than 99.5g because of the mass of the strings.

I have two more capillary tubes left. One will be used in a final pendulum test, the other will be used in a "dry fire" (no projectile) to see how much momentum the propellant gases contribute to the pendulum. I'll have to use a far lighter pendulum, probably completely empty or close to it. This will be compared to the total momentum imparted by the previous shots, and I should be able to get a good idea of how fast the rounds are moving.

Also, I have the pictures you requested. These show the full launcher from the outside. I'm not getting into posting a whole archive of pictures until I make it nice and pretty and post it on the Projects board. I might also upload a picture of an airsoft round in about 50 pieces sometime later.

DYI, Fri Aug 14 2009, 12:02AM

I conducted another pendulum test today, this time with a 99.5g pendulum. The mass of the round+wadding was measured at 140mg, +/-5mg. Height reached was 0.18m, consistent with 125J total kinetic energy, and 107J kinetic energy in the projectile. Unfortunately, the voltage reading system is broken, so I can say only that a minimum efficiency of 21% was reached. It is worth noting that the pendulum completed a half rotation before it reached maximum height, so the reading obtained will actually be slightly low. Once again, any assumptions made here were conservative - the pendulum probably reached more like 0.19m, and it was likely slightly heavier than 99.5g because of the mass of the strings.

I have two more capillary tubes left. One will be used in a final pendulum test, the other will be used in a "dry fire" (no projectile) to see how much momentum the propellant gases contribute to the pendulum. I'll have to use a far lighter pendulum, probably completely empty or close to it. This will be compared to the total momentum imparted by the previous shots, and I should be able to get a good idea of how fast the rounds are moving.

Also, I have the pictures you requested. These show the full launcher from the outside. I'm not getting into posting a whole archive of pictures until I make it nice and pretty and post it on the Projects board. I might also upload a picture of an airsoft round in about 50 pieces sometime later.

Re: ETG Development

Gunner, Fri Aug 14 2009, 07:04AM

I am not 100% sure what do you mean with "capillary" tube? :) PS. Is that hot glue thing somekind of recoil thing?

Gunner, Fri Aug 14 2009, 07:04AM

I am not 100% sure what do you mean with "capillary" tube? :) PS. Is that hot glue thing somekind of recoil thing?

Re: ETG Development

DYI, Sat Aug 15 2009, 02:26AM

Hot glue? No hot melt glue or anything similar is shown on any of the photos or schematics posted on this thread. The materials used in construction are the same as those indicated in the diagram on the first page.

As for the capillary tube, it's an important part of many plasma generators. It is a very small diameter plastic tube which creates and projects the plasma. A thin wire is "exploded" inside the tube, producing a high current arc which ablates and ionizes the walls of the tube, thus generating the plasma, which then expands and flows out the open end of the tube. You'll have to look online for a more detailed explanation.

DYI, Sat Aug 15 2009, 02:26AM

Hot glue? No hot melt glue or anything similar is shown on any of the photos or schematics posted on this thread. The materials used in construction are the same as those indicated in the diagram on the first page.

As for the capillary tube, it's an important part of many plasma generators. It is a very small diameter plastic tube which creates and projects the plasma. A thin wire is "exploded" inside the tube, producing a high current arc which ablates and ionizes the walls of the tube, thus generating the plasma, which then expands and flows out the open end of the tube. You'll have to look online for a more detailed explanation.

Re: ETG Development

rp181, Sat Aug 15 2009, 02:55AM

Have you tried increasing the surface area of the discharge tube? Sanding with rough grit or grooving (or threading) may help, depending on the power level.

EDIT: You may want to get a LCR meter, to back up your claims.

rp181, Sat Aug 15 2009, 02:55AM

Have you tried increasing the surface area of the discharge tube? Sanding with rough grit or grooving (or threading) may help, depending on the power level.

EDIT: You may want to get a LCR meter, to back up your claims.

Re: ETG Development

DYI, Sun Aug 16 2009, 12:13AM

I haven't yet tried any methods of increasing the internal surface area of the capillary tube, and I doubt that my current measuring techniques would be sufficient to discern the difference. I'm not worried about backing up my claims at the moment. This is, after all, an R&D thread, not something from the Projects board. How would an LCR meter help anyway? Prove that the capacitor is really 16uF? How could I "prove" what the charge voltage is? Or how much the pendulum weighs, or if the round is really a painted steel ball bearing which carries more momentum? Trying to prove such things is pointless, in my opinion, and that's not even getting into the possibilities of video editing.

Today I measured the momentum transfer from the exhaust gases to the pendulum from the same distance as my previous tests, and it is surprisingly high - with no projectile impacting it, a 15g pendulum rose 0.10m above its starting position, meaning an imparted momentum of 0.021 kg*m/s. With this accounted for, the corrected ballistic efficiency is 20%, and the efficiency from capacitor to projectile (wadding excluded here) is ~17%, a more believable figure. Of course, with a tighter fitting barrel, wadding would be unnecessary. Once again, all figures stated are the most conservative they can be while still being realistic.

DYI, Sun Aug 16 2009, 12:13AM

I haven't yet tried any methods of increasing the internal surface area of the capillary tube, and I doubt that my current measuring techniques would be sufficient to discern the difference. I'm not worried about backing up my claims at the moment. This is, after all, an R&D thread, not something from the Projects board. How would an LCR meter help anyway? Prove that the capacitor is really 16uF? How could I "prove" what the charge voltage is? Or how much the pendulum weighs, or if the round is really a painted steel ball bearing which carries more momentum? Trying to prove such things is pointless, in my opinion, and that's not even getting into the possibilities of video editing.

Today I measured the momentum transfer from the exhaust gases to the pendulum from the same distance as my previous tests, and it is surprisingly high - with no projectile impacting it, a 15g pendulum rose 0.10m above its starting position, meaning an imparted momentum of 0.021 kg*m/s. With this accounted for, the corrected ballistic efficiency is 20%, and the efficiency from capacitor to projectile (wadding excluded here) is ~17%, a more believable figure. Of course, with a tighter fitting barrel, wadding would be unnecessary. Once again, all figures stated are the most conservative they can be while still being realistic.

Re: ETG Development

rp181, Sun Aug 16 2009, 02:57PM

There will always be something, but may as well cover the basics. Any progress on the break wire chrono?

Increasing the surface area could result in a more compact gun, perhaps handheld.

rp181, Sun Aug 16 2009, 02:57PM

There will always be something, but may as well cover the basics. Any progress on the break wire chrono?

Increasing the surface area could result in a more compact gun, perhaps handheld.

Re: ETG Development

DYI, Fri Aug 21 2009, 02:39AM

No progress on the break wire chrony yet, I've been working on other things. I also have a job, which does take up some of my time. All things considered, it's amazing how much I manage to get done on this.

And now for a picture. It doesn't really give me any new information, but I thought it was a cool looking crater...

It was hard to get a good angle, and the picture really doesn't do justice to the crater, which is 50mm deep and 36mm in diameter.

DYI, Fri Aug 21 2009, 02:39AM

No progress on the break wire chrony yet, I've been working on other things. I also have a job, which does take up some of my time. All things considered, it's amazing how much I manage to get done on this.