Third generation railgun project

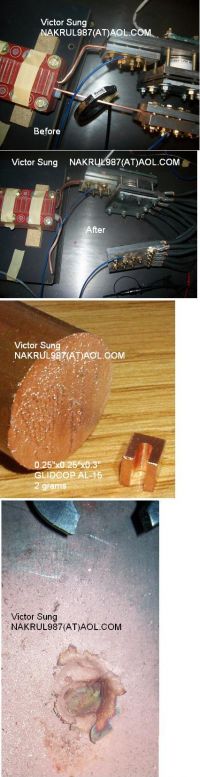

badastronaut, Sun May 18 2008, 10:44PMPlease take a look at the attached teaser images.

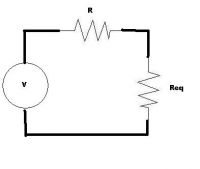

The third generation railgun was fired on May 16, 2008. The target was a 1/4" thick steel plate, and the projectile was made from GLIDCOP AL-15 and had a mass of 2 grams. It almost went through the steel as there is a large bump on the back of the plate. The projectile was accelerated from rest, and I had to use a hammer to load it in the railgun.

Does anyone know why there is so much material around the impact crater?

Please ask lots of questions.

Re: Third generation railgun project

ea6b607, Sun May 18 2008, 11:03PM

Wow, I would love to know more about this one. Anyways the material around the crater is due to aluminum (your projectile) being the softer metal. Quite common to see the same thing from soft lead shells as well.

ea6b607, Sun May 18 2008, 11:03PM

Wow, I would love to know more about this one. Anyways the material around the crater is due to aluminum (your projectile) being the softer metal. Quite common to see the same thing from soft lead shells as well.

Re: Third generation railgun project

rp181, Mon May 19 2008, 12:27AM

Amazing! How many KJ? specs on the SCR? how much did it cost (SCR and whole project)?

rp181, Mon May 19 2008, 12:27AM

Amazing! How many KJ? specs on the SCR? how much did it cost (SCR and whole project)?

Re: Third generation railgun project

badastronaut, Mon May 19 2008, 12:57AM

The projectile is made of GLIDCOP AL-15, which as a copper alloy, not aluminum. However, the first projectile I used was a 600mg aluminum block, and it broke into 3 pieces before hitting the steel plate.

The capacitor bank stores about 20kJ. The SCR is rated for 1kA continuous and 14kA pulsed. It is used as a sacrificial switch since it would be too expensive otherwise. I will show you a picture of what happened to the stud mount SCR. The stud mount SCR didn't do too well, so I switched to the hockey puck type. I had them donated to me for a separate unrelated project that never went.

The whole project cost probably well under $2000.

I have high speed video running at 25000 fps, but it is 8megs. You can't see much in the video because the muzzle flash was too bright.

badastronaut, Mon May 19 2008, 12:57AM

The projectile is made of GLIDCOP AL-15, which as a copper alloy, not aluminum. However, the first projectile I used was a 600mg aluminum block, and it broke into 3 pieces before hitting the steel plate.

The capacitor bank stores about 20kJ. The SCR is rated for 1kA continuous and 14kA pulsed. It is used as a sacrificial switch since it would be too expensive otherwise. I will show you a picture of what happened to the stud mount SCR. The stud mount SCR didn't do too well, so I switched to the hockey puck type. I had them donated to me for a separate unrelated project that never went.

The whole project cost probably well under $2000.

I have high speed video running at 25000 fps, but it is 8megs. You can't see much in the video because the muzzle flash was too bright.

Re: Third generation railgun project

Mathias, Mon May 19 2008, 01:10AM

Well you know , some parts of the the projectile/armature also the surface of the rails , melt/evaporates , cause of the joule heating and friction , this metalic vapor is also blown out from the gun (same as gunpowder from a convecional firearm) and it cooled down on contact with the steel plate

Mathias, Mon May 19 2008, 01:10AM

Well you know , some parts of the the projectile/armature also the surface of the rails , melt/evaporates , cause of the joule heating and friction , this metalic vapor is also blown out from the gun (same as gunpowder from a convecional firearm) and it cooled down on contact with the steel plate

Re: Third generation railgun project

rp181, Mon May 19 2008, 02:20AM

what is the rail and rail enclosure made off?

rp181, Mon May 19 2008, 02:20AM

what is the rail and rail enclosure made off?

Re: Third generation railgun project

badastronaut, Mon May 19 2008, 02:28AM

Alloy 110 copper and flame retardant electrical grade fiberglass.

When an aluminum projectile is used, aluminum film covers the area around the crater. There might be a spec or two of copper, but it is mostly the material from the projectile.

badastronaut, Mon May 19 2008, 02:28AM

Alloy 110 copper and flame retardant electrical grade fiberglass.

When an aluminum projectile is used, aluminum film covers the area around the crater. There might be a spec or two of copper, but it is mostly the material from the projectile.

Re: Third generation railgun project

tesla500, Mon May 19 2008, 02:57AM

Very nice project!

What type and rating capacitors are you using? How often do the rails need to be replaced?

David

tesla500, Mon May 19 2008, 02:57AM

Very nice project!

What type and rating capacitors are you using? How often do the rails need to be replaced?

David

Re: Third generation railgun project

rp181, Mon May 19 2008, 03:04AM

How thick are the rails and rail enclosure?

rp181, Mon May 19 2008, 03:04AM

How thick are the rails and rail enclosure?

Re: Third generation railgun project

badastronaut, Mon May 19 2008, 03:23AM

The capacitor bank is composed of 70 electrolytic capacitors, each rated for 3900uF at 400V. They are in all parallel. The actual capacitance is 0.2585 +/- 0.005 F.

It has only been fired 2 times. It looks like the rails have to be replaced each time as well as the sacrificial SCR. Future work would be to improve the design to allow the rails to last longer. The bending of the naked rails at the breech side don't help.

I have attached a picture of what I meant about the two types of projectiles creating craters covered with material mostly from the projectile.

Also, I have loaded a picture of the capacitor bank. The lightbulbs are used to discharge any residual energy in the caps.

Rails are 0.125" thick, and the enclosure is 3"x2" cross sectional. The gun is 16" long

badastronaut, Mon May 19 2008, 03:23AM

The capacitor bank is composed of 70 electrolytic capacitors, each rated for 3900uF at 400V. They are in all parallel. The actual capacitance is 0.2585 +/- 0.005 F.

It has only been fired 2 times. It looks like the rails have to be replaced each time as well as the sacrificial SCR. Future work would be to improve the design to allow the rails to last longer. The bending of the naked rails at the breech side don't help.

I have attached a picture of what I meant about the two types of projectiles creating craters covered with material mostly from the projectile.

Also, I have loaded a picture of the capacitor bank. The lightbulbs are used to discharge any residual energy in the caps.

Rails are 0.125" thick, and the enclosure is 3"x2" cross sectional. The gun is 16" long

Re: Third generation railgun project

Steve Conner, Mon May 19 2008, 09:45AM

Holy sh That is one of the more impressive railguns I've seen in the years I've been involved with 4hv. Looks like you need a lot more bracing of every conductor in the whole setup though, to keep your Lorentz forces under control. Remember that every part of the circuit feels just as much force as the projectile does.

That is one of the more impressive railguns I've seen in the years I've been involved with 4hv. Looks like you need a lot more bracing of every conductor in the whole setup though, to keep your Lorentz forces under control. Remember that every part of the circuit feels just as much force as the projectile does.

I imagine the projectile more or less exploded on impact, and the material around the crater is the remains of it. The copper alloy is probably quite soft, and the projectile might have got hot enough to soften it even more. Or maybe like another poster mentioned, the projectile partly melts in the barrel, so the gun actually shoots a cloud of molten copper droplets with a hot slug of copper in the middle

Steve Conner, Mon May 19 2008, 09:45AM

Holy sh

That is one of the more impressive railguns I've seen in the years I've been involved with 4hv. Looks like you need a lot more bracing of every conductor in the whole setup though, to keep your Lorentz forces under control. Remember that every part of the circuit feels just as much force as the projectile does.

That is one of the more impressive railguns I've seen in the years I've been involved with 4hv. Looks like you need a lot more bracing of every conductor in the whole setup though, to keep your Lorentz forces under control. Remember that every part of the circuit feels just as much force as the projectile does.I imagine the projectile more or less exploded on impact, and the material around the crater is the remains of it. The copper alloy is probably quite soft, and the projectile might have got hot enough to soften it even more. Or maybe like another poster mentioned, the projectile partly melts in the barrel, so the gun actually shoots a cloud of molten copper droplets with a hot slug of copper in the middle

Re: Third generation railgun project

Quantum Singularity, Mon May 19 2008, 12:02PM

I agree. Very nice. Too bad you've only gotten two shots. That's the problem I have with railguns and why I abandoned my project... just seems like they don't hold up well. You didn't say if you were able to record any data... velocity/ efficiency? About the copper coating around the impact, I'd say you got a couple things going on, both from the impact and like mentioned from the muzzle flash as well. But I'd wager a lot is from the impact, you didn't punch through, so the full amount of energy was dissipated in the impact. Being that the projectile was probably already pretty hot, I'd think that upon impact it probably partly liquefied and vaporized. How much of the copper did you recover? That should pretty much tell you.

Quantum Singularity, Mon May 19 2008, 12:02PM

I agree. Very nice. Too bad you've only gotten two shots. That's the problem I have with railguns and why I abandoned my project... just seems like they don't hold up well. You didn't say if you were able to record any data... velocity/ efficiency? About the copper coating around the impact, I'd say you got a couple things going on, both from the impact and like mentioned from the muzzle flash as well. But I'd wager a lot is from the impact, you didn't punch through, so the full amount of energy was dissipated in the impact. Being that the projectile was probably already pretty hot, I'd think that upon impact it probably partly liquefied and vaporized. How much of the copper did you recover? That should pretty much tell you.

Re: Third generation railgun project

badastronaut, Tue May 20 2008, 04:05AM

For the aluminum projectile, there was nothing left of it except aluminum oxide dust everywhere. The copper alloy projectile seems to be either vaporized or welded to the steel plate. There is no evidence that it survived intact after hitting the steel plate.

I do have oscilloscope data. Peak current is about 200kA, peak power is about 50MW, and pulsewidth is about 600us. I was unable to find the speed of the projectile because the muzzle flash blinded the high speed camera. I am estimating a speed of 900-1500m/s for the copper alloy projectile.

I have attached some high speed footage of the copper alloy projectile shot.

]x7.avi[/file]

badastronaut, Tue May 20 2008, 04:05AM

For the aluminum projectile, there was nothing left of it except aluminum oxide dust everywhere. The copper alloy projectile seems to be either vaporized or welded to the steel plate. There is no evidence that it survived intact after hitting the steel plate.

I do have oscilloscope data. Peak current is about 200kA, peak power is about 50MW, and pulsewidth is about 600us. I was unable to find the speed of the projectile because the muzzle flash blinded the high speed camera. I am estimating a speed of 900-1500m/s for the copper alloy projectile.

I have attached some high speed footage of the copper alloy projectile shot.

]x7.avi[/file]

Re: Third generation railgun project

Dr. Shark, Tue May 20 2008, 02:32PM

Badastro, I am bowing down in respect to you, that is some really impressive stuff you did. In your posts in the old 4HV you have shared a lot of theoretical understanding about railguns, so would you care to elaborate a little bit about what makes this gun so much better than the usual amateur attempts ("spark shooters")?

It does not seem like you took any measures to increase the inductance gradient in the gun, so probably most of the work went into getting the resistance in the circuit really, really small. I guess your capacitor bank is around 0.5mOhm, and from the way you described hammering the projectile into the barrel I take the resistance of the sliding contact to be of a similar magnitude.

Guessing L´=5*10^-7 and R=2*10^-3 this is definitely one of the better guns out there, but where is your secret? Following your own maths here At 100m/s you will still be burning about 40J in the resistance for each Joule transferred to the armature, so getting the projectile up to an efficient speed from rest seems like a massive feat to achieve.

At 100m/s you will still be burning about 40J in the resistance for each Joule transferred to the armature, so getting the projectile up to an efficient speed from rest seems like a massive feat to achieve.

Dr. Shark, Tue May 20 2008, 02:32PM

Badastro, I am bowing down in respect to you, that is some really impressive stuff you did. In your posts in the old 4HV you have shared a lot of theoretical understanding about railguns, so would you care to elaborate a little bit about what makes this gun so much better than the usual amateur attempts ("spark shooters")?

It does not seem like you took any measures to increase the inductance gradient in the gun, so probably most of the work went into getting the resistance in the circuit really, really small. I guess your capacitor bank is around 0.5mOhm, and from the way you described hammering the projectile into the barrel I take the resistance of the sliding contact to be of a similar magnitude.

Guessing L´=5*10^-7 and R=2*10^-3 this is definitely one of the better guns out there, but where is your secret? Following your own maths here

At 100m/s you will still be burning about 40J in the resistance for each Joule transferred to the armature, so getting the projectile up to an efficient speed from rest seems like a massive feat to achieve.

At 100m/s you will still be burning about 40J in the resistance for each Joule transferred to the armature, so getting the projectile up to an efficient speed from rest seems like a massive feat to achieve.Re: Third generation railgun project

Mathias, Tue May 20 2008, 08:09PM

What i dont really understand is how come that there's even a bit of the armature is left still be intact after firing the gun ?

I mean , what i have read from other sources whom were using way less energy , if they were'nt using some kind of launching mechanism/procedure , (so that the armature would gain some starting velocity) , then they armature would just evaporate without begining to accelarate .

If i didn't misinterpreted something , then if you have to hammer the armature in it's place to start with then, it should be stuck untill most of it's surface had melted ,am i right? So im guessing alot of the energy should be wasted there

Mathias, Tue May 20 2008, 08:09PM

What i dont really understand is how come that there's even a bit of the armature is left still be intact after firing the gun ?

I mean , what i have read from other sources whom were using way less energy , if they were'nt using some kind of launching mechanism/procedure , (so that the armature would gain some starting velocity) , then they armature would just evaporate without begining to accelarate .

If i didn't misinterpreted something , then if you have to hammer the armature in it's place to start with then, it should be stuck untill most of it's surface had melted ,am i right? So im guessing alot of the energy should be wasted there

Re: Third generation railgun project

badastronaut, Tue May 20 2008, 09:52PM

Railguns don't need to have any sort of injection or starting velocity. I think that's a myth perpetuated by Powerlabs. Another myth is that the projectile will weld to the rails. This is simply not true under a certain condition.

The projectile is solid metal, and it takes a lot of energy to vaporize metal. From Joule heating alone, this would have to mean that the projectile is made of some highly resistive material, which it is not. If the projectile vaporizes from Joule heating, then the rails would similarly vaporize. If the rails and projectile are made of the same material and have the same cross sectional area, then they would heat up at similar rates assuming no motion and perfect contact.

It is possible to calculate how much the rails will heat up. In this case, they would heat up by about 80 degrees C, which was a factor in choosing the dimensions of the rails.

Remember that not all of the initial stored capacitor bank energy is dissipated in the projectile as heat; only a proportionally small amount of it is. Therefore, it doesn't vaporize.

If there is enough contact force and contact area, then the rail-projectile interface will not melt. It did in fact melt for the first shot with the aluminum projectile. I haven't had a chance to look at the rails for the copper alloy projectile. If the interface melts, I would think that it would enable the projectile to be accelerated more easily because of reduced friction. A lot of energy is being wasted there, but the proportion is small compared to the total energy stored.

As for projectile welding, the only way it could have significant welding is if the current stopped flowing after that interface melted before the projectile gets a chance to accelerate. If that is the case, then the capacitor bank is too small to be used for a railgun with or without injection. A properly sized capacitor bank will accelerate the projectile before the metal has a chance to cool down and weld.

I don't actually know what the inductance gradient is for certain, but I think it is in the range of 3e-7 to 5e-7. The resistance of the entire circuit is 1.3milliohms. That resistance was found by matching data to simulated parameters. The capacitor bank resistance is somewhere around 0.3 milliohms. I think a very large amount of energy is being wasted blowing the rails apart, which makes the effective resistance bigger than 1 milliohm since it presents an extra voltage drop across the circuit. The best estimate of speed I have for the copper alloy projectile is 1200 m/s.

The secret to railguns is being able to deliver a large action integral using as little energy as possible. Action is defined as the time integral of current squared. It is non-linear and not conserved. You can directly increase the action integral by either increasing stored capacitor energy or decreasing resistance or both.

This essentially means that you need to have as small of a resistance as possible. This is the reason why I keep telling people to put their capacitors in parallel for railguns. Any other configuration is wasteful. This the problem with the powerlabs railgun in that he has too many capacitors in series. Increasing inductance gradient is a good thing but it is very difficult to do compared to how easy it is to increase the action integral.

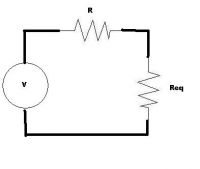

For an even simpler explanation, take a look at the diagram below. Assume that we can model the transfer of electrical energy into mechanical energy with a resister Req. If all of the other resistances are lumped into R, the problem becomes how do transfer a larger proportion of energy into Req relative to R? The answer is to increase the ratio of Req to R. Even better would be to make R zero.

Also, resistance affects efficiency non-linearly. The smaller it is, the bigger effect it has. The Powerlabs railgun supposedly used ultra low resistance oxygen free copper rails. The reason why this doesn't work is because the resistance of his capacitor bank was far larger than the change in resistance of his rails. He might have shaved off 0.1 milliohms by using the special rails, but his capacitor bank's resistance is probably around 10 or more milliohms, hence poor performance.

Ask more questions please.

badastronaut, Tue May 20 2008, 09:52PM

Railguns don't need to have any sort of injection or starting velocity. I think that's a myth perpetuated by Powerlabs. Another myth is that the projectile will weld to the rails. This is simply not true under a certain condition.

The projectile is solid metal, and it takes a lot of energy to vaporize metal. From Joule heating alone, this would have to mean that the projectile is made of some highly resistive material, which it is not. If the projectile vaporizes from Joule heating, then the rails would similarly vaporize. If the rails and projectile are made of the same material and have the same cross sectional area, then they would heat up at similar rates assuming no motion and perfect contact.

It is possible to calculate how much the rails will heat up. In this case, they would heat up by about 80 degrees C, which was a factor in choosing the dimensions of the rails.

Remember that not all of the initial stored capacitor bank energy is dissipated in the projectile as heat; only a proportionally small amount of it is. Therefore, it doesn't vaporize.

If there is enough contact force and contact area, then the rail-projectile interface will not melt. It did in fact melt for the first shot with the aluminum projectile. I haven't had a chance to look at the rails for the copper alloy projectile. If the interface melts, I would think that it would enable the projectile to be accelerated more easily because of reduced friction. A lot of energy is being wasted there, but the proportion is small compared to the total energy stored.

As for projectile welding, the only way it could have significant welding is if the current stopped flowing after that interface melted before the projectile gets a chance to accelerate. If that is the case, then the capacitor bank is too small to be used for a railgun with or without injection. A properly sized capacitor bank will accelerate the projectile before the metal has a chance to cool down and weld.

I don't actually know what the inductance gradient is for certain, but I think it is in the range of 3e-7 to 5e-7. The resistance of the entire circuit is 1.3milliohms. That resistance was found by matching data to simulated parameters. The capacitor bank resistance is somewhere around 0.3 milliohms. I think a very large amount of energy is being wasted blowing the rails apart, which makes the effective resistance bigger than 1 milliohm since it presents an extra voltage drop across the circuit. The best estimate of speed I have for the copper alloy projectile is 1200 m/s.

The secret to railguns is being able to deliver a large action integral using as little energy as possible. Action is defined as the time integral of current squared. It is non-linear and not conserved. You can directly increase the action integral by either increasing stored capacitor energy or decreasing resistance or both.

This essentially means that you need to have as small of a resistance as possible. This is the reason why I keep telling people to put their capacitors in parallel for railguns. Any other configuration is wasteful. This the problem with the powerlabs railgun in that he has too many capacitors in series. Increasing inductance gradient is a good thing but it is very difficult to do compared to how easy it is to increase the action integral.

For an even simpler explanation, take a look at the diagram below. Assume that we can model the transfer of electrical energy into mechanical energy with a resister Req. If all of the other resistances are lumped into R, the problem becomes how do transfer a larger proportion of energy into Req relative to R? The answer is to increase the ratio of Req to R. Even better would be to make R zero.

Also, resistance affects efficiency non-linearly. The smaller it is, the bigger effect it has. The Powerlabs railgun supposedly used ultra low resistance oxygen free copper rails. The reason why this doesn't work is because the resistance of his capacitor bank was far larger than the change in resistance of his rails. He might have shaved off 0.1 milliohms by using the special rails, but his capacitor bank's resistance is probably around 10 or more milliohms, hence poor performance.

Ask more questions please.

Re: Third generation railgun project

Andyman, Tue May 20 2008, 09:56PM

Wow. Just wow. That is absolutely INCREDIBLE!

Wow. Just wow. That is absolutely INCREDIBLE!  That looks more like the impact of a .40 S&W round!!

That looks more like the impact of a .40 S&W round!!

To answer your question, the material is the splatter of the vaporized copper. The same thing happens with lead bullets at steel plates (I go shooting). When it hits, it turns into powder, and the force of the "explosion" embeds the particles into the surface of the steel. This attachment is probably only a few millionths of an inch deep.

That's my guess.

For the switch, you should put all of the sacrificial SCRs in parallel for current/voltage sharing.

Andyman, Tue May 20 2008, 09:56PM

Wow. Just wow. That is absolutely INCREDIBLE!

Wow. Just wow. That is absolutely INCREDIBLE!  That looks more like the impact of a .40 S&W round!!

That looks more like the impact of a .40 S&W round!!To answer your question, the material is the splatter of the vaporized copper. The same thing happens with lead bullets at steel plates (I go shooting). When it hits, it turns into powder, and the force of the "explosion" embeds the particles into the surface of the steel. This attachment is probably only a few millionths of an inch deep.

That's my guess.

For the switch, you should put all of the sacrificial SCRs in parallel for current/voltage sharing.

Re: Third generation railgun project

badastronaut, Tue May 20 2008, 09:58PM

Well, the SCR's are too small by about an order of a magnitude or more, and I only have one left.... :P

What kind of gun and ammo does it take to do similar damage to a 1/4" thick steel plate? What does it take to punch through it?

badastronaut, Tue May 20 2008, 09:58PM

Well, the SCR's are too small by about an order of a magnitude or more, and I only have one left.... :P

What kind of gun and ammo does it take to do similar damage to a 1/4" thick steel plate? What does it take to punch through it?

Re: Third generation railgun project

rp181, Wed May 21 2008, 12:29AM

Do you think 1 set of rails or multi stage like ea6's would preform better? same energy, multi stage the power would be split between the rails (seperate banks).

Sam barros used a current limiting inductor, do you have such? yours is only ~foot long, is this because you didnt limit the current for a short pulse?

rp181, Wed May 21 2008, 12:29AM

Do you think 1 set of rails or multi stage like ea6's would preform better? same energy, multi stage the power would be split between the rails (seperate banks).

Sam barros used a current limiting inductor, do you have such? yours is only ~foot long, is this because you didnt limit the current for a short pulse?

Re: Third generation railgun project

badastronaut, Wed May 21 2008, 01:00AM

I can't prove why multistage would help except to reduce the effect of really long rails. Multistage is much more complicated, and I can't justify using them.

I don't use an inductor, and I can't prove that they are helpful at all except to reduce didt, which can be a problem for solid state switches. The resistance of the inductor would also hurt performance dramatically. For my design, I actually tried to reduce inductance as much as possible so that the current won't oscillate given the low circuit resistance. The total inductance is about 0.2uH. My ideal railgun model says that the performance will be the same inductor or not. Real life factors such as finite rail length and friction changes this answer.

This railgun is actually a modification of a previous railgun. The length was chosen 4 or 5 years ago based on material and funding availability. I didn't want to have another one built, so it stuck.

I think the use of an inductor is another myth created by Sam. He says using them would help, but he doesn't prove why they might help or even give an explanation. Pulse length has no bearing on performance assuming the rails are infinitely long, frictionless, and superconducting. Only the action integral matters to any significant degree. It can also be proven that inductance does not change the value of action.

badastronaut, Wed May 21 2008, 01:00AM

I can't prove why multistage would help except to reduce the effect of really long rails. Multistage is much more complicated, and I can't justify using them.

I don't use an inductor, and I can't prove that they are helpful at all except to reduce didt, which can be a problem for solid state switches. The resistance of the inductor would also hurt performance dramatically. For my design, I actually tried to reduce inductance as much as possible so that the current won't oscillate given the low circuit resistance. The total inductance is about 0.2uH. My ideal railgun model says that the performance will be the same inductor or not. Real life factors such as finite rail length and friction changes this answer.

This railgun is actually a modification of a previous railgun. The length was chosen 4 or 5 years ago based on material and funding availability. I didn't want to have another one built, so it stuck.

I think the use of an inductor is another myth created by Sam. He says using them would help, but he doesn't prove why they might help or even give an explanation. Pulse length has no bearing on performance assuming the rails are infinitely long, frictionless, and superconducting. Only the action integral matters to any significant degree. It can also be proven that inductance does not change the value of action.

Re: Third generation railgun project

rp181, Wed May 21 2008, 01:04AM

Rather then SCR's, why dont you use an injector? This takes away the requirement of the SCR.

How do you determine the ideal rail length as to avoid extra friction/wasted EM energy?

rp181, Wed May 21 2008, 01:04AM

Rather then SCR's, why dont you use an injector? This takes away the requirement of the SCR.

How do you determine the ideal rail length as to avoid extra friction/wasted EM energy?

Re: Third generation railgun project

ea6b607, Wed May 21 2008, 01:32AM

rp find the pulse length and calculate how far it will travel by the time the pulse is minimal. What gauge wire do you have connecting each parallel set of capacitor to the SCR. Also, with an SCR you can't set the projectile in the prime place. Would a large mechanical switch work better as it is possible to construct one with considerable lower resistance and nearly as fast of close time? Also, is there any reason why everyone always uses lytics (I did because they where cheap) or is there another reason?

ea6b607, Wed May 21 2008, 01:32AM

rp find the pulse length and calculate how far it will travel by the time the pulse is minimal. What gauge wire do you have connecting each parallel set of capacitor to the SCR. Also, with an SCR you can't set the projectile in the prime place. Would a large mechanical switch work better as it is possible to construct one with considerable lower resistance and nearly as fast of close time? Also, is there any reason why everyone always uses lytics (I did because they where cheap) or is there another reason?

Re: Third generation railgun project

Andyman, Wed May 21 2008, 04:45AM

If that really is 1/4 inch steel plate, I'd say the power of the projectile is coming close to a light sniper rifle round like .223 or .243. I don't think a .45 or a 357 magnum would quite pierce a plate like that.

Andyman, Wed May 21 2008, 04:45AM

If that really is 1/4 inch steel plate, I'd say the power of the projectile is coming close to a light sniper rifle round like .223 or .243. I don't think a .45 or a 357 magnum would quite pierce a plate like that.

Re: Third generation railgun project

badastronaut, Wed May 21 2008, 05:21AM

How much energy would those sniper rounds and magnum rounds have? How much energy do you think went into the steel plate?

Yes, electrolytics are used because they are cheaper. That's pretty much the only reason.

What is the prime place? With the SCR I can set the projectile anywhere I want. I used 4 AWG welding cable.

The pulse length is under 600 microseconds. This is too fast to have a mechanical switch close before current reaches too high of a value. Bouncing of the contacts are also a problem. Other than that, a mechanical switch is much more complicated and expensive to implement in my case. That might be different in yours. That switch would probably be more dangerous than the capacitor bank.

For rail length, you run simulations, or you can size your rails so short that the caps aren't discharged all the way when the projectile exits. Most people size their rails way too long. With the cap banks they use, they could make do with rails less than a half an inch long. Friction isn't that big of a deal since the magnitude of the friction force is dwarfed by the EM forces. Although friction is the reason why railguns don't work on the really small scale unless you use plasma armatures. You can make a small railgun with a rolling projectile, a 9v battery, and magnets since the rolling rod armature has little friction.

I don't use an injector because they are not necessary, they are more complicated, more expensive, and more dangerous in my situation. That might be different in yours. There's nothing wrong with using an injector. It will in fact increase efficiency, but the reason is mechanical, not electrical. The injector will impart a fixed momentum to the projectile, and the railgun will also impart its own fixed momentum to the projectile with no injection. With injection, the momentums add together, so the speed you get out is the initial speed plus the speed without injector. Simulations indicate that this relationship is approximately true because of rail resistance and other factors.

Another reason for not using an injector is that I would have to inject the projectile at like 2500m/s in order to have it fully inside the rails before the current reaches something like 5000A. Otherwise current will rise too high before the projectile fully contacts the rails and it will explode from the high current density. I suppose this is where you might use an inductor or even a saturable reactor, but this will require longer rails and the extra resistance will hurt performance though injection will help mitigate this.

badastronaut, Wed May 21 2008, 05:21AM

How much energy would those sniper rounds and magnum rounds have? How much energy do you think went into the steel plate?

Yes, electrolytics are used because they are cheaper. That's pretty much the only reason.

What is the prime place? With the SCR I can set the projectile anywhere I want. I used 4 AWG welding cable.

The pulse length is under 600 microseconds. This is too fast to have a mechanical switch close before current reaches too high of a value. Bouncing of the contacts are also a problem. Other than that, a mechanical switch is much more complicated and expensive to implement in my case. That might be different in yours. That switch would probably be more dangerous than the capacitor bank.

For rail length, you run simulations, or you can size your rails so short that the caps aren't discharged all the way when the projectile exits. Most people size their rails way too long. With the cap banks they use, they could make do with rails less than a half an inch long. Friction isn't that big of a deal since the magnitude of the friction force is dwarfed by the EM forces. Although friction is the reason why railguns don't work on the really small scale unless you use plasma armatures. You can make a small railgun with a rolling projectile, a 9v battery, and magnets since the rolling rod armature has little friction.

I don't use an injector because they are not necessary, they are more complicated, more expensive, and more dangerous in my situation. That might be different in yours. There's nothing wrong with using an injector. It will in fact increase efficiency, but the reason is mechanical, not electrical. The injector will impart a fixed momentum to the projectile, and the railgun will also impart its own fixed momentum to the projectile with no injection. With injection, the momentums add together, so the speed you get out is the initial speed plus the speed without injector. Simulations indicate that this relationship is approximately true because of rail resistance and other factors.

Another reason for not using an injector is that I would have to inject the projectile at like 2500m/s in order to have it fully inside the rails before the current reaches something like 5000A. Otherwise current will rise too high before the projectile fully contacts the rails and it will explode from the high current density. I suppose this is where you might use an inductor or even a saturable reactor, but this will require longer rails and the extra resistance will hurt performance though injection will help mitigate this.

Re: Third generation railgun project

Andyman, Wed May 21 2008, 05:53AM

A .223 ranges from 1.5 to 1.8 kJ and from 2750 to 3750 ft/s. The .243 is more powerful and is around 2.8 kJ and between 3 and 4k ft/s. 357 magnum is a smaller round and is from 600-800J at 1-1.5k ft/s.

If I were to guess, based on the steel plates I've shot up before, I would estimate around 1kj is going into that target.

The 223 goes through our 1/4 inch steel plate so it's less than 1.5kJ, but probably more than a 357 which would just dent the metal.

Andyman, Wed May 21 2008, 05:53AM

A .223 ranges from 1.5 to 1.8 kJ and from 2750 to 3750 ft/s. The .243 is more powerful and is around 2.8 kJ and between 3 and 4k ft/s. 357 magnum is a smaller round and is from 600-800J at 1-1.5k ft/s.

If I were to guess, based on the steel plates I've shot up before, I would estimate around 1kj is going into that target.

The 223 goes through our 1/4 inch steel plate so it's less than 1.5kJ, but probably more than a 357 which would just dent the metal.

Re: Third generation railgun project

Gunner, Fri Jun 13 2008, 09:58PM

Can you say that is that possible to make a railgun that has 5kJ capbank and works with effiency 10-20% (500-1000J KE)?

I mean, without injector.

Gunner, Fri Jun 13 2008, 09:58PM

Can you say that is that possible to make a railgun that has 5kJ capbank and works with effiency 10-20% (500-1000J KE)?

I mean, without injector.

Re: Third generation railgun project

badastronaut, Mon Jun 16 2008, 04:15AM

Yes, and no. In theory it is possible to do, but with actual parts, it is too difficult. With 5kJ and ordinary capacitors and setup, expect efficiency to be an order of magnitude lower than what you desire or even less than that. If you do it really really well, then you could do slightly better. This is all considering without injection. Please give it a try and see how well you can do.

badastronaut, Mon Jun 16 2008, 04:15AM

Yes, and no. In theory it is possible to do, but with actual parts, it is too difficult. With 5kJ and ordinary capacitors and setup, expect efficiency to be an order of magnitude lower than what you desire or even less than that. If you do it really really well, then you could do slightly better. This is all considering without injection. Please give it a try and see how well you can do.

Re: Third generation railgun project

Gunner, Mon Jun 16 2008, 08:35AM

OK...but I think that I`m gonna do that with injector and multistaged because It`s hard to find good SCR for that...

Gunner, Mon Jun 16 2008, 08:35AM

OK...but I think that I`m gonna do that with injector and multistaged because It`s hard to find good SCR for that...

Re: Third generation railgun project

badastronaut, Tue Jun 17 2008, 10:39AM

That sounds excellent! Please keep us informed about the progress of your project.

badastronaut, Tue Jun 17 2008, 10:39AM

That sounds excellent! Please keep us informed about the progress of your project.

Re: Third generation railgun project

Gunner, Thu Jun 19 2008, 08:40AM

Yes I will but I have to decide which one I will do:Railgun or ETG...:P

Gunner, Thu Jun 19 2008, 08:40AM

Yes I will but I have to decide which one I will do:Railgun or ETG...:P

Print this page