DIY high voltage & high power transformer

Kizmo, Fri Jul 20 2007, 08:41PMThings have changed, look latest posts

Re: DIY high voltage & high power transformer

Sulaiman, Fri Jul 20 2007, 08:48PM

If at all possible you should not introduce an air gap into the magnetic circuit

it will (dramatically) increase the current that the transformer draws with no load connected

and it will give poorer regulation (change in output voltage vs output current.

Can you take a photo' from the side ?

i.e. turn the transformer by 90 degrees.

Unless the laminations are welded together it may be possible to extract them.

Sulaiman, Fri Jul 20 2007, 08:48PM

If at all possible you should not introduce an air gap into the magnetic circuit

it will (dramatically) increase the current that the transformer draws with no load connected

and it will give poorer regulation (change in output voltage vs output current.

Can you take a photo' from the side ?

i.e. turn the transformer by 90 degrees.

Unless the laminations are welded together it may be possible to extract them.

Re: DIY high voltage & high power transformer

Kizmo, Fri Jul 20 2007, 08:57PM

Laminations are just glued together. This transformer has quite thin laminations, about 0.3 or 0.4mm, that makes about 230 layers of metal. Friend told me that heating the core to 250-300 degrees C would make glue so weak that it would be possible to disassemble whole thing into hundreds of U and I shaped metal strips. Im just wondering how on earth that can be assembled backwards :D

EDIT:

Air gap could be minimized by carefully sanding (and then lapping with water sandpaper) both pieces so that rough bandsaw finish disappears?

Kizmo, Fri Jul 20 2007, 08:57PM

Laminations are just glued together. This transformer has quite thin laminations, about 0.3 or 0.4mm, that makes about 230 layers of metal. Friend told me that heating the core to 250-300 degrees C would make glue so weak that it would be possible to disassemble whole thing into hundreds of U and I shaped metal strips. Im just wondering how on earth that can be assembled backwards :D

EDIT:

Air gap could be minimized by carefully sanding (and then lapping with water sandpaper) both pieces so that rough bandsaw finish disappears?

Re: DIY high voltage & high power transformer

Finn Hammer, Fri Jul 20 2007, 09:30PM

The glue is lacquer, really. It doesn`t penetrate far in between the laminations. It is mostly on the outside. And it cracks easily-

Use a wood chisel to separate the lams, and pull them out with a heavy duty plier. The first 5 or ten will get bent badly. after that, when there is place, with a little care, you can easily get them out. Takes a lot of cleaning, though.

Go for it, nothing beats the feeling of winding your own!

Cheers, Finn Hammer

Finn Hammer, Fri Jul 20 2007, 09:30PM

Kizmo wrote ...

Laminations are just glued together. This transformer has quite thin laminations, about 0.3 or 0.4mm, that makes about 230 layers of metal. Friend told me that heating the core to 250-300 degrees C would make glue so weak that it would be possible to disassemble whole thing into hundreds of U and I shaped metal strips. Im just wondering how on earth that can be assembled backwards :D

Laminations are just glued together. This transformer has quite thin laminations, about 0.3 or 0.4mm, that makes about 230 layers of metal. Friend told me that heating the core to 250-300 degrees C would make glue so weak that it would be possible to disassemble whole thing into hundreds of U and I shaped metal strips. Im just wondering how on earth that can be assembled backwards :D

The glue is lacquer, really. It doesn`t penetrate far in between the laminations. It is mostly on the outside. And it cracks easily-

Use a wood chisel to separate the lams, and pull them out with a heavy duty plier. The first 5 or ten will get bent badly. after that, when there is place, with a little care, you can easily get them out. Takes a lot of cleaning, though.

Kizmo wrote ...

EDIT:

Air gap could be minimized by carefully sanding (and then lapping with water sandpaper) both pieces so that rough bandsaw finish disappears?

Cut like you showed, and you will have to wind the coil directly on the core. A machine shop can surface grind the mating faces, but you cannot do it with the method you described. Being a toolmaker myself, I can assure you, that it takes a skilled metalworker to get the level of accuracy required, to reduce leakage flux to a reasonable level.EDIT:

Air gap could be minimized by carefully sanding (and then lapping with water sandpaper) both pieces so that rough bandsaw finish disappears?

Go for it, nothing beats the feeling of winding your own!

Cheers, Finn Hammer

Re: DIY high voltage & high power transformer

Kizmo, Fri Jul 20 2007, 10:20PM

Its true that nothing beats DIY HV things :)

I just ordered some copper wire for secondary (0.20mm, 2.6km) and some polyester based transformer insulation tape to insulate secondary winding layers (Dielectric strength: 7500 V) Now i just need to start building some sort of rev counter to my lathe :)

Kizmo, Fri Jul 20 2007, 10:20PM

Its true that nothing beats DIY HV things :)

I just ordered some copper wire for secondary (0.20mm, 2.6km) and some polyester based transformer insulation tape to insulate secondary winding layers (Dielectric strength: 7500 V) Now i just need to start building some sort of rev counter to my lathe :)

Re: DIY high voltage & high power transformer

Sulaiman, Sat Jul 21 2007, 02:46AM

I really would go with Finn's method,

I've dis-assembled a few laminated steel transformers

the loss of one or two laminations in the extraction process

is far better than introducing an air gap.

Use a solvent to clean the laminations prior to re-assembly

Once re-assembled tap (HIT) the laminations together at the top and bottom

to make the E and I sections of each layer have as small an air gap as possible

to 'discourage' the magnetic flux from 'jumping' sideways from lamination to lamination

this will minimise losses due to eddy currents.

Then apply thin varnish and allow it to seep between laminations to hold them in place

and reduce hum/buzz.

Winding with 0.2mm wire and insulating with tape each layer will be quite tedious

do some research on winding techniques first

and make sure that you do not wind to the ends of the insulation or overall insulation will be difficult.

For the voltage that you are aiming for I would;

- varnish each layer before applying tape

or preferably

- use craft/brown paper instead of tape and immerse the whole transformer in oil.

Just because your transformer insulation seems ok for a few minutes (or days)

doesn't mean it will last for months or years.

If not under oil, the corona at 20 kV + will slowly 'eat' the insulation.

Sulaiman, Sat Jul 21 2007, 02:46AM

I really would go with Finn's method,

I've dis-assembled a few laminated steel transformers

the loss of one or two laminations in the extraction process

is far better than introducing an air gap.

Use a solvent to clean the laminations prior to re-assembly

Once re-assembled tap (HIT) the laminations together at the top and bottom

to make the E and I sections of each layer have as small an air gap as possible

to 'discourage' the magnetic flux from 'jumping' sideways from lamination to lamination

this will minimise losses due to eddy currents.

Then apply thin varnish and allow it to seep between laminations to hold them in place

and reduce hum/buzz.

Winding with 0.2mm wire and insulating with tape each layer will be quite tedious

do some research on winding techniques first

and make sure that you do not wind to the ends of the insulation or overall insulation will be difficult.

For the voltage that you are aiming for I would;

- varnish each layer before applying tape

or preferably

- use craft/brown paper instead of tape and immerse the whole transformer in oil.

Just because your transformer insulation seems ok for a few minutes (or days)

doesn't mean it will last for months or years.

If not under oil, the corona at 20 kV + will slowly 'eat' the insulation.

Re: DIY high voltage & high power transformer

Hazmatt_(The Underdog), Sat Jul 21 2007, 03:57AM

You'll want to insulate for coil to coil breakdown too by placing several layers of an insulating material between the two, Cambric paper or Fish paper are good for this. Then you want to also insulate the HV coil from the core with pieces of the same paper on top and on bottom of the coil. This will reduce the risk of corona from the ends of the coil. I would go a step further and use some kind of silicone insulating material between the paper end cap and the coil as well.

Hazmatt_(The Underdog), Sat Jul 21 2007, 03:57AM

You'll want to insulate for coil to coil breakdown too by placing several layers of an insulating material between the two, Cambric paper or Fish paper are good for this. Then you want to also insulate the HV coil from the core with pieces of the same paper on top and on bottom of the coil. This will reduce the risk of corona from the ends of the coil. I would go a step further and use some kind of silicone insulating material between the paper end cap and the coil as well.

Re: DIY high voltage & high power transformer

Finn Hammer, Sat Jul 21 2007, 10:40AM

Insulation btwn. layers is one thing, and certainly a factor. with around 50 layers in a 20kV coil, there are 400 volts between layers.

Another, more urgent need, is acheived by the interleaving material: maintaining a winding without overlapping turns. Everytime you make an overlapping turn, you waste radial space for a whole layer!

There is limited space in a transformer, so each layer has to be filled with the maximum possible turns.

You _must_ put it under oil. You will realize this the moment you turn it on. there will be blue corona, buzzing and hissing like a beeswarm.

If you have corona in an airgap, you gain nothing by adding solid dielectric. The field strength in the remaining (now shorter) airgap will increase.

The voltage drop across individual layes, in a sandwich of dielectric materials, is determined by the dielectric constant of the individual material.

Higher dielectric constant means lower drop.

Let`s say we have a 10mm air gap between 100mm balls. Breakdown voltage is 29kV in air.

So with 25kV across this gap there is no corona.

Now we introduce a 9mm thich slab of dielectric with a dielectric constant of 2,2.

The voltage drop across the solid dielectric becomes ~20kV leaving 5kV across the remaining millimeter of air.

50kV/cm in air is way into corona territory.

You cannot insulate your way out of a corona problem, unless you exclude the air completely. Oil is the easiest way, solid potting cured under heavy vacuum is another method

Cheers, Finn Hammer

Finn Hammer, Sat Jul 21 2007, 10:40AM

Insulation btwn. layers is one thing, and certainly a factor. with around 50 layers in a 20kV coil, there are 400 volts between layers.

Another, more urgent need, is acheived by the interleaving material: maintaining a winding without overlapping turns. Everytime you make an overlapping turn, you waste radial space for a whole layer!

There is limited space in a transformer, so each layer has to be filled with the maximum possible turns.

You _must_ put it under oil. You will realize this the moment you turn it on. there will be blue corona, buzzing and hissing like a beeswarm.

Hazmatt_(The Underdog) wrote ...

Then you want to also insulate the HV coil from the core with pieces of the same paper on top and on bottom of the coil. This will reduce the risk of corona from the ends of the coil.

Hazmat:Then you want to also insulate the HV coil from the core with pieces of the same paper on top and on bottom of the coil. This will reduce the risk of corona from the ends of the coil.

If you have corona in an airgap, you gain nothing by adding solid dielectric. The field strength in the remaining (now shorter) airgap will increase.

The voltage drop across individual layes, in a sandwich of dielectric materials, is determined by the dielectric constant of the individual material.

Higher dielectric constant means lower drop.

Let`s say we have a 10mm air gap between 100mm balls. Breakdown voltage is 29kV in air.

So with 25kV across this gap there is no corona.

Now we introduce a 9mm thich slab of dielectric with a dielectric constant of 2,2.

The voltage drop across the solid dielectric becomes ~20kV leaving 5kV across the remaining millimeter of air.

50kV/cm in air is way into corona territory.

You cannot insulate your way out of a corona problem, unless you exclude the air completely. Oil is the easiest way, solid potting cured under heavy vacuum is another method

Cheers, Finn Hammer

Re: DIY high voltage & high power transformer

Dr. Dark Current, Sat Jul 21 2007, 11:10AM

Dr. Dark Current, Sat Jul 21 2007, 11:10AM

Finn Hammer wrote ...

Insulation btwn. layers is one thing, and certainly a factor. with around 50 layers in a 20kV coil, there are 400 volts between layers.

Actually, for 20kv ac and 50 layers, there are 800 volts ac (or 1130 vpeak) between the two "ends" of 2 layers.Insulation btwn. layers is one thing, and certainly a factor. with around 50 layers in a 20kV coil, there are 400 volts between layers.

Re: DIY high voltage & high power transformer

Finn Hammer, Sat Jul 21 2007, 01:50PM

Forgot the back and forth.

Thanks for reminding.

Cheers, Finn hammer

Finn Hammer, Sat Jul 21 2007, 01:50PM

jmartis wrote ...

Whoops, my bad.Finn Hammer wrote ...

Insulation btwn. layers is one thing, and certainly a factor. with around 50 layers in a 20kV coil, there are 400 volts between layers.

Actually, for 20kv ac and 50 layers, there are 800 volts ac (or 1130 vpeak) between the two "ends" of 2 layers.Insulation btwn. layers is one thing, and certainly a factor. with around 50 layers in a 20kV coil, there are 400 volts between layers.

Forgot the back and forth.

Thanks for reminding.

Cheers, Finn hammer

Re: DIY high voltage & high power transformer

Kizmo, Sat Jul 21 2007, 05:21PM

I decided to take laminations apart, it was a lot easier than i first thought:

Kizmo, Sat Jul 21 2007, 05:21PM

I decided to take laminations apart, it was a lot easier than i first thought:

Re: DIY high voltage & high power transformer

Sulaiman, Sat Jul 21 2007, 05:55PM

GOOD !

Now is the tine to look for a suitable container for the transformer and oil.

To save on oil and weight the container should be as small as possible.

That's a fantastic core and primary you've got there

worth making a good transformer.

Sulaiman, Sat Jul 21 2007, 05:55PM

GOOD !

Now is the tine to look for a suitable container for the transformer and oil.

To save on oil and weight the container should be as small as possible.

That's a fantastic core and primary you've got there

worth making a good transformer.

Re: DIY high voltage & high power transformer

Kizmo, Sun Jul 22 2007, 08:55AM

Transformer is now fully disassembled and it was success, all laminations are ok. Now i need to scrap all loose lacquer away.

Lets talk about transformer design, i know that there is a lot of math involved.

Specs of this core are following:

- 30.5cm^2

- 50Hz

- transformer was rated at 1200VA

I have lots of 0.20mm copper wire and im planning to make secondary HV winding with that stuff. What i need to know (or calculate) to get values for primary winding? Good www-site about transformer design for dummies would be great :)

Kizmo, Sun Jul 22 2007, 08:55AM

Transformer is now fully disassembled and it was success, all laminations are ok. Now i need to scrap all loose lacquer away.

Lets talk about transformer design, i know that there is a lot of math involved.

Specs of this core are following:

- 30.5cm^2

- 50Hz

- transformer was rated at 1200VA

I have lots of 0.20mm copper wire and im planning to make secondary HV winding with that stuff. What i need to know (or calculate) to get values for primary winding? Good www-site about transformer design for dummies would be great :)

Re: DIY high voltage & high power transformer

Dr. Dark Current, Sun Jul 22 2007, 09:16AM

Wrap 10 turns around the core, turn the transformer on, measure voltage across these 10 turns, divide by 10 and you have the volts/turn for your core.

Dr. Dark Current, Sun Jul 22 2007, 09:16AM

Kizmo wrote ...

What i need to know (or calculate) to get values for primary winding? Good www-site about transformer design for dummies would be great :)

(edit, I probably got something wrong)What i need to know (or calculate) to get values for primary winding? Good www-site about transformer design for dummies would be great :)

Wrap 10 turns around the core, turn the transformer on, measure voltage across these 10 turns, divide by 10 and you have the volts/turn for your core.

Re: DIY high voltage & high power transformer

Finn Hammer, Sun Jul 22 2007, 10:23AM

I am wondering about 2 things you wrote in the first post:

You write that there are 90 turns on the primary and that you intend to use half of it.

90 turns sounds unreal, a core like this will support around 0.9 volts per turn, so for 240 volts in, there should be 270 turns.

How to determine the total voltage sec. out:

You have 0.2mm wire, which probably measures 0.24 with lacquer?

Get some 0.05 mylar sheets to insulate each layer.

Each layer will fill 0,3mm

Measure how thick the total coil can be and divide with 0.3, you have number of layers.

Amount of turns per layer:

You cannot wind all the way to the end, but need to make some space for insulation. so the bottom layer will be like 10mm shorter than the core window, and the top winding will be like 40mm shorter.

________ooooooooooooo_________

_______oo ooooooooooooo________

______ooooooooooooooooo_____ __

_____ooooooooooooooooooo______

____oooooooooooo ooooooooo_____

___ooooooooooooooooooooooo____

In average, the windings will be 25mm shorter than the window length.

Subtract 25mm from window length, and divide by 0.25 to give windings per layer. now multiply by total layers, to give total amount of turns.

Multiply by 0.9 to give RMS winding voltage, and 1.41 to give peak voltage.

Hope this helps.

Cheers, Finn Hammer

Finn Hammer, Sun Jul 22 2007, 10:23AM

I am wondering about 2 things you wrote in the first post:

You write that there are 90 turns on the primary and that you intend to use half of it.

90 turns sounds unreal, a core like this will support around 0.9 volts per turn, so for 240 volts in, there should be 270 turns.

How to determine the total voltage sec. out:

You have 0.2mm wire, which probably measures 0.24 with lacquer?

Get some 0.05 mylar sheets to insulate each layer.

Each layer will fill 0,3mm

Measure how thick the total coil can be and divide with 0.3, you have number of layers.

Amount of turns per layer:

You cannot wind all the way to the end, but need to make some space for insulation. so the bottom layer will be like 10mm shorter than the core window, and the top winding will be like 40mm shorter.

________ooooooooooooo_________

_______oo ooooooooooooo________

______ooooooooooooooooo_____ __

_____ooooooooooooooooooo______

____oooooooooooo ooooooooo_____

___ooooooooooooooooooooooo____

In average, the windings will be 25mm shorter than the window length.

Subtract 25mm from window length, and divide by 0.25 to give windings per layer. now multiply by total layers, to give total amount of turns.

Multiply by 0.9 to give RMS winding voltage, and 1.41 to give peak voltage.

Hope this helps.

Cheers, Finn Hammer

Re: DIY high voltage & high power transformer

Kizmo, Sun Jul 22 2007, 01:02PM

I haven't fully understand how important that Volts/turn ratio is. Im guessing it has something to do with efficiency/iron losses?

Kizmo, Sun Jul 22 2007, 01:02PM

Finn Hammer wrote ...

You write that there are 90 turns on the primary and that you intend to use half of it.

90 turns sounds unreal, a core like this will support around 0.9 volts per turn, so for 240 volts in, there should be 270 turns.

I was wrong with that, i thought first that there were only 1½ layer of primary winding but there was 3½ layers. So target should be around 0.9V/turn. You write that there are 90 turns on the primary and that you intend to use half of it.

90 turns sounds unreal, a core like this will support around 0.9 volts per turn, so for 240 volts in, there should be 270 turns.

I haven't fully understand how important that Volts/turn ratio is. Im guessing it has something to do with efficiency/iron losses?

Re: DIY high voltage & high power transformer

Sulaiman, Sun Jul 22 2007, 01:56PM

A couple of thoughts;

1)

Do you really need 20 kV rms

less voltage = much easier insulation.

Consider the final design of whatever it is that this transformer is going to power.

2)

No matter what voltage you decide on

it would be much easier to insulate/protect from corona

if you split the secondary in two.

e.g. Instead of one 20 kV winding (0V and 20kVrms)

use two windings, with a center-tap to ground/earth/0V (10-0-10 kVrms)

Sulaiman, Sun Jul 22 2007, 01:56PM

A couple of thoughts;

1)

Do you really need 20 kV rms

less voltage = much easier insulation.

Consider the final design of whatever it is that this transformer is going to power.

2)

No matter what voltage you decide on

it would be much easier to insulate/protect from corona

if you split the secondary in two.

e.g. Instead of one 20 kV winding (0V and 20kVrms)

use two windings, with a center-tap to ground/earth/0V (10-0-10 kVrms)

Re: DIY high voltage & high power transformer

Kizmo, Sun Jul 22 2007, 02:03PM

Well, as you can see, this is my 1st DIY transformer project so please be patient - and im open for ideas - how you would do this :)

Kizmo, Sun Jul 22 2007, 02:03PM

Well, as you can see, this is my 1st DIY transformer project so please be patient - and im open for ideas - how you would do this :)

Re: DIY high voltage & high power transformer

Finn Hammer, Sun Jul 22 2007, 02:39PM

It has to do with flux density in the core.

A ferromagnetic material has a high permeability, therefore it increases the inductance of the coil that surrounds it. This permeability is linked to the flux density, in a way that is described by the B-H curve.

Initially, the permeability is low, than it increases and stays high untill the flux density reaches typically 1.6 Tesla (typical nos for transformer lams.)

Beyond 1.6 T, the iron saturates, and the permeability starts to drop.

If you apply more volts per turn than the core can handle, the flux density increases beyond the saturation level.

Then the inductance starts to drop, the inductance decreases, and too much current starts to flow.

The volts per turn ratio is the only parameter you need to know, to make a 50Hz transformer work.

The real beauty of a transformer is, that the primary coil has enough inductance to keep the current low, when the load reflected from the secondary is low.

How long is the winding window, and how wide is it from secondary core to primary winding.?

I`d like to teke a shot at a layout.

Are you still determined to put it under oil?

Cheers, Finn Hammer

Finn Hammer, Sun Jul 22 2007, 02:39PM

Kizmo wrote ...

I haven't fully understand how important that Volts/turn ratio is. Im guessing it has something to do with efficiency/iron losses?

I haven't fully understand how important that Volts/turn ratio is. Im guessing it has something to do with efficiency/iron losses?

It has to do with flux density in the core.

A ferromagnetic material has a high permeability, therefore it increases the inductance of the coil that surrounds it. This permeability is linked to the flux density, in a way that is described by the B-H curve.

Initially, the permeability is low, than it increases and stays high untill the flux density reaches typically 1.6 Tesla (typical nos for transformer lams.)

Beyond 1.6 T, the iron saturates, and the permeability starts to drop.

If you apply more volts per turn than the core can handle, the flux density increases beyond the saturation level.

Then the inductance starts to drop, the inductance decreases, and too much current starts to flow.

The volts per turn ratio is the only parameter you need to know, to make a 50Hz transformer work.

The real beauty of a transformer is, that the primary coil has enough inductance to keep the current low, when the load reflected from the secondary is low.

How long is the winding window, and how wide is it from secondary core to primary winding.?

I`d like to teke a shot at a layout.

Are you still determined to put it under oil?

Cheers, Finn Hammer

Re: DIY high voltage & high power transformer

Sulaiman, Sun Jul 22 2007, 03:03PM

I would;

1) Clean the laminations with a solvent such as petrol (gasoline) rather than scratch them up

2) Clean up and save the secondary wire - thick rectangular copper for winding is very useful

.....Coilgun, ring launcher, Tesla Coil primary ........

3) Decide what I want the final transformer for.

Here are a few suggestions with possible output requirements;

3.1) Jacobs Ladder. 5-0-5 kVrms to 10-0-10 kVrms

3.2) Spark Gap TC. 5-0-5 kVrms to 10-0-10 kVrms

3.3) Isolation Transformer. Dis-assemble a second transformer and use two primaries on one core for 230:230 Vac

3.4) Experiments with inductance; Bolt all the "U" sections together and bolt all the "I" sections together,

Put back the primary and secondary windings on the "U" section

3.4.1) with a 1.5V battery feel how powerful the "I" section is attracted to the "U" section for the two different coils.

3.4.2) put a neon across the 230V winding and briefly apply a 1.5V battery to the 12V winding,

with and without the "I" sections.

3.4.3) measure the current into the coil using 230Vac on the 230Vac winding

with different airgaps between the "U" and "I" sections

Consider how this could be used in series with a second transformer for current-limiting.

Requires current limiting

Requires current limiting

Anyone else got any good ideas for Kizmo ?

Sulaiman, Sun Jul 22 2007, 03:03PM

I would;

1) Clean the laminations with a solvent such as petrol (gasoline) rather than scratch them up

2) Clean up and save the secondary wire - thick rectangular copper for winding is very useful

.....Coilgun, ring launcher, Tesla Coil primary ........

3) Decide what I want the final transformer for.

Here are a few suggestions with possible output requirements;

3.1) Jacobs Ladder. 5-0-5 kVrms to 10-0-10 kVrms

3.2) Spark Gap TC. 5-0-5 kVrms to 10-0-10 kVrms

3.3) Isolation Transformer. Dis-assemble a second transformer and use two primaries on one core for 230:230 Vac

3.4) Experiments with inductance; Bolt all the "U" sections together and bolt all the "I" sections together,

Put back the primary and secondary windings on the "U" section

3.4.1) with a 1.5V battery feel how powerful the "I" section is attracted to the "U" section for the two different coils.

3.4.2) put a neon across the 230V winding and briefly apply a 1.5V battery to the 12V winding,

with and without the "I" sections.

3.4.3) measure the current into the coil using 230Vac on the 230Vac winding

with different airgaps between the "U" and "I" sections

Consider how this could be used in series with a second transformer for current-limiting.

Requires current limiting

Requires current limitingAnyone else got any good ideas for Kizmo ?

Re: DIY high voltage & high power transformer

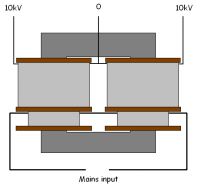

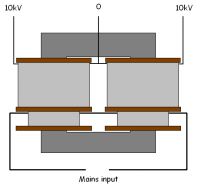

Kizmo, Sun Jul 22 2007, 03:28PM

1. Done

2. Done, got several meters of 8x3mm copper wire

Something like TC powersupply or Jacobs ladder (or both..) are in my mind. 10-0-10 kVrms could be done under oil?

Here are some measures from naked core before disassembly:

I saw somewhere this kind of setup with UI core:

I could use same kind of structure?

EDIT: I just realized that im running out of space here so 5-0-5 is more doable IMO

Kizmo, Sun Jul 22 2007, 03:28PM

Sulaiman wrote ...

1) Clean the laminations with a solvent such as petrol (gasoline) rather than scratch them up

2) Clean up and save the secondary wire - thick rectangular copper for winding is very useful

.....Coilgun, ring launcher, Tesla Coil primary ........

3) Decide what I want the final transformer for.

Here are a few suggestions with possible output requirements;

3.1) Jacobs Ladder. 5-0-5 kVrms to 10-0-10 kVrms

3.2) Spark Gap TC. 5-0-5 kVrms to 10-0-10 kVrms

1) Clean the laminations with a solvent such as petrol (gasoline) rather than scratch them up

2) Clean up and save the secondary wire - thick rectangular copper for winding is very useful

.....Coilgun, ring launcher, Tesla Coil primary ........

3) Decide what I want the final transformer for.

Here are a few suggestions with possible output requirements;

3.1) Jacobs Ladder. 5-0-5 kVrms to 10-0-10 kVrms

3.2) Spark Gap TC. 5-0-5 kVrms to 10-0-10 kVrms

1. Done

2. Done, got several meters of 8x3mm copper wire

Something like TC powersupply or Jacobs ladder (or both..) are in my mind. 10-0-10 kVrms could be done under oil?

Here are some measures from naked core before disassembly:

I saw somewhere this kind of setup with UI core:

I could use same kind of structure?

EDIT: I just realized that im running out of space here so 5-0-5 is more doable IMO

Re: DIY high voltage & high power transformer

Sulaiman, Sun Jul 22 2007, 04:22PM

Yes you could do that;

if you re-assemble the cores nicely there's no need to re-do the primary,

just put two 5kV (or 10kV) windings on the other side.

Sulaiman, Sun Jul 22 2007, 04:22PM

Yes you could do that;

if you re-assemble the cores nicely there's no need to re-do the primary,

just put two 5kV (or 10kV) windings on the other side.

Re: DIY high voltage & high power transformer

Marko, Sat Jul 28 2007, 06:46PM

Hey, this is a beautiful core.

I would definitely save the primary (it is very nice) and build the secondary completely on the other side. Why you think to use half of the primary? Don't you have 230V available?

If you have the remaining bobbin you could also use it as a base for your secondary, although it will need a lot more insulation to be safe.

Marko, Sat Jul 28 2007, 06:46PM

Hey, this is a beautiful core.

I would definitely save the primary (it is very nice) and build the secondary completely on the other side. Why you think to use half of the primary? Don't you have 230V available?

If you have the remaining bobbin you could also use it as a base for your secondary, although it will need a lot more insulation to be safe.

Re: DIY high voltage & high power transformer

Kizmo, Sun Jul 29 2007, 05:57PM

I will use the old primary which has 229 turns to be exact. It is wound with quite thick wire (measures with lacquer slightly over 2mm). New secondary will be done with .20mm wire. How primary winding wire thickness affects to transformer features?

I had little shopping moment and already have these:

- 3.6kms (2.23 miles) .20mm (AVG 32) copper wire

- 0.05mm mylar sheets

- Thin urethane based lacquer for metal/plastic surfaces

My homemade winding machine (old lathe) is also operational, i have cheap step counter as turn counter. I Will take some pictures when things get rolling. (Ill start by making one half of sec winding)

Kizmo, Sun Jul 29 2007, 05:57PM

I will use the old primary which has 229 turns to be exact. It is wound with quite thick wire (measures with lacquer slightly over 2mm). New secondary will be done with .20mm wire. How primary winding wire thickness affects to transformer features?

I had little shopping moment and already have these:

- 3.6kms (2.23 miles) .20mm (AVG 32) copper wire

- 0.05mm mylar sheets

- Thin urethane based lacquer for metal/plastic surfaces

My homemade winding machine (old lathe) is also operational, i have cheap step counter as turn counter. I Will take some pictures when things get rolling. (Ill start by making one half of sec winding)

Re: DIY high voltage & high power transformer

Sulaiman, Sun Jul 29 2007, 06:44PM

The amp.turns for the secondary are usually a tiny bit less for the secondary than the primary,

and the current capacity of a wire is proportional to it's cross-sectional area,

so assuming your 0.2 mm wire is (like mine) actual copper diameter

and the primary is 1.8mm actual copper diameter

Then Ns = Np x (1.8 / 0.2)^2 = Np x 81

So an "ideal" transformer using 0.2mm wire would have 229 x 81 = 18549 turns

and a no-load voltage of 230 x 81 = 18630 Volts rms.

I'd be tempted to go with TWO secondaries of 10,000 turns each,

with an output voltage of 10-0-10 kVrms.

Under oil this transformer should be ok to 2500 W easily.

Sulaiman, Sun Jul 29 2007, 06:44PM

The amp.turns for the secondary are usually a tiny bit less for the secondary than the primary,

and the current capacity of a wire is proportional to it's cross-sectional area,

so assuming your 0.2 mm wire is (like mine) actual copper diameter

and the primary is 1.8mm actual copper diameter

Then Ns = Np x (1.8 / 0.2)^2 = Np x 81

So an "ideal" transformer using 0.2mm wire would have 229 x 81 = 18549 turns

and a no-load voltage of 230 x 81 = 18630 Volts rms.

I'd be tempted to go with TWO secondaries of 10,000 turns each,

with an output voltage of 10-0-10 kVrms.

Under oil this transformer should be ok to 2500 W easily.

Re: DIY high voltage & high power transformer

Kizmo, Mon Oct 01 2007, 07:03PM

Well, back to the old topic :)

I dont have anymore that core which i planned to use (actually i have it but it works as ballast now)

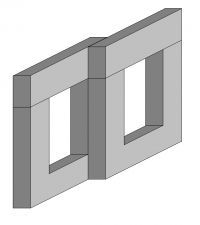

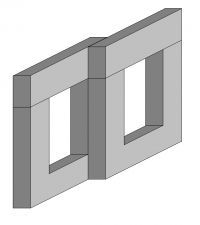

BUT i got even bigger core and some new ideas. I made one prototype like this:

Primary winding has too much turns still (im aiming to around 0.9V/turn). Each 'loop' has cross-section area of 18cm^2 -> inside the primary winding 36cm^2. MOT secondary represents HV winding and brown 2-turn coil is for measuring volts/turns ratio. Primary is done with AWG12 copper wire mainly because it was very cheap (10eur/200m from flee market).

So, what do you think, is there possibility that this could work, plan is that there will be 4 separate 5kV windings, two per 'loop'

Kizmo, Mon Oct 01 2007, 07:03PM

Well, back to the old topic :)

I dont have anymore that core which i planned to use (actually i have it but it works as ballast now)

BUT i got even bigger core and some new ideas. I made one prototype like this:

Primary winding has too much turns still (im aiming to around 0.9V/turn). Each 'loop' has cross-section area of 18cm^2 -> inside the primary winding 36cm^2. MOT secondary represents HV winding and brown 2-turn coil is for measuring volts/turns ratio. Primary is done with AWG12 copper wire mainly because it was very cheap (10eur/200m from flee market).

So, what do you think, is there possibility that this could work, plan is that there will be 4 separate 5kV windings, two per 'loop'

Re: DIY high voltage & high power transformer

Sulaiman, Mon Oct 01 2007, 08:13PM

I wouldn't split the core like that;

I'd do it like in the drawing that you posted Sun Jul 22 2007, 04:27PM

why?

each secondary winding in your new arrangement would get 1/2 the primary flux

so each secondary would require 2x the number of turns compared to the drawing of Sun Jul 22 2007, 04:27PM

for a given voltage.

You will be using more wire than neccessary hence heavier, costlier and most importantly, less efficient.

AND

the flux coupling between primary and secondary would not be as good

so the output will appear to have some inductance in series with it

reducing the maximum output.

The old true and tried methods are often best!

Sulaiman, Mon Oct 01 2007, 08:13PM

I wouldn't split the core like that;

I'd do it like in the drawing that you posted Sun Jul 22 2007, 04:27PM

why?

each secondary winding in your new arrangement would get 1/2 the primary flux

so each secondary would require 2x the number of turns compared to the drawing of Sun Jul 22 2007, 04:27PM

for a given voltage.

You will be using more wire than neccessary hence heavier, costlier and most importantly, less efficient.

AND

the flux coupling between primary and secondary would not be as good

so the output will appear to have some inductance in series with it

reducing the maximum output.

The old true and tried methods are often best!

Re: DIY high voltage & high power transformer

Shaun, Mon Oct 01 2007, 11:57PM

There's a reason why E-core transformers have both windings on the center part (see MOT). If you trace out the magnetic circuit in the core(s) you will see that half of it is essentially a "short". As Sulaiman said, the secondary only gets half possible flux.

Shaun, Mon Oct 01 2007, 11:57PM

There's a reason why E-core transformers have both windings on the center part (see MOT). If you trace out the magnetic circuit in the core(s) you will see that half of it is essentially a "short". As Sulaiman said, the secondary only gets half possible flux.

Re: DIY high voltage & high power transformer

Kizmo, Sat Jan 26 2008, 12:04PM

Now its finally time to actually *do* something, not just speculate :)

Recently i acquired even bigger core, this time it has a lot of space for windings. This will be the final thing:

http://koti.mbnet.fi/kizmo/misc/muhennin/220108/kokovertailu.jpg

It measures outer dimensions of 25cm x 25cm x 8cm and has cross-section area of 40cm^2.. and weights like hell for my broken back. Today i will assemble that core with polyester resin. I haven't decided yet will it be 'dry' or oil insulated thing, it depends which i will get easier; high voltage mylar/kapton plastic or proper transformer oil. I have build several tools for assembling this core, it wont be easy to align laminations exactly when you have only 10 minutes before resin starts to harden. So everything *must* be dead-on planned and built.

Today i will assemble that core with polyester resin. I haven't decided yet will it be 'dry' or oil insulated thing, it depends which i will get easier; high voltage mylar/kapton plastic or proper transformer oil. I have build several tools for assembling this core, it wont be easy to align laminations exactly when you have only 10 minutes before resin starts to harden. So everything *must* be dead-on planned and built.

Main points of design:

- 240V/400V primaries

- Total secondary voltage 15kV-20kV

- It must be constructed so that if(when) sec. insulation fails, i can disassemble it for repair without jackhammer

- Oil is not problem, but it does make things a bit oily.. eww

Kizmo, Sat Jan 26 2008, 12:04PM

Now its finally time to actually *do* something, not just speculate :)

Recently i acquired even bigger core, this time it has a lot of space for windings. This will be the final thing:

http://koti.mbnet.fi/kizmo/misc/muhennin/220108/kokovertailu.jpg

It measures outer dimensions of 25cm x 25cm x 8cm and has cross-section area of 40cm^2.. and weights like hell for my broken back.

Today i will assemble that core with polyester resin. I haven't decided yet will it be 'dry' or oil insulated thing, it depends which i will get easier; high voltage mylar/kapton plastic or proper transformer oil. I have build several tools for assembling this core, it wont be easy to align laminations exactly when you have only 10 minutes before resin starts to harden. So everything *must* be dead-on planned and built.

Today i will assemble that core with polyester resin. I haven't decided yet will it be 'dry' or oil insulated thing, it depends which i will get easier; high voltage mylar/kapton plastic or proper transformer oil. I have build several tools for assembling this core, it wont be easy to align laminations exactly when you have only 10 minutes before resin starts to harden. So everything *must* be dead-on planned and built. Main points of design:

- 240V/400V primaries

- Total secondary voltage 15kV-20kV

- It must be constructed so that if(when) sec. insulation fails, i can disassemble it for repair without jackhammer

- Oil is not problem, but it does make things a bit oily.. eww

Re: DIY high voltage & high power transformer

Dr. Dark Current, Sat Jan 26 2008, 12:29PM

Kizmo, that's scary, where did you get that core? O_o

And what do you plan to use the xfmr for when it's finished?

Dr. Dark Current, Sat Jan 26 2008, 12:29PM

Kizmo, that's scary, where did you get that core? O_o

And what do you plan to use the xfmr for when it's finished?

Re: DIY high voltage & high power transformer

Kizmo, Sat Jan 26 2008, 12:41PM

That was main xfmr from 8kW UPS (3x 380/415V -> 3x 129V @ 7820VA). It was 3-phase transformer but i modified it by cutting center 'leg' away from each lamination to make more space.

http://koti.mbnet.fi/kizmo/misc/muhennin/210108/purettu.jpg

http://koti.mbnet.fi/kizmo/misc/muhennin/220108/leikkaus.jpg

It will be used as multi-purpose high voltage transformer (arc pulling, jacobs ladders, burning stuff etc) and maybe with spark gap teslacoil. Secondary will be done with .3mm magnet wire. I would be a lot easier to just buy PT or small PIG but they are *really* hard to obtain here and almost impossible to buy because of health and safety regulations.

Kizmo, Sat Jan 26 2008, 12:41PM

jmartis wrote ...

Kizmo, that's scary, where did you get that core? O_o

And what do you plan to use the xfmr for when it's finished?

Kizmo, that's scary, where did you get that core? O_o

And what do you plan to use the xfmr for when it's finished?

That was main xfmr from 8kW UPS (3x 380/415V -> 3x 129V @ 7820VA). It was 3-phase transformer but i modified it by cutting center 'leg' away from each lamination to make more space.

http://koti.mbnet.fi/kizmo/misc/muhennin/210108/purettu.jpg

http://koti.mbnet.fi/kizmo/misc/muhennin/220108/leikkaus.jpg

It will be used as multi-purpose high voltage transformer (arc pulling, jacobs ladders, burning stuff etc) and maybe with spark gap teslacoil. Secondary will be done with .3mm magnet wire. I would be a lot easier to just buy PT or small PIG but they are *really* hard to obtain here and almost impossible to buy because of health and safety regulations.

Re: DIY high voltage & high power transformer

Logan Kennedy, Sun Jan 27 2008, 12:33AM

Wow, that thing will be a beast when complete. Very dangerous indeed.

Logan Kennedy, Sun Jan 27 2008, 12:33AM

Wow, that thing will be a beast when complete. Very dangerous indeed.

Re: DIY high voltage & high power transformer

Dr. Dark Current, Sun Jan 27 2008, 07:54AM

Dr. Dark Current, Sun Jan 27 2008, 07:54AM

wrote ...

Recently i acquired even bigger core, this time it has a lot of space for windings. This will be the final thing:

http://koti.mbnet.fi/kizmo/misc/muhennin/220108/kokovertailu.jpg

It measures outer dimensions of 25cm x 25cm x 8cm and has cross-section area of 40cm^2..

I've just read this, with 40cm^2 the core is good only to about 1.6KVA continuous on open air. Maybe a little more with active cooling.Recently i acquired even bigger core, this time it has a lot of space for windings. This will be the final thing:

http://koti.mbnet.fi/kizmo/misc/muhennin/220108/kokovertailu.jpg

It measures outer dimensions of 25cm x 25cm x 8cm and has cross-section area of 40cm^2..

Re: DIY high voltage & high power transformer

Kizmo, Sun Jan 27 2008, 10:42AM

I know the math, but that is weird, i have one 4kVA transformer (200V -> 606V) which has 38cm^2 core

Kizmo, Sun Jan 27 2008, 10:42AM

I know the math, but that is weird, i have one 4kVA transformer (200V -> 606V) which has 38cm^2 core

Re: DIY high voltage & high power transformer

Dr. Dark Current, Sun Jan 27 2008, 12:18PM

Dr. Dark Current, Sun Jan 27 2008, 12:18PM

Kizmo wrote ...

I know the math, but that is weird, i have one 4kVA transformer (200V -> 606V) which has 38cm^2 core

and is it for continuous use? I have one xfmr from 300W UPS which has ~10cm^2 cross section...I know the math, but that is weird, i have one 4kVA transformer (200V -> 606V) which has 38cm^2 core

Re: DIY high voltage & high power transformer

Kizmo, Sun Jan 27 2008, 12:24PM

I have no idea. I will 'overpower' this core heavily because it won't be running for hours.. never

Kizmo, Sun Jan 27 2008, 12:24PM

I have no idea. I will 'overpower' this core heavily because it won't be running for hours.. never

Print this page