secondary damage (fixable?)

jameselectric, Fri Mar 30 2007, 12:00AMwell i finally got my dc resonant sg coil running last night. I got about 3 foot arcs out of it. I decided to pour the juice to her. I experianced carbon tracks and racing arcs and then my coil lit no more

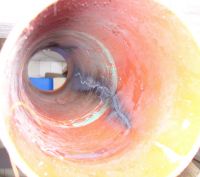

.Here is a pic of the damage to the inside of the coil. is it as easy as cleaning the inside and getting rid of the carbon tracks? there is no damage to the outside. or is it time to wind a new coil?

.Here is a pic of the damage to the inside of the coil. is it as easy as cleaning the inside and getting rid of the carbon tracks? there is no damage to the outside. or is it time to wind a new coil?Thanks everyone,

James

Re: secondary damage (fixable?)

ShawnLG, Fri Mar 30 2007, 12:11AM

It looks like it's burned in deep. You would need to wind another one because it would happen again if you could get it clean. Your coil form looks like it's made of fiber glass. Not a very good insulator. You should of used polypropylene form.

ShawnLG, Fri Mar 30 2007, 12:11AM

It looks like it's burned in deep. You would need to wind another one because it would happen again if you could get it clean. Your coil form looks like it's made of fiber glass. Not a very good insulator. You should of used polypropylene form.

Re: secondary damage (fixable?)

jameselectric, Fri Mar 30 2007, 02:47AM

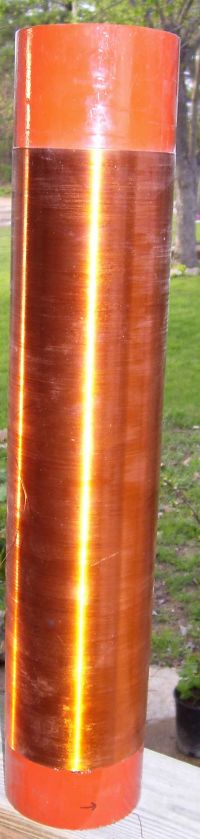

the form is pvc pipe covered with red high voltage insulating varnish. we use this on the induction heat treating machines at work on the inductors. The windings are on a 4.250 by 17 high. should i change any of the dimesions if i decide to wind a new coil?

Thanks

jameselectric, Fri Mar 30 2007, 02:47AM

the form is pvc pipe covered with red high voltage insulating varnish. we use this on the induction heat treating machines at work on the inductors. The windings are on a 4.250 by 17 high. should i change any of the dimesions if i decide to wind a new coil?

Thanks

Re: secondary damage (fixable?)

Self Defenestrate, Fri Mar 30 2007, 03:12AM

If you got internal arc-over at higher powers, make your secondary bigger. Wider, with the same height might be alright, as lower fres will keep insulative losses low, and corona at bay. Keep your 'ponents cooler too.

Self Defenestrate, Fri Mar 30 2007, 03:12AM

If you got internal arc-over at higher powers, make your secondary bigger. Wider, with the same height might be alright, as lower fres will keep insulative losses low, and corona at bay. Keep your 'ponents cooler too.

Re: secondary damage (fixable?)

Terry Fritz, Fri Mar 30 2007, 05:30PM

Hi,

It's pretty bad there. But you have nothing to loose. He's what I would do (might want to wait a bit to see if anybody has any better ideas though). Sand, carve, grind, dremel out as much of the black path as possible. Auto parts stores have high voltage dielectric grease used in auto high voltage ignitions. It is just silcone grease probably in a tube next to the glues and such for about $7*. Smear, rub and force it into the arc path. If that does not stop it, nothing will. It is sort of my "emergency slime"

Some high voltage "corona dope" used in TV's and such is actually rather conductive and is meant to cover sharp edges. I don't know if that would be the case with your varnish though. I guess the second time "I" would avoid the varnish. All kinds of coil's work find with just the usual coatings. Often, the simpler it is, the less that can go wrong.

It has been reported the PVC may sometimes have contaminates in it too. I have started checking forms with a light on the other side shining through looking for "odd things" in it. I have dug a few things out of it before winding before. Not sure how much there is too that but...

The form should be sanded to remove any surface dirt and wiped with alcohol. Some people are even afraid of "touching it" once cleaned in fear a finger print might be conductive enough... But the usual poly coating should stop things like that anyway.

* Mine is "AGS Dielectric Silicone Compound Cat no. DS-1". You may have to ask where they hide it at the counter.

Cheers,

Terry

Terry Fritz, Fri Mar 30 2007, 05:30PM

Hi,

It's pretty bad there. But you have nothing to loose. He's what I would do (might want to wait a bit to see if anybody has any better ideas though). Sand, carve, grind, dremel out as much of the black path as possible. Auto parts stores have high voltage dielectric grease used in auto high voltage ignitions. It is just silcone grease probably in a tube next to the glues and such for about $7*. Smear, rub and force it into the arc path. If that does not stop it, nothing will. It is sort of my "emergency slime"

Some high voltage "corona dope" used in TV's and such is actually rather conductive and is meant to cover sharp edges. I don't know if that would be the case with your varnish though. I guess the second time "I" would avoid the varnish. All kinds of coil's work find with just the usual coatings. Often, the simpler it is, the less that can go wrong.

It has been reported the PVC may sometimes have contaminates in it too. I have started checking forms with a light on the other side shining through looking for "odd things" in it. I have dug a few things out of it before winding before. Not sure how much there is too that but...

The form should be sanded to remove any surface dirt and wiped with alcohol. Some people are even afraid of "touching it" once cleaned in fear a finger print might be conductive enough... But the usual poly coating should stop things like that anyway.

* Mine is "AGS Dielectric Silicone Compound Cat no. DS-1". You may have to ask where they hide it at the counter.

Cheers,

Terry

Print this page