Diodes dying on can crusher

Billybobjoe, Tue Feb 13 2007, 09:11PMWith the help of Steve Ward in finding some microwave oven style capacitors, I've constructed my own eletromagnetic can crusher. The setup involves 24, 1.02 uf MO caps in parallel, charged by a variac controlled 9kv 30 ma NST, through a full wave rectifier consisting of 20 1N4007's in series for each leg.

The main power switch is thick SCH. 80 PVC "tee" fitting, with two thick brass rods very close to each other inside. The fitting is pressurized with air to around 150 PSI, and when released with the bank charged, the gap triggers.

MY question is, why do my full wave rectifiers keep failing? I've gotten two successful low power shots (which make some nice marks on the can), one with a series 1N4007 full wave rectifier (only rated at 9kv, so failure was practicaly expected). My 20kv full wave was also killed. I'm assuming this has something to do with the feedback from my main coil sending a high frequency current back to them. Would constructing a rectifier from some HV diodes with a fast recovery time work?

What does everyone else use to rectify their HV?

Obviously disconnecting the HV supply after the bank is charged would work, but really isn't possible becasue the caps. have a fairly low internal resistance and drain quickly (good for safety though).

EDIT - By the rectifiers failing, I mean a direct short across all four legs in any direction.

Re: Diodes dying on can crusher

Eric, Tue Feb 13 2007, 09:46PM

If I understand your setup correctly, the answer is that the voltage reversal from the work coil is conducting back through the bridge rectifier. The currents involved would be nearly the peak current through the work coil so that's going to zap pretty much any rectifier you put in there.

You need to disconnect the bridge rectifier from the caps before firing.

Eric, Tue Feb 13 2007, 09:46PM

If I understand your setup correctly, the answer is that the voltage reversal from the work coil is conducting back through the bridge rectifier. The currents involved would be nearly the peak current through the work coil so that's going to zap pretty much any rectifier you put in there.

You need to disconnect the bridge rectifier from the caps before firing.

Re: Diodes dying on can crusher

Steve Conner, Tue Feb 13 2007, 11:01PM

I agree with Eric. Just connect the charging supply across the discharge switch instead of the cap bank. Then it will see a short during discharge, which isn't anywhere near as bad as voltage reversal. Two large HV rated power resistors (say 1k 50w) one in series with each wire of the charging supply wouldn't hurt, to mop up the remaining transient from the spark gap firing.

Steve Conner, Tue Feb 13 2007, 11:01PM

I agree with Eric. Just connect the charging supply across the discharge switch instead of the cap bank. Then it will see a short during discharge, which isn't anywhere near as bad as voltage reversal. Two large HV rated power resistors (say 1k 50w) one in series with each wire of the charging supply wouldn't hurt, to mop up the remaining transient from the spark gap firing.

Re: Diodes dying on can crusher

Billybobjoe, Tue Feb 13 2007, 11:46PM

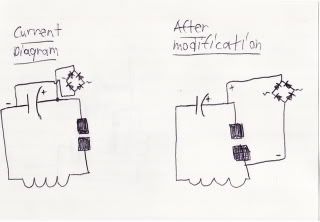

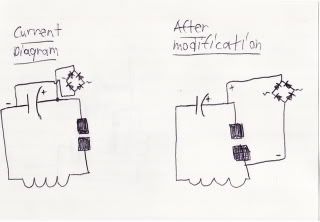

Ok, so would this poorly drawn (I swear it looks better on paper) diagram be correct:

Perhaps I'm missing something, but if the voltage reversal was high enough to jump the open switch in the original setup and ruin the rectifier, why couldn't it do the same in the revised schematic?

Billybobjoe, Tue Feb 13 2007, 11:46PM

Ok, so would this poorly drawn (I swear it looks better on paper) diagram be correct:

Perhaps I'm missing something, but if the voltage reversal was high enough to jump the open switch in the original setup and ruin the rectifier, why couldn't it do the same in the revised schematic?

Re: Diodes dying on can crusher

Dr. Slack, Wed Feb 14 2007, 07:55AM

When the spark in the gap is lit, consider it a dead short.

The current keeps flowing in the inductance, and in your original it tries to reverse charge the caps. It can't do that because it finds the bridge rectivfiier across the caps (now reversed), and flows through that instead.

In the counter-intuitive gap across the charger arrangement, the spark gap protects the rectifier, and the bulk of the current flows into the capacitors. Current limiting the charger supply with series resistors as Mr Conner suggested dramatically reduces any current that flows in the rectifier, mops up odd spikes, doesn't really reduce charging efficiency, all good really.

I usually build a single break-before-make switch that disconnects the supply in same movement as closing the gap to be really bomb-proof, but I must admit that Steve's resistors would be mechanically simpler, and very nearly as safe.

Dr. Slack, Wed Feb 14 2007, 07:55AM

When the spark in the gap is lit, consider it a dead short.

The current keeps flowing in the inductance, and in your original it tries to reverse charge the caps. It can't do that because it finds the bridge rectivfiier across the caps (now reversed), and flows through that instead.

In the counter-intuitive gap across the charger arrangement, the spark gap protects the rectifier, and the bulk of the current flows into the capacitors. Current limiting the charger supply with series resistors as Mr Conner suggested dramatically reduces any current that flows in the rectifier, mops up odd spikes, doesn't really reduce charging efficiency, all good really.

I usually build a single break-before-make switch that disconnects the supply in same movement as closing the gap to be really bomb-proof, but I must admit that Steve's resistors would be mechanically simpler, and very nearly as safe.

Re: Diodes dying on can crusher

Tesladownunder, Wed Feb 14 2007, 08:22AM

You need to understand 4 things:

1 That the diodes charging a capacitor will have to take a short circuit in the instant that you start charging. So you need to have a current limited supply (which you have at 30mA) OR a resistor capable of limiting current. Eg for a 10kv supply with 1A diodes you need a 10K resistor for continuous use (or perhaps a bit less as charging probably takes tens of seconds to get going so perhaps 5k for single peak use at a time).

However, and this is where your problem is,

2 When the caps discharge into the coil, the energy is transferred to the coils field. When the voltage drops, the field drops and in resonant fashion the energy goes back into charging the capacitor IN REVERSE to perhaps 60% ie 6kV. What happens next is different with a single rectifying diode versus a bridge.

Consider the single rectifying diode first. So now you have a 10kV supply in series (not parallel as the polarity has changed) with a 6kV cap (which is not current limited) which is short circuited. ie 16kv short protection needed. ie a resistor of 16k (1.6k peak) would be needed in a non current limited supply. This is not the worst case which is when there is no can so closer to 100% reversal ie 20K continuous (or say 2k peak).

I can't really work out what you would need with a NST supply, where part is current limited and part not. Resistor power rating is modest since only a brief peak as the coil and cap continue to oscillate.

But with the second case of the bridge rectifier, things are much worse. Basically that 6kV reverse charged cap can discharge its full energy into the diodes which are now short circuiting it. So all the energy is captured by the diodes in 1000's of amps. A series resistor of 6k would limit peak current for 60% reversal. The power capacity will need to dissipate a proportion of the 1.2kJ cap storage, so perhaps 100 W might or might not be ok for one off shots.

Actually it is not strictly the cap that discharges the energy but the coil's collapsing field and the capacitor will never get charged with the short circuit.

I remember once that my CRO was saying no voltage reversal and I didn't believe it so I put a diode across the cap. I covered myself with a blast shield - except for my arm which got a bit of exploded diode in it confirming the voltage reversal.

3 1N4007's don't have a good frequency response. My can crusher discharges in 30us which is a bit fast for these diodes so there may be a dv/dt problem as well.

4 A 9kV NST is about 13kV peak or more if turned too high (ie over 70V input) so figures may need to be adjusted.

So if using a bridge rectifier:

1 Use faster diodes (or a lot more) rated at 10kV per leg minimum ie 20kV standoff.

2 Use a series resistor of 10k minimum at 100W and you should be OK. (A bit more than what Steve said)

3 Use your "current" diagram.

I personally use fast diodes and ? 60k 40W and have had no problems up to 6kV but it charges slowly and needs to be updated

TDU

Tesladownunder, Wed Feb 14 2007, 08:22AM

You need to understand 4 things:

1 That the diodes charging a capacitor will have to take a short circuit in the instant that you start charging. So you need to have a current limited supply (which you have at 30mA) OR a resistor capable of limiting current. Eg for a 10kv supply with 1A diodes you need a 10K resistor for continuous use (or perhaps a bit less as charging probably takes tens of seconds to get going so perhaps 5k for single peak use at a time).

However, and this is where your problem is,

2 When the caps discharge into the coil, the energy is transferred to the coils field. When the voltage drops, the field drops and in resonant fashion the energy goes back into charging the capacitor IN REVERSE to perhaps 60% ie 6kV. What happens next is different with a single rectifying diode versus a bridge.

Consider the single rectifying diode first. So now you have a 10kV supply in series (not parallel as the polarity has changed) with a 6kV cap (which is not current limited) which is short circuited. ie 16kv short protection needed. ie a resistor of 16k (1.6k peak) would be needed in a non current limited supply. This is not the worst case which is when there is no can so closer to 100% reversal ie 20K continuous (or say 2k peak).

I can't really work out what you would need with a NST supply, where part is current limited and part not. Resistor power rating is modest since only a brief peak as the coil and cap continue to oscillate.

But with the second case of the bridge rectifier, things are much worse. Basically that 6kV reverse charged cap can discharge its full energy into the diodes which are now short circuiting it. So all the energy is captured by the diodes in 1000's of amps. A series resistor of 6k would limit peak current for 60% reversal. The power capacity will need to dissipate a proportion of the 1.2kJ cap storage, so perhaps 100 W might or might not be ok for one off shots.

Actually it is not strictly the cap that discharges the energy but the coil's collapsing field and the capacitor will never get charged with the short circuit.

I remember once that my CRO was saying no voltage reversal and I didn't believe it so I put a diode across the cap. I covered myself with a blast shield - except for my arm which got a bit of exploded diode in it confirming the voltage reversal.

3 1N4007's don't have a good frequency response. My can crusher discharges in 30us which is a bit fast for these diodes so there may be a dv/dt problem as well.

4 A 9kV NST is about 13kV peak or more if turned too high (ie over 70V input) so figures may need to be adjusted.

So if using a bridge rectifier:

1 Use faster diodes (or a lot more) rated at 10kV per leg minimum ie 20kV standoff.

2 Use a series resistor of 10k minimum at 100W and you should be OK. (A bit more than what Steve said)

3 Use your "current" diagram.

I personally use fast diodes and ? 60k 40W and have had no problems up to 6kV but it charges slowly and needs to be updated

TDU

Re: Diodes dying on can crusher

Dr. Shark, Wed Feb 14 2007, 10:43AM

What has been said so far by Cönnör etc. is correct, I have had the same problem in my railgun setup, and this suggestion would solve the problem.

Not so sure about TDUs "faster diodes" thing, since the diodes are not supposed to see anything else than 60Hz mains frequency.

One thing to add though: The blowing diodes are just trying to tell you that you have a voltage reversal problem that you need to address, otherwise the livetime of your caps will be shortened (even more). Some kind of crowbar circuit is allways a good idea when discharging a capacitor bank into an inductive load. A hefty high voltage diode and a resistor would do it, but would probably be more expensive than replacing blown caps every now and then.

Dr. Shark, Wed Feb 14 2007, 10:43AM

What has been said so far by Cönnör etc. is correct, I have had the same problem in my railgun setup, and this suggestion would solve the problem.

Not so sure about TDUs "faster diodes" thing, since the diodes are not supposed to see anything else than 60Hz mains frequency.

One thing to add though: The blowing diodes are just trying to tell you that you have a voltage reversal problem that you need to address, otherwise the livetime of your caps will be shortened (even more). Some kind of crowbar circuit is allways a good idea when discharging a capacitor bank into an inductive load. A hefty high voltage diode and a resistor would do it, but would probably be more expensive than replacing blown caps every now and then.

Re: Diodes dying on can crusher

Billybobjoe, Wed Feb 14 2007, 05:06PM

I understand now, thanks guys. My rectifier was taking all of the reversal in place of the capacitors. I'll go with the modified diagram and perhaps a 100k resistor across each charging leg. Does that seem like an appropriate value? Anything too low and there is a chance of excessive current through the rectifier, correct? Also keep in mind that I'm not charging to 9kv. To keep a good safety margin around 8kv will be my max.

Joe, I'll definitely consider a crowbar circuit for similar future projects, but this capacitor bank only cost about $25 (although all of the heavy duty solder connections took some time) so as you mentioned it may not be economical.

Billybobjoe, Wed Feb 14 2007, 05:06PM

I understand now, thanks guys. My rectifier was taking all of the reversal in place of the capacitors. I'll go with the modified diagram and perhaps a 100k resistor across each charging leg. Does that seem like an appropriate value? Anything too low and there is a chance of excessive current through the rectifier, correct? Also keep in mind that I'm not charging to 9kv. To keep a good safety margin around 8kv will be my max.

Joe, I'll definitely consider a crowbar circuit for similar future projects, but this capacitor bank only cost about $25 (although all of the heavy duty solder connections took some time) so as you mentioned it may not be economical.

Re: Diodes dying on can crusher

Tesladownunder, Thu Feb 15 2007, 01:04AM

The diodes do see more than 60Hz. They see 9kV at 60Hz then on top of this the cap goes from 9kV in one polarity to 6 kV in the opposite polarity in a time constant determined by the caps but in my case is 30us.

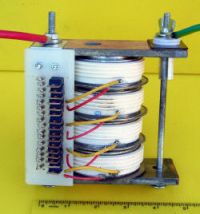

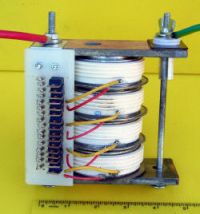

Forget the crowbar circuit. I have tried to catch the reversal with 4 puck SCR's in a 2kJ defibrillator cap circuit (not my big one). They got to 12,500A then blew when I went higher. Partly that was poor design but partly the massive current pulse.

Details on my site here. Pic shows the crowbar SCR's.

Peter

Tesladownunder, Thu Feb 15 2007, 01:04AM

The diodes do see more than 60Hz. They see 9kV at 60Hz then on top of this the cap goes from 9kV in one polarity to 6 kV in the opposite polarity in a time constant determined by the caps but in my case is 30us.

Forget the crowbar circuit. I have tried to catch the reversal with 4 puck SCR's in a 2kJ defibrillator cap circuit (not my big one). They got to 12,500A then blew when I went higher. Partly that was poor design but partly the massive current pulse.

Details on my site here. Pic shows the crowbar SCR's.

Peter

Re: Diodes dying on can crusher

Dr. Shark, Thu Feb 15 2007, 12:09PM

Good point Peter. I love your experiments. I've got two more possible explanations for the failure of your pucks though:

1)The datasheets of similar hockeypuck usually specify some maximum dI/dt such as 100A/us. I think this is due to mechanical stress within the silicon die, but I don't know for sure. You probably exceeded this rating by a factor of 100 or so.

2) You did not place any additional resistance in the freewheeling circuit made up of the coil and the SCR's. This means that all the energy stored in the field, a few kJ probably, ended up in the junction resistance of the silicon die. Again, very deadly. Adding a resistor in series with the SCR would give the current a place to be dissipated safely, but still keep voltage reversal at a minimum.

Dr. Shark, Thu Feb 15 2007, 12:09PM

Good point Peter. I love your experiments. I've got two more possible explanations for the failure of your pucks though:

1)The datasheets of similar hockeypuck usually specify some maximum dI/dt such as 100A/us. I think this is due to mechanical stress within the silicon die, but I don't know for sure. You probably exceeded this rating by a factor of 100 or so.

2) You did not place any additional resistance in the freewheeling circuit made up of the coil and the SCR's. This means that all the energy stored in the field, a few kJ probably, ended up in the junction resistance of the silicon die. Again, very deadly. Adding a resistor in series with the SCR would give the current a place to be dissipated safely, but still keep voltage reversal at a minimum.

Re: Diodes dying on can crusher

Fusion, Thu Feb 15 2007, 12:32PM

1N4007 is rated 1Arms, 1000V and 30Apeak

Diode BY255 gives 3Arms, 1300V and support 200A peak

Resistor must be calculated for:

R>Vmax/Ipeak during discharge

Also R>V/Irms during charge

So if V=9kV and Ipk=200A, R would be >45 ohms.

I would set two resistors: one in positive and another in nagative line in order to isolate both lines in order avoid disconnect wires during discharge.

If you do not change configuration after can crunch you can have great voltage that can be over diode voltage rate, but I think diodes would support them with the resistors

Fusion, Thu Feb 15 2007, 12:32PM

1N4007 is rated 1Arms, 1000V and 30Apeak

Diode BY255 gives 3Arms, 1300V and support 200A peak

Resistor must be calculated for:

R>Vmax/Ipeak during discharge

Also R>V/Irms during charge

So if V=9kV and Ipk=200A, R would be >45 ohms.

I would set two resistors: one in positive and another in nagative line in order to isolate both lines in order avoid disconnect wires during discharge.

If you do not change configuration after can crunch you can have great voltage that can be over diode voltage rate, but I think diodes would support them with the resistors

Re: Diodes dying on can crusher

Billybobjoe, Fri Feb 16 2007, 02:05AM

Thanks!! Those BY255's will simplify things, now I'll have to see what kind of HV resistors I can find (the thread above this one might be useful).

Billybobjoe, Fri Feb 16 2007, 02:05AM

Fusion wrote ...

1N4007 is rated 1Arms, 1000V and 30Apeak

Diode BY255 gives 3Arms, 1300V and support 200A peak

Resistor must be calculated for:

R>Vmax/Ipeak during discharge

Also R>V/Irms during charge

So if V=9kV and Ipk=200A, R would be >45 ohms.

I would set two resistors: one in positive and another in nagative line in order to isolate both lines in order avoid disconnect wires during discharge.

1N4007 is rated 1Arms, 1000V and 30Apeak

Diode BY255 gives 3Arms, 1300V and support 200A peak

Resistor must be calculated for:

R>Vmax/Ipeak during discharge

Also R>V/Irms during charge

So if V=9kV and Ipk=200A, R would be >45 ohms.

I would set two resistors: one in positive and another in nagative line in order to isolate both lines in order avoid disconnect wires during discharge.

Thanks!! Those BY255's will simplify things, now I'll have to see what kind of HV resistors I can find (the thread above this one might be useful).

Print this page