need help to make magnetizer coil fixture

rajheman, Thu Mar 02 2017, 07:01AMAt last i made the 10kj capacitor bank by gaining knowledge step by step from reading so many articles. i have successfully discharged 3kj of energy from capacitor bank by launching aluminum disks with mechanical switch.

my main goal is to magnetize neodymium magnets. for that i need a coil to magnetize the empty neodymium disks of 4 inch dia * 1 inch height.

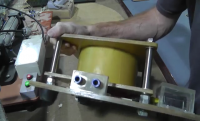

so for that i want to make a magnetize coil fixture as shown in this video

please guide me how to build a fixture . as per my guess its a 6mm copper tube coil solenoid sandwiched between electrical hylam sheet.i don't know how many turns the solenoid is. and is 6mm copper tube is enough or do i need go for more thicker coil ??

Thanks in advance for your valuable suggestions

Re: need help to make magnetizer coil fixture

Sulaiman, Thu Mar 02 2017, 03:10PM

use F = B^2.A/2.Uo (or similar) to calculate the forces on the pole pieces before you start

Sulaiman, Thu Mar 02 2017, 03:10PM

use F = B^2.A/2.Uo (or similar) to calculate the forces on the pole pieces before you start

Re: need help to make magnetizer coil fixture

klugesmith, Thu Mar 09 2017, 01:17AM

I don't see any pole pieces or yoke. Never heard of an air-core magnetizing fixture.

On closer investigation, industrial magnetizing fixtures for NIB material seem to get the job done without pole pieces. For example:https://youtu.be/eMb2tSPrkc0 One reference said the impulsive B fields can be as high as 5 teslas.

Lack of iron doesn't excuse you from following Sulaiman's advice: Figure the mechanical forces which will tend to make your coil expand in the radial direction and contract in the axial direction.

Rajeheman, please edit your post to clarify that the embedded pictures are not your own work. They're frames from the online video whose link you posted.

The size of your fixture (and generally, the mass of its copper) will dictate the instantaneous electrical power needed to meet your ampere-turns goal. The more copper, the less power you need per ampere-turn.

After that, you get to make a trade-off between the wire thickness and the number of turns packed into the winding area. Same as trading off amperes vs. volts, to match your power source, with no change in efficiency. But step 1 is to get a handle on how many ampere-turns you need. Finite-element (or other) DC field solvers care about the winding's size and current density, not on how finely it's partitioned into series-connected turns.

klugesmith, Thu Mar 09 2017, 01:17AM

I don't see any pole pieces or yoke. Never heard of an air-core magnetizing fixture.

On closer investigation, industrial magnetizing fixtures for NIB material seem to get the job done without pole pieces. For example:https://youtu.be/eMb2tSPrkc0 One reference said the impulsive B fields can be as high as 5 teslas.

Lack of iron doesn't excuse you from following Sulaiman's advice: Figure the mechanical forces which will tend to make your coil expand in the radial direction and contract in the axial direction.

Rajeheman, please edit your post to clarify that the embedded pictures are not your own work. They're frames from the online video whose link you posted.

The size of your fixture (and generally, the mass of its copper) will dictate the instantaneous electrical power needed to meet your ampere-turns goal. The more copper, the less power you need per ampere-turn.

After that, you get to make a trade-off between the wire thickness and the number of turns packed into the winding area. Same as trading off amperes vs. volts, to match your power source, with no change in efficiency. But step 1 is to get a handle on how many ampere-turns you need. Finite-element (or other) DC field solvers care about the winding's size and current density, not on how finely it's partitioned into series-connected turns.

Re: need help to make magnetizer coil fixture

Sulaiman, Thu Mar 09 2017, 01:38AM

The pole pieces were cones, flux concentrators.

I suspect that the failures in the video were caused by the forces exerted by the cones.

I was surprised that the pole pieces / flux concentrators worked for NdFeB

I would have expected better results without steel when magnetizing NdFeB

Sulaiman, Thu Mar 09 2017, 01:38AM

The pole pieces were cones, flux concentrators.

I suspect that the failures in the video were caused by the forces exerted by the cones.

I was surprised that the pole pieces / flux concentrators worked for NdFeB

I would have expected better results without steel when magnetizing NdFeB

Print this page