Direct Methanol Fuel Cell Project.

Patrick, Fri Jan 20 2017, 11:26AMPlatinum Ruthenium and Platinum black, 5 layer MEA.

I meant to put this in the general science forum. can it be moved mods ?

Re: Direct Methanol Fuel Cell Project.

Bjørn, Fri Jan 20 2017, 01:06PM

Moved

Bjørn, Fri Jan 20 2017, 01:06PM

Moved

Re: Direct Methanol Fuel Cell Project.

2Spoons, Fri Jan 20 2017, 09:30PM

Will be watching this one with interest. What did that cost you?

2Spoons, Fri Jan 20 2017, 09:30PM

Will be watching this one with interest. What did that cost you?

Re: Direct Methanol Fuel Cell Project.

Patrick, Fri Jan 20 2017, 09:46PM

59 US$ , 4mg/cm^2 Platinum/Ruthenium and 4mg/cm^2 Platinum/Carbon on the other side. 2.2 cm square, 5cm^2 active area with 10cm N117 Nafion membrane around the edge.

PLA and ABS are destroyed by methanol. So that rules out my 3d printer.

i bought such a small one due to my fear of catalyst poisoning.

im still trying to figure out how the catalyst loading affects current and surface area. they offer 0.03mg up to 4mg, per cm^2 which is big in cost.

I think the anode is the Pt/Ru (fuel) side from here:

The cathode side is the oxidizer and Pt/Carbon side.

Im having a hard time getting datasheets of any kind from the company, despite having purchased a product and many emails. thats making me mad.

Im also not sure how to seal the Nafion sides in a leak proof way, im not sure if silicone adhesive would work. the "thiol-group" based epoxies are totally ruled out, as fuel cell PEMs of all types are massacred by the tiniest of sulfur presence.

Patrick, Fri Jan 20 2017, 09:46PM

2Spoons wrote ...

Will be watching this one with interest. What did that cost you?

Will be watching this one with interest. What did that cost you?

59 US$ , 4mg/cm^2 Platinum/Ruthenium and 4mg/cm^2 Platinum/Carbon on the other side. 2.2 cm square, 5cm^2 active area with 10cm N117 Nafion membrane around the edge.

PLA and ABS are destroyed by methanol. So that rules out my 3d printer.

i bought such a small one due to my fear of catalyst poisoning.

im still trying to figure out how the catalyst loading affects current and surface area. they offer 0.03mg up to 4mg, per cm^2 which is big in cost.

I think the anode is the Pt/Ru (fuel) side from here:

The cathode side is the oxidizer and Pt/Carbon side.

Im having a hard time getting datasheets of any kind from the company, despite having purchased a product and many emails. thats making me mad.

Im also not sure how to seal the Nafion sides in a leak proof way, im not sure if silicone adhesive would work. the "thiol-group" based epoxies are totally ruled out, as fuel cell PEMs of all types are massacred by the tiniest of sulfur presence.

Re: Direct Methanol Fuel Cell Project.

Carbon_Rod, Wed Jan 25 2017, 06:31PM

Regular cheap Delrin works around most Alcohols including Methanol.

Milling machines cut Acetal Plastics with ease, and o-ring seal channels are easy to route out (follow the manufacturers specs, as most failures are from engineers trying to guess the seal tolerances).

Note that some silicone based stuff may not be Methanol friendly, so carefully check the documentation of whatever adhesives are around.

Carbon_Rod, Wed Jan 25 2017, 06:31PM

Regular cheap Delrin works around most Alcohols including Methanol.

Milling machines cut Acetal Plastics with ease, and o-ring seal channels are easy to route out (follow the manufacturers specs, as most failures are from engineers trying to guess the seal tolerances).

Note that some silicone based stuff may not be Methanol friendly, so carefully check the documentation of whatever adhesives are around.

Re: Direct Methanol Fuel Cell Project.

Conundrum, Thu Jan 26 2017, 08:08AM

Absolutely fascinating, thanks for sharing.

Going to forward this to Jim, Adrian and Marcel at the Digital Greenhouse as this might well be a potential application for 3-D milling machines.

A little tip, the infamous "black plastic" unrecyclable food containers might be a good starting point.

From experience a simple test for sulphur is to put a prepared piece of copper PCB on the surface to be tested and heat it up, a change from copper colour to black in a few minutes would show that the material is contaminated.

Works for me with Cu + elemental sulphur even in a domestic oven at 55C.

Also worth noting, anything made of rubber would be out as vulcanization uses sulphur so this would be a bad idea.

I wonder if the damage is reversible and anything to do with sulphide formation, if so then there might be a way to repair damaged PEMs with sulphur poisoning using a similar mechanism to desulphating lead acid cells?

Conundrum, Thu Jan 26 2017, 08:08AM

Absolutely fascinating, thanks for sharing.

Going to forward this to Jim, Adrian and Marcel at the Digital Greenhouse as this might well be a potential application for 3-D milling machines.

A little tip, the infamous "black plastic" unrecyclable food containers might be a good starting point.

From experience a simple test for sulphur is to put a prepared piece of copper PCB on the surface to be tested and heat it up, a change from copper colour to black in a few minutes would show that the material is contaminated.

Works for me with Cu + elemental sulphur even in a domestic oven at 55C.

Also worth noting, anything made of rubber would be out as vulcanization uses sulphur so this would be a bad idea.

I wonder if the damage is reversible and anything to do with sulphide formation, if so then there might be a way to repair damaged PEMs with sulphur poisoning using a similar mechanism to desulphating lead acid cells?

Re: Direct Methanol Fuel Cell Project.

Patrick, Fri Jan 27 2017, 11:17AM

Ive been assured theyre getting the datasheets together. My 0.002 inch thick stainless steel foil has arrived its #309 and the 300 family does well against methanol. ive been trying to polyurethane and aluminum mold form patterns using a 60 ton press so we'll so. other up dates to follow.

After a long call with an expert.

-distilled water and DI water are best to control molarity.

-Ions in water (Cu, Fe, S) or dissolved from plumbing within the fuel cell are poisonous. Stainless solves this.

-even then the super-acid Nafion membrane will react and degrade stainless steel over 10-30k hours. coatings are often used.

-350mA per cm^2 is more attainable.

-Nylon and Teflon are good choices.

-low pressure drop and molar concentration are important to over all balance of plant and fast response to load changes.

im still tring to figure out a good parallel flow tube field where each parallel tube is fed evenly and some dont hog more fluid than others.

Patrick, Fri Jan 27 2017, 11:17AM

Ive been assured theyre getting the datasheets together. My 0.002 inch thick stainless steel foil has arrived its #309 and the 300 family does well against methanol. ive been trying to polyurethane and aluminum mold form patterns using a 60 ton press so we'll so. other up dates to follow.

After a long call with an expert.

-distilled water and DI water are best to control molarity.

-Ions in water (Cu, Fe, S) or dissolved from plumbing within the fuel cell are poisonous. Stainless solves this.

-even then the super-acid Nafion membrane will react and degrade stainless steel over 10-30k hours. coatings are often used.

-350mA per cm^2 is more attainable.

-Nylon and Teflon are good choices.

-low pressure drop and molar concentration are important to over all balance of plant and fast response to load changes.

im still tring to figure out a good parallel flow tube field where each parallel tube is fed evenly and some dont hog more fluid than others.

Re: Direct Methanol Fuel Cell Project.

Conundrum, Sat Jan 28 2017, 07:44AM

Um.. what you need then is the water equivalent of a constant current.

Conundrum, Sat Jan 28 2017, 07:44AM

Um.. what you need then is the water equivalent of a constant current.

Re: Direct Methanol Fuel Cell Project.

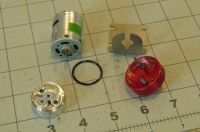

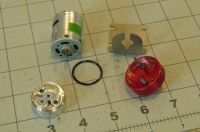

Patrick, Sat Jan 28 2017, 08:52AM

I think the pump was an oversight on my part.

Aluminum, copper, unknown steel and plastic, sigh.

i think its on to the peristaltic pump type.

Patrick, Sat Jan 28 2017, 08:52AM

I think the pump was an oversight on my part.

Aluminum, copper, unknown steel and plastic, sigh.

i think its on to the peristaltic pump type.

Re: Direct Methanol Fuel Cell Project.

hen918, Sat Jan 28 2017, 11:19AM

it looks like a little gear pump to me.

A peristaltic pump has one continuous flexible tube (sometimes the same tube that supplies it), a cam flattens the tube turns, forcing the liquid through the pump.

A peristaltic pump would be better for lower contaminants, but would probably have a lower flow.

hen918, Sat Jan 28 2017, 11:19AM

Patrick wrote ...

I think the pump was an oversight on my part.

....

Aluminum, copper, unknown steel and plastic, sigh.

i think its on to the peristaltic pump type.

I think the pump was an oversight on my part.

....

Aluminum, copper, unknown steel and plastic, sigh.

i think its on to the peristaltic pump type.

it looks like a little gear pump to me.

A peristaltic pump has one continuous flexible tube (sometimes the same tube that supplies it), a cam flattens the tube turns, forcing the liquid through the pump.

A peristaltic pump would be better for lower contaminants, but would probably have a lower flow.

Re: Direct Methanol Fuel Cell Project.

Patrick, Sat Jan 28 2017, 11:00PM

the real issue is equal flow trough out the paralleled flow channels. I dont want to put in artificial restrictions in as we would with resistors.

EDIT:

I measured the dry resistance of the 4mg^2 Pl/B side. It was 2.6 ohms per 0.95 inches.

the 4mg^2 Pl/Ru side is so close as to be the same i think.

this tells me that the carbon cloth really controls absolute resistance. But i measured across almost an inch. so reducing resistance means more contact area with out blocking surface area. Thinness of the carbon layer also matters. A single side of the cell is 0.03".

Patrick, Sat Jan 28 2017, 11:00PM

hen918 wrote ...

it looks like a little gear pump to me.

A peristaltic pump has one continuous flexible tube (sometimes the same tube that supplies it), a cam flattens the tube turns, forcing the liquid through the pump.

A peristaltic pump would be better for lower contaminants, but would probably have a lower flow.

yes its a tiny gear pump. Ill use a peristolic without fittings just super-soft silicone RC engine tubing. Im looking at the flow requirements too. Patrick wrote ...

I think the pump was an oversight on my part.

....

Aluminum, copper, unknown steel and plastic, sigh.

i think its on to the peristaltic pump type.

I think the pump was an oversight on my part.

....

Aluminum, copper, unknown steel and plastic, sigh.

i think its on to the peristaltic pump type.

it looks like a little gear pump to me.

A peristaltic pump has one continuous flexible tube (sometimes the same tube that supplies it), a cam flattens the tube turns, forcing the liquid through the pump.

A peristaltic pump would be better for lower contaminants, but would probably have a lower flow.

the real issue is equal flow trough out the paralleled flow channels. I dont want to put in artificial restrictions in as we would with resistors.

EDIT:

I measured the dry resistance of the 4mg^2 Pl/B side. It was 2.6 ohms per 0.95 inches.

the 4mg^2 Pl/Ru side is so close as to be the same i think.

this tells me that the carbon cloth really controls absolute resistance. But i measured across almost an inch. so reducing resistance means more contact area with out blocking surface area. Thinness of the carbon layer also matters. A single side of the cell is 0.03".

Re: Direct Methanol Fuel Cell Project.

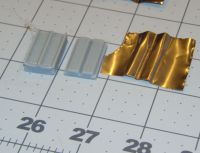

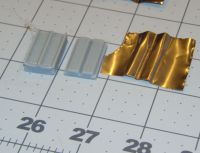

Patrick, Sun Jan 29 2017, 09:45PM

Im trying to figure out the distance from piont to point and flat to flat for these 1/4-28 UNF plumbing bits.

Heres a 3d printed positive

and negative form. the foil took shape easily with only a few turns of the C-clamp.

The foil is actually better in shape than these pics show.

Patrick, Sun Jan 29 2017, 09:45PM

Im trying to figure out the distance from piont to point and flat to flat for these 1/4-28 UNF plumbing bits.

Heres a 3d printed positive

and negative form. the foil took shape easily with only a few turns of the C-clamp.

The foil is actually better in shape than these pics show.

Re: Direct Methanol Fuel Cell Project.

Carbon_Rod, Mon Jan 30 2017, 04:16AM

@Patrick

Do you know if the membraneless Peroxide+Methanol fuel cells are commercially available yet?

This paper may offer some fluid handling tips:

Carbon_Rod, Mon Jan 30 2017, 04:16AM

@Patrick

Do you know if the membraneless Peroxide+Methanol fuel cells are commercially available yet?

This paper may offer some fluid handling tips:

Re: Direct Methanol Fuel Cell Project.

Patrick, Mon Jan 30 2017, 08:59AM

it looks like the forming of the channels isnt as difficult as i thought it would be.

Patrick, Mon Jan 30 2017, 08:59AM

it looks like the forming of the channels isnt as difficult as i thought it would be.

Re: Direct Methanol Fuel Cell Project.

Patrick, Tue Jan 31 2017, 06:03PM

it just shriveled up.

the Naifion shriveld up and one side slowly peeled off.

Patrick, Tue Jan 31 2017, 06:03PM

it just shriveled up.

the Naifion shriveld up and one side slowly peeled off.

Re: Direct Methanol Fuel Cell Project.

Carbon_Rod, Tue Jan 31 2017, 07:31PM

This discusses the properties of pre-stetched Naifion in more detail:

I am sceptical the carrier-pack was Naifion as well, but it may be difficult to know as the manufacturer is being secretive.

Science hurts sometimes, and the best people I've met make mistakes everyday...

Carbon_Rod, Tue Jan 31 2017, 07:31PM

This discusses the properties of pre-stetched Naifion in more detail:

I am sceptical the carrier-pack was Naifion as well, but it may be difficult to know as the manufacturer is being secretive.

Science hurts sometimes, and the best people I've met make mistakes everyday...

Re: Direct Methanol Fuel Cell Project.

Patrick, Tue Jan 31 2017, 09:03PM

This is a great PDF, i cant find many like it do to pay-walls, and i can get e-books and research materials from chico at the moment since im not an active student.

i dont know if it needs to be restrained or not ? or if the Naifion can be epoxied to or not.

Patrick, Tue Jan 31 2017, 09:03PM

This is a great PDF, i cant find many like it do to pay-walls, and i can get e-books and research materials from chico at the moment since im not an active student.

i dont know if it needs to be restrained or not ? or if the Naifion can be epoxied to or not.

Re: Direct Methanol Fuel Cell Project.

Carbon_Rod, Tue Jan 31 2017, 10:13PM

"i dont know if it needs to be restrained or not ?"

I don’t think it will be your biggest efficiency loss at this point given the structural tears.

"or if the Naifion can be epoxied to or not."

Epoxy is not good for TFE based plastics...

Is there a reason to avoid a traditional mechanical lamination structure?

Carbon_Rod, Tue Jan 31 2017, 10:13PM

"i dont know if it needs to be restrained or not ?"

I don’t think it will be your biggest efficiency loss at this point given the structural tears.

"or if the Naifion can be epoxied to or not."

Epoxy is not good for TFE based plastics...

Is there a reason to avoid a traditional mechanical lamination structure?

Re: Direct Methanol Fuel Cell Project.

Patrick, Wed Feb 01 2017, 10:15AM

when I came back from work it was dry and flat like normal.

Patrick, Wed Feb 01 2017, 10:15AM

Carbon_Rod wrote ...

Is there a reason to avoid a traditional mechanical lamination structure?

Not sure what this means. text books just show a simple diagram.Is there a reason to avoid a traditional mechanical lamination structure?

when I came back from work it was dry and flat like normal.

Re: Direct Methanol Fuel Cell Project.

Carbon_Rod, Wed Feb 01 2017, 07:37PM

This covers the general idea of a pile, but does not include documentation about coolant manifolds.

The stack up is usually made of many cells bolted together into a single block to get the low cell voltages up to usable levels.

Local units that were tested on buses (later converted back to diesel due to operational costs) used relatively thin H2 fuel distribution manifolds that looked similar to water-jet cut stencils.

Also, recall most stainless includes different percentages of nickel (a catalyst itself under some conditions), and often 316L is more corrosion resistant than the common 304 style grades (that can get rust spots more easily if the oxide layer is damaged, or galvanic corrosion occurs with other contacted metals). I don't think it should pose a problem for your set-up, but it should be documented somewhere if these are going to be used long term.

Carbon_Rod, Wed Feb 01 2017, 07:37PM

This covers the general idea of a pile, but does not include documentation about coolant manifolds.

The stack up is usually made of many cells bolted together into a single block to get the low cell voltages up to usable levels.

Local units that were tested on buses (later converted back to diesel due to operational costs) used relatively thin H2 fuel distribution manifolds that looked similar to water-jet cut stencils.

Also, recall most stainless includes different percentages of nickel (a catalyst itself under some conditions), and often 316L is more corrosion resistant than the common 304 style grades (that can get rust spots more easily if the oxide layer is damaged, or galvanic corrosion occurs with other contacted metals). I don't think it should pose a problem for your set-up, but it should be documented somewhere if these are going to be used long term.

Re: Direct Methanol Fuel Cell Project.

Patrick, Mon Feb 06 2017, 06:05AM

I dont think the Naifion is supposed to see liquid water. thats why it has the hydrophobic carbon coating on the catalyst section itself. i dont know what will seal the edge of the nafion though. will tub and tile silicone stick to teflon and similar plastics ?

Patrick, Mon Feb 06 2017, 06:05AM

I dont think the Naifion is supposed to see liquid water. thats why it has the hydrophobic carbon coating on the catalyst section itself. i dont know what will seal the edge of the nafion though. will tub and tile silicone stick to teflon and similar plastics ?

Re: Direct Methanol Fuel Cell Project.

Carbon_Rod, Mon Feb 06 2017, 08:24AM

"I dont think the Naifion is supposed to see liquid water. thats why it has the hydrophobic carbon coating on the catalyst section itself. "

Hard to say given your supplier... The other literature seems to suggest liquid + filtered-air exchange cells typically add unspecified water moisture to the gas feed to improve the gas-exposed plate's conductivity.

"will tub and tile silicone stick to teflon and similar plastics ?"

Most likely no, and that vinegar smell is a rather corrosive acetic acid that is infamous for damaging electronics.

The additives for mildew prevention may also be problematic in some situations.

Your can ask a local Loctite/3M rep about chemically resistant non-corrosive RTV silicones, and if they sell a aeronautics grade epoxy composite that will adhere without damaging the plastics. However, the adhesives may never really permanently bond as the membrane shape may change over time.

Carbon_Rod, Mon Feb 06 2017, 08:24AM

"I dont think the Naifion is supposed to see liquid water. thats why it has the hydrophobic carbon coating on the catalyst section itself. "

Hard to say given your supplier... The other literature seems to suggest liquid + filtered-air exchange cells typically add unspecified water moisture to the gas feed to improve the gas-exposed plate's conductivity.

"will tub and tile silicone stick to teflon and similar plastics ?"

Most likely no, and that vinegar smell is a rather corrosive acetic acid that is infamous for damaging electronics.

The additives for mildew prevention may also be problematic in some situations.

Your can ask a local Loctite/3M rep about chemically resistant non-corrosive RTV silicones, and if they sell a aeronautics grade epoxy composite that will adhere without damaging the plastics. However, the adhesives may never really permanently bond as the membrane shape may change over time.

Re: Direct Methanol Fuel Cell Project.

..., Mon Feb 06 2017, 08:47AM

You might try reading the manual for the 'diy fuel cell car' kits, (eg ) which has an exploded diagram of the cell and some comments on using it. The kit is not very expensive (

) which has an exploded diagram of the cell and some comments on using it. The kit is not very expensive (  ) might be worth it to get one just to get the electrode assemblies.

) might be worth it to get one just to get the electrode assemblies.

IIRC the instructions in the kit I had say that the cell can be disassembled, but that it should only be done when it is completely dry otherwise the MEA will wrinkle.

..., Mon Feb 06 2017, 08:47AM

You might try reading the manual for the 'diy fuel cell car' kits, (eg

) which has an exploded diagram of the cell and some comments on using it. The kit is not very expensive (

) which has an exploded diagram of the cell and some comments on using it. The kit is not very expensive (  ) might be worth it to get one just to get the electrode assemblies.

) might be worth it to get one just to get the electrode assemblies.IIRC the instructions in the kit I had say that the cell can be disassembled, but that it should only be done when it is completely dry otherwise the MEA will wrinkle.

Re: Direct Methanol Fuel Cell Project.

Patrick, Mon Feb 06 2017, 07:04PM

EDIT: i just bought 0.005" Teflon sheet, so we'll see if that works. If i can 3D print a nylon square on both sides, then squish the gasket i think that will work.

Patrick, Mon Feb 06 2017, 07:04PM

... wrote ...

You might try reading the manual for the 'diy fuel cell car' kits, (eg ) which has an exploded diagram of the cell and some comments on using it. The kit is not very expensive (

) which has an exploded diagram of the cell and some comments on using it. The kit is not very expensive (  ) might be worth it to get one just to get the electrode assemblies.

) might be worth it to get one just to get the electrode assemblies.

IIRC the instructions in the kit I had say that the cell can be disassembled, but that it should only be done when it is completely dry otherwise the MEA will wrinkle.

yes they use a thin silicone gasket. i guess thats what i should use.You might try reading the manual for the 'diy fuel cell car' kits, (eg

) which has an exploded diagram of the cell and some comments on using it. The kit is not very expensive (

) which has an exploded diagram of the cell and some comments on using it. The kit is not very expensive (  ) might be worth it to get one just to get the electrode assemblies.

) might be worth it to get one just to get the electrode assemblies.IIRC the instructions in the kit I had say that the cell can be disassembled, but that it should only be done when it is completely dry otherwise the MEA will wrinkle.

EDIT: i just bought 0.005" Teflon sheet, so we'll see if that works. If i can 3D print a nylon square on both sides, then squish the gasket i think that will work.

Re: Direct Methanol Fuel Cell Project.

Patrick, Sun Feb 12 2017, 03:48AM

Ok Ive gotten some results and gained some confidence, so Im launching a $650 for a single cell research effort.

The full page from my website is here:

Patrick, Sun Feb 12 2017, 03:48AM

Ok Ive gotten some results and gained some confidence, so Im launching a $650 for a single cell research effort.

The full page from my website is here:

Re: Direct Methanol Fuel Cell Project.

Carbon_Rod, Sun Feb 12 2017, 05:49AM

Remember the general public isn't interested in a potential use of technology, and will respond better to conditioned familiar product marketing structures.

You need to consider:

1. 3D print a box that looks like an apple product already ( )

)

2. Add a single $3 3A 5v USB boost converter on the fewest cells you can (lower your unit cost to just above your fab costs * 5)

3. Film a local army grunt hire.... using it to charge his phone in some dump... to talk to his mom

4. Highlight the shelf life compared to regular batteries, and ship it in a US Pelican case

5. Keep all profits in liquid cash (never use debt, don't be tempted to do everything yourselves)

These guys published a good series on DFM, and can help you grow later:

Good luck,

Rod

Carbon_Rod, Sun Feb 12 2017, 05:49AM

Remember the general public isn't interested in a potential use of technology, and will respond better to conditioned familiar product marketing structures.

You need to consider:

1. 3D print a box that looks like an apple product already (

)

)2. Add a single $3 3A 5v USB boost converter on the fewest cells you can (lower your unit cost to just above your fab costs * 5)

3. Film a local army grunt hire.... using it to charge his phone in some dump... to talk to his mom

4. Highlight the shelf life compared to regular batteries, and ship it in a US Pelican case

5. Keep all profits in liquid cash (never use debt, don't be tempted to do everything yourselves)

These guys published a good series on DFM, and can help you grow later:

Good luck,

Rod

Re: Direct Methanol Fuel Cell Project.

Patrick, Sun Feb 12 2017, 08:58AM

Ty carbon.

Patrick, Sun Feb 12 2017, 08:58AM

Ty carbon.

Re: Direct Methanol Fuel Cell Project.

Conundrum, Mon Feb 13 2017, 03:39AM

Yeah, also try non reactive materials like Ta, I've used SiC before because despite being a really lousy conductor it is very nonreactive.

Conundrum, Mon Feb 13 2017, 03:39AM

Yeah, also try non reactive materials like Ta, I've used SiC before because despite being a really lousy conductor it is very nonreactive.

Re: Direct Methanol Fuel Cell Project.

Patrick, Mon Feb 20 2017, 03:04AM

heres some pics :

This is 3 grams of methanol in 100g of DI water. It turned white in an instant.

i wetted it out uniformly.

Eventually I got it up to 0.552 mV on my Fluke series 2 multimeter on the mV setting. Temp stayed at 66 F.

Im trying to remember how to calculate molar solution. its been a while. and after 10 hour shifts mine mind gets blurry going through my old notes.

Patrick, Mon Feb 20 2017, 03:04AM

heres some pics :

This is 3 grams of methanol in 100g of DI water. It turned white in an instant.

i wetted it out uniformly.

Eventually I got it up to 0.552 mV on my Fluke series 2 multimeter on the mV setting. Temp stayed at 66 F.

Im trying to remember how to calculate molar solution. its been a while. and after 10 hour shifts mine mind gets blurry going through my old notes.

Print this page