CO2 cartridge closures

klugesmith, Thu Dec 24 2015, 09:16AMDisposable cartridges of carbon dioxide are inexpensively manufactured by machine, like light bulbs. Here's one copy of "How It's Made", including a few seconds of induction annealing:

Today you can get a box of forty 12-gram Powerlets at Wal-mart for US $14.

Today you can get a box of forty 12-gram Powerlets at Wal-mart for US $14.  Made from a few pennies worth of steel, CO2, and wood pulp.

Made from a few pennies worth of steel, CO2, and wood pulp.Anyway, I've been thinking about using an empty CO2 cartridge as a retort for small-scale distillation of certain fluids. Nominal sizes up to 25 gram are available with 3/8"-24 threaded necks, same thread as most flare nuts for 3/16" OD tubing and compression nuts for 1/4" OD tubing. With no inflatory use for the CO2, or source of used bottles, I'm about ready to waste some in order to study the threaded neck internal dimensions.

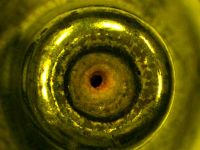

For practice I sectioned a used non-threaded cylinder. Was surprised to discover a nonmetallic sealing compound, perhaps originally an O-ring. How can that hold CO2 for years at 60 bar pressure, since we know that gas permeates through rubber? Might the elastomer transmit enough pressure from the swaged end to produce & maintain a metal-to-metal seal?

Re: CO2 cartridge closures

rikkitikkitavi, Thu May 05 2016, 06:44AM

It could be either a low permeability elastomer, or a laminated one, for cost reasons ,cheaper elastomer wtih a diffusion barrier inside, fex metal foil. I cant see that the pressure of the metal to metal connection at the low pressure of 60 bar would create a diffusion thigt metal seal, typically you need compression fittings exerting pressures of kbars on the metal.

rikkitikkitavi, Thu May 05 2016, 06:44AM

It could be either a low permeability elastomer, or a laminated one, for cost reasons ,cheaper elastomer wtih a diffusion barrier inside, fex metal foil. I cant see that the pressure of the metal to metal connection at the low pressure of 60 bar would create a diffusion thigt metal seal, typically you need compression fittings exerting pressures of kbars on the metal.

Re: CO2 cartridge closures

Enceladus, Thu Feb 09 2017, 02:53AM

The cross sectional area blocked by the seal is pretty miniscule and CO2 is a pretty bulky molecule. It's not like it's hydrogen or helium. Try blowing up a balloon with CO2 and see how long it takes to leak out. Probably a lot longer than you think. Besides, I'm sure some gas does escape from cartridges that are stores for extended periods. I's not like you would really notice that only 8g remained after 5 years.

I've tried tapping the throat of cartridges like what you're suggesting. It works fine up to about 1/4"-20tpi but the trickier part is using the die to thread the outside of such a small tube. I used to just carefully drill out the neck until I got a snug fit with the tube and then solder it in place.

I think a better choice for a small distiller vessel is glass though so you can see whats going on inside. It's pretty easy to repurpose a light bulb or test tube for such a thing. Obviously that doesn't last long where drastic changes in temperature are expected.

Enceladus, Thu Feb 09 2017, 02:53AM

The cross sectional area blocked by the seal is pretty miniscule and CO2 is a pretty bulky molecule. It's not like it's hydrogen or helium. Try blowing up a balloon with CO2 and see how long it takes to leak out. Probably a lot longer than you think. Besides, I'm sure some gas does escape from cartridges that are stores for extended periods. I's not like you would really notice that only 8g remained after 5 years.

I've tried tapping the throat of cartridges like what you're suggesting. It works fine up to about 1/4"-20tpi but the trickier part is using the die to thread the outside of such a small tube. I used to just carefully drill out the neck until I got a snug fit with the tube and then solder it in place.

I think a better choice for a small distiller vessel is glass though so you can see whats going on inside. It's pretty easy to repurpose a light bulb or test tube for such a thing. Obviously that doesn't last long where drastic changes in temperature are expected.

Print this page