3D Printed Salt Water Capacitor...

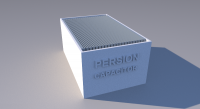

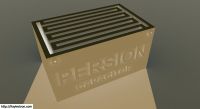

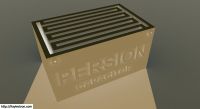

Slava, Fri Aug 28 2015, 09:48PMHey everyone! I just 3D CAD'ed a salt water capacitor (Google Sketchup 2015). I have not printed it or tested it yet. I will do that next week when the 3D LAB opens.

Re: 3D Printed Salt Water Capacitor...

Slava, Fri Aug 28 2015, 10:17PM

Modified...

Slava, Fri Aug 28 2015, 10:17PM

Modified...

Re: 3D Printed Salt Water Capacitor...

Slava, Sat Aug 29 2015, 02:24AM

The ones I designed before were too large for a 3D printer. Here is one optimized for a 8" x 8" x 8" printer...

Slava, Sat Aug 29 2015, 02:24AM

The ones I designed before were too large for a 3D printer. Here is one optimized for a 8" x 8" x 8" printer...

Re: 3D Printed Salt Water Capacitor...

klugesmith, Sat Aug 29 2015, 04:06AM

Very cool looking. Thank you for sharing.

ESR might be an issue with plates made of salt water.

Do you have any estimates for the dielectric parameters of a 3-D-printed wall?

Effective thickness, dielectric constant, breakdown voltage, etc.

You could measure those parameters with a single rectangular wall, which would be much faster and cheaper to print.

That would also be the fast way to compare different printable resins (called filaments, right?).

Can you invert the design, so that solid matter and empty space trade places?

Then 3-D print the two sets of plates, using electrically conductive filament material (lower rho than salt water), and use oil as the dielectric.

klugesmith, Sat Aug 29 2015, 04:06AM

Very cool looking. Thank you for sharing.

ESR might be an issue with plates made of salt water.

Do you have any estimates for the dielectric parameters of a 3-D-printed wall?

Effective thickness, dielectric constant, breakdown voltage, etc.

You could measure those parameters with a single rectangular wall, which would be much faster and cheaper to print.

That would also be the fast way to compare different printable resins (called filaments, right?).

Can you invert the design, so that solid matter and empty space trade places?

Then 3-D print the two sets of plates, using electrically conductive filament material (lower rho than salt water), and use oil as the dielectric.

Re: 3D Printed Salt Water Capacitor...

hen918, Sat Aug 29 2015, 01:02PM

Fused filament 3d prints are usually permeable, as I found out when printing a coffee mug which can only be used as a pen pot due to the fact that any liquid content seeps out.

This problem might be resolved in the laser type printing or by getting the printer to extrude more filament.

hen918, Sat Aug 29 2015, 01:02PM

Fused filament 3d prints are usually permeable, as I found out when printing a coffee mug which can only be used as a pen pot due to the fact that any liquid content seeps out.

This problem might be resolved in the laser type printing or by getting the printer to extrude more filament.

Re: 3D Printed Salt Water Capacitor...

Antonio, Sat Aug 29 2015, 01:24PM

I agree that very probably the plates will leak and the capacitor will be a short circuit. Maybe you can adjust the density of the material to avoid leaks, depending on the printing technology. The idea of using conductive filament may work. I have tried to make something similar, but so far all the printings failed. The parts perpendicular to the lateral walls need supporting structures.

Antonio, Sat Aug 29 2015, 01:24PM

I agree that very probably the plates will leak and the capacitor will be a short circuit. Maybe you can adjust the density of the material to avoid leaks, depending on the printing technology. The idea of using conductive filament may work. I have tried to make something similar, but so far all the printings failed. The parts perpendicular to the lateral walls need supporting structures.

Re: 3D Printed Salt Water Capacitor...

Slava, Sat Aug 29 2015, 05:17PM

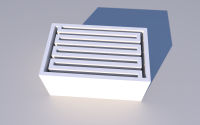

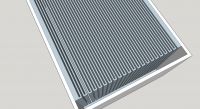

I redesigned it with 3mm space for fluid and 3mm thick walls.

Slava, Sat Aug 29 2015, 05:17PM

I redesigned it with 3mm space for fluid and 3mm thick walls.

Re: 3D Printed Salt Water Capacitor...

Slava, Sat Aug 29 2015, 05:51PM

BTW... I'm using an industrial grade 3D printer with super high resolution. I don't think water will go through the 3mm thick wall. I'm worried about internal arcing though...

Slava, Sat Aug 29 2015, 05:51PM

BTW... I'm using an industrial grade 3D printer with super high resolution. I don't think water will go through the 3mm thick wall. I'm worried about internal arcing though...

Re: 3D Printed Salt Water Capacitor...

Slava, Sat Aug 29 2015, 09:31PM

Does anyone know where I can do cheap high quality 3D printing? The build space must be 7" x 7" x 7" or larger.

Thanks

Slava, Sat Aug 29 2015, 09:31PM

Does anyone know where I can do cheap high quality 3D printing? The build space must be 7" x 7" x 7" or larger.

Thanks

Re: 3D Printed Salt Water Capacitor...

Dr. Slack, Sun Aug 30 2015, 06:39AM

a) cheap

b) high quality

Pick any one out of two!

Dr. Slack, Sun Aug 30 2015, 06:39AM

Slava wrote ...

Does anyone know where I can do cheap high quality 3D printing? The build space must be 7" x 7" x 7" or larger.

Thanks

Does anyone know where I can do cheap high quality 3D printing? The build space must be 7" x 7" x 7" or larger.

Thanks

a) cheap

b) high quality

Pick any one out of two!

Re: 3D Printed Salt Water Capacitor...

Slava, Sun Aug 30 2015, 02:00PM

By high quality, I mean high resolution.

Slava, Sun Aug 30 2015, 02:00PM

By high quality, I mean high resolution.

Re: 3D Printed Salt Water Capacitor...

klugesmith, Sun Aug 30 2015, 02:30PM

As mentioned before, you can learn more about the printer and material properties with a much smaller and simpler test structure.

klugesmith, Sun Aug 30 2015, 02:30PM

Slava wrote ...

BTW... I'm using an industrial grade 3D printer with super high resolution. I don't think water will go through the 3mm thick wall. I'm worried about internal arcing though...

Do you really want a practical, reproducible capacitor?BTW... I'm using an industrial grade 3D printer with super high resolution. I don't think water will go through the 3mm thick wall. I'm worried about internal arcing though...

As mentioned before, you can learn more about the printer and material properties with a much smaller and simpler test structure.

Re: 3D Printed Salt Water Capacitor...

Slava, Sun Aug 30 2015, 02:45PM

I designed it as if it was to be made using injection molding. It's about the same thickness as a beer bottle (often used as a salt water capacitor) ...

Polystyrene: 19.7 MV / meter (@19.8 MV/m --> 19 700 volts / mm)

Polyethylene: 19 - 160 MV / meter

Glass: 9.8 - 13.8 MV / meter (@13.8MV/m --> 13,800 volts / mm) (@9.8MV/m --> 9,800 volts / mm)

Wall thickness = 3mm

Slava, Sun Aug 30 2015, 02:45PM

I designed it as if it was to be made using injection molding. It's about the same thickness as a beer bottle (often used as a salt water capacitor) ...

Polystyrene: 19.7 MV / meter (@19.8 MV/m --> 19 700 volts / mm)

Polyethylene: 19 - 160 MV / meter

Glass: 9.8 - 13.8 MV / meter (@13.8MV/m --> 13,800 volts / mm) (@9.8MV/m --> 9,800 volts / mm)

Wall thickness = 3mm

Re: 3D Printed Salt Water Capacitor...

Slava, Sun Aug 30 2015, 05:26PM

Slava, Sun Aug 30 2015, 05:26PM

Re: 3D Printed Salt Water Capacitor...

Bored Chemist, Sun Aug 30 2015, 07:09PM

can you radius the corners- it may help improve the breakdown strength.

Bored Chemist, Sun Aug 30 2015, 07:09PM

can you radius the corners- it may help improve the breakdown strength.

Re: 3D Printed Salt Water Capacitor...

2Spoons, Sun Aug 30 2015, 10:17PM

The more compelling reason to radius your corners is to stop capillary action drawing salt water up to the top, creating a clearance issue, and flashover. Don't forget, your creepage /clearance distances will need to be quite high - probably 100mm or more. And dry!

2Spoons, Sun Aug 30 2015, 10:17PM

The more compelling reason to radius your corners is to stop capillary action drawing salt water up to the top, creating a clearance issue, and flashover. Don't forget, your creepage /clearance distances will need to be quite high - probably 100mm or more. And dry!

Re: 3D Printed Salt Water Capacitor...

tarakan2, Mon Aug 31 2015, 06:36AM

Filament fusion fabrication is rarely solid or else it tends to warp. If you print 1 extruder thickness wide it may leak. Metal electrodes may still corrode. Why not make it circular or hexagonal with a spiral filling?

tarakan2, Mon Aug 31 2015, 06:36AM

Filament fusion fabrication is rarely solid or else it tends to warp. If you print 1 extruder thickness wide it may leak. Metal electrodes may still corrode. Why not make it circular or hexagonal with a spiral filling?

Re: 3D Printed Salt Water Capacitor...

Conundrum, Wed Sept 09 2015, 10:30AM

I'd be interested to see if this can allow me to make 3D printed lead acids.. even low quality ones. £49 for a 12Ah 12V, they can go and whistle.

Also its quite feasible to 3D print the paste holders as well, and fill them with lead impregnated carbon graphite.

The capacity will still suck but hopefully I can fine tune it and match up the good electrodes.

Mg-ion are becoming feasible, also they are a lot safer. 2.7V fully charged, electrolyte is an organic salt similar to lithium.

Water getting into the electrolyte is actually easy to fix just by encasing the whole assembly in a hermetically sealed casing similar to a hard drive.

Conundrum, Wed Sept 09 2015, 10:30AM

I'd be interested to see if this can allow me to make 3D printed lead acids.. even low quality ones. £49 for a 12Ah 12V, they can go and whistle.

Also its quite feasible to 3D print the paste holders as well, and fill them with lead impregnated carbon graphite.

The capacity will still suck but hopefully I can fine tune it and match up the good electrodes.

Mg-ion are becoming feasible, also they are a lot safer. 2.7V fully charged, electrolyte is an organic salt similar to lithium.

Water getting into the electrolyte is actually easy to fix just by encasing the whole assembly in a hermetically sealed casing similar to a hard drive.

Re: 3D Printed Salt Water Capacitor...

hen918, Wed Sept 09 2015, 05:58PM

The person who wrote the web page you linked to seems to worry about the toxicity of lead; I would be more worried about the acid!

hen918, Wed Sept 09 2015, 05:58PM

Conundrum wrote ...

I'd be interested to see if this can allow me to make 3D printed lead acids.. even low quality ones. £49 for a 12Ah 12V, they can go and whistle.

Also its quite feasible to 3D print the paste holders as well, and fill them with lead impregnated carbon graphite.

The capacity will still suck but hopefully I can fine tune it and match up the good electrodes.

Mg-ion are becoming feasible, also they are a lot safer. 2.7V fully charged, electrolyte is an organic salt similar to lithium.

Water getting into the electrolyte is actually easy to fix just by encasing the whole assembly in a hermetically sealed casing similar to a hard drive.

I'd be interested to see if this can allow me to make 3D printed lead acids.. even low quality ones. £49 for a 12Ah 12V, they can go and whistle.

Also its quite feasible to 3D print the paste holders as well, and fill them with lead impregnated carbon graphite.

The capacity will still suck but hopefully I can fine tune it and match up the good electrodes.

Mg-ion are becoming feasible, also they are a lot safer. 2.7V fully charged, electrolyte is an organic salt similar to lithium.

Water getting into the electrolyte is actually easy to fix just by encasing the whole assembly in a hermetically sealed casing similar to a hard drive.

The person who wrote the web page you linked to seems to worry about the toxicity of lead; I would be more worried about the acid!

Print this page