electromechanical amplifier

Salvador, Fri Jun 19 2015, 04:00PMHi I wanted to ask a question, I have a picture attached , a crude one but I hope you will be able to understand the idea behind it.

the overall question here is , whether it would work the way I will describe or not?

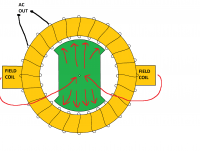

So the stator is wound in a toroidal way like toroidal transformers, it has one coil or winding on it which is the output coil, at the sides the stator material goes out to form rectangular cubes or circles on each of which a field coil wound be wound , the field coil at each side is wound in such a way so that the same poles on both sides would face inwards , the other two alike poles face outwards from the stator and are carried by an endplate (red arrow in the drawing) to the rotor, the idea is that at any given half period of AC one pole would face into the stator while the other would go through the rotor to enter the stator via the airgap.so the flux meets at the airgap at two places where the rotor is the closest , now as the rotor rotates the high flux density areas are being dragged around with the rotor, but the flux through the rotor is induced by the field coils ,

the question is would the output frequency and waveform reseble that of the current fed into the field coils or not ?

the very idea is that the conditions for induction are satisfied because of the changing flux density location , but since there is only one coil and no poles but rather just a changing flux the induced output current shoudl resemble the magnetic field that induced it and the field resembles the current that created it which is the current that went into the field coils.

in other words frequency and waveform being independatn of rpm , resembling an amplifier, rather than a typical generator.

what do you think?

Re: electromechanical amplifier

Salvador, Fri Jun 19 2015, 04:02PM

P.S. I apolgize for another thread as I only now remembered that I had created one similar to this , anyways it has a better drawing so maybe you can keep it, thanks.

Salvador, Fri Jun 19 2015, 04:02PM

P.S. I apolgize for another thread as I only now remembered that I had created one similar to this , anyways it has a better drawing so maybe you can keep it, thanks.

Re: electromechanical amplifier

Ash Small, Fri Jun 19 2015, 05:48PM

A car alternator works in a similar fashion, with the rotor coil being energized sufficiently for the output from the stator coils to match the load (approximately).

Could your question be answered by feeding AC into the rotor of a car alternator, spinning it, and seeing what output you get from the stator coils?

Ash Small, Fri Jun 19 2015, 05:48PM

A car alternator works in a similar fashion, with the rotor coil being energized sufficiently for the output from the stator coils to match the load (approximately).

Could your question be answered by feeding AC into the rotor of a car alternator, spinning it, and seeing what output you get from the stator coils?

Re: electromechanical amplifier

Salvador, Fri Jun 19 2015, 06:17PM

i guess normally the alternator feeds dc into the rotor then poles spin past stator coils inducing current of frequency that varies with the rpm of the rotor which is then rectified , + the feedback tells how strong the dc into the rotor needs to be to match for need and rpm correct?

i guess it's called the voltage regulator or something like that.

well maybe i could try your idea Ash, but I assume the alternator still has more than one pole on the stator , by pole I mean coils, and also if remember correctly frokm last time seeing one the rotor was shaped like triangles coming from each end where each pole is located so taht makes the rotor with many poles like one after another like N-S-N-S-N and so on so i guess ti would work then , because here the idea is to maintain the frequency and waveform from the small signal that goes into the field coil to the large magnified output , and the only way I see that being done is to have one coil and a rotor that is similar to those in reluctance motors where it provides just the magnetic flux path , all other opnes have poles located on the rotor.

I dont know what do you think?

i seacrhed google and looks like all alternator rotors are pretty much the same having multiple N-S poles one after another so technically it's different from an oridnary generator which cannot produce an output based on input but rather based on the rpm of it's rotor that determine the frequency.

Salvador, Fri Jun 19 2015, 06:17PM

i guess normally the alternator feeds dc into the rotor then poles spin past stator coils inducing current of frequency that varies with the rpm of the rotor which is then rectified , + the feedback tells how strong the dc into the rotor needs to be to match for need and rpm correct?

i guess it's called the voltage regulator or something like that.

well maybe i could try your idea Ash, but I assume the alternator still has more than one pole on the stator , by pole I mean coils, and also if remember correctly frokm last time seeing one the rotor was shaped like triangles coming from each end where each pole is located so taht makes the rotor with many poles like one after another like N-S-N-S-N and so on so i guess ti would work then , because here the idea is to maintain the frequency and waveform from the small signal that goes into the field coil to the large magnified output , and the only way I see that being done is to have one coil and a rotor that is similar to those in reluctance motors where it provides just the magnetic flux path , all other opnes have poles located on the rotor.

I dont know what do you think?

i seacrhed google and looks like all alternator rotors are pretty much the same having multiple N-S poles one after another so technically it's different from an oridnary generator which cannot produce an output based on input but rather based on the rpm of it's rotor that determine the frequency.

Re: electromechanical amplifier

Ash Small, Fri Jun 19 2015, 07:55PM

Yes, that's pretty much the case.

I'm not quite sure what you are trying to do. If you feed the AC in at the correct frequency, I think you might re-invent the synchronous motor (you'd need to apply a voltage to the stator windings as well)

(you'd need to apply a voltage to the stator windings as well)

EDIT: Actually, I think you'd probably end up with one AC signal superimposed on top of another one.

Ash Small, Fri Jun 19 2015, 07:55PM

Salvador wrote ...

i guess normally the alternator feeds dc into the rotor then poles spin past stator coils inducing current of frequency that varies with the rpm of the rotor which is then rectified , + the feedback tells how strong the dc into the rotor needs to be to match for need and rpm correct?

i guess it's called the voltage regulator or something like that.

i guess normally the alternator feeds dc into the rotor then poles spin past stator coils inducing current of frequency that varies with the rpm of the rotor which is then rectified , + the feedback tells how strong the dc into the rotor needs to be to match for need and rpm correct?

i guess it's called the voltage regulator or something like that.

Yes, that's pretty much the case.

Salvador wrote ...

I dont know what do you think?

I dont know what do you think?

I'm not quite sure what you are trying to do. If you feed the AC in at the correct frequency, I think you might re-invent the synchronous motor

(you'd need to apply a voltage to the stator windings as well)

(you'd need to apply a voltage to the stator windings as well)EDIT: Actually, I think you'd probably end up with one AC signal superimposed on top of another one.

Re: electromechanical amplifier

radiotech, Sat Jun 20 2015, 07:55AM

You might want to look at the Amplidyne. It is amplifying generator.

There is a good description here.

radiotech, Sat Jun 20 2015, 07:55AM

You might want to look at the Amplidyne. It is amplifying generator.

There is a good description here.

Re: electromechanical amplifier

Salvador, Sat Jun 20 2015, 09:21AM

I have looked at amplidyes before their interesting.Well I;m kinda tired I have talked ideas like these with multiple people on internet and rarely if anyone seems to understand what I'm trying to do even to the point where one could give me a feedback of whether it works or not.

the idea here is simple , a generator whose output frequency and also waveform to an extent resembles the input taht was fed into the field coils.seems like would be a handy thing to me atleast, one could amke smaller generators for the same output power especially where low rpm applications are used.

you are correct ash in saying that even if the rotor doesnt rotate it would still wrks as a very crappy tranbsformer since the way it is built, maybe you can explain the bit about the synchronous motor reinvention more indebt? would it function as a brushless motor also ? could it be fed with DC?

in one other forums where I asked this very question one guy is trying to tell me that the flux would produce cancelling currents in the stator coil and almoust no output would be produced but I don;'t think thats true because at any given moment only one pole goes through the rotor in other words at any given moment the flux through the rotor point only in one direction the other pole is the stator so i think this reasoning is correct ?

Salvador, Sat Jun 20 2015, 09:21AM

I have looked at amplidyes before their interesting.Well I;m kinda tired I have talked ideas like these with multiple people on internet and rarely if anyone seems to understand what I'm trying to do even to the point where one could give me a feedback of whether it works or not.

the idea here is simple , a generator whose output frequency and also waveform to an extent resembles the input taht was fed into the field coils.seems like would be a handy thing to me atleast, one could amke smaller generators for the same output power especially where low rpm applications are used.

you are correct ash in saying that even if the rotor doesnt rotate it would still wrks as a very crappy tranbsformer since the way it is built, maybe you can explain the bit about the synchronous motor reinvention more indebt? would it function as a brushless motor also ? could it be fed with DC?

in one other forums where I asked this very question one guy is trying to tell me that the flux would produce cancelling currents in the stator coil and almoust no output would be produced but I don;'t think thats true because at any given moment only one pole goes through the rotor in other words at any given moment the flux through the rotor point only in one direction the other pole is the stator so i think this reasoning is correct ?

Re: electromechanical amplifier

Ash Small, Sat Jun 20 2015, 12:38PM

It has brushes, so can't really be called 'brushless', although the brushes aren't configured as they are on a conventional 'brushed' motor. These alternators have 'slip rings' rather than 'commutators', so they don't perform the 'switching action' that a commutator does. You would need a driver circuit like a conventional 'BLDC' motor (It 'should' spin even if you just feed it AC, but you'd need to energise the stator windings.) It would probably make more sense to drive the stator coils like a three phase BLDC and just feed DC to the rotor. The rotor would then act like the permanent magnets do on the rotor of a conventional BLDC motor.

Ash Small, Sat Jun 20 2015, 12:38PM

Salvador wrote ...

you are correct ash in saying that even if the rotor doesnt rotate it would still wrks as a very crappy tranbsformer since the way it is built, maybe you can explain the bit about the synchronous motor reinvention more indebt? would it function as a brushless motor also ? could it be fed with DC?

you are correct ash in saying that even if the rotor doesnt rotate it would still wrks as a very crappy tranbsformer since the way it is built, maybe you can explain the bit about the synchronous motor reinvention more indebt? would it function as a brushless motor also ? could it be fed with DC?

It has brushes, so can't really be called 'brushless', although the brushes aren't configured as they are on a conventional 'brushed' motor. These alternators have 'slip rings' rather than 'commutators', so they don't perform the 'switching action' that a commutator does. You would need a driver circuit like a conventional 'BLDC' motor (It 'should' spin even if you just feed it AC, but you'd need to energise the stator windings.) It would probably make more sense to drive the stator coils like a three phase BLDC and just feed DC to the rotor. The rotor would then act like the permanent magnets do on the rotor of a conventional BLDC motor.

Re: electromechanical amplifier

Salvador, Sat Jun 20 2015, 01:05PM

Oh maybe I didn't explain every bit the way I should have. The very drawing I attached or my idea whatever you call it is a brushless design.

everything is like pictured in the drawing except the red arrows show not the path for electrical wiring or connections but the magnetic flux path as there would be something similar to an " endplate" that would take the flux from the outer poles of the field coils and provide a path for the flux to go through the rotor so that it could then reach the airgap and go back into the stator where the other pole is located.

as the rotor would turn these areas of high magnetic flux would be dragged along the stator coil and should induce current whose frequency and waveform should follow that which was fed into the field coils.

I would really like to hear whether this could work like that as the only other option I have right now is to take an old asychronous AC induction motor rewind the stator the way I ahve shown here and then cut the two sides off from the squirrel cage rotor to make it resemble this kind of rotor and then feed it with the flux the way i have shown and see what happens but thats quite a lot of work to be done so i thought to ask first for some opinions.

Salvador, Sat Jun 20 2015, 01:05PM

Oh maybe I didn't explain every bit the way I should have. The very drawing I attached or my idea whatever you call it is a brushless design.

everything is like pictured in the drawing except the red arrows show not the path for electrical wiring or connections but the magnetic flux path as there would be something similar to an " endplate" that would take the flux from the outer poles of the field coils and provide a path for the flux to go through the rotor so that it could then reach the airgap and go back into the stator where the other pole is located.

as the rotor would turn these areas of high magnetic flux would be dragged along the stator coil and should induce current whose frequency and waveform should follow that which was fed into the field coils.

I would really like to hear whether this could work like that as the only other option I have right now is to take an old asychronous AC induction motor rewind the stator the way I ahve shown here and then cut the two sides off from the squirrel cage rotor to make it resemble this kind of rotor and then feed it with the flux the way i have shown and see what happens but thats quite a lot of work to be done so i thought to ask first for some opinions.

Re: electromechanical amplifier

Ash Small, Sat Jun 20 2015, 01:15PM

Can't you knock up something really basic using a toroidal core and some magnets (or simple electromagnets)?

You'd only need a couple of simple bearings and some offcuts of wood, or something (and a few other odds and ends)

You'll only need a 'measurable voltage', and any old oscilloscope will do.

You could use a small mains transformer for the AC signal, maybe, or generate it some other way.

Ash Small, Sat Jun 20 2015, 01:15PM

Can't you knock up something really basic using a toroidal core and some magnets (or simple electromagnets)?

You'd only need a couple of simple bearings and some offcuts of wood, or something (and a few other odds and ends)

You'll only need a 'measurable voltage', and any old oscilloscope will do.

You could use a small mains transformer for the AC signal, maybe, or generate it some other way.

Re: electromechanical amplifier

Salvador, Sat Jun 20 2015, 04:58PM

well im starting to think that way , the biggest problem would be to make the field coil attachments because one end needs to be physically part of the stator while the other pole has to have a magnetic path around the staor into the rotor

to get anything uself out the airgaps for the flux paths to the rotor would need to be as small as possible ,

but when you think about it what does your intellectual guess say ? does it even sounds plausible because if it's not working in theory why should I waste time and money to try it in real life thast why i'm asking before.

Salvador, Sat Jun 20 2015, 04:58PM

well im starting to think that way , the biggest problem would be to make the field coil attachments because one end needs to be physically part of the stator while the other pole has to have a magnetic path around the staor into the rotor

to get anything uself out the airgaps for the flux paths to the rotor would need to be as small as possible ,

but when you think about it what does your intellectual guess say ? does it even sounds plausible because if it's not working in theory why should I waste time and money to try it in real life thast why i'm asking before.

Re: electromechanical amplifier

Ash Small, Sat Jun 20 2015, 05:42PM

Even if the gaps aren't 'ideal' you should still be able to measure what's happening.

I'd start by finding a toroidal core. Once you've decided on that, sizes of everything else are easy.

Ash Small, Sat Jun 20 2015, 05:42PM

Even if the gaps aren't 'ideal' you should still be able to measure what's happening.

I'd start by finding a toroidal core. Once you've decided on that, sizes of everything else are easy.

Re: electromechanical amplifier

Salvador, Sat Jun 20 2015, 06:04PM

i have an idea to just get an old induction motor strip of its coils and wind it toroidally , where wires in one direction go through the slots where the coils normally are located and come back through the outside and into the slots again ,

i could cut the rotor on both sides to make it more simlar to the one in my drawing, anyways ash why you didnt say what your thoughts are on the theory of this idea? is it even worth trying or do you honestly don't know , I would like to hear your and ofcourse other's opinion on the mater.

Salvador, Sat Jun 20 2015, 06:04PM

i have an idea to just get an old induction motor strip of its coils and wind it toroidally , where wires in one direction go through the slots where the coils normally are located and come back through the outside and into the slots again ,

i could cut the rotor on both sides to make it more simlar to the one in my drawing, anyways ash why you didnt say what your thoughts are on the theory of this idea? is it even worth trying or do you honestly don't know , I would like to hear your and ofcourse other's opinion on the mater.

Re: electromechanical amplifier

Ash Small, Sun Jun 21 2015, 10:24PM

I don't fully understand what you are trying to do, so I suggest you build a 'model', apply some small AC signal to it, spin it up, and use any old 'scope to 'see' exactly what happens

I used to make simple electric motors as a kid by winding the rotor windings around pieces of wood, using nails as bearings. the commutators were the only 'tricky' bit, but I used to just use copper wire and I got acceptable results (they used to spin pretty fast)

You could spin yours up using a belt and a couple of pulleys. Large elastic bands can be used as drivebelts if nothing else is to hand.

Ash Small, Sun Jun 21 2015, 10:24PM

I don't fully understand what you are trying to do, so I suggest you build a 'model', apply some small AC signal to it, spin it up, and use any old 'scope to 'see' exactly what happens

I used to make simple electric motors as a kid by winding the rotor windings around pieces of wood, using nails as bearings. the commutators were the only 'tricky' bit, but I used to just use copper wire and I got acceptable results (they used to spin pretty fast)

You could spin yours up using a belt and a couple of pulleys. Large elastic bands can be used as drivebelts if nothing else is to hand.

Re: electromechanical amplifier

radiotech, Thu Jun 25 2015, 08:49AM

Consider a 6 pole, wound rotor synchronous motor, which is being started

on a 60 Hz power line. As it starts the rotor is connected to slip rings. and

resistors are attached to the slip rings.

Just as it starts, the rotor is the secondary of a very large transformer. As it

moves, there is a high frequency current produced in the resistors. As it

speeds up, the frequency of this current reduces. As it approaches the speed

it is intended to run at, the rotor current approaches DC.

In practice, an automatic relay operates at a precise moment as the rotor

current approaches DC, and the resistors are switched out, and a DC power

source, is connected. At that moment the speed of the motor locks on to

a sub multiple of the power line's angular velocity.

Somewhere in this description, your idea for a machine may lie.

Perhaps there is a training video on line about synchronous machines.

A Vulcan mind-meld with those who have actually experienced the

ills and joys of such machines would help too.

radiotech, Thu Jun 25 2015, 08:49AM

Consider a 6 pole, wound rotor synchronous motor, which is being started

on a 60 Hz power line. As it starts the rotor is connected to slip rings. and

resistors are attached to the slip rings.

Just as it starts, the rotor is the secondary of a very large transformer. As it

moves, there is a high frequency current produced in the resistors. As it

speeds up, the frequency of this current reduces. As it approaches the speed

it is intended to run at, the rotor current approaches DC.

In practice, an automatic relay operates at a precise moment as the rotor

current approaches DC, and the resistors are switched out, and a DC power

source, is connected. At that moment the speed of the motor locks on to

a sub multiple of the power line's angular velocity.

Somewhere in this description, your idea for a machine may lie.

Perhaps there is a training video on line about synchronous machines.

A Vulcan mind-meld with those who have actually experienced the

ills and joys of such machines would help too.

Re: electromechanical amplifier

Salvador, Thu Jun 25 2015, 02:10PM

Well not a very common motor the one you described , well actually i believe very similar except for the comuttator with brushes instead of slip rings and brushes is the universal motor , it too ahs a wound rotor , just that instead of the rotor behaving like a bar magnet that locks and fol;lows the mains frequency it constantly pushes itself against the field of the stator.

well my idea is actually much simpler than these, instead of having poles you just arrange a coil in a way that the flux cuts the wires that go only in one direction , then you vary the flux density along the length of the coil to have induction at all, and then you can vary the flux itself with a certain frequency and waveform and this variation should mirror in the output from the coil.

the very key being that the output follows the waveform and frequency of the input field coil signal.By doing this one can adjust the generator to its load by just adjusting the frequency.

in a local AC grid this would require an AC to DC inverter to then convert the output to the grid 50 or 60hz. Or you just have to run the generator itself on 50hz Sine wave. but in places like submarines, airplanes and other areas where small lightweight generators are needed or HVDC lines the high frequency AC output could just be rectified and then fed into the grid.

Salvador, Thu Jun 25 2015, 02:10PM

Well not a very common motor the one you described , well actually i believe very similar except for the comuttator with brushes instead of slip rings and brushes is the universal motor , it too ahs a wound rotor , just that instead of the rotor behaving like a bar magnet that locks and fol;lows the mains frequency it constantly pushes itself against the field of the stator.

well my idea is actually much simpler than these, instead of having poles you just arrange a coil in a way that the flux cuts the wires that go only in one direction , then you vary the flux density along the length of the coil to have induction at all, and then you can vary the flux itself with a certain frequency and waveform and this variation should mirror in the output from the coil.

the very key being that the output follows the waveform and frequency of the input field coil signal.By doing this one can adjust the generator to its load by just adjusting the frequency.

in a local AC grid this would require an AC to DC inverter to then convert the output to the grid 50 or 60hz. Or you just have to run the generator itself on 50hz Sine wave. but in places like submarines, airplanes and other areas where small lightweight generators are needed or HVDC lines the high frequency AC output could just be rectified and then fed into the grid.

Re: electromechanical amplifier

Salvador, Thu Jul 09 2015, 08:31PM

So I'm back as some of you suggested and as I thought myself I made a prototype.I kinda lame one but it has the things I think it should have.

I havent yet fully tested it only half way there and I have some doubts about whether it would work as I want it to work or work at all, but I want to give you some pictures and ask what do you think?

the welded screws attached to the stator are meant to be magnetic flux paths from the field coils to the rotor, as the idea is to have the flux go through the airgap at the rght angle so alike poles are faced both into the rotor and the other alike poles are forced into the stator and they should meet through the airgap.

the rotor has a shape that when it rotates it drags the area of high flux density around the stator.

i couldnt post the pictures here because the filesize was too big.

Salvador, Thu Jul 09 2015, 08:31PM

So I'm back as some of you suggested and as I thought myself I made a prototype.I kinda lame one but it has the things I think it should have.

I havent yet fully tested it only half way there and I have some doubts about whether it would work as I want it to work or work at all, but I want to give you some pictures and ask what do you think?

the welded screws attached to the stator are meant to be magnetic flux paths from the field coils to the rotor, as the idea is to have the flux go through the airgap at the rght angle so alike poles are faced both into the rotor and the other alike poles are forced into the stator and they should meet through the airgap.

the rotor has a shape that when it rotates it drags the area of high flux density around the stator.

i couldnt post the pictures here because the filesize was too big.

Re: electromechanical amplifier

mister_rf, Sat Jul 11 2015, 08:36PM

Well, if you don’t increase the number of turns in the coils, there will be no success. IMO try at least fifty time more than the actual design.

mister_rf, Sat Jul 11 2015, 08:36PM

Well, if you don’t increase the number of turns in the coils, there will be no success. IMO try at least fifty time more than the actual design.

Re: electromechanical amplifier

Salvador, Tue Jul 14 2015, 05:53PM

sadly it doesnt work , even with such little count of turns on windings i ashould have got atleast something on the meter.

maybe its due to the geometry of a ac induction motor's stator where the windings are kinda into the stator and the part that first encounters the flux is the stator metal itself, or maybe my idea doesnt work.

but theoretically everything should work, one pole is always in the stator , the other pole in the rotor , the rotor geometry is shaped as in pictures so that as the rotor rotates the areas of high flux rotate with it , the signal into the field coil is AC.the output coils should get induced current o the frequency of the field current but magnified due to the fact that the rotor stator airgap has a varying and physically moving flux.

sadly most poeple whom i have asked are not interested into thinking about it.

Salvador, Tue Jul 14 2015, 05:53PM

sadly it doesnt work , even with such little count of turns on windings i ashould have got atleast something on the meter.

maybe its due to the geometry of a ac induction motor's stator where the windings are kinda into the stator and the part that first encounters the flux is the stator metal itself, or maybe my idea doesnt work.

but theoretically everything should work, one pole is always in the stator , the other pole in the rotor , the rotor geometry is shaped as in pictures so that as the rotor rotates the areas of high flux rotate with it , the signal into the field coil is AC.the output coils should get induced current o the frequency of the field current but magnified due to the fact that the rotor stator airgap has a varying and physically moving flux.

sadly most poeple whom i have asked are not interested into thinking about it.

Re: electromechanical amplifier

Ash Small, Tue Jul 14 2015, 06:44PM

I suggested building something simple from scratch, starting with a toroidal core. I think your present setup is prone to leakage inductance.

I'm not saying your idea will work, though, just trying to give some 'constructive criticism'.

As you point out, I would have expected the meters to indicate something.

Ash Small, Tue Jul 14 2015, 06:44PM

I suggested building something simple from scratch, starting with a toroidal core. I think your present setup is prone to leakage inductance.

I'm not saying your idea will work, though, just trying to give some 'constructive criticism'.

As you point out, I would have expected the meters to indicate something.

Print this page