Reforming capacitors in equipment?

klugesmith, Mon Jun 15 2015, 06:52PMI've reformed electrolytic capacitors on the bench, even charting voltage and leakage current for days.

Now looking for a simpler way to get old vacuum tube (valve) equipment back in service. In this case, an adjustable regulated power supply meant for (and made with) tubes. It's been stored outdoors under a tarp for a few years, but served me well before that.

I'd prefer not to open it up for inspection (and removal of insect remains etc.).

How about just powering it up with reduced AC voltage from a variac, and allowing a few hours between each voltage increase? I don't think any internal currents could be higher than normal. But might rectifier cathodes be damaged by operation with inordinately low filament voltage? Schematic diagram and chassis images are easy to find on the Internet.

How many of you tubeheads would simply plug it in, turn it on, and see if it works?

Re: Reforming capacitors in equipment?

Bored Chemist, Mon Jun 15 2015, 07:24PM

It looks like a lovely old bit of kit. It's possible that just plugging it in and slowly cranking up the volts would work.

But imagine that it doesn't and you wreck it just because you couldn't be bothered to remove the dead spider across the circuit somewhere.

Surely it has to be worth taking a minute to clean the dust out?

Bored Chemist, Mon Jun 15 2015, 07:24PM

It looks like a lovely old bit of kit. It's possible that just plugging it in and slowly cranking up the volts would work.

But imagine that it doesn't and you wreck it just because you couldn't be bothered to remove the dead spider across the circuit somewhere.

Surely it has to be worth taking a minute to clean the dust out?

Re: Reforming capacitors in equipment?

mister_rf, Mon Jun 15 2015, 09:08PM

IMO I’ll be more concerned about tackling the rust and corrosion that has attacked the electric switches and probably most importantly interconnects.

mister_rf, Mon Jun 15 2015, 09:08PM

IMO I’ll be more concerned about tackling the rust and corrosion that has attacked the electric switches and probably most importantly interconnects.

Re: Reforming capacitors in equipment?

Ash Small, Mon Jun 15 2015, 11:28PM

It may well have dried out capacitors inside too. If so, you may well get flames coming out of the vents.

I've destroyed valve guitar amps and valve TV's this way

Ash Small, Mon Jun 15 2015, 11:28PM

It may well have dried out capacitors inside too. If so, you may well get flames coming out of the vents.

I've destroyed valve guitar amps and valve TV's this way

Re: Reforming capacitors in equipment?

Blackcurrant, Tue Jun 16 2015, 12:56PM

Give it a good clean. I've also seen tubes that have fallen out, plus if you look inside you may save wildlife from a fiery death

Blackcurrant, Tue Jun 16 2015, 12:56PM

Give it a good clean. I've also seen tubes that have fallen out, plus if you look inside you may save wildlife from a fiery death

Re: Reforming capacitors in equipment?

klugesmith, Tue Jun 16 2015, 06:58PM

So far, so good. Thanks to all for advising caution. I opened the unit and evicted a couple of live spiders. Vacuumed out dust, cobwebs, and some empty spider skins. The layout in there is very open and clean (stay tuned for pictures). Circuit from schematic is easy to follow.

With all seven tubes removed, I bridged both vacuum rectifier sockets with silicon diodes in series with 100K resistors. Started with 25% of nominal AC voltage and waited for bus voltages to stabilize as capacitor dielectrics were reformed. Progressively cranked up the AC voltage and reduced the series resistors. This morning I stopped at 75% of nominal AC & no series resistor, when positive bus reached about 550 volts. Don't want the already-overstressed 1N4006 rectifier to suffer a fiery death, especially if unattended.

Now two shunt regulator tubes are back in place. Their internal pass-through connections allow power to reach more circuitry. Front panel bias voltage output and control knob (0 to -150) are working. Next step is to plug in the vacuum rectifiers and finish ramping up the AC voltage.

klugesmith, Tue Jun 16 2015, 06:58PM

So far, so good. Thanks to all for advising caution. I opened the unit and evicted a couple of live spiders. Vacuumed out dust, cobwebs, and some empty spider skins. The layout in there is very open and clean (stay tuned for pictures). Circuit from schematic is easy to follow.

With all seven tubes removed, I bridged both vacuum rectifier sockets with silicon diodes in series with 100K resistors. Started with 25% of nominal AC voltage and waited for bus voltages to stabilize as capacitor dielectrics were reformed. Progressively cranked up the AC voltage and reduced the series resistors. This morning I stopped at 75% of nominal AC & no series resistor, when positive bus reached about 550 volts. Don't want the already-overstressed 1N4006 rectifier to suffer a fiery death, especially if unattended.

Now two shunt regulator tubes are back in place. Their internal pass-through connections allow power to reach more circuitry. Front panel bias voltage output and control knob (0 to -150) are working. Next step is to plug in the vacuum rectifiers and finish ramping up the AC voltage.

Re: Reforming capacitors in equipment?

klugesmith, Mon Jun 22 2015, 08:37AM

I am happy to have brought the old power supply back into service without cutting corners.

It made quick work of testing a well-worn magic eye tube that I'd picked up at the flea market for $1.

For people unfamiliar with these analog Vacuum Fluorescent Displays, they first appeared in 1935, on high-end radio receivers, as tuning indicators. When I was a child in the 1960's, our family's Grundig tape recorder had a magic eye recording level meter. Even then I bet they cost less than moving-coil meters. No magnets, bearings, springs, backlights, etc. -- just another dual triode sharing filament and anode power with other tubes.

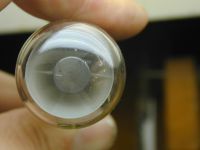

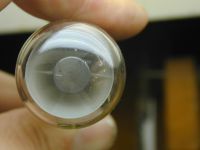

This specimen was disappointingly dim from phosphor wear, even running at 400 V instead of the suggested 250 V. (These pictures were taken in a dimly lit room). I bet it spent most of its working hours displaying a constant dark sector about 60 degrees wide. Here we see the display progressively reduced from maximum (around 90 degrees):

Without power, the burns on target are easy to see.

Sorry about the unnecessarily large image files.

klugesmith, Mon Jun 22 2015, 08:37AM

I am happy to have brought the old power supply back into service without cutting corners.

It made quick work of testing a well-worn magic eye tube that I'd picked up at the flea market for $1.

For people unfamiliar with these analog Vacuum Fluorescent Displays, they first appeared in 1935, on high-end radio receivers, as tuning indicators. When I was a child in the 1960's, our family's Grundig tape recorder had a magic eye recording level meter. Even then I bet they cost less than moving-coil meters. No magnets, bearings, springs, backlights, etc. -- just another dual triode sharing filament and anode power with other tubes.

This specimen was disappointingly dim from phosphor wear, even running at 400 V instead of the suggested 250 V. (These pictures were taken in a dimly lit room). I bet it spent most of its working hours displaying a constant dark sector about 60 degrees wide. Here we see the display progressively reduced from maximum (around 90 degrees):

Without power, the burns on target are easy to see.

Sorry about the unnecessarily large image files.

Re: Reforming capacitors in equipment?

klugesmith, Fri Aug 07 2015, 07:21PM

Before putting the cover back onto the 400 volt power supply, I took more pictures with the tubes exposed.

Here it sits behind a transistor radio novelty with simulated vacuum tubes. So the image has orange light sources representing at least three different physical processes.

klugesmith, Fri Aug 07 2015, 07:21PM

Before putting the cover back onto the 400 volt power supply, I took more pictures with the tubes exposed.

Here it sits behind a transistor radio novelty with simulated vacuum tubes. So the image has orange light sources representing at least three different physical processes.

Re: Reforming capacitors in equipment?

klugesmith, Sun Aug 04 2019, 07:06AM

Found an Eico 378 audio signal generator like this one, while cleaning up patio. Don't know how it got there.

Time to see if the 50-year-old electrolytic capacitors can be reformed. I think the power supply shown earlier in this thread will be handy for that. Or use the oscillator's own power transformer, on a variac, after removing all three tubes and bypassing the 6X4 rectifier with a semiconductor diode and high-value resistor.

Found some articles about the importance of capacitor reforming in "modern" solid state equipment, like VFD units:

Writer gives example of a factory process that's shut down because a VFD failed. Fortunately, there's an identical spare VFD on hand for that contingency. It's quickly installed, powered up, and immediately fails. On account of being stored for four years without power, then skipping the manufacturer's capacitor-reforming protocol.

For plant engineers who don't want to deal with reforming, they suggest powering up each spare every six months or so. Kind of like regularly scheduled operation of emergency electric generators.

What do you all think about less demanding stuff, like consumer audio equipment? Is it foolish to just plug in a solid-state stereo receiver that's been idle for 10 years, or foolish to pay attention to its capacitors?

klugesmith, Sun Aug 04 2019, 07:06AM

Found an Eico 378 audio signal generator like this one, while cleaning up patio. Don't know how it got there.

Time to see if the 50-year-old electrolytic capacitors can be reformed. I think the power supply shown earlier in this thread will be handy for that. Or use the oscillator's own power transformer, on a variac, after removing all three tubes and bypassing the 6X4 rectifier with a semiconductor diode and high-value resistor.

Found some articles about the importance of capacitor reforming in "modern" solid state equipment, like VFD units:

Writer gives example of a factory process that's shut down because a VFD failed. Fortunately, there's an identical spare VFD on hand for that contingency. It's quickly installed, powered up, and immediately fails. On account of being stored for four years without power, then skipping the manufacturer's capacitor-reforming protocol.

For plant engineers who don't want to deal with reforming, they suggest powering up each spare every six months or so. Kind of like regularly scheduled operation of emergency electric generators.

What do you all think about less demanding stuff, like consumer audio equipment? Is it foolish to just plug in a solid-state stereo receiver that's been idle for 10 years, or foolish to pay attention to its capacitors?

Re: Reforming capacitors in equipment?

MRMILSTAR, Sun Aug 04 2019, 02:04PM

"Simulated vacuum tubes". That's a new one for me.

MRMILSTAR, Sun Aug 04 2019, 02:04PM

"Simulated vacuum tubes". That's a new one for me.

Re: Reforming capacitors in equipment?

Patrick, Wed Aug 07 2019, 06:57PM

One thing you could do on future similar projects, if the caps are beyond recovery do to "dry-out" is to cut the old original cap body off carefully, then 3d print or make some widget to hold a modern cap in its internal place. The original cosmetic appearance would remain with the performance guarantee of modern caps. "IE Chinese deception method "

And i love this :

the term "suggested" seems to be what we 4hv'ers thrive on.

Patrick, Wed Aug 07 2019, 06:57PM

One thing you could do on future similar projects, if the caps are beyond recovery do to "dry-out" is to cut the old original cap body off carefully, then 3d print or make some widget to hold a modern cap in its internal place. The original cosmetic appearance would remain with the performance guarantee of modern caps. "IE Chinese deception method "

And i love this :

even running at 400 V instead of the suggested 250 V.

the term "suggested" seems to be what we 4hv'ers thrive on.

Print this page