Propeller Physics and VABs Program.

Patrick, Sat Nov 15 2014, 05:42AMIve got permission to use VABs but the link expired since Purdue university hosting service went into the trash can. the AnalSwift company has told me how to get going again, and ive foun the PDF manual.

in a few days theyll release a link and ill start loading prop sections in. There is a problem however, i dont know how to use matrix math.

PDF:

]vabsmanual.pdf[/file]

Re: Propeller Physics and VABs Program.

Sulaiman, Sat Nov 15 2014, 08:10AM

just had a quick skim through of the VABs manual

and I don't see how it will help your uav design much;

. it will not help at all with propellor shape/speed/size design

. the static stresses on the airframe are negligible compared to landing/crashing

(to simulate all variables is impractical)

. even if you could work out optimal profiles for beams etc.

you are stuck with commercially available shapes (uniform rods, tubes, slabs etc.)

I guess you will have to rely on;

. experience of others

. intuition

. field trials

Sulaiman, Sat Nov 15 2014, 08:10AM

just had a quick skim through of the VABs manual

and I don't see how it will help your uav design much;

. it will not help at all with propellor shape/speed/size design

. the static stresses on the airframe are negligible compared to landing/crashing

(to simulate all variables is impractical)

. even if you could work out optimal profiles for beams etc.

you are stuck with commercially available shapes (uniform rods, tubes, slabs etc.)

I guess you will have to rely on;

. experience of others

. intuition

. field trials

Re: Propeller Physics and VABs Program.

Shrad, Sat Nov 15 2014, 09:58AM

for matrix math you can have a look at scipy which is a matlab equivalent in python...

Shrad, Sat Nov 15 2014, 09:58AM

for matrix math you can have a look at scipy which is a matlab equivalent in python...

Re: Propeller Physics and VABs Program.

Ash Small, Sat Nov 15 2014, 12:38PM

I've just looked at the VABS manual too, and it does look a bit disappointing. It would appear from first glance that it is only useful for working out the stresses in a 'pre-defined' propeller blade, as opposed to helping to arrive at a blade design.

I'm not sure yet whether we can input different designs and then compare lift generated in various scenarios, as there is a relationship between the lift generated and stresses within the blade.

To elaborate, if it predicts the 'bending moment' at the blade root, then this is proportional (if not equal to) the lift generated by the blade. and this could be very useful when comparing different blade designs under different conditions

I don't think it tells us anything about losses associated with disc area, etc., however I'm not sure about this, as the 'downward force' exerted by the propeller is equal to the 'upward force' of the accelerated column of air.

This certainly requires a bit more thought.

Ash Small, Sat Nov 15 2014, 12:38PM

I've just looked at the VABS manual too, and it does look a bit disappointing. It would appear from first glance that it is only useful for working out the stresses in a 'pre-defined' propeller blade, as opposed to helping to arrive at a blade design.

I'm not sure yet whether we can input different designs and then compare lift generated in various scenarios, as there is a relationship between the lift generated and stresses within the blade.

To elaborate, if it predicts the 'bending moment' at the blade root, then this is proportional (if not equal to) the lift generated by the blade. and this could be very useful when comparing different blade designs under different conditions

I don't think it tells us anything about losses associated with disc area, etc., however I'm not sure about this, as the 'downward force' exerted by the propeller is equal to the 'upward force' of the accelerated column of air.

This certainly requires a bit more thought.

Re: Propeller Physics and VABs Program.

Patrick, Sat Nov 15 2014, 06:51PM

Is there any fluid flow or prop Sim anyone knows about? I see random things on our great all knowing Google overlord.

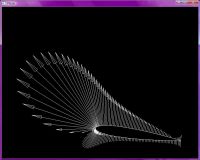

EDIT, found this :

Patrick, Sat Nov 15 2014, 06:51PM

Is there any fluid flow or prop Sim anyone knows about? I see random things on our great all knowing Google overlord.

EDIT, found this :

Re: Propeller Physics and VABs Program.

Andy, Sat Nov 15 2014, 09:11PM

If you don't mind waiting 2-3months, I could writre a program to do the simulations, but then back of the note book cacultions, should be enought.

pressure/velocity = volume

velocity^2

pressure = volume

energy in energy out at 100%

In the past did research on wind turbine, which pretty much work in the opposite theory, but a TSR of greater than 1> is more efficiency but, the torgure is low, a high torgue but low efficiency is a there low tip to speed ratio, in other wards,

if you could make high velocity flow, but without the power of two then it would be the most force, but high velocity and air volume, formulas workout to the same value, "1", so the other equation come into play, if you wan't high moverabilty, make the velocity high to make the power change quick, which will make a unstable aircraft, make the velocity slow, will make a stable craft, the power in and out is the same. the one thing above that isn't in the theory is pressure, that can be reality to weight, in which the gradient of the atmosphere changes with alternative, the pressure changes, which relates to a drop in pressure, and there fore weight, but multi formula maths, says that there is more advances in high altitude, as velocity=P/V is easy and P = V2/V is lower so less pressure more volume gets turned into speed, all in all you can't change the energy input, much, but at high altitude, with a good Carma you will get better effect, forgot the back flow from ground hover, which might confuse you if you add it to statical models.

Hope it helps

Andy, Sat Nov 15 2014, 09:11PM

If you don't mind waiting 2-3months, I could writre a program to do the simulations, but then back of the note book cacultions, should be enought.

pressure/velocity = volume

velocity^2

pressure = volume

energy in energy out at 100%

In the past did research on wind turbine, which pretty much work in the opposite theory, but a TSR of greater than 1> is more efficiency but, the torgure is low, a high torgue but low efficiency is a there low tip to speed ratio, in other wards,

if you could make high velocity flow, but without the power of two then it would be the most force, but high velocity and air volume, formulas workout to the same value, "1", so the other equation come into play, if you wan't high moverabilty, make the velocity high to make the power change quick, which will make a unstable aircraft, make the velocity slow, will make a stable craft, the power in and out is the same. the one thing above that isn't in the theory is pressure, that can be reality to weight, in which the gradient of the atmosphere changes with alternative, the pressure changes, which relates to a drop in pressure, and there fore weight, but multi formula maths, says that there is more advances in high altitude, as velocity=P/V is easy and P = V2/V is lower so less pressure more volume gets turned into speed, all in all you can't change the energy input, much, but at high altitude, with a good Carma you will get better effect, forgot the back flow from ground hover, which might confuse you if you add it to statical models.

Hope it helps

Re: Propeller Physics and VABs Program.

Ash Small, Sat Nov 15 2014, 09:30PM

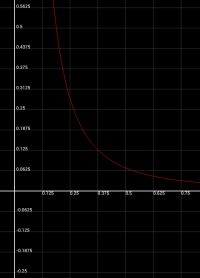

You've not taken losses into account here, Andy, which increase as prop size decreases and as air speed increases.

The most efficient is always large diameter and low RPM, and it's pretty much exponential, very similar to the 'drag equation'.

Certainly looks worth downloading, unfortunately, the website appears to have crashed at the moment.

Ash Small, Sat Nov 15 2014, 09:30PM

Andy wrote ...

If you don't mind waiting 2-3months, I could writre a program to do the simulations, but then back of the note book cacultions, should be enought.

pressure/velocity = volume

velocity^2

pressure = volume

energy in energy out at 100%

In the past did research on wind turbine, which pretty much work in the opposite theory, but a TSR of greater than 1> is more efficiency but, the torgure is low, a high torgue but low efficiency is a there low tip to speed ratio, in other wards,

if you could make high velocity flow, but without the power of two then it would be the most force, but high velocity and air volume, formulas workout to the same value, "1", so the other equation come into play, if you wan't high moverabilty, make the velocity high to make the power change quick, which will make a unstable aircraft, make the velocity slow, will make a stable craft, the power in and out is the same. the one thing above that isn't in the theory is pressure, that can be reality to weight, in which the gradient of the atmosphere changes with alternative, the pressure changes, which relates to a drop in pressure, and there fore weight, but multi formula maths, says that there is more advances in high altitude, as velocity=P/V is easy and P = V2/V is lower so less pressure more volume gets turned into speed, all in all you can't change the energy input, much, but at high altitude, with a good Carma you will get better effect, forgot the back flow from ground hover, which might confuse you if you add it to statical models.

Hope it helps

If you don't mind waiting 2-3months, I could writre a program to do the simulations, but then back of the note book cacultions, should be enought.

pressure/velocity = volume

velocity^2

pressure = volume

energy in energy out at 100%

In the past did research on wind turbine, which pretty much work in the opposite theory, but a TSR of greater than 1> is more efficiency but, the torgure is low, a high torgue but low efficiency is a there low tip to speed ratio, in other wards,

if you could make high velocity flow, but without the power of two then it would be the most force, but high velocity and air volume, formulas workout to the same value, "1", so the other equation come into play, if you wan't high moverabilty, make the velocity high to make the power change quick, which will make a unstable aircraft, make the velocity slow, will make a stable craft, the power in and out is the same. the one thing above that isn't in the theory is pressure, that can be reality to weight, in which the gradient of the atmosphere changes with alternative, the pressure changes, which relates to a drop in pressure, and there fore weight, but multi formula maths, says that there is more advances in high altitude, as velocity=P/V is easy and P = V2/V is lower so less pressure more volume gets turned into speed, all in all you can't change the energy input, much, but at high altitude, with a good Carma you will get better effect, forgot the back flow from ground hover, which might confuse you if you add it to statical models.

Hope it helps

You've not taken losses into account here, Andy, which increase as prop size decreases and as air speed increases.

The most efficient is always large diameter and low RPM, and it's pretty much exponential, very similar to the 'drag equation'.

Certainly looks worth downloading, unfortunately, the website appears to have crashed at the moment.

Re: Propeller Physics and VABs Program.

Patrick, Sat Nov 15 2014, 10:59PM

but i hope SU^2 has a GUI, and DXF import. i cant learn a complicated new program and learn embedded C at the same time.

Patrick, Sat Nov 15 2014, 10:59PM

but i hope SU^2 has a GUI, and DXF import. i cant learn a complicated new program and learn embedded C at the same time.

Re: Propeller Physics and VABs Program.

Ash Small, Sat Nov 15 2014, 11:09PM

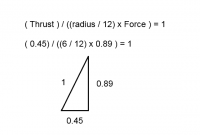

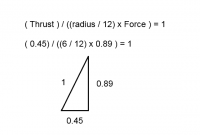

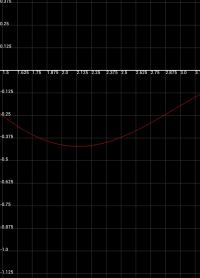

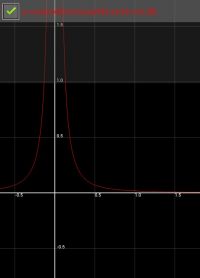

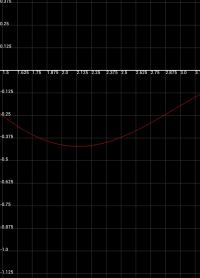

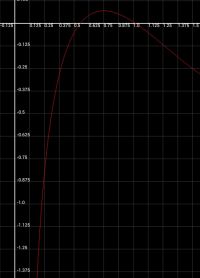

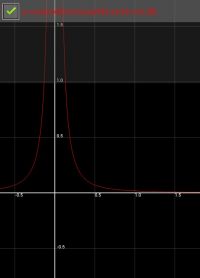

Just been doing some maths, Patrick. Can you check my transposition?

I came up with this:

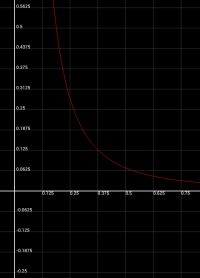

Power required = square root (Force^3 / (4.9 x Area))

Force remains constant while hovering for a fixed mass multicopter, the 4.9 is 4 times density of air, also a constant, so, at a glance you can see that, as area increases, required power decreases.

I transposed it from here:

"Note that these calculations are only valid for when the incoming air is accelerated from a standstill - for example when hovering."

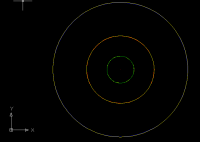

EDIT: Now, if we know the mass of the 'copter, we know the force required for hovering (9.8 Newtons per kg?), so then we just plot a graph of power required against disc area and we have a graph that 'should' tell us something

EDIT2: We also need to know number of rotors (n), and divide mass by n, then multiply power by n, to get total power in Watts, etc.

EDIT3: As Sulaiman pointed out (and as I pointed out in the 'other' thread for a 'heptacopter') for a hexacopter, if the rotors are close enough together, the losses are even less, but I'd like to see a graph for tri-copter against hexacopter of the same mass. The tricopter will presumably have less overall mass, though.

Let's hope that link for SU^2 works again soon.

Ash Small, Sat Nov 15 2014, 11:09PM

Just been doing some maths, Patrick. Can you check my transposition?

I came up with this:

Power required = square root (Force^3 / (4.9 x Area))

Force remains constant while hovering for a fixed mass multicopter, the 4.9 is 4 times density of air, also a constant, so, at a glance you can see that, as area increases, required power decreases.

I transposed it from here:

"Note that these calculations are only valid for when the incoming air is accelerated from a standstill - for example when hovering."

EDIT: Now, if we know the mass of the 'copter, we know the force required for hovering (9.8 Newtons per kg?), so then we just plot a graph of power required against disc area and we have a graph that 'should' tell us something

EDIT2: We also need to know number of rotors (n), and divide mass by n, then multiply power by n, to get total power in Watts, etc.

EDIT3: As Sulaiman pointed out (and as I pointed out in the 'other' thread for a 'heptacopter') for a hexacopter, if the rotors are close enough together, the losses are even less, but I'd like to see a graph for tri-copter against hexacopter of the same mass. The tricopter will presumably have less overall mass, though.

Let's hope that link for SU^2 works again soon.

Re: Propeller Physics and VABs Program.

Andy, Sun Nov 16 2014, 02:25AM

Ash you missed the point about to arrive at

to arrive at  , the veolicty is to the power, ether reuqires more power input or generators more thrust

, the veolicty is to the power, ether reuqires more power input or generators more thrust

Andy, Sun Nov 16 2014, 02:25AM

Ash you missed the point about

to arrive at

to arrive at  , the veolicty is to the power, ether reuqires more power input or generators more thrust

, the veolicty is to the power, ether reuqires more power input or generators more thrust

Re: Propeller Physics and VABs Program.

Ash Small, Sun Nov 16 2014, 02:53AM

Post edited.

Maybe I missed your point.

Looking at this again, the velocity bit is where all the losses originate. The larger the 'disc area', the lower the velocity for the same 'lift'.

I think this is why the 'v to the power' term disappears.

Is this the point you were making?

EDIT: It also states that "the "efficiency" of an otherwise-perfect thruster, is proportional to the area of the cross section of the propelled volume of fluid"

Ash Small, Sun Nov 16 2014, 02:53AM

Andy wrote ...

Ash you missed the point about to arrive at

to arrive at  , the veolicty is to the power, ether reuqires more power input or generators more thrust

, the veolicty is to the power, ether reuqires more power input or generators more thrust

Ash you missed the point about

to arrive at

to arrive at  , the veolicty is to the power, ether reuqires more power input or generators more thrust

, the veolicty is to the power, ether reuqires more power input or generators more thrust

Post edited.

Maybe I missed your point.

Looking at this again, the velocity bit is where all the losses originate. The larger the 'disc area', the lower the velocity for the same 'lift'.

I think this is why the 'v to the power' term disappears.

Is this the point you were making?

EDIT: It also states that "the "efficiency" of an otherwise-perfect thruster, is proportional to the area of the cross section of the propelled volume of fluid"

Re: Propeller Physics and VABs Program.

Ash Small, Mon Nov 17 2014, 03:57AM

Sorry about the double post, but new information:

Ok, 102g requires 1N (1kG/9.81) and 1kG requires 9.81N

9.81^3 = 944

944/(4.9x0.5m^2) = 385

square root 385 = 19W

With 1m^2 disc area, power required is 13.9W

With 2m^2 disc area power required is (Curiously) 9.81W

These figures don't take into account any other losses in the system, but they do demonstrate the point. They are all based on total 'copter mass of 1kg, with a single rotor.

So, in this case, quadrupling the disc area halves the power required, which doubles the flight time.

31.5 inch dia rotor gives 0.5m^2 disc area

and 63 inch diameter rotor gives 2m^2 disc area

We just need to calculate for some more realistic figures.

Ash Small, Mon Nov 17 2014, 03:57AM

Sorry about the double post, but new information:

Ok, 102g requires 1N (1kG/9.81) and 1kG requires 9.81N

9.81^3 = 944

944/(4.9x0.5m^2) = 385

square root 385 = 19W

With 1m^2 disc area, power required is 13.9W

With 2m^2 disc area power required is (Curiously) 9.81W

These figures don't take into account any other losses in the system, but they do demonstrate the point. They are all based on total 'copter mass of 1kg, with a single rotor.

So, in this case, quadrupling the disc area halves the power required, which doubles the flight time.

31.5 inch dia rotor gives 0.5m^2 disc area

and 63 inch diameter rotor gives 2m^2 disc area

We just need to calculate for some more realistic figures.

Re: Propeller Physics and VABs Program.

Patrick, Mon Nov 17 2014, 10:03PM

I cant figure out how to use this software,(SU^2) its a .tgz , which i un-compressed, but i dont know which file to use?

there appears to be know .exe , so do i have to compile this ?

And...

Patrick, Mon Nov 17 2014, 10:03PM

I cant figure out how to use this software,(SU^2) its a .tgz , which i un-compressed, but i dont know which file to use?

there appears to be know .exe , so do i have to compile this ?

And...

Re: Propeller Physics and VABs Program.

Shrad, Tue Nov 18 2014, 08:18AM

linux program which is to be compiled ;)

Shrad, Tue Nov 18 2014, 08:18AM

linux program which is to be compiled ;)

Re: Propeller Physics and VABs Program.

Patrick, Tue Nov 18 2014, 08:38AM

So how do I compile the windows version? is it 32 or 64 bits ?

Patrick, Tue Nov 18 2014, 08:38AM

So how do I compile the windows version? is it 32 or 64 bits ?

Re: Propeller Physics and VABs Program.

Patrick, Wed Nov 26 2014, 03:55AM

im wondering how to use these, or how to choose one.

im wondering how to use these, or how to choose one.

i may just use this one.

i cant get this to work on my computer : its got all kinds of instructions and possibilities scattered on his pages. i just need one java method that will work.

its got all kinds of instructions and possibilities scattered on his pages. i just need one java method that will work.

EDIT: i may have it working...

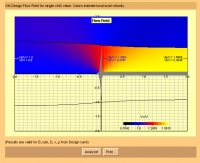

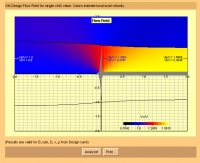

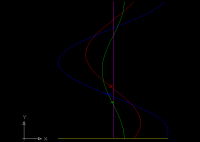

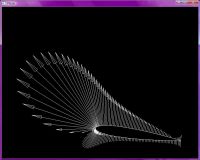

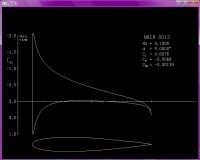

im not sure what the Vx and Vt numbers mean, but the graph and gradient are amazing.

Patrick, Wed Nov 26 2014, 03:55AM

im wondering how to use these, or how to choose one.

im wondering how to use these, or how to choose one. i may just use this one.

i cant get this to work on my computer :

its got all kinds of instructions and possibilities scattered on his pages. i just need one java method that will work.

its got all kinds of instructions and possibilities scattered on his pages. i just need one java method that will work. EDIT: i may have it working...

im not sure what the Vx and Vt numbers mean, but the graph and gradient are amazing.

Re: Propeller Physics and VABs Program.

Shrad, Wed Nov 26 2014, 08:15AM

glad you have sorted this out,

if you have to use a linux program you can always create a virtual machine and install a small linux distribution like debian

it's a project on its own but you can repurpose it as a scientific computation machine by installing python and scipy

along with some µC able to run python and communicate with a host PC in python, this could prove as useful as a labview setup

Shrad, Wed Nov 26 2014, 08:15AM

glad you have sorted this out,

if you have to use a linux program you can always create a virtual machine and install a small linux distribution like debian

it's a project on its own but you can repurpose it as a scientific computation machine by installing python and scipy

along with some µC able to run python and communicate with a host PC in python, this could prove as useful as a labview setup

Re: Propeller Physics and VABs Program.

Patrick, Wed Nov 26 2014, 10:26AM

im thinking of buying one of these 18 inch props then utting it in pieces. one piece form the tip and so on to the hub. while measuring the critical dimensions. however scaling with fluids always worries me. but going from a 18 to a 26 incher wouldnt be as sketchy as scaling from 10 to 26.

then utting it in pieces. one piece form the tip and so on to the hub. while measuring the critical dimensions. however scaling with fluids always worries me. but going from a 18 to a 26 incher wouldnt be as sketchy as scaling from 10 to 26.

its tempting to make a mold using my 3D printer, and lay up props out of CF. those 26 - 29 inch props are just to expensive to be putting into a tree.

Patrick, Wed Nov 26 2014, 10:26AM

im thinking of buying one of these 18 inch props

then utting it in pieces. one piece form the tip and so on to the hub. while measuring the critical dimensions. however scaling with fluids always worries me. but going from a 18 to a 26 incher wouldnt be as sketchy as scaling from 10 to 26.

then utting it in pieces. one piece form the tip and so on to the hub. while measuring the critical dimensions. however scaling with fluids always worries me. but going from a 18 to a 26 incher wouldnt be as sketchy as scaling from 10 to 26.its tempting to make a mold using my 3D printer, and lay up props out of CF. those 26 - 29 inch props are just to expensive to be putting into a tree.

Re: Propeller Physics and VABs Program.

Ash Small, Wed Nov 26 2014, 03:58PM

The other option would be to put a series of 'theoretical' dimensions into a 3D CAD package, and then produce a 'net'. From this you could program a 3D printer to produce a mold.

Ash Small, Wed Nov 26 2014, 03:58PM

The other option would be to put a series of 'theoretical' dimensions into a 3D CAD package, and then produce a 'net'. From this you could program a 3D printer to produce a mold.

Re: Propeller Physics and VABs Program.

Patrick, Wed Nov 26 2014, 09:24PM

Patrick, Wed Nov 26 2014, 09:24PM

Ash Small wrote ...

The other option would be to put a series of 'theoretical' dimensions into a 3D CAD package, and then produce a 'net'. From this you could program a 3D printer to produce a mold.

i dont get this... elaborate please.The other option would be to put a series of 'theoretical' dimensions into a 3D CAD package, and then produce a 'net'. From this you could program a 3D printer to produce a mold.

Re: Propeller Physics and VABs Program.

Shrad, Thu Nov 27 2014, 08:58AM

model your prop, split in two parts along the most practical axis, apply in negative to a filled box, and obtain a 3D printable mold which you can scale at will

Shrad, Thu Nov 27 2014, 08:58AM

model your prop, split in two parts along the most practical axis, apply in negative to a filled box, and obtain a 3D printable mold which you can scale at will

Re: Propeller Physics and VABs Program.

Uspring, Thu Nov 27 2014, 10:26AM

Uspring, Thu Nov 27 2014, 10:26AM

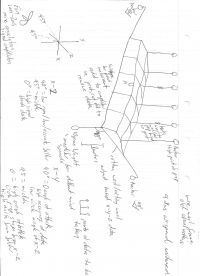

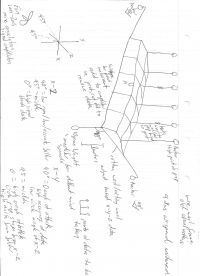

im not sure what the Vx and Vt numbers mean, but the graph and gradient are amazing.Vx is the horizontal air velocity. I wonder how accurate this simulation is, since it doesn't seem to include the air viscosity. A sudden jump in air velocity e.g. at the boundary of the slip streams tail to the surrounding air looks unlikely.

Re: Propeller Physics and VABs Program.

Ash Small, Thu Nov 27 2014, 04:29PM

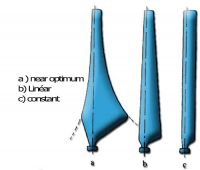

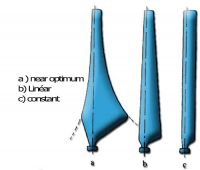

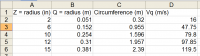

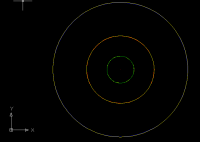

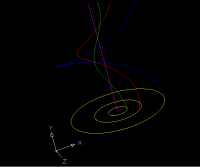

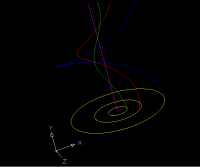

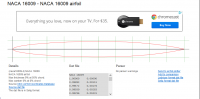

Well, theoretically, if we know the disc area and the RPM when hovering, we should be able to work out theoretical airspeed (of the accelerated column).

Theoretically, all the air wants to be at the same velocity (we can discuss this in detail later)

so, at various points from the nub to the tip we can calculated the required 'angle of attack' (I've not taken 'slip' into consideration yet)

once we have a series of angles at various distances from the hub we can plot the shape, and then adjust for NACA profile, or whatever.

Starting from the 'theoretical optimum' should give useful data to enable us to work out slip, and other losses by comparing thrust, RPM and power consumed.

Ash Small, Thu Nov 27 2014, 04:29PM

Patrick wrote ...

Ash Small wrote ...

The other option would be to put a series of 'theoretical' dimensions into a 3D CAD package, and then produce a 'net'. From this you could program a 3D printer to produce a mold.

i dont get this... elaborate please.The other option would be to put a series of 'theoretical' dimensions into a 3D CAD package, and then produce a 'net'. From this you could program a 3D printer to produce a mold.

Well, theoretically, if we know the disc area and the RPM when hovering, we should be able to work out theoretical airspeed (of the accelerated column).

Theoretically, all the air wants to be at the same velocity (we can discuss this in detail later)

so, at various points from the nub to the tip we can calculated the required 'angle of attack' (I've not taken 'slip' into consideration yet)

once we have a series of angles at various distances from the hub we can plot the shape, and then adjust for NACA profile, or whatever.

Starting from the 'theoretical optimum' should give useful data to enable us to work out slip, and other losses by comparing thrust, RPM and power consumed.

Re: Propeller Physics and VABs Program.

Patrick, Tue Dec 02 2014, 04:06AM

for a hovering prop, wouldnt the slip be 100%?

also, the outer radius produces most of the thrust. if this is true, and we go to the tip, then the tip captures the most air mass and accelerates it to the constant screw speed,

Or, does each x posistion of radius capture the same air mass, making up for velocity change with increase picth towrads the root?

EDIT: im really trying to figure out a 0 to x axis (radius) with a 0 to y axis (acceleration) function, im not sure if this is linear or not? i guess i would have to give dimensions for the prop...

Patrick, Tue Dec 02 2014, 04:06AM

for a hovering prop, wouldnt the slip be 100%?

also, the outer radius produces most of the thrust. if this is true, and we go to the tip, then the tip captures the most air mass and accelerates it to the constant screw speed,

Or, does each x posistion of radius capture the same air mass, making up for velocity change with increase picth towrads the root?

EDIT: im really trying to figure out a 0 to x axis (radius) with a 0 to y axis (acceleration) function, im not sure if this is linear or not? i guess i would have to give dimensions for the prop...

Re: Propeller Physics and VABs Program.

Ash Small, Tue Dec 02 2014, 03:23PM

No. The column of air is being accelerated with a force equal to 9.81 newtons per KG of 'copter mass.

(Actually, now you mention it, you may be correct, I'm used to marine props where lift itself isn't a factor, just the boat's velocity. but the same principle applies, I think, because a force is still being generated. (hovering requires a force of 9.81 newtons per kG of 'copter mass)

I think what I actually mean here is the propeller efficiency. I may need to consider this some more.

You still want the accelerated air velocity to be 'theoretically' constant throughout the column, which means that the angle of attack of the propeller has to be greater towards the centre as the propeller velocity is less than at the tip, which travels at a greater velocity. (In practice this isn't the case as losses close to the hub increase with increased angle of attack, but as this produces very little of the 'overall' thrust, we can reduce drag here without unduly affecting overall lift.)

Obviously, a prop with less pitch needs to rotate faster to generate the same force, but we already know you want a thin section rotating fast for efficiency, so you want a fairly shallow pitch (all the 'copter design stuff tells us this)

If the angle at the tip(x) is theta, then the angle at 1/2x has to be 2 x theta, the angle at 3/4x needs to be 1.5 x theta, and the angle at 1/4x needs to be 4 x theta. In order to keep drag low, we need high RPM, so that 4 times theta is still small. (this assumes a constant blede width)

The ratio of radius to circumferance is constant (2 x pi x r, or pi x d),

Ash Small, Tue Dec 02 2014, 03:23PM

Patrick wrote ...

for a hovering prop, wouldnt the slip be 100%?

for a hovering prop, wouldnt the slip be 100%?

No. The column of air is being accelerated with a force equal to 9.81 newtons per KG of 'copter mass.

(Actually, now you mention it, you may be correct, I'm used to marine props where lift itself isn't a factor, just the boat's velocity. but the same principle applies, I think, because a force is still being generated. (hovering requires a force of 9.81 newtons per kG of 'copter mass)

I think what I actually mean here is the propeller efficiency. I may need to consider this some more.

Patrick wrote ...

also, the outer radius produces most of the thrust. if this is true, and we go to the tip, then the tip captures the most air mass and accelerates it to the constant screw speed,

Or, does each x posistion of radius capture the same air mass, making up for velocity change with increase picth towrads the root?

EDIT: im really trying to figure out a 0 to x axis (radius) with a 0 to y axis (acceleration) function, im not sure if this is linear or not? i guess i would have to give dimensions for the prop...

also, the outer radius produces most of the thrust. if this is true, and we go to the tip, then the tip captures the most air mass and accelerates it to the constant screw speed,

Or, does each x posistion of radius capture the same air mass, making up for velocity change with increase picth towrads the root?

EDIT: im really trying to figure out a 0 to x axis (radius) with a 0 to y axis (acceleration) function, im not sure if this is linear or not? i guess i would have to give dimensions for the prop...

You still want the accelerated air velocity to be 'theoretically' constant throughout the column, which means that the angle of attack of the propeller has to be greater towards the centre as the propeller velocity is less than at the tip, which travels at a greater velocity. (In practice this isn't the case as losses close to the hub increase with increased angle of attack, but as this produces very little of the 'overall' thrust, we can reduce drag here without unduly affecting overall lift.)

Obviously, a prop with less pitch needs to rotate faster to generate the same force, but we already know you want a thin section rotating fast for efficiency, so you want a fairly shallow pitch (all the 'copter design stuff tells us this)

If the angle at the tip(x) is theta, then the angle at 1/2x has to be 2 x theta, the angle at 3/4x needs to be 1.5 x theta, and the angle at 1/4x needs to be 4 x theta. In order to keep drag low, we need high RPM, so that 4 times theta is still small. (this assumes a constant blede width)

The ratio of radius to circumferance is constant (2 x pi x r, or pi x d),

Re: Propeller Physics and VABs Program.

Patrick, Tue Dec 02 2014, 11:26PM

Patrick, Tue Dec 02 2014, 11:26PM

Ash Small wrote ...

You still want the accelerated air velocity to be 'theoretically' constant throughout the column, which means that the angle of attack of the propeller has to be greater towards the centre as the propeller velocity is less than at the tip, which travels at a greater velocity. (In practice this isn't the case as losses close to the hub increase with increased angle of attack, but as this produces very little of the 'overall' thrust, we can reduce drag here without unduly affecting overall lift.)

Obviously, a prop with less pitch needs to rotate faster to generate the same force, but we already know you want a thin section rotating fast for efficiency, so you want a fairly shallow pitch (all the 'copter design stuff tells us this)

If the angle at the tip(x) is theta, then the angle at 1/2x has to be 2 x theta, the angle at 3/4x needs to be 1.5 x theta, and the angle at 1/4x needs to be 4 x theta. In order to keep drag low, we need high RPM, so that 4 times theta is still small. (this assumes a constant blede width)

The ratio of radius to circumferance is constant (2 x pi x r, or pi x d),

this is what I needed to know, sometimes I get it, then lose it all in a blur.You still want the accelerated air velocity to be 'theoretically' constant throughout the column, which means that the angle of attack of the propeller has to be greater towards the centre as the propeller velocity is less than at the tip, which travels at a greater velocity. (In practice this isn't the case as losses close to the hub increase with increased angle of attack, but as this produces very little of the 'overall' thrust, we can reduce drag here without unduly affecting overall lift.)

Obviously, a prop with less pitch needs to rotate faster to generate the same force, but we already know you want a thin section rotating fast for efficiency, so you want a fairly shallow pitch (all the 'copter design stuff tells us this)

If the angle at the tip(x) is theta, then the angle at 1/2x has to be 2 x theta, the angle at 3/4x needs to be 1.5 x theta, and the angle at 1/4x needs to be 4 x theta. In order to keep drag low, we need high RPM, so that 4 times theta is still small. (this assumes a constant blede width)

The ratio of radius to circumferance is constant (2 x pi x r, or pi x d),

Re: Propeller Physics and VABs Program.

Ash Small, Wed Dec 03 2014, 01:16AM

I have read that the limiting factor should be centripetal (or centrifugal, I can't remember the difference offhand, might be the drink ) force acting on the prop, although drag is also a factor, as is the 'bending moment' in the blade itself, but the limiting factor in most 'copter designs is centripetal (or centrifugal) forces.

) force acting on the prop, although drag is also a factor, as is the 'bending moment' in the blade itself, but the limiting factor in most 'copter designs is centripetal (or centrifugal) forces.

Also, you want a a thin, lightweight section, and high RPM.

Hope this helps.

EDIT: Centrifugal, I think or is it both, as they act against each other?

or is it both, as they act against each other?

Ash Small, Wed Dec 03 2014, 01:16AM

I have read that the limiting factor should be centripetal (or centrifugal, I can't remember the difference offhand, might be the drink

) force acting on the prop, although drag is also a factor, as is the 'bending moment' in the blade itself, but the limiting factor in most 'copter designs is centripetal (or centrifugal) forces.

) force acting on the prop, although drag is also a factor, as is the 'bending moment' in the blade itself, but the limiting factor in most 'copter designs is centripetal (or centrifugal) forces.Also, you want a a thin, lightweight section, and high RPM.

Hope this helps.

EDIT: Centrifugal, I think

or is it both, as they act against each other?

or is it both, as they act against each other?Re: Propeller Physics and VABs Program.

Shrad, Wed Dec 03 2014, 07:59AM

wouldn't it be the component of both vectors and the acceleration?

Shrad, Wed Dec 03 2014, 07:59AM

wouldn't it be the component of both vectors and the acceleration?

Re: Propeller Physics and VABs Program.

Ash Small, Wed Dec 03 2014, 12:00PM

Can you be more specific, please. Are you querying the centripetal/centrifugal bit, or the x axis, y axis bit, or the 'slip' bit?

I don't want to reply to the wrong question

Ash Small, Wed Dec 03 2014, 12:00PM

Shrad wrote ...

wouldn't it be the component of both vectors and the acceleration?

wouldn't it be the component of both vectors and the acceleration?

Can you be more specific, please. Are you querying the centripetal/centrifugal bit, or the x axis, y axis bit, or the 'slip' bit?

I don't want to reply to the wrong question

Re: Propeller Physics and VABs Program.

Shrad, Wed Dec 03 2014, 01:11PM

I was mentioning the centripetal/centrifugal vectors which are of opposite direction, but combines with the acceleration force vector

as I see it, at constant speed acceleration is null, and centripetal/centrifugal forces being of opposite direction and at equilibrium, a propeller designed for those parameters will hold without problem

now accelerate or decelerate, and you combine a third force vector which will induce stress in another direction

I was simply thinking about the system being incomplete without the acceleration force vector, and was actually wondering if I was right or not ;)

Shrad, Wed Dec 03 2014, 01:11PM

I was mentioning the centripetal/centrifugal vectors which are of opposite direction, but combines with the acceleration force vector

as I see it, at constant speed acceleration is null, and centripetal/centrifugal forces being of opposite direction and at equilibrium, a propeller designed for those parameters will hold without problem

now accelerate or decelerate, and you combine a third force vector which will induce stress in another direction

I was simply thinking about the system being incomplete without the acceleration force vector, and was actually wondering if I was right or not ;)

Re: Propeller Physics and VABs Program.

Ash Small, Wed Dec 03 2014, 02:38PM

Yes, you are correct, Shrad, and that does become a factor to be taken into consideration when working out the peak forces on the blades, but for now, we're just considering the 'hovering' scenario, as the maths is much simpler.

The point I was making, I think, is that you want to keep the mass of the blades low, as this minimises the centripetal/centrifugal forces.

I suspect that we'll end up with pure CF blades, with no foam, etc. as carbon has huge tensile strength to combat the centripetal/centrifugal forces and will therefore allow the thinnest section, etc. and also facilitate high RPM.

Ash Small, Wed Dec 03 2014, 02:38PM

Shrad wrote ...

I was mentioning the centripetal/centrifugal vectors which are of opposite direction, but combines with the acceleration force vector

as I see it, at constant speed acceleration is null, and centripetal/centrifugal forces being of opposite direction and at equilibrium, a propeller designed for those parameters will hold without problem

now accelerate or decelerate, and you combine a third force vector which will induce stress in another direction

I was simply thinking about the system being incomplete without the acceleration force vector, and was actually wondering if I was right or not ;)

I was mentioning the centripetal/centrifugal vectors which are of opposite direction, but combines with the acceleration force vector

as I see it, at constant speed acceleration is null, and centripetal/centrifugal forces being of opposite direction and at equilibrium, a propeller designed for those parameters will hold without problem

now accelerate or decelerate, and you combine a third force vector which will induce stress in another direction

I was simply thinking about the system being incomplete without the acceleration force vector, and was actually wondering if I was right or not ;)

Yes, you are correct, Shrad, and that does become a factor to be taken into consideration when working out the peak forces on the blades, but for now, we're just considering the 'hovering' scenario, as the maths is much simpler.

The point I was making, I think, is that you want to keep the mass of the blades low, as this minimises the centripetal/centrifugal forces.

I suspect that we'll end up with pure CF blades, with no foam, etc. as carbon has huge tensile strength to combat the centripetal/centrifugal forces and will therefore allow the thinnest section, etc. and also facilitate high RPM.

Re: Propeller Physics and VABs Program.

Shrad, Wed Dec 03 2014, 03:20PM

hovering in a controlled environment?

in my point of view hovering is the result of constant acceleration/deceleration in reaction to the environment (wind, turbulence, etc...)

if you account that it's part of the deal, then I think you still have to account these stresses even if they are reduced, as different materials will have different behaviors facing such small and perpetual variations of forces (flexing, vibrating, etc...)

maybe error calculation can help take that into account? I recall from my courses back in the past that it's not that hard to calculate

Shrad, Wed Dec 03 2014, 03:20PM

hovering in a controlled environment?

in my point of view hovering is the result of constant acceleration/deceleration in reaction to the environment (wind, turbulence, etc...)

if you account that it's part of the deal, then I think you still have to account these stresses even if they are reduced, as different materials will have different behaviors facing such small and perpetual variations of forces (flexing, vibrating, etc...)

maybe error calculation can help take that into account? I recall from my courses back in the past that it's not that hard to calculate

Re: Propeller Physics and VABs Program.

Ash Small, Wed Dec 03 2014, 07:18PM

That's correct, all that 'bending moments in a beam' stuff is pretty straightforward, but the maths I provided above only applies to hovering, and is for the 'ideal' case. Obviously the blade has to withstand greater forces than when hovering, as, RPM will be higher when ascending, manouvering, etc. The 'hovering in ideal conditions' scenario gives us a good starting point, though.

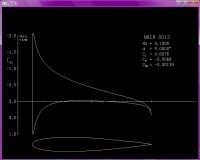

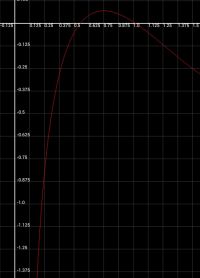

Manouverability will also require lightweight blades (manouverability will suffer as disc area increases, but as we've already seen from the maths above and from the graph that BigBad posted in the 'other' thread, large disc area is essential for efficiency), in order to accelerate/decelerate the rotors quickly they will have to be as lightweight as possible.

Drag is the other factor that requires a thin blade section.

High RPM does facilitate a small 'angle of attack', but does increase the centripetal/centrifugal forces in the blade. From what I've read about full size 'copters, it's these forces that ultimately determine maximum RPM, as strength is proportional to mass. As the mass of the blade increases, the strength increases, but so do the centripetal/centrifugal forces within it, due to the incresed mass.

Ash Small, Wed Dec 03 2014, 07:18PM

Shrad wrote ...

hovering in a controlled environment?

in my point of view hovering is the result of constant acceleration/deceleration in reaction to the environment (wind, turbulence, etc...)

if you account that it's part of the deal, then I think you still have to account these stresses even if they are reduced, as different materials will have different behaviors facing such small and perpetual variations of forces (flexing, vibrating, etc...)

maybe error calculation can help take that into account? I recall from my courses back in the past that it's not that hard to calculate

hovering in a controlled environment?

in my point of view hovering is the result of constant acceleration/deceleration in reaction to the environment (wind, turbulence, etc...)

if you account that it's part of the deal, then I think you still have to account these stresses even if they are reduced, as different materials will have different behaviors facing such small and perpetual variations of forces (flexing, vibrating, etc...)

maybe error calculation can help take that into account? I recall from my courses back in the past that it's not that hard to calculate

That's correct, all that 'bending moments in a beam' stuff is pretty straightforward, but the maths I provided above only applies to hovering, and is for the 'ideal' case. Obviously the blade has to withstand greater forces than when hovering, as, RPM will be higher when ascending, manouvering, etc. The 'hovering in ideal conditions' scenario gives us a good starting point, though.

Manouverability will also require lightweight blades (manouverability will suffer as disc area increases, but as we've already seen from the maths above and from the graph that BigBad posted in the 'other' thread, large disc area is essential for efficiency), in order to accelerate/decelerate the rotors quickly they will have to be as lightweight as possible.

Drag is the other factor that requires a thin blade section.

High RPM does facilitate a small 'angle of attack', but does increase the centripetal/centrifugal forces in the blade. From what I've read about full size 'copters, it's these forces that ultimately determine maximum RPM, as strength is proportional to mass. As the mass of the blade increases, the strength increases, but so do the centripetal/centrifugal forces within it, due to the incresed mass.

Re: Propeller Physics and VABs Program.

Shrad, Wed Dec 03 2014, 07:34PM

how about a really lightweight body, even with foamy material, which would then be dipped in a carbon fiber and resin mix in a very light mix, many times like a lacker?

it would ensure minimal physical weight, maximum surface resistance, and the outer layer would maintain the cohesion of the innards...

Shrad, Wed Dec 03 2014, 07:34PM

how about a really lightweight body, even with foamy material, which would then be dipped in a carbon fiber and resin mix in a very light mix, many times like a lacker?

it would ensure minimal physical weight, maximum surface resistance, and the outer layer would maintain the cohesion of the innards...

Re: Propeller Physics and VABs Program.

Patrick, Wed Dec 03 2014, 07:52PM

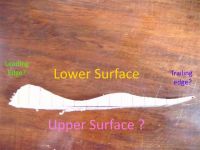

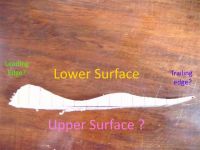

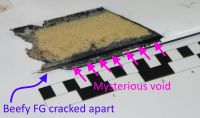

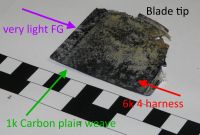

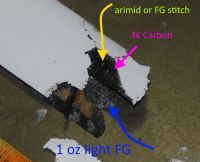

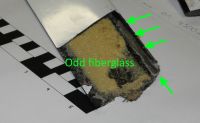

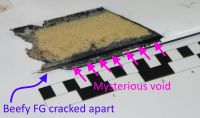

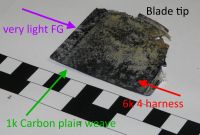

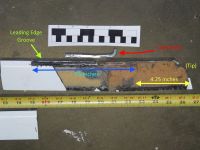

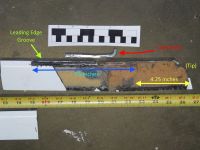

with my 3D printer, printing nearly hollow structures, with minimal shear web, ive blown out my tail at 15+ meters above ground as Andrew predicted

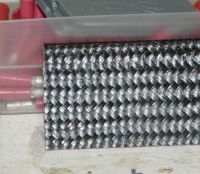

These are about 18 inch props, note the root area. its also steep there. (about 80 to 120 us$, for two)

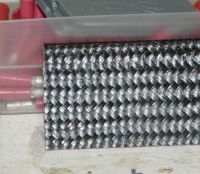

these are 26 inch props, they go all the way up to 29 inch and from 5 to 8 pitch. (about 300 us$ for two)

Patrick, Wed Dec 03 2014, 07:52PM

Shrad wrote ...

how about a really lightweight body, even with foamy material, which would then be dipped in a carbon fiber and resin mix in a very light mix, many times like a lacker?

it would ensure minimal physical weight, maximum surface resistance, and the outer layer would maintain the cohesion of the innards...

The problem is, (as ive layed up many fiberglass, CF and aramid fiber structures), they are already so thin at the mid and outer radius theres' no space for shear web or lightening pockets / foam.how about a really lightweight body, even with foamy material, which would then be dipped in a carbon fiber and resin mix in a very light mix, many times like a lacker?

it would ensure minimal physical weight, maximum surface resistance, and the outer layer would maintain the cohesion of the innards...

with my 3D printer, printing nearly hollow structures, with minimal shear web, ive blown out my tail at 15+ meters above ground as Andrew predicted

These are about 18 inch props, note the root area. its also steep there. (about 80 to 120 us$, for two)

these are 26 inch props, they go all the way up to 29 inch and from 5 to 8 pitch. (about 300 us$ for two)

Re: Propeller Physics and VABs Program.

Shrad, Wed Dec 03 2014, 09:18PM

I guess any handmade one would still be far away from a commercial unit anyway

Shrad, Wed Dec 03 2014, 09:18PM

I guess any handmade one would still be far away from a commercial unit anyway

Re: Propeller Physics and VABs Program.

Ash Small, Wed Dec 03 2014, 10:48PM

Blades specifically designed for the application should out perform anything that is commercially available.

Solid CF gives the the highest strength and lowest drag (and highest RPM, so smallest pitch, thus reducing drag even more)

EDIT: Those blades are designed for high disc loading. They resemble some further down the 'efficiency scale' in the graph in the 'other thread'.

Ash Small, Wed Dec 03 2014, 10:48PM

Shrad wrote ...

I guess any handmade one would still be far away from a commercial unit anyway

I guess any handmade one would still be far away from a commercial unit anyway

Blades specifically designed for the application should out perform anything that is commercially available.

Solid CF gives the the highest strength and lowest drag (and highest RPM, so smallest pitch, thus reducing drag even more)

EDIT: Those blades are designed for high disc loading. They resemble some further down the 'efficiency scale' in the graph in the 'other thread'.

Re: Propeller Physics and VABs Program.

Patrick, Thu Dec 04 2014, 03:57AM

would a symmetric heli blade be better? should we make improvements in that direction? maybe add undercamber to the root side.

Patrick, Thu Dec 04 2014, 03:57AM

Ash Small wrote ...

EDIT: Those blades are designed for high disc loading. They resemble some further down the 'efficiency scale' in the graph in the 'other thread'.

EDIT: Those blades are designed for high disc loading. They resemble some further down the 'efficiency scale' in the graph in the 'other thread'.

would a symmetric heli blade be better? should we make improvements in that direction? maybe add undercamber to the root side.

Re: Propeller Physics and VABs Program.

Ash Small, Thu Dec 04 2014, 04:21PM

Well, the props you posted above certainly look more like the rotors on a V-22 Osprey than conventional 'copter blades.

The V-22 does have high disc loading (even higher than originally planned, as rotor diameter was reduced from 43 feet to 38 feet in order to facilitate below deck storage on carriers).

The kind of prop used on conventional aircraft can be wider with plenty of camber/angle of attack, as it's designed to travel forwards at hundreds of miles per hour, a completely different scenario to hovering, where that design will produce loads of drag.

If we want low disc loading, I think the best approach would be to start with total estimated mass of the 'copter, and number of rotors, then decide on the disc loading we're after, and then see what the disc area of each prop comes out at.

The disc loading on the V-22 is around 100kg/m^2, and power to mass ratio is 427W/kg, compared to the disc loading of Atlas, the human powered helicopter, which is less than 0.1kg/m^2.

It may be worth working out the disc loadind on your existing tri-copter first,

The point I'm making, I suppose, is that the blade design is also dependant on disc loading. It may also be worth looking at the disc loading that the rotors posted above are designed for.

Conventional copters get down to under 20kg/M^2, we should be looking to do better than this, if we're after greater efficiency and longer flight times. (I think we should be aiming for less than 5kg/M^2, maybe even less )

)

EDIT: The Robinson R-22 has a disc loading of 14kg/m^2.

You can see the cross section etc in the photo. Admittedly, this is designed for use with a swashplate, so we may want to include some twist and maybe taper it a bit towards the tip

Ash Small, Thu Dec 04 2014, 04:21PM

Well, the props you posted above certainly look more like the rotors on a V-22 Osprey than conventional 'copter blades.

The V-22 does have high disc loading (even higher than originally planned, as rotor diameter was reduced from 43 feet to 38 feet in order to facilitate below deck storage on carriers).

The kind of prop used on conventional aircraft can be wider with plenty of camber/angle of attack, as it's designed to travel forwards at hundreds of miles per hour, a completely different scenario to hovering, where that design will produce loads of drag.

If we want low disc loading, I think the best approach would be to start with total estimated mass of the 'copter, and number of rotors, then decide on the disc loading we're after, and then see what the disc area of each prop comes out at.

The disc loading on the V-22 is around 100kg/m^2, and power to mass ratio is 427W/kg, compared to the disc loading of Atlas, the human powered helicopter, which is less than 0.1kg/m^2.

It may be worth working out the disc loadind on your existing tri-copter first,

The point I'm making, I suppose, is that the blade design is also dependant on disc loading. It may also be worth looking at the disc loading that the rotors posted above are designed for.

Conventional copters get down to under 20kg/M^2, we should be looking to do better than this, if we're after greater efficiency and longer flight times. (I think we should be aiming for less than 5kg/M^2, maybe even less

)

)EDIT: The Robinson R-22 has a disc loading of 14kg/m^2.

You can see the cross section etc in the photo. Admittedly, this is designed for use with a swashplate, so we may want to include some twist and maybe taper it a bit towards the tip

Re: Propeller Physics and VABs Program.

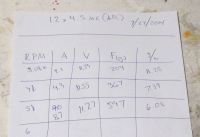

Patrick, Thu Dec 04 2014, 10:31PM

ok so lets start this way.

1,430 g AUW.

3 rotors, all 12in diameter, 3.8 pitch, called a "slow-fly" prop.

while moderately maneuvering, a drew 31 amps at about 10.7 volts. from A 3 Ccell lipo (12.6 fully charged, 9.9v discharged)

im also having a battery problem, but we'll deal with that later.

Patrick, Thu Dec 04 2014, 10:31PM

ok so lets start this way.

1,430 g AUW.

3 rotors, all 12in diameter, 3.8 pitch, called a "slow-fly" prop.

while moderately maneuvering, a drew 31 amps at about 10.7 volts. from A 3 Ccell lipo (12.6 fully charged, 9.9v discharged)

im also having a battery problem, but we'll deal with that later.

Re: Propeller Physics and VABs Program.

Ash Small, Thu Dec 04 2014, 10:57PM

Thanks for posting the figures. I've had a drink or three, so won't look at it tonight, and I'm pretty busy tomorrow, so may not get round to looking at it until saturday morning. The maths isn't difficult, though, it's all posted above, if you want to look into it before then

Ash Small, Thu Dec 04 2014, 10:57PM

Patrick wrote ...

ok so lets start this way.

1,430 g AUW.

3 rotors, all 12in diameter, 3.8 pitch, called a "slow-fly" prop.

while moderately maneuvering, a drew 31 amps at about 10.7 volts. from A 3 Ccell lipo (12.6 fully charged, 9.9v discharged)

im also having a battery problem, but we'll deal with that later.

ok so lets start this way.

1,430 g AUW.

3 rotors, all 12in diameter, 3.8 pitch, called a "slow-fly" prop.

while moderately maneuvering, a drew 31 amps at about 10.7 volts. from A 3 Ccell lipo (12.6 fully charged, 9.9v discharged)

im also having a battery problem, but we'll deal with that later.

Thanks for posting the figures. I've had a drink or three, so won't look at it tonight, and I'm pretty busy tomorrow, so may not get round to looking at it until saturday morning. The maths isn't difficult, though, it's all posted above, if you want to look into it before then

Re: Propeller Physics and VABs Program.

Ash Small, Fri Dec 05 2014, 07:04AM

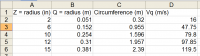

I was up early this morning and looked at the figures over a coffee. It only took a couple of minutes to work out the following:

331.7 watts

0.86 m^2

1.66kg/m^2 (disc loading)

232 W/kg

(Maybe someone can check my maths. Maths isn't my strongpoint, especially first thing in the morning)

The disc loading looks ok, but any improvement will still give increased efficiency. I've done a quick calculation on theoretical power required, if there are no losses, and came up with a figure of 32W/kg, so, from the above figures, 200W/kg is being wasted in losses. While we're never going to get close to the 'theoretical' efficiency, and the figures you supplied aren't for hovering in ideal conditions, it does give us a starting point. I think if we can get more data from your test rig, we should be able to get some realistic comparisons of different blade profiles, etc., and extrapolate from there. (It's still early here, I'll need to check the figures etc later. Do we have RPM figures as well? I think you posted some in the other thread when you were using the test rig. Also any data from the manufacturers would be useful regarding RPM, etc. I suspect that the props you used are designed for higher disc loading, and that significant improvements can be made with different profile blades.)

Ash Small, Fri Dec 05 2014, 07:04AM

I was up early this morning and looked at the figures over a coffee. It only took a couple of minutes to work out the following:

331.7 watts

0.86 m^2

1.66kg/m^2 (disc loading)

232 W/kg

(Maybe someone can check my maths. Maths isn't my strongpoint, especially first thing in the morning)

The disc loading looks ok, but any improvement will still give increased efficiency. I've done a quick calculation on theoretical power required, if there are no losses, and came up with a figure of 32W/kg, so, from the above figures, 200W/kg is being wasted in losses. While we're never going to get close to the 'theoretical' efficiency, and the figures you supplied aren't for hovering in ideal conditions, it does give us a starting point. I think if we can get more data from your test rig, we should be able to get some realistic comparisons of different blade profiles, etc., and extrapolate from there. (It's still early here, I'll need to check the figures etc later. Do we have RPM figures as well? I think you posted some in the other thread when you were using the test rig. Also any data from the manufacturers would be useful regarding RPM, etc. I suspect that the props you used are designed for higher disc loading, and that significant improvements can be made with different profile blades.)

Re: Propeller Physics and VABs Program.

Patrick, Fri Dec 05 2014, 08:22AM

Im thinking that adding a third blade. Even with tip loss, the captured air mass, accelerated less may make up for it.

these current props are 12x3.8

there are 13x4.7, and 14x4.7 props too. I should probly dyno these too.

they did have lists of data, all categorized at rpm intervals, but theyve take it down from their site. ill get them as soon as i can.

Patrick, Fri Dec 05 2014, 08:22AM

Im thinking that adding a third blade. Even with tip loss, the captured air mass, accelerated less may make up for it.

these current props are 12x3.8

there are 13x4.7, and 14x4.7 props too. I should probly dyno these too.

they did have lists of data, all categorized at rpm intervals, but theyve take it down from their site. ill get them as soon as i can.

Re: Propeller Physics and VABs Program.

Ash Small, Fri Dec 05 2014, 09:33PM

Two blades spinning faster is the same as three blades, assuming you spread the load evenly. You could just be overcomplicating things. 'Copters with more than two blades have very high disc loading, like the V-22 Osprey.

I made a mistake in the maths I posted this morning, I added the disc areas first, instead of dividing the mass by 3. I'll correct it in the morning.

Ash Small, Fri Dec 05 2014, 09:33PM

Patrick wrote ...

Im thinking that adding a third blade. Even with tip loss, the captured air mass, accelerated less may make up for it.

these current props are 12x3.8

there are 13x4.7, and 14x4.7 props too. I should probly dyno these too.

they did have lists of data, all categorized at rpm intervals, but theyve take it down from their site. ill get them as soon as i can.

Im thinking that adding a third blade. Even with tip loss, the captured air mass, accelerated less may make up for it.

these current props are 12x3.8

there are 13x4.7, and 14x4.7 props too. I should probly dyno these too.

they did have lists of data, all categorized at rpm intervals, but theyve take it down from their site. ill get them as soon as i can.

Two blades spinning faster is the same as three blades, assuming you spread the load evenly. You could just be overcomplicating things. 'Copters with more than two blades have very high disc loading, like the V-22 Osprey.

I made a mistake in the maths I posted this morning, I added the disc areas first, instead of dividing the mass by 3. I'll correct it in the morning.

Re: Propeller Physics and VABs Program.

Patrick, Fri Dec 05 2014, 10:03PM

but dont we want the same thrust from lower tip speed (higher mass)? or does having 3 not change the the mass near the tip exiting near the tip?

Patrick, Fri Dec 05 2014, 10:03PM

Ash Small wrote ...

Two blades spinning faster is the same as three blades, assuming you spread the load evenly.

Two blades spinning faster is the same as three blades, assuming you spread the load evenly.

but dont we want the same thrust from lower tip speed (higher mass)? or does having 3 not change the the mass near the tip exiting near the tip?

Re: Propeller Physics and VABs Program.

Ash Small, Fri Dec 05 2014, 10:44PM

Well, it affects the total mass, if nothing else. Then there's balancing the thing...

Ash Small, Fri Dec 05 2014, 10:44PM

Patrick wrote ...

but dont we want the same thrust from lower tip speed (higher mass)? or does having 3 not change the the mass near the tip exiting near the tip?

Ash Small wrote ...

Two blades spinning faster is the same as three blades, assuming you spread the load evenly.

Two blades spinning faster is the same as three blades, assuming you spread the load evenly.

but dont we want the same thrust from lower tip speed (higher mass)? or does having 3 not change the the mass near the tip exiting near the tip?

Well, it affects the total mass, if nothing else. Then there's balancing the thing...

Re: Propeller Physics and VABs Program.

Shrad, Sat Dec 06 2014, 11:21AM

what about curvy blades to add contact surface with the air? that's another mean of increasing moved air mass, no?

Shrad, Sat Dec 06 2014, 11:21AM

what about curvy blades to add contact surface with the air? that's another mean of increasing moved air mass, no?

Re: Propeller Physics and VABs Program.

Ash Small, Sat Dec 06 2014, 01:20PM

Curvy blades, as you call them, increase drag, if they have too much 'curve'. You'll get eddy currents behind the blade. With marine props, you can get a state where you get cavities of vacuum behind the blades. This situation is called 'cavitation' and is generally detrimental. It can also cause pitting of the prop, which can be very detrimental.

So called 'super-cavitationg' props used for offshore powerboat racing exploit this phenomenon, with the back of the prop running in air or vacuum to reduce drag on the back of the prop, but these are still less than 50% efficient, compared to a well designed ship propeller, which can be over 90% efficient.

This is something we need to consider here, in order to get an efficient design, the blades need to disturb the air as little as possible in order to reduce drag. The air should flow over the blade, without turbulence being created in the 'wake' of the blade. Any turbulence here represents losses.

At least, that's my understanding

Ash Small, Sat Dec 06 2014, 01:20PM

Shrad wrote ...

what about curvy blades to add contact surface with the air? that's another mean of increasing moved air mass, no?

what about curvy blades to add contact surface with the air? that's another mean of increasing moved air mass, no?

Curvy blades, as you call them, increase drag, if they have too much 'curve'. You'll get eddy currents behind the blade. With marine props, you can get a state where you get cavities of vacuum behind the blades. This situation is called 'cavitation' and is generally detrimental. It can also cause pitting of the prop, which can be very detrimental.

So called 'super-cavitationg' props used for offshore powerboat racing exploit this phenomenon, with the back of the prop running in air or vacuum to reduce drag on the back of the prop, but these are still less than 50% efficient, compared to a well designed ship propeller, which can be over 90% efficient.

This is something we need to consider here, in order to get an efficient design, the blades need to disturb the air as little as possible in order to reduce drag. The air should flow over the blade, without turbulence being created in the 'wake' of the blade. Any turbulence here represents losses.

At least, that's my understanding

Re: Propeller Physics and VABs Program.

Andy, Sat Dec 06 2014, 07:37PM

Hi Patrick, just being doing something and have a couple of ideas.

Have a prop at the top with deep pitch slow rpm, then one,two,three below with faster and faster rpm but less pitch.

have a by-pass vent for the top prop that is pressure controlled, normal closed but as wind movement etc happens it gets forced open.

Have two gearboxes 2 motors and four prop would probable be effeinct.

sometimes birds fly in a "u" shape to go in level flight, maybe use fly-by-wire to program effeinct movements for x-z plane, but use the y plane differently.

Don't design the UAV for hovering but more effeinct for movement.

A couple of cents :)

Andy, Sat Dec 06 2014, 07:37PM

Hi Patrick, just being doing something and have a couple of ideas.

Have a prop at the top with deep pitch slow rpm, then one,two,three below with faster and faster rpm but less pitch.

have a by-pass vent for the top prop that is pressure controlled, normal closed but as wind movement etc happens it gets forced open.

Have two gearboxes 2 motors and four prop would probable be effeinct.

sometimes birds fly in a "u" shape to go in level flight, maybe use fly-by-wire to program effeinct movements for x-z plane, but use the y plane differently.

Don't design the UAV for hovering but more effeinct for movement.

A couple of cents :)

Re: Propeller Physics and VABs Program.

Patrick, Mon Dec 08 2014, 02:29AM

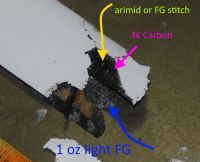

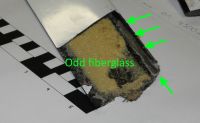

one guy is using pipe, then cutting it off to make his own props.

composite parts.

composite parts.

pipe cut props.

pipe cut props.

odd one.

odd one.

Someone says just about any prop can be 70% or so efficient. Since were approaching 100% as an asymptote, eventually theres no advantage in going all out for that last 1%. (im tipsy so this was probly said already) So lets find out what the efficiency of the APC 10, 11, 12 and 13 MR's are, then we'll see how much margin is at stake.

APC has all these numbers, just waiting for re-posting them.

Patrick, Mon Dec 08 2014, 02:29AM

one guy is using pipe, then cutting it off to make his own props.

composite parts.

composite parts. pipe cut props.

pipe cut props. odd one.

odd one.Someone says just about any prop can be 70% or so efficient. Since were approaching 100% as an asymptote, eventually theres no advantage in going all out for that last 1%. (im tipsy so this was probly said already) So lets find out what the efficiency of the APC 10, 11, 12 and 13 MR's are, then we'll see how much margin is at stake.

APC has all these numbers, just waiting for re-posting them.

Re: Propeller Physics and VABs Program.

Ash Small, Mon Dec 08 2014, 12:36PM

Well, I don't know how the bloke in the first link is getting 60PSI of vacuum. 15PSI is the limit of all conventional vacuum systems

I think we discussed laying up on a cylindrical form before. You still need to consider leading and trailing edges, etc.

I'm still of the opinion that all of those commercially available props are designed for much higher disc loadings than we want, so will be inefficient at low disc loadings.

I think we need to consider RPM next, once we know that we should be able to do some initial calculations on blade profile, angle of attack, etc.

Ash Small, Mon Dec 08 2014, 12:36PM

Patrick wrote ...

one guy is using pipe, then cutting it off to make his own props.

composite parts.

composite parts.

pipe cut props.

pipe cut props.

odd one.

odd one.

Someone says just about any prop can be 70% or so efficient. Since were approaching 100% as an asymptote, eventually theres no advantage in going all out for that last 1%. (im tipsy so this was probly said already) So lets find out what the efficiency of the APC 10, 11, 12 and 13 MR's are, then we'll see how much margin is at stake.

APC has all these numbers, just waiting for re-posting them.

one guy is using pipe, then cutting it off to make his own props.

composite parts.

composite parts. pipe cut props.

pipe cut props. odd one.

odd one.Someone says just about any prop can be 70% or so efficient. Since were approaching 100% as an asymptote, eventually theres no advantage in going all out for that last 1%. (im tipsy so this was probly said already) So lets find out what the efficiency of the APC 10, 11, 12 and 13 MR's are, then we'll see how much margin is at stake.

APC has all these numbers, just waiting for re-posting them.

Well, I don't know how the bloke in the first link is getting 60PSI of vacuum. 15PSI is the limit of all conventional vacuum systems

I think we discussed laying up on a cylindrical form before. You still need to consider leading and trailing edges, etc.

I'm still of the opinion that all of those commercially available props are designed for much higher disc loadings than we want, so will be inefficient at low disc loadings.

I think we need to consider RPM next, once we know that we should be able to do some initial calculations on blade profile, angle of attack, etc.

Re: Propeller Physics and VABs Program.

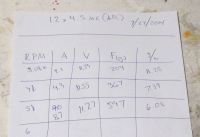

Patrick, Mon Dec 08 2014, 06:19PM

That "Test Pilot Mafia" guy... thats me .

.

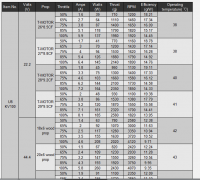

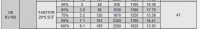

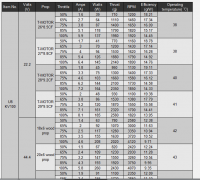

Various configurations. It seems they dont want CF props to see more than 22.2 V, the wood props are rated to 44.4 V at near 4,000RPM.

the best effciency from 19.4 g/W to 15.6 g/W.

this varies across 1,100 to 1,550 RPM.

From 50 to 75 % throttle, (this is where hover and simple maneuvering is done.)

The best efficiency i measured on my thrust stand was 8.7 grams. 19.4 is 2.2 times better per unit of power.

Pics of the U8. its a pancake motor, just not sure why these physical shapes are chosen, still studying this too.

in any case, as youve said low RPM at large diameter yields high effciency. the above props, ive been told "explosively liberate" themselves at 6,000RPM or so. (i dont know if they're thin at the hub or what)

Patrick, Mon Dec 08 2014, 06:19PM

That "Test Pilot Mafia" guy... thats me

.

.

Various configurations. It seems they dont want CF props to see more than 22.2 V, the wood props are rated to 44.4 V at near 4,000RPM.

the best effciency from 19.4 g/W to 15.6 g/W.

this varies across 1,100 to 1,550 RPM.

From 50 to 75 % throttle, (this is where hover and simple maneuvering is done.)

The best efficiency i measured on my thrust stand was 8.7 grams. 19.4 is 2.2 times better per unit of power.

Pics of the U8. its a pancake motor, just not sure why these physical shapes are chosen, still studying this too.

in any case, as youve said low RPM at large diameter yields high effciency. the above props, ive been told "explosively liberate" themselves at 6,000RPM or so. (i dont know if they're thin at the hub or what)

Re: Propeller Physics and VABs Program.

Shrad, Mon Dec 08 2014, 06:55PM

I just saw on Discovery that porsche 318 motors are pancake motors of that kind, so there should clearly be other advantages than form factor...

Shrad, Mon Dec 08 2014, 06:55PM

I just saw on Discovery that porsche 318 motors are pancake motors of that kind, so there should clearly be other advantages than form factor...

Re: Propeller Physics and VABs Program.

Ash Small, Mon Dec 08 2014, 10:31PM

Patrick, just got back after a long day, but on the subject of props disintegrating at high RPM, there are basically two factors. One is if they are designed for high disc loading they will be producing loads of thrust at high RPM. The other is that if designed for high disc loading they will be much heavier, and therefore the centripetal/centrifugal forces are also high.

I think a low disc loading prop will spin much faster, due to it's low mass and due to it not generating a lot of thrust.

I know I previously said 'a big prop at low RPM, but I should have said 'or a big prop at the same RPM with less cross section'. I think we want fairly high prop RPM for increased manouverability.

If we increase RPM, we can reduce mass and cross section, have less angle of attack, etc.

The only limit seems to be, apart from centripetal/centrifugal stuff, drag on the blades, but we can reduce turbulence behind the blade, and improve laminar flow.

Does this make any sense?

I'll have a look at the charts you posted tomorrow.

Ash Small, Mon Dec 08 2014, 10:31PM

Patrick, just got back after a long day, but on the subject of props disintegrating at high RPM, there are basically two factors. One is if they are designed for high disc loading they will be producing loads of thrust at high RPM. The other is that if designed for high disc loading they will be much heavier, and therefore the centripetal/centrifugal forces are also high.

I think a low disc loading prop will spin much faster, due to it's low mass and due to it not generating a lot of thrust.

I know I previously said 'a big prop at low RPM, but I should have said 'or a big prop at the same RPM with less cross section'. I think we want fairly high prop RPM for increased manouverability.

If we increase RPM, we can reduce mass and cross section, have less angle of attack, etc.

The only limit seems to be, apart from centripetal/centrifugal stuff, drag on the blades, but we can reduce turbulence behind the blade, and improve laminar flow.

Does this make any sense?

I'll have a look at the charts you posted tomorrow.

Re: Propeller Physics and VABs Program.

Andy, Tue Dec 09 2014, 02:29AM

Apologies Ash,

2m2v2, dropping back to or base shifting equals v3(velocity cubed) 6 = v*1/2

2m2v2, dropping back to or base shifting equals v3(velocity cubed) 6 = v*1/2

If we take power in watts used P = 1/2mv2, releatising that a system is equal and opposite and that opposite energy gets removed out of the system to a larger system, we have 2mv2*2, the opposite value(1/2) 4 = v

v3/v4 power is 75% effeiect ln(75%) = 25% loss with a increase in speed per step, 50% of 75% is 42.5% which is the effeinect of blades and props to convert and use energy in wind flow.

Andy, Tue Dec 09 2014, 02:29AM

Apologies Ash,

You've not taken losses into account here, Andy, which increase as prop size decreases and as air speed increases.Just doing some thinking and F = 1/2mv2 using double simposim position becomes

The most efficient is always large diameter and low RPM, and it's pretty much exponential, very similar to the 'drag equation'.

2m2v2, dropping back to or base shifting equals v3(velocity cubed) 6 = v*1/2

2m2v2, dropping back to or base shifting equals v3(velocity cubed) 6 = v*1/2If we take power in watts used P = 1/2mv2, releatising that a system is equal and opposite and that opposite energy gets removed out of the system to a larger system, we have 2mv2*2, the opposite value(1/2) 4 = v

v3/v4 power is 75% effeiect ln(75%) = 25% loss with a increase in speed per step, 50% of 75% is 42.5% which is the effeinect of blades and props to convert and use energy in wind flow.

Re: Propeller Physics and VABs Program.

Patrick, Tue Dec 09 2014, 05:20AM

Text files !

i found this math interesting :

]per3_10x45mr.txt[/file] multi-rotor

]per3_10x55mr.txt[/file] multi-rotor

]per3_11x38sf.txt[/file] slo-fly

]per3_12x38sf.txt[/file] slo-fly

]per3_12x45mr.txt[/file] multi-rotor

]per3_14x55mr.txt[/file] multi-rotor

if we look at 0 to 3 mph, we see most of the power being used as static force. Right?

Patrick, Tue Dec 09 2014, 05:20AM

Text files !

i found this math interesting :

]per3_10x45mr.txt[/file] multi-rotor

]per3_10x55mr.txt[/file] multi-rotor