Toroid Types

Graham Armitage, Wed Sept 24 2014, 08:18PMDoes anyone have a formula or even anecdotal data on the capacitance of a regular spun or duct-tube toroid versus the ring toroids. How does spacing between the individual rings or number of rings affect the overall capacitance?

Re: Toroid Types

Steve Conner, Wed Sept 24 2014, 08:57PM

To a first approximation, the skeleton toroid has pretty much the same capacitance as an ordinary toroid of the same dimensions. I think everyone just assumes this.

Tesla believed the capacitance of a conductor was simply proportional to the surface area of metal, but the truth is somewhat more complicated.

Steve Conner, Wed Sept 24 2014, 08:57PM

To a first approximation, the skeleton toroid has pretty much the same capacitance as an ordinary toroid of the same dimensions. I think everyone just assumes this.

Tesla believed the capacitance of a conductor was simply proportional to the surface area of metal, but the truth is somewhat more complicated.

Re: Toroid Types

Graham Armitage, Thu Sept 25 2014, 12:13PM

Thanks Steve, that is good to know. I may give it a try on the coil I am building now.

Graham Armitage, Thu Sept 25 2014, 12:13PM

Thanks Steve, that is good to know. I may give it a try on the coil I am building now.

Re: Toroid Types

Mads Barnkob, Thu Sept 25 2014, 12:52PM

I have tried modelling all kinds of toroid shapes in JAVATC and the math used in that calculator suggests the same as Steve says, it is very close results to the same amount of surface area, with little regard to how its formed.

Someone did post FEMM simulations of skeleton toroids a long while back, it might have been Kizmo, try to search for it :)

Mads Barnkob, Thu Sept 25 2014, 12:52PM

I have tried modelling all kinds of toroid shapes in JAVATC and the math used in that calculator suggests the same as Steve says, it is very close results to the same amount of surface area, with little regard to how its formed.

Someone did post FEMM simulations of skeleton toroids a long while back, it might have been Kizmo, try to search for it :)

Re: Toroid Types

Graham Armitage, Thu Sept 25 2014, 05:06PM

Seems that thread may have gone missing - others looking for it too. For now I am ok with knowing it's close the JAVATC formula. I am curious which factors would have the biggest impact on the capacitance. Does number of rings or spacing have an impact? What is the smallest number of rings you can get away with without drastically affecting the capacitance? At some point I would imagine that it decreases with less rings, but by how much?

As I said, more academic curiosity at this point. Will probably try build one and see how it goes.

Thanks again

Graham Armitage, Thu Sept 25 2014, 05:06PM

Seems that thread may have gone missing - others looking for it too. For now I am ok with knowing it's close the JAVATC formula. I am curious which factors would have the biggest impact on the capacitance. Does number of rings or spacing have an impact? What is the smallest number of rings you can get away with without drastically affecting the capacitance? At some point I would imagine that it decreases with less rings, but by how much?

As I said, more academic curiosity at this point. Will probably try build one and see how it goes.

Thanks again

Re: Toroid Types

Steve Conner, Fri Sept 26 2014, 04:06PM

Reducing the number of rings will affect the breakdown voltage more than the capacitance.

The argument goes something like this: Since the rings are all at the same potential, there must be points in between them at the same potential as this. The set of these points is an "equipotential surface". The shape of the surface is constrained to be smooth by Laplace's equation or some similar math babble. If you could see it (FEMM can help) it would look somewhat as if the structure had been shrink wrapped. Now, because all points on this surface are at the same potential as the metal rings, it follows that the surface could be replaced with a real metal surface connected to the rings, without changing the capacitance.

If you could see it (FEMM can help) it would look somewhat as if the structure had been shrink wrapped. Now, because all points on this surface are at the same potential as the metal rings, it follows that the surface could be replaced with a real metal surface connected to the rings, without changing the capacitance.

Reducing the number of rings reduces the breakdown voltage because the "ribs" stick out of the "shrink wrap" more.

Steve Conner, Fri Sept 26 2014, 04:06PM

Reducing the number of rings will affect the breakdown voltage more than the capacitance.

The argument goes something like this: Since the rings are all at the same potential, there must be points in between them at the same potential as this. The set of these points is an "equipotential surface". The shape of the surface is constrained to be smooth by Laplace's equation or some similar math babble.

If you could see it (FEMM can help) it would look somewhat as if the structure had been shrink wrapped. Now, because all points on this surface are at the same potential as the metal rings, it follows that the surface could be replaced with a real metal surface connected to the rings, without changing the capacitance.

If you could see it (FEMM can help) it would look somewhat as if the structure had been shrink wrapped. Now, because all points on this surface are at the same potential as the metal rings, it follows that the surface could be replaced with a real metal surface connected to the rings, without changing the capacitance.Reducing the number of rings reduces the breakdown voltage because the "ribs" stick out of the "shrink wrap" more.

Re: Toroid Types

Graham Armitage, Sat Sept 27 2014, 11:17AM

That is interesting. Excellent description ! When you put it like that it makes a lot of sense - very easy to picture. I would think that a plastic framework covered with a collection of rounded-edge discs would have the same effect too. One could start getting creative with toroid construction. Aluminum and copper tubing makes ring toroids expensive (I think I read that Eric Goodchild spent $250 per toroid on his larger coils). I have heard of plastic rings being covered in aluminum tape to reduce cost, but not quite as nice as aluminum tubing.

Time to get creative !

Graham Armitage, Sat Sept 27 2014, 11:17AM

That is interesting. Excellent description ! When you put it like that it makes a lot of sense - very easy to picture. I would think that a plastic framework covered with a collection of rounded-edge discs would have the same effect too. One could start getting creative with toroid construction. Aluminum and copper tubing makes ring toroids expensive (I think I read that Eric Goodchild spent $250 per toroid on his larger coils). I have heard of plastic rings being covered in aluminum tape to reduce cost, but not quite as nice as aluminum tubing.

Time to get creative !

Re: Toroid Types

Mads Barnkob, Sat Sept 27 2014, 03:06PM

I found 7 rings of 25mm coax cable for mobile antenna installations. Only cost me cable scrap price from a junk yard. It has a hard plastic outer shell, then a 1mm thick, 25mm diameter aluminium screen, filled with PE foam and a 8mm copper tube in the middle.

Cheap, light weight, perfect. Get creative and you can build awesome stuff for nothing :)

Mads Barnkob, Sat Sept 27 2014, 03:06PM

I found 7 rings of 25mm coax cable for mobile antenna installations. Only cost me cable scrap price from a junk yard. It has a hard plastic outer shell, then a 1mm thick, 25mm diameter aluminium screen, filled with PE foam and a 8mm copper tube in the middle.

Cheap, light weight, perfect. Get creative and you can build awesome stuff for nothing :)

Re: Toroid Types

Uspring, Sat Sept 27 2014, 06:53PM

Too thin tubing should be avoided. I once had a 24" diameter toroid made from quarter inch copper tubes. There were arcs going from the bottom of the toroid into the primary inspite of a big breakout rod on top.

Uspring, Sat Sept 27 2014, 06:53PM

Too thin tubing should be avoided. I once had a 24" diameter toroid made from quarter inch copper tubes. There were arcs going from the bottom of the toroid into the primary inspite of a big breakout rod on top.

Re: Toroid Types

Graham Armitage, Sun Sept 28 2014, 02:33AM

What was the gap between the rings? Using the shrink wrap analogy that Steve described, small diameter tubing would presumably have to be very close together to start approximating a solid toroid. I would imagine, in general the smaller the spacing the better. Could there be a minimum ratio of Diam:spacing that still achieves, say 95% capacitance of a solid toroid? Just speculating here...

Graham Armitage, Sun Sept 28 2014, 02:33AM

Uspring wrote ...

Too thin tubing should be avoided. I once had a 24" diameter toroid made from quarter inch copper tubes. There were arcs going from the bottom of the toroid into the primary inspite of a big breakout rod on top.

Too thin tubing should be avoided. I once had a 24" diameter toroid made from quarter inch copper tubes. There were arcs going from the bottom of the toroid into the primary inspite of a big breakout rod on top.

What was the gap between the rings? Using the shrink wrap analogy that Steve described, small diameter tubing would presumably have to be very close together to start approximating a solid toroid. I would imagine, in general the smaller the spacing the better. Could there be a minimum ratio of Diam:spacing that still achieves, say 95% capacitance of a solid toroid? Just speculating here...

Re: Toroid Types

Steve Conner, Sun Sept 28 2014, 09:02AM

FWIW, the "frame covered in rounded edge discs" actually works, it is used in some ultra high voltage test rigs in the power industry.

There's probably a mathematically optimal shape for the disc, but if you imagine the structure shrink wrapped and try to avoid sharp edges poking through the wrap, you won't go far wrong.

Steve Conner, Sun Sept 28 2014, 09:02AM

FWIW, the "frame covered in rounded edge discs" actually works, it is used in some ultra high voltage test rigs in the power industry.

There's probably a mathematically optimal shape for the disc, but if you imagine the structure shrink wrapped and try to avoid sharp edges poking through the wrap, you won't go far wrong.

Re: Toroid Types

Uspring, Sun Sept 28 2014, 10:06AM

Spacing between ring was about 2cm. I later replaced the toroid by a solid one of the same overall size. Didn't even have to retune the coil and the arc problems went away. I think thin tubing is much more an issue regarding unwanted breakout rather than capacitance.

Uspring, Sun Sept 28 2014, 10:06AM

Spacing between ring was about 2cm. I later replaced the toroid by a solid one of the same overall size. Didn't even have to retune the coil and the arc problems went away. I think thin tubing is much more an issue regarding unwanted breakout rather than capacitance.

Re: Toroid Types

Kizmo, Sun Sept 28 2014, 05:40PM

My stacked ring toroid has space between tubes that is roughly 1.5x the tube diameter.

Works well enough, i do get stray spark now and then but that happens at low power. Crank it up and the main streamer from breakout rod does the energy drawing all alone :D

Kizmo, Sun Sept 28 2014, 05:40PM

My stacked ring toroid has space between tubes that is roughly 1.5x the tube diameter.

Works well enough, i do get stray spark now and then but that happens at low power. Crank it up and the main streamer from breakout rod does the energy drawing all alone :D

Re: Toroid Types

Graham Armitage, Mon Sept 29 2014, 11:35AM

Yup, that's what I was thinking about, but on a smaller scale.

From what I am hearing, keeping the rings closer together definitely helps. The fact that the ring toroid can be swapped out with the solid one and no re-tuning is required answers the question about capacitance difference (or lack thereof).

Graham Armitage, Mon Sept 29 2014, 11:35AM

Steve Conner wrote ...

FWIW, the "frame covered in rounded edge discs" actually works, it is used in some ultra high voltage test rigs in the power industry.

FWIW, the "frame covered in rounded edge discs" actually works, it is used in some ultra high voltage test rigs in the power industry.

Yup, that's what I was thinking about, but on a smaller scale.

From what I am hearing, keeping the rings closer together definitely helps. The fact that the ring toroid can be swapped out with the solid one and no re-tuning is required answers the question about capacitance difference (or lack thereof).

Re: Toroid Types

Graham Armitage, Mon Sept 29 2014, 06:41PM

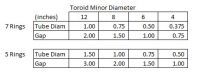

So I combed through photos and websites, pulling anecdotal data from working ring toroids. Coupling that with the feedback from this thread, I came up with some tables with rough numbers. To be used as a guideline for ring-toroid construction. Would like to know if this matches what others have done successfully through experimentation?

Graham Armitage, Mon Sept 29 2014, 06:41PM

So I combed through photos and websites, pulling anecdotal data from working ring toroids. Coupling that with the feedback from this thread, I came up with some tables with rough numbers. To be used as a guideline for ring-toroid construction. Would like to know if this matches what others have done successfully through experimentation?

Re: Toroid Types

Dr. Slack, Mon Sept 29 2014, 07:16PM

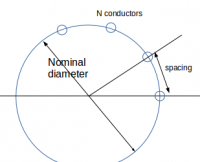

My interest was piqued by the discussion on partial surface toroids, as it's always been a puzzle to me why so many folks use hard to make continuous surfaces rather than bent pipe or mesh.

I especially like Steve's 'shrink wrap' analogy for what happens to the electric potential around a bundled conductor (as the power line companies call those multiple conductors you see strung across the country to reduce the electric field and hence corona losses on their cables).

So I thought I'd put some numbers to the hand-waving, to see just how effective mesh is compared to solid.

Rather than do the sums for a toroid, I set up the equations for a cylinder, which will produce the same form of results, and the same results as the toroid becomes skinnier.

Rather than set up the conductive surfaces in a Finite Element solver like atlc or something, or do any serious analytical stuff, I instead chose the method of using linear superposition to sum the potential from each conductor, of either a central charge of N units, or N wires each carrying unit charge. The voltage of any equipotential gives the capacitance that a conductor with that profile would have. Although in general the equipotential contours are not exact circles, the approximation to a circle is remarkably good, especially for small radius conductors.

Results for a few selected geometries

The bundle's nominal diameter is that of the wire centres. The equivalent solid cyclinder is given with respect to this dimension. The bundle overall diameter will be a little larger, to the tune of one wire diameter.

The wires are dimensioned as a fraction of their spacing. So a 0.2 diameter conductor fills 20% of the surface, regardless of how many there are spaced round the bundle. This may not be the most consistent way to present it, but it was how I coded it, and you only need to mess about with pi to get to and from absolute dimensions.

For 6 conductors of diameter 0.02 spacing,

the bundle is equivalent to a solid cylinder of 63% nominal diameter

for 0.2, 92%

for 0.4, 99.2%

For 12 conductors of diameter 0.02 spacing,

the bundle is equivalent to a solid curface of 79% of nominal diameter

for 0.2, 95.7%

for 0.4, 99.6%

For 24 conductors of diameter 0.02 spacing,

the bundle is equivalent to 89.1% of nominal diameter

for 0.2, 97.8%

For 100 conductors of diameter 0.02 spacing,

the bundle is equivalent to 97.3% of nominal diameter

Dr. Slack, Mon Sept 29 2014, 07:16PM

My interest was piqued by the discussion on partial surface toroids, as it's always been a puzzle to me why so many folks use hard to make continuous surfaces rather than bent pipe or mesh.

I especially like Steve's 'shrink wrap' analogy for what happens to the electric potential around a bundled conductor (as the power line companies call those multiple conductors you see strung across the country to reduce the electric field and hence corona losses on their cables).

So I thought I'd put some numbers to the hand-waving, to see just how effective mesh is compared to solid.

Rather than do the sums for a toroid, I set up the equations for a cylinder, which will produce the same form of results, and the same results as the toroid becomes skinnier.

Rather than set up the conductive surfaces in a Finite Element solver like atlc or something, or do any serious analytical stuff, I instead chose the method of using linear superposition to sum the potential from each conductor, of either a central charge of N units, or N wires each carrying unit charge. The voltage of any equipotential gives the capacitance that a conductor with that profile would have. Although in general the equipotential contours are not exact circles, the approximation to a circle is remarkably good, especially for small radius conductors.

Results for a few selected geometries

The bundle's nominal diameter is that of the wire centres. The equivalent solid cyclinder is given with respect to this dimension. The bundle overall diameter will be a little larger, to the tune of one wire diameter.

The wires are dimensioned as a fraction of their spacing. So a 0.2 diameter conductor fills 20% of the surface, regardless of how many there are spaced round the bundle. This may not be the most consistent way to present it, but it was how I coded it, and you only need to mess about with pi to get to and from absolute dimensions.

For 6 conductors of diameter 0.02 spacing,

the bundle is equivalent to a solid cylinder of 63% nominal diameter

for 0.2, 92%

for 0.4, 99.2%

For 12 conductors of diameter 0.02 spacing,

the bundle is equivalent to a solid curface of 79% of nominal diameter

for 0.2, 95.7%

for 0.4, 99.6%

For 24 conductors of diameter 0.02 spacing,

the bundle is equivalent to 89.1% of nominal diameter

for 0.2, 97.8%

For 100 conductors of diameter 0.02 spacing,

the bundle is equivalent to 97.3% of nominal diameter

Re: Toroid Types

Dr. Dark Current, Mon Sept 29 2014, 07:21PM

The effective capacitance also depends on the secondary coil dimensions and relative topload positioning. I believe JavaTC assumes this.

Dr. Dark Current, Mon Sept 29 2014, 07:21PM

The effective capacitance also depends on the secondary coil dimensions and relative topload positioning. I believe JavaTC assumes this.

Print this page