Novel flying machines

Dr. Slack, Fri May 02 2014, 08:10AMI've been following Patrick's anguish over duration for hovering machines, and the fact that it seems it's difficult to break the laws of physics. Short of Tony Stark's mobile-phone-sized fusion reactor (or whatever it was), it seems it's not going to change radically any time soon.

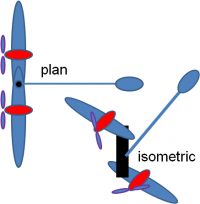

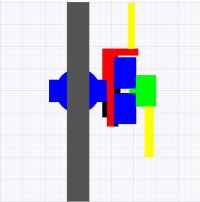

I did have this idea,

which I now realise has two fatal balance flaws as drawn, and while the centre of mass one can be fixed, the centre of lift one cannot. The idea was to have longer, more efficient wings counter-rotating in the hover, and a more conventional fixed-wing configuration for getting to and from the loiter site, both of which should contribute to better fuel economy. It turns out that this is too far out of the box to work. But, it might stimulate others to new ideas.

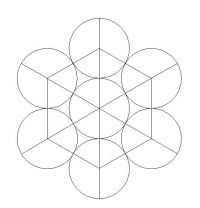

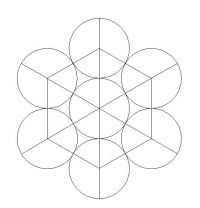

This is one I posted a long while ago, in a similar effort

It's a quad with a wing in the middle. It doesn't improve the hover at all, but for getting to and from the working site, it can rotate to fly more conventionally. As the quad rotors can now provide all the pitch, yaw and roll required, the wing can be rigid. As drawn, the very short wing won't be very efficient, however any improvement might be worth having. A longer wing would compromise gust stability further.

Energy storage and energy conversion is key. Kjoules per kg - batteries are rubbish, hydrogen in tanks is rubbish, hydrocarbon fuel in a light tank is brilliant. Fuel cells are very expensive, generator/electric motors are heavy, so is it possible just to use a petrol engined fan, and tame its performance without the mechanical complexty of a helicopter?

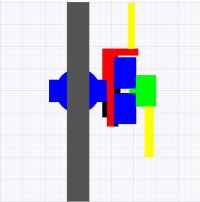

What about these two ideas? A weedwhacker motor drives a simple prop, to generate nominally all of the downforce. In the first idea, the two downwards facing fans basically support their own weight, and provide fast pitch and roll control as a quad copter would. They both rotate opposite to the main fan, to provide some of the counter rotation, the bulk of which is supplied by the sideways blowing fan.

In the second idea, only two fans are used for control, with vectored thrust.

The second might be slightly lighter, but the first would be simpler mechanically.

The IC engine speed is servoed for vertical speed and position, which might result in fairly crude vertical stability. For a surveillance platform with downwards or slant facing cameras, this would probably not matter. If the number of control fans increased to 4 in a quad arrangement, then fine control is available vertically as well, and it's basically a small quad with a big fan in the middle.

Control power could be from batteries, which would be simpler initially, or from a small generator, which would allow the whole vehicle to be refuelled in seconds. A smaller generator with high C LiFePo4s for handling bursts may be a useful hybrid. The electrical consumption ought to be a tiny fraction of the consumption of a similar weight all electric vehicle.

So, what duration could you get from a gas driven fan?

The challenge is to come up with something that stands a chance of having the manouvrability of a multi-rotor, without the mechanical complexity of a helicopter, and a duration of an hour or more

Re: Novel flying machines

Ash Small, Fri May 02 2014, 09:27AM

Ok, I'll throw one in too. It's not really novel, it uses technology that's over a century old, but if the trend is towards hydrogen power, why not store the hydrogen as a gas, and use it for lift?

This gets you airborne without using any power. You can carry additional fuel, either as compressed H2, or whatever is convenient. As you use up the 'heavier than air' fuel/batteries/whatever, you can also burn H2 from the 'envelope' to maintain height, etc. You could even have an 'on board' H2 powered compressor for reducing lift when landing.

Only disadvantages are size and not too good in high winds. (and possible risk of fire).

Ash Small, Fri May 02 2014, 09:27AM

Ok, I'll throw one in too. It's not really novel, it uses technology that's over a century old, but if the trend is towards hydrogen power, why not store the hydrogen as a gas, and use it for lift?

This gets you airborne without using any power. You can carry additional fuel, either as compressed H2, or whatever is convenient. As you use up the 'heavier than air' fuel/batteries/whatever, you can also burn H2 from the 'envelope' to maintain height, etc. You could even have an 'on board' H2 powered compressor for reducing lift when landing.

Only disadvantages are size and not too good in high winds. (and possible risk of fire).

Re: Novel flying machines

BigBad, Fri May 02 2014, 03:43PM

I'm not quite sure why this is such a big issue; the world record for conventional electric helicopters is over an hour using lithium ion batteries.

BigBad, Fri May 02 2014, 03:43PM

I'm not quite sure why this is such a big issue; the world record for conventional electric helicopters is over an hour using lithium ion batteries.

Re: Novel flying machines

Patrick, Fri May 02 2014, 05:15PM

yep fusion reactor, thats what i need, should have sobered up and thought of this first.

Patrick, Fri May 02 2014, 05:15PM

yep fusion reactor, thats what i need, should have sobered up and thought of this first.

Re: Novel flying machines

Dr. Slack, Fri May 02 2014, 07:55PM

well I figure long blades have less induced drag, so helis ought to beat multirotors for efficiency, so why are there so many of the latter about? Is it just the cool factor, or is it that you can replace all that nasty mechanics at the heli hub with a microcontroller and multiple purchased fans? So taking the enterprise from the professional to the amateur space?

So would a heli-sized top fan without any mechanics (for amateur simplicity) coupled with 2 or 3 stabilising fans on booms like I've drawn above achieve a big improvement in mission time?

Dr. Slack, Fri May 02 2014, 07:55PM

BigBad wrote ...

I'm not quite sure why this is such a big issue; the world record for conventional electric helicopters is over an hour using lithium ion batteries.

I'm not quite sure why this is such a big issue; the world record for conventional electric helicopters is over an hour using lithium ion batteries.

well I figure long blades have less induced drag, so helis ought to beat multirotors for efficiency, so why are there so many of the latter about? Is it just the cool factor, or is it that you can replace all that nasty mechanics at the heli hub with a microcontroller and multiple purchased fans? So taking the enterprise from the professional to the amateur space?

So would a heli-sized top fan without any mechanics (for amateur simplicity) coupled with 2 or 3 stabilising fans on booms like I've drawn above achieve a big improvement in mission time?

Re: Novel flying machines

BigBad, Fri May 02 2014, 09:17PM

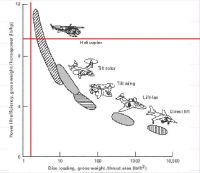

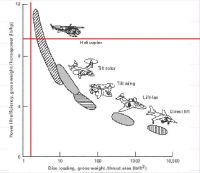

I think the quad/single doesn't make a huge difference to a first approximation, it's mostly the disc loading that matters.

There might be some Reynolds number thing, but mostly you just want a large total disc area and a nice even downdraft speed through the rotors.

The second order stuff is a different story though; you have to worry about the tip vortexes; there's going to be recirculation around the outside of the vehicle; I'm thinking a single rotor can be designed to better to control those kinds of losses, although ducting the fans might help a lot, but this adds mass.

BigBad, Fri May 02 2014, 09:17PM

I think the quad/single doesn't make a huge difference to a first approximation, it's mostly the disc loading that matters.

There might be some Reynolds number thing, but mostly you just want a large total disc area and a nice even downdraft speed through the rotors.

The second order stuff is a different story though; you have to worry about the tip vortexes; there's going to be recirculation around the outside of the vehicle; I'm thinking a single rotor can be designed to better to control those kinds of losses, although ducting the fans might help a lot, but this adds mass.

Re: Novel flying machines

Ash Small, Fri May 02 2014, 09:23PM

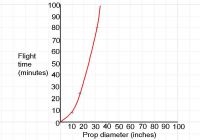

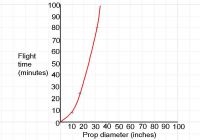

Well, the larger the prop, the more efficient it is, the trade-off is increased mass, although a slower turning prop may have a thinner section if less forces are involved, etc.....

Ash Small, Fri May 02 2014, 09:23PM

Dr. Slack wrote ...

So would a heli-sized top fan without any mechanics (for amateur simplicity) coupled with 2 or 3 stabilising fans on booms like I've drawn above achieve a big improvement in mission time?

So would a heli-sized top fan without any mechanics (for amateur simplicity) coupled with 2 or 3 stabilising fans on booms like I've drawn above achieve a big improvement in mission time?

Well, the larger the prop, the more efficient it is, the trade-off is increased mass, although a slower turning prop may have a thinner section if less forces are involved, etc.....

Re: Novel flying machines

Patrick, Fri May 02 2014, 10:05PM

Ive been reading and re-reading the above comments and previous threads.

first there are those on kickstarter persuing the wing with quad idea, and that idea may work well. The real advantage it has is the forward speed allows greater distance covered hence area possibly within reach goes up as the area of a circle.

next weed-whacker/chainsaws are disasters to mod for this purpose, the evolution 0.91NX is nearly 2hp for 180$ and 1lb, (better than a fuel cell in cost, mass and output) there is an ace helicopter RC pilot who's already got a quad with a single engine driving variable pitch props by belts.

is nearly 2hp for 180$ and 1lb, (better than a fuel cell in cost, mass and output) there is an ace helicopter RC pilot who's already got a quad with a single engine driving variable pitch props by belts.

As per previous comments, yes the multrotor reduces the cost of the same capable helo. those RC helos have enormously complicated parts, many of them, and all precision machined, as soon as you crash you obliterate 2000$ of a 3000$ machine. So avoiding the little expensive parts is the real attraction to multirotors. but we seem to eat the loss when compared to disc loading.

i may be outsmarting myself witht the power source, perhaps the prop s what should be looking at. the convetional props for multirotors look like minor-ly modified fixed wing props for forward high speed flight. as sulaiman and others have said, perhaps a wide chord, undercambered prop would do better using the power i do have on the machine.

as for electric flight time of 1+ hour, BigBad. ive researched these thoruoghly, there basically 10% machine, 90% lithium ion. which at shallow draw rates appear more dense than Li-poly battereis, i think. but need long duration, with a useful instrument payload.

so theres the balance... total mass of machine, power source/density onboard, and how power is coupled to the air....right?

im planning a differnt propeller, given my skill with composites. a three blade, undercambered, wide chord, hopefully not lethal eperimental prop. then graph against conventional props.

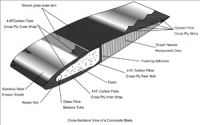

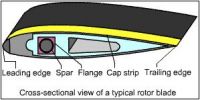

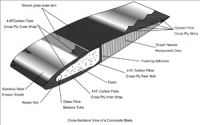

pics of the AR drone version 1.0 (commercial product)

the above pics show a radical deviation from common mulltirotor and fixed wing props.

note the wide chord toward the hub/root, as Sulaiman advocates for, note the extreme undercamber too.

Patrick, Fri May 02 2014, 10:05PM

Ive been reading and re-reading the above comments and previous threads.

first there are those on kickstarter persuing the wing with quad idea, and that idea may work well. The real advantage it has is the forward speed allows greater distance covered hence area possibly within reach goes up as the area of a circle.

next weed-whacker/chainsaws are disasters to mod for this purpose, the evolution 0.91NX

is nearly 2hp for 180$ and 1lb, (better than a fuel cell in cost, mass and output) there is an ace helicopter RC pilot who's already got a quad with a single engine driving variable pitch props by belts.

is nearly 2hp for 180$ and 1lb, (better than a fuel cell in cost, mass and output) there is an ace helicopter RC pilot who's already got a quad with a single engine driving variable pitch props by belts. As per previous comments, yes the multrotor reduces the cost of the same capable helo. those RC helos have enormously complicated parts, many of them, and all precision machined, as soon as you crash you obliterate 2000$ of a 3000$ machine. So avoiding the little expensive parts is the real attraction to multirotors. but we seem to eat the loss when compared to disc loading.

i may be outsmarting myself witht the power source, perhaps the prop s what should be looking at. the convetional props for multirotors look like minor-ly modified fixed wing props for forward high speed flight. as sulaiman and others have said, perhaps a wide chord, undercambered prop would do better using the power i do have on the machine.

as for electric flight time of 1+ hour, BigBad. ive researched these thoruoghly, there basically 10% machine, 90% lithium ion. which at shallow draw rates appear more dense than Li-poly battereis, i think. but need long duration, with a useful instrument payload.

so theres the balance... total mass of machine, power source/density onboard, and how power is coupled to the air....right?

im planning a differnt propeller, given my skill with composites. a three blade, undercambered, wide chord, hopefully not lethal eperimental prop. then graph against conventional props.

pics of the AR drone version 1.0 (commercial product)

the above pics show a radical deviation from common mulltirotor and fixed wing props.

note the wide chord toward the hub/root, as Sulaiman advocates for, note the extreme undercamber too.

Re: Novel flying machines

Ash Small, Sat May 03 2014, 12:38PM

I think Patrick's assymetrical tri-copter is the simplest alternative to the 'swash plate' used in conventional helicopters.

Fewer blades will always be more efficient.

There comes a point, due to increased payload or range requirements where IC engines do become more efficient than batteries as the mass of fuel compared to mass of battery pack predominates, although, as Patrick has demonstrated, the weight of ancillaries is greater for IC engines (tank, but the maths improve as size increases) IC engine compared to electric motor, etc.

As I suggested in the other thread, without inputting all of these parameters into a graph it's difficult to say precisely where this transition occurs. You first need to define payload and range (flight time), and then work from there.

Ash Small, Sat May 03 2014, 12:38PM

Dr. Slack wrote ...

well I figure long blades have less induced drag, so helis ought to beat multirotors for efficiency, so why are there so many of the latter about? Is it just the cool factor, or is it that you can replace all that nasty mechanics at the heli hub with a microcontroller and multiple purchased fans? So taking the enterprise from the professional to the amateur space?

So would a heli-sized top fan without any mechanics (for amateur simplicity) coupled with 2 or 3 stabilising fans on booms like I've drawn above achieve a big improvement in mission time?

BigBad wrote ...

I'm not quite sure why this is such a big issue; the world record for conventional electric helicopters is over an hour using lithium ion batteries.

I'm not quite sure why this is such a big issue; the world record for conventional electric helicopters is over an hour using lithium ion batteries.

well I figure long blades have less induced drag, so helis ought to beat multirotors for efficiency, so why are there so many of the latter about? Is it just the cool factor, or is it that you can replace all that nasty mechanics at the heli hub with a microcontroller and multiple purchased fans? So taking the enterprise from the professional to the amateur space?

So would a heli-sized top fan without any mechanics (for amateur simplicity) coupled with 2 or 3 stabilising fans on booms like I've drawn above achieve a big improvement in mission time?

I think Patrick's assymetrical tri-copter is the simplest alternative to the 'swash plate' used in conventional helicopters.

Fewer blades will always be more efficient.

There comes a point, due to increased payload or range requirements where IC engines do become more efficient than batteries as the mass of fuel compared to mass of battery pack predominates, although, as Patrick has demonstrated, the weight of ancillaries is greater for IC engines (tank, but the maths improve as size increases) IC engine compared to electric motor, etc.

As I suggested in the other thread, without inputting all of these parameters into a graph it's difficult to say precisely where this transition occurs. You first need to define payload and range (flight time), and then work from there.

Re: Novel flying machines

Patrick, Sat May 03 2014, 05:01PM

Yep agree, but graphs are only as good as there input data, so that's the real hand up.

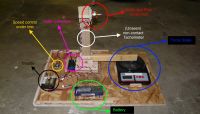

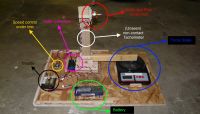

I am in a furious re-build of my thrust stand, to get that data. And conduct comparative testing. While I normally fly with 511g of battery, I'll probably drop that to 200g lipo, plus the IC engine 500g, plus minor tankage.

Many of the ultra light and micro heli's and multis have gears to slow the prop. I presume there matching the motors best speed and toque band to power usage for the force needed in a static hover?

Yet the larger drones don't seem to do this.

As previously stated, the swash plate is the real boogie man that comes for engineers in the night. Curtis Youngblood uses belts on his IC quad, and the tail rotor from a large heli. So he holds constant rpm on the IC, then varies the pitch, but has no real swash plate, to separate roll and pitch from a single rotor, as it's not needed.

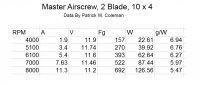

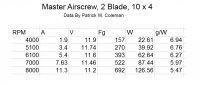

Propeller link :

Patrick, Sat May 03 2014, 05:01PM

Yep agree, but graphs are only as good as there input data, so that's the real hand up.

I am in a furious re-build of my thrust stand, to get that data. And conduct comparative testing. While I normally fly with 511g of battery, I'll probably drop that to 200g lipo, plus the IC engine 500g, plus minor tankage.

Many of the ultra light and micro heli's and multis have gears to slow the prop. I presume there matching the motors best speed and toque band to power usage for the force needed in a static hover?

Yet the larger drones don't seem to do this.

As previously stated, the swash plate is the real boogie man that comes for engineers in the night. Curtis Youngblood uses belts on his IC quad, and the tail rotor from a large heli. So he holds constant rpm on the IC, then varies the pitch, but has no real swash plate, to separate roll and pitch from a single rotor, as it's not needed.

Propeller link :

Re: Novel flying machines

Conundrum, Sat May 03 2014, 06:42PM

Are we allowed to mention LENR on here, given that NASA have had verifiable positive results with the terahertz driven nickel lattice?

Albeit very low (3* heat gain) and needing hundreds of Watts input as both heat and THz radiation generated by a highly inefficient third harmonic process.

EDIT:- Also adding idea about using a hybrid of supercapacitor and low rate Li-Po as these can handle much more power.

Slow charge the supercap via Li-Pos and discharge through a feedback driven ZVS into the motor to ensure constant current

and have an array of these charging and discharging to allow constant motor drive.

-A

Conundrum, Sat May 03 2014, 06:42PM

Are we allowed to mention LENR on here, given that NASA have had verifiable positive results with the terahertz driven nickel lattice?

Albeit very low (3* heat gain) and needing hundreds of Watts input as both heat and THz radiation generated by a highly inefficient third harmonic process.

EDIT:- Also adding idea about using a hybrid of supercapacitor and low rate Li-Po as these can handle much more power.

Slow charge the supercap via Li-Pos and discharge through a feedback driven ZVS into the motor to ensure constant current

and have an array of these charging and discharging to allow constant motor drive.

-A

Re: Novel flying machines

Patrick, Sat May 03 2014, 07:33PM

Note : the evolution .91nx is 570g. 1400 watts/2Hp extract-able power.

But that fuel cell still ticks me off, with all there dam graphs , showing it better than lipo.

Patrick, Sat May 03 2014, 07:33PM

Conundrum wrote ...

Are we allowed to mention LENR on here, given that NASA have had verifiable positive results with the terahertz driven nickel lattice?

Albeit very low (3* heat gain) and needing hundreds of Watts input as both heat and THz radiation generated by a highly inefficient third harmonic process.

EDIT:- Also adding idea about using a hybrid of supercapacitor and low rate Li-Po as these can handle much more power.

Slow charge the supercap via Li-Pos and discharge through a feedback driven ZVS into the motor to ensure constant current

and have an array of these charging and discharging to allow constant motor drive.

-A

it would all have to fit on a 1.5kg machine, with those parts adding 500g or less, (2kg AUW). Otherwise I think IC engines win.Are we allowed to mention LENR on here, given that NASA have had verifiable positive results with the terahertz driven nickel lattice?

Albeit very low (3* heat gain) and needing hundreds of Watts input as both heat and THz radiation generated by a highly inefficient third harmonic process.

EDIT:- Also adding idea about using a hybrid of supercapacitor and low rate Li-Po as these can handle much more power.

Slow charge the supercap via Li-Pos and discharge through a feedback driven ZVS into the motor to ensure constant current

and have an array of these charging and discharging to allow constant motor drive.

-A

Note : the evolution .91nx is 570g. 1400 watts/2Hp extract-able power.

But that fuel cell still ticks me off, with all there dam graphs , showing it better than lipo.

Re: Novel flying machines

Conundrum, Sat May 03 2014, 08:50PM

I always wondered why fuel cells are so inefficient, do they recombine non electrically like LEDs?

ie produce heat instead of EMF?

It occurs to me that if I was to scratch build an ultra lightweight SOFC and run it at pulsed high temperature, for the short times it was cooling down the efficiency gain would offset the thermal cycling effects.

Conundrum, Sat May 03 2014, 08:50PM

I always wondered why fuel cells are so inefficient, do they recombine non electrically like LEDs?

ie produce heat instead of EMF?

It occurs to me that if I was to scratch build an ultra lightweight SOFC and run it at pulsed high temperature, for the short times it was cooling down the efficiency gain would offset the thermal cycling effects.

Re: Novel flying machines

Ash Small, Sat May 03 2014, 08:53PM

As previously mentioned, a larger, slower turning prop is 'always' more efficient, so decide on maximum permissible diameter, and work from there.

I think you only need two servo's to drive a swash plate. I'll try and find time to sketch something.

Ash Small, Sat May 03 2014, 08:53PM

As previously mentioned, a larger, slower turning prop is 'always' more efficient, so decide on maximum permissible diameter, and work from there.

I think you only need two servo's to drive a swash plate. I'll try and find time to sketch something.

Re: Novel flying machines

Patrick, Sat May 03 2014, 08:57PM

10 to 12 inches seems to be the max rotating diameter for a practical machine you can get in and out of a car. This is why a tend to favor 3 blades over 2.

Patrick, Sat May 03 2014, 08:57PM

Conundrum wrote ...

I always wondered why fuel cells are so inefficient, do they recombine non electrically like LEDs?

ie produce heat instead of EMF?

It occurs to me that if I was to scratch build an ultra lightweight SOFC and run it at pulsed high temperature, for the short times it was cooling down the efficiency gain would offset the thermal cycling effects.

Not sure if pulsing is the solution, but in 10 to 20 years PEMs will be useless in high power applications. Rendered obsolete by Chinese domination of precious and rare-earth metals, SOFC however have been and will continue to improve faster then the PEMs.I always wondered why fuel cells are so inefficient, do they recombine non electrically like LEDs?

ie produce heat instead of EMF?

It occurs to me that if I was to scratch build an ultra lightweight SOFC and run it at pulsed high temperature, for the short times it was cooling down the efficiency gain would offset the thermal cycling effects.

10 to 12 inches seems to be the max rotating diameter for a practical machine you can get in and out of a car. This is why a tend to favor 3 blades over 2.

Re: Novel flying machines

Carbon_Rod, Sun May 04 2014, 01:47AM

@Ash Small

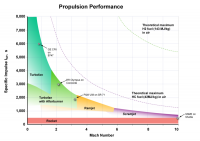

In theory the fuel is quite viable:

@Conundrum

Solid chemical fuel cells have been used in military equipment for decades, as in their inert form have a practically indefinite shelf life. There were civilian transport applications proposed, but were unsuccessful for numerous reasons.

@BigBad

However, FAA regulations limit electric motor driven craft to under 6kW IIRC, but Policy 8130(H) may simply make them illegal altogether. Private UAVs must now be under 26 lbs due to federal laws.

The air cooled 2 cycle gas powered engines are usually illegal to fly in municipal areas.

However, these have the added benefit of getting lighter as the fuel is consumed.

Carbon_Rod, Sun May 04 2014, 01:47AM

@Ash Small

In theory the fuel is quite viable:

@Conundrum

Solid chemical fuel cells have been used in military equipment for decades, as in their inert form have a practically indefinite shelf life. There were civilian transport applications proposed, but were unsuccessful for numerous reasons.

@BigBad

However, FAA regulations limit electric motor driven craft to under 6kW IIRC, but Policy 8130(H) may simply make them illegal altogether. Private UAVs must now be under 26 lbs due to federal laws.

The air cooled 2 cycle gas powered engines are usually illegal to fly in municipal areas.

However, these have the added benefit of getting lighter as the fuel is consumed.

Re: Novel flying machines

Patrick, Sun May 04 2014, 04:11AM

i need about 100g of Russian plutonium to dangle 600 feet above my town. customs need not be alerted as Im a college student. The FBI need not be worried, im trust worthy.

once you have a fission or fusion reactor light enough to fly, propulsion efficiency really turns into a trivial matter.

(maybe i just need an RTG.) mental note: rob NASA at next inter-planetary launch opportunity.

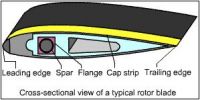

More prop pics...

AR Drone V1

AR Drone V1

Conventional propellers

pics

note the curve.

note the curvature and width

light electric heli blades.

Patrick, Sun May 04 2014, 04:11AM

i need about 100g of Russian plutonium to dangle 600 feet above my town. customs need not be alerted as Im a college student. The FBI need not be worried, im trust worthy.

once you have a fission or fusion reactor light enough to fly, propulsion efficiency really turns into a trivial matter.

(maybe i just need an RTG.) mental note: rob NASA at next inter-planetary launch opportunity.

More prop pics...

AR Drone V1

AR Drone V1

Conventional propellers

pics

note the curve.

note the curvature and width

light electric heli blades.

Re: Novel flying machines

Dr. Slack, Sun May 04 2014, 06:06AM

Right, let's have somebody come up with some numbers here.

Go back to this machine. A 2-blade fixed-geometry gas power heli stabilised with small electric rotors.

Now, according to this website , a 30" long 2 blade prop 15" pitch will generate 13lbs lift at 2500rpm consuming < 1kW. It's obviously a very niave equation, as thrust is independent of pitch, and power directly proportional to, all the way down to zero pitch, which is wrong. So I'm not expecting accuracy, just trying to find a reasonable ball-park by staying away from the extremes. A 2 blade can be turned to fit through a car door, a lower pitch should consume less power for similar thrust, and the power is significantly less than the max output of a 0.91, though it would need a drive belt to get its high rpm down to 2500. I spent max 3 minutes there, so didn't investigate more than a couple of combinations, but I feel I've at least got a handle on the sorts of things that might be possible.

, a 30" long 2 blade prop 15" pitch will generate 13lbs lift at 2500rpm consuming < 1kW. It's obviously a very niave equation, as thrust is independent of pitch, and power directly proportional to, all the way down to zero pitch, which is wrong. So I'm not expecting accuracy, just trying to find a reasonable ball-park by staying away from the extremes. A 2 blade can be turned to fit through a car door, a lower pitch should consume less power for similar thrust, and the power is significantly less than the max output of a 0.91, though it would need a drive belt to get its high rpm down to 2500. I spent max 3 minutes there, so didn't investigate more than a couple of combinations, but I feel I've at least got a handle on the sorts of things that might be possible.

Now the question, how fast does a 0.91 use fuel when generating 1.2kW. How long will it run on say 500g, or even 1kg of fuel for a 16% initial mass fraction? Searches for fuel consumption come up much leaner than searches for prop thrust, though they do hint that this is the right ballpark, and that there's a significant difference between 2 and 4 stroke.

Dr. Slack, Sun May 04 2014, 06:06AM

Right, let's have somebody come up with some numbers here.

Go back to this machine. A 2-blade fixed-geometry gas power heli stabilised with small electric rotors.

Now, according to this website

, a 30" long 2 blade prop 15" pitch will generate 13lbs lift at 2500rpm consuming < 1kW. It's obviously a very niave equation, as thrust is independent of pitch, and power directly proportional to, all the way down to zero pitch, which is wrong. So I'm not expecting accuracy, just trying to find a reasonable ball-park by staying away from the extremes. A 2 blade can be turned to fit through a car door, a lower pitch should consume less power for similar thrust, and the power is significantly less than the max output of a 0.91, though it would need a drive belt to get its high rpm down to 2500. I spent max 3 minutes there, so didn't investigate more than a couple of combinations, but I feel I've at least got a handle on the sorts of things that might be possible.

, a 30" long 2 blade prop 15" pitch will generate 13lbs lift at 2500rpm consuming < 1kW. It's obviously a very niave equation, as thrust is independent of pitch, and power directly proportional to, all the way down to zero pitch, which is wrong. So I'm not expecting accuracy, just trying to find a reasonable ball-park by staying away from the extremes. A 2 blade can be turned to fit through a car door, a lower pitch should consume less power for similar thrust, and the power is significantly less than the max output of a 0.91, though it would need a drive belt to get its high rpm down to 2500. I spent max 3 minutes there, so didn't investigate more than a couple of combinations, but I feel I've at least got a handle on the sorts of things that might be possible.Now the question, how fast does a 0.91 use fuel when generating 1.2kW. How long will it run on say 500g, or even 1kg of fuel for a 16% initial mass fraction? Searches for fuel consumption come up much leaner than searches for prop thrust, though they do hint that this is the right ballpark, and that there's a significant difference between 2 and 4 stroke.

Re: Novel flying machines

Conundrum, Sun May 04 2014, 06:41AM

Interesting re. SOFCs.

Probably a stupid question, but could lasers be used to superheat something like a SOFC to avoid the need for a continuous heat source?

Also feasible, using lasers to do direct conversion ie internal combustion but using this method means novel engine designs can be used without needing to design out troublesome knocking and other problems.

My colleagues at work being impressed with my knowledge of engines did express a little disbelief at my suggestion of making a rotary engine using multiple smaller 2 stroke engines kludged together but in theory a Wankel engine like arrangement if mechanically stable could work even though the combustion chambers are not directly linked.

but in theory a Wankel engine like arrangement if mechanically stable could work even though the combustion chambers are not directly linked.

Many of the small engines used in lawnmowers and hedge trimmers are basically identical and often they are discarded for reasons such as non terminal gearbox failure or some trivial electrical problem.

"As the rotor's apex seals pass over the spark plug hole, compressed charge can be lost from the charge chamber to the exhaust chamber, entailing fuel in the exhaust, reducing efficiency, and giving high emissions. This may be overcome by using laser ignition, eliminating traditional spark plugs, which may give a narrow slit in the motor housing the rotor apex seals can fully cover with no loss of compression from one chamber to another. The laser plug can fire its spark through the narrow slit. "

(wikipedia)

-A

Conundrum, Sun May 04 2014, 06:41AM

Interesting re. SOFCs.

Probably a stupid question, but could lasers be used to superheat something like a SOFC to avoid the need for a continuous heat source?

Also feasible, using lasers to do direct conversion ie internal combustion but using this method means novel engine designs can be used without needing to design out troublesome knocking and other problems.

My colleagues at work being impressed with my knowledge of engines did express a little disbelief at my suggestion of making a rotary engine using multiple smaller 2 stroke engines kludged together

but in theory a Wankel engine like arrangement if mechanically stable could work even though the combustion chambers are not directly linked.

but in theory a Wankel engine like arrangement if mechanically stable could work even though the combustion chambers are not directly linked.Many of the small engines used in lawnmowers and hedge trimmers are basically identical and often they are discarded for reasons such as non terminal gearbox failure or some trivial electrical problem.

"As the rotor's apex seals pass over the spark plug hole, compressed charge can be lost from the charge chamber to the exhaust chamber, entailing fuel in the exhaust, reducing efficiency, and giving high emissions. This may be overcome by using laser ignition, eliminating traditional spark plugs, which may give a narrow slit in the motor housing the rotor apex seals can fully cover with no loss of compression from one chamber to another. The laser plug can fire its spark through the narrow slit. "

(wikipedia)

-A

Re: Novel flying machines

Ash Small, Sun May 04 2014, 12:35PM

Well, it's a reasonable assumption, at least when looking for somewhere to start, that the IC engine is most efficient at the same RPM as maximum torque is produced (if looking for a ballpark).

Now, two strokes are generally less efficient, but four strokes are invariably heavier, and any lighter, tuned engine will be less efficient than a larger (read heavier) engine in a lower state of tune.

It's beginning to become clear why swash plates enabling variable pitch control are the favoured method of controlling thrust.

Ash Small, Sun May 04 2014, 12:35PM

Dr. Slack wrote ...

Now the question, how fast does a 0.91 use fuel when generating 1.2kW. How long will it run on say 500g, or even 1kg of fuel for a 16% initial mass fraction? Searches for fuel consumption come up much leaner than searches for prop thrust, though they do hint that this is the right ballpark, and that there's a significant difference between 2 and 4 stroke.

Now the question, how fast does a 0.91 use fuel when generating 1.2kW. How long will it run on say 500g, or even 1kg of fuel for a 16% initial mass fraction? Searches for fuel consumption come up much leaner than searches for prop thrust, though they do hint that this is the right ballpark, and that there's a significant difference between 2 and 4 stroke.

Well, it's a reasonable assumption, at least when looking for somewhere to start, that the IC engine is most efficient at the same RPM as maximum torque is produced (if looking for a ballpark).

Now, two strokes are generally less efficient, but four strokes are invariably heavier, and any lighter, tuned engine will be less efficient than a larger (read heavier) engine in a lower state of tune.

It's beginning to become clear why swash plates enabling variable pitch control are the favoured method of controlling thrust.

Re: Novel flying machines

Patrick, Sun May 04 2014, 04:09PM

Dr. Slack,

first, i menat to post this earlier the .91nx will produce 80% power for a little more than 1minute with 1 fl oz of nitro-alcohol.

Second, i do include ducts to break the tip vortex, and improve human safety. so turning the props isnt enough.

third, im getting my thrust stand up today or tomarrow so i can get us real numbers.

Patrick, Sun May 04 2014, 04:09PM

Dr. Slack,

first, i menat to post this earlier the .91nx will produce 80% power for a little more than 1minute with 1 fl oz of nitro-alcohol.

Second, i do include ducts to break the tip vortex, and improve human safety. so turning the props isnt enough.

third, im getting my thrust stand up today or tomarrow so i can get us real numbers.

Re: Novel flying machines

Carbon_Rod, Mon May 05 2014, 05:02AM

“Weed eater†2-cycle engines usually have a diaphragm carburetor.

And are therefore the easiest 1.3 hp motor you can buy used for under $50 that will work for flying.

Indeed, the drag losses from more rotors make them less efficient, but the lift is ultimately limited by the sectional area the blades cover. Thus 2 blades may generally improve flight times, but has the same limitation of the mass it can actually lift off the ground. Therefore a quad can lift slightly more than a tri-copter with the same diameter props, but a quad with 3 blade props will not necessarily improve lift depending on the machine.

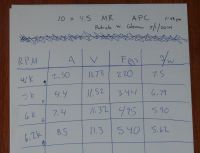

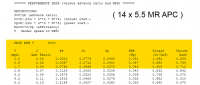

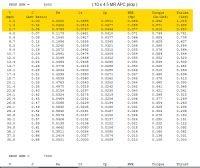

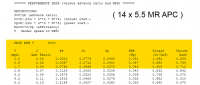

Typically we also buy the plastic 1045/1045R (10â€x4.5†Props) in bulk, as they work well for inexpensive quads. Note, while a $2k 1.5kg ATJ-120Ti RC turbine can produce over 12kg thrust, it is not really useful for VTOL craft.

Carbon_Rod, Mon May 05 2014, 05:02AM

“Weed eater†2-cycle engines usually have a diaphragm carburetor.

And are therefore the easiest 1.3 hp motor you can buy used for under $50 that will work for flying.

Indeed, the drag losses from more rotors make them less efficient, but the lift is ultimately limited by the sectional area the blades cover. Thus 2 blades may generally improve flight times, but has the same limitation of the mass it can actually lift off the ground. Therefore a quad can lift slightly more than a tri-copter with the same diameter props, but a quad with 3 blade props will not necessarily improve lift depending on the machine.

Typically we also buy the plastic 1045/1045R (10â€x4.5†Props) in bulk, as they work well for inexpensive quads. Note, while a $2k 1.5kg ATJ-120Ti RC turbine can produce over 12kg thrust, it is not really useful for VTOL craft.

Re: Novel flying machines

Patrick, Mon May 05 2014, 05:12AM

but carbon rod, those engines are enormous blocks of milled aluminum...

yeah the RC turbines are expensive. Ive crashed electrics many times, but recovered almost everything of value but the airframe. with jet turbines in a crash you tend to have kerosene fires that destroy everything as circuit boards seem to burn well above 1200F. (crashing into the dirt at 220mph contributes to the destruction too.)

and as with fuel cells they are crap for VTOL.

PICS!

Patrick, Mon May 05 2014, 05:12AM

but carbon rod, those engines are enormous blocks of milled aluminum...

yeah the RC turbines are expensive. Ive crashed electrics many times, but recovered almost everything of value but the airframe. with jet turbines in a crash you tend to have kerosene fires that destroy everything as circuit boards seem to burn well above 1200F. (crashing into the dirt at 220mph contributes to the destruction too.)

and as with fuel cells they are crap for VTOL.

PICS!

Re: Novel flying machines

Dr. Slack, Mon May 05 2014, 05:51AM

ooh, ouch, an ounce a minute? That's 2kg and hour, give or take. Which is not the order-of-magnitude better than small electric props I had hoped.

But maybe, if you use a 4 stroke, and use less power through lower pitch heli blades rather than power through a known flaky propulsion blade calculator ...

I was kind of assuming not to use ducts, to just let it all hang out and look more like a copter. A 30" duct would weigh a lot. However, the difference between accidentally flying too close to an object and nudging it with a duct, and nudging it with the tip of a 30" diameter heli rotor, would be spectacular.

Dr. Slack, Mon May 05 2014, 05:51AM

Patrick wrote ...

first, i menat to post this earlier the .91nx will produce 80% power for a little more than 1minute with 1 fl oz of nitro-alcohol.

first, i menat to post this earlier the .91nx will produce 80% power for a little more than 1minute with 1 fl oz of nitro-alcohol.

ooh, ouch, an ounce a minute? That's 2kg and hour, give or take. Which is not the order-of-magnitude better than small electric props I had hoped.

But maybe, if you use a 4 stroke, and use less power through lower pitch heli blades rather than power through a known flaky propulsion blade calculator ...

I was kind of assuming not to use ducts, to just let it all hang out and look more like a copter. A 30" duct would weigh a lot. However, the difference between accidentally flying too close to an object and nudging it with a duct, and nudging it with the tip of a 30" diameter heli rotor, would be spectacular.

Re: Novel flying machines

Patrick, Mon May 05 2014, 05:57AM

i came up with 1.8kg per hour. not great, so im thinking the variable collective pitch tri-prop maybe the next step/

my most recent machine (Gen 3), destroyed in scientific action. watch at least the last 14 seconds.

Dr. Slack and others,

would finding an effcient "power band" of RPM and torque and holding constant RPM while torque and power out vary be useful? (for a specific motor and prop.) In so using a variable pitch propeller. most of the power i think we lose is from rapid acceleration/decelerations from the PID loops. (steve connor and i discussed conservation of momentum in a related thread.) it just seems like at the least id gain faster response, with less overshoot, if not more lift for the same size battery.

i say this, because commercial companies seem to put a lot of thought into the drive train, but we home tinker'ers seem to just randomly pick a motor, then randomly pick a prop and throw it in the air, hoping for the best.

i also think:

a first step is power storage or conversion. (battery or chemistry)

a second step is coupling so as to be useful. (drive train ending with a prop)

Patrick, Mon May 05 2014, 05:57AM

i came up with 1.8kg per hour. not great, so im thinking the variable collective pitch tri-prop maybe the next step/

Dr. Slack wrote ...

However, the difference between accidentally flying too close to an object and nudging it with a duct, and nudging it with the tip of a 30" diameter heli rotor, would be spectacular.

I watched the following machine descend into the tree and it tumbled and threw blades like you wouldnt believe. However, the difference between accidentally flying too close to an object and nudging it with a duct, and nudging it with the tip of a 30" diameter heli rotor, would be spectacular.

my most recent machine (Gen 3), destroyed in scientific action. watch at least the last 14 seconds.

Dr. Slack and others,

would finding an effcient "power band" of RPM and torque and holding constant RPM while torque and power out vary be useful? (for a specific motor and prop.) In so using a variable pitch propeller. most of the power i think we lose is from rapid acceleration/decelerations from the PID loops. (steve connor and i discussed conservation of momentum in a related thread.) it just seems like at the least id gain faster response, with less overshoot, if not more lift for the same size battery.

i say this, because commercial companies seem to put a lot of thought into the drive train, but we home tinker'ers seem to just randomly pick a motor, then randomly pick a prop and throw it in the air, hoping for the best.

i also think:

a first step is power storage or conversion. (battery or chemistry)

a second step is coupling so as to be useful. (drive train ending with a prop)

Re: Novel flying machines

BigBad, Mon May 05 2014, 01:09PM

It might be theoretically a good idea to do a hybrid; you drive the motor with an electric motor, which spins the main rotors at virtually constant speed, and then have a gas turbine which has more power than you need to fly, and then there's a small battery to buffer it.

So the gas turbine would turn on and charge the battery, and then shut down and the vehicle would fly on the battery for a while, and then turn back on again.

The reason it might make sense is that the energy density of the fuel is so much higher than a lithium ion battery, and provided the gas turbine/generator isn't too heavy it will still weigh less.

BigBad, Mon May 05 2014, 01:09PM

It might be theoretically a good idea to do a hybrid; you drive the motor with an electric motor, which spins the main rotors at virtually constant speed, and then have a gas turbine which has more power than you need to fly, and then there's a small battery to buffer it.

So the gas turbine would turn on and charge the battery, and then shut down and the vehicle would fly on the battery for a while, and then turn back on again.

The reason it might make sense is that the energy density of the fuel is so much higher than a lithium ion battery, and provided the gas turbine/generator isn't too heavy it will still weigh less.

Re: Novel flying machines

Patrick, Mon May 05 2014, 08:34PM

This is worth researching, but if it requires 34 mosfets and diodes, and adds 200g to a 2kg machine were still screwed.

Patrick, Mon May 05 2014, 08:34PM

BigBad wrote ...

It might be theoretically a good idea to do a hybrid; you drive the motor with an electric motor, which spins the main rotors at virtually constant speed, and then have a gas turbine which has more power than you need to fly, and then there's a small battery to buffer it.

So the gas turbine would turn on and charge the battery, and then shut down and the vehicle would fly on the battery for a while, and then turn back on again.

The reason it might make sense is that the energy density of the fuel is so much higher than a lithium ion battery, and provided the gas turbine/generator isn't too heavy it will still weigh less.

It might be theoretically a good idea to do a hybrid; you drive the motor with an electric motor, which spins the main rotors at virtually constant speed, and then have a gas turbine which has more power than you need to fly, and then there's a small battery to buffer it.

So the gas turbine would turn on and charge the battery, and then shut down and the vehicle would fly on the battery for a while, and then turn back on again.

The reason it might make sense is that the energy density of the fuel is so much higher than a lithium ion battery, and provided the gas turbine/generator isn't too heavy it will still weigh less.

This is worth researching, but if it requires 34 mosfets and diodes, and adds 200g to a 2kg machine were still screwed.

Re: Novel flying machines

BigBad, Tue May 06 2014, 12:00PM

It's theoretically good, but I don't think it works nearly as well in practice. Gas turbines don't scale down very well, they lose efficiency and gain weight.

It might work better with a piston engine though.

BigBad, Tue May 06 2014, 12:00PM

It's theoretically good, but I don't think it works nearly as well in practice. Gas turbines don't scale down very well, they lose efficiency and gain weight.

It might work better with a piston engine though.

Re: Novel flying machines

Dr. Slack, Tue May 06 2014, 02:03PM

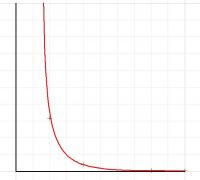

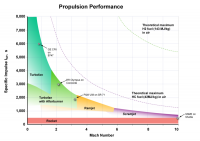

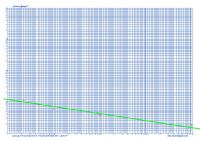

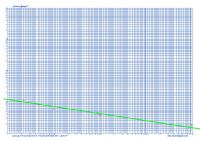

I'd be interested to see a bunch of graphs, if anybody has the bench facilities, or the data, of ...

a) the drive power requirements and weight of a system giving say 100N thrust, for where the lifting element is 3 or 4 ducted fans, or one open heli rotor

b) the weight of an energy store to rotary shaft system versus running time, for say 1kw shaft power, for energy stores of different battery chemistries, gas, nitro alcohol, and various 2 stroke, 4 stroke, series hybrid, in/outrunner motors. I would expect that for minutes, LiFePo would dominate, and for 10s of minutes, 4 stroke, but the graphs would tell.

Then with all of those curves, some usable machines ought to lie at the intersections of the highest curves.

Dr. Slack, Tue May 06 2014, 02:03PM

I'd be interested to see a bunch of graphs, if anybody has the bench facilities, or the data, of ...

a) the drive power requirements and weight of a system giving say 100N thrust, for where the lifting element is 3 or 4 ducted fans, or one open heli rotor

b) the weight of an energy store to rotary shaft system versus running time, for say 1kw shaft power, for energy stores of different battery chemistries, gas, nitro alcohol, and various 2 stroke, 4 stroke, series hybrid, in/outrunner motors. I would expect that for minutes, LiFePo would dominate, and for 10s of minutes, 4 stroke, but the graphs would tell.

Then with all of those curves, some usable machines ought to lie at the intersections of the highest curves.

Re: Novel flying machines

Steve Conner, Tue May 06 2014, 03:46PM

The beauty of the direct drive multirotor is its simplicity

Steve Conner, Tue May 06 2014, 03:46PM

The beauty of the direct drive multirotor is its simplicity

Re: Novel flying machines

Patrick, Fri May 09 2014, 07:53PM

whats he difference wih these types of motors: (pancake motor)

(pancake motor)

and the traditional motors like mine:

Patrick, Fri May 09 2014, 07:53PM

whats he difference wih these types of motors:

(pancake motor)

(pancake motor)and the traditional motors like mine:

Re: Novel flying machines

Steve Conner, Fri May 09 2014, 08:55PM

The pancake motor is larger diameter with lots of poles. That means it is designed for a higher torque and lower RPM than a traditional shaped motor. You would use it with a large diameter, slow turning prop to get lots of thrust at low speed, for efficient hovering.

Steve Conner, Fri May 09 2014, 08:55PM

The pancake motor is larger diameter with lots of poles. That means it is designed for a higher torque and lower RPM than a traditional shaped motor. You would use it with a large diameter, slow turning prop to get lots of thrust at low speed, for efficient hovering.

Re: Novel flying machines

Patrick, Fri May 09 2014, 09:29PM

this means im outside the effciancy curve im trying to aim for.

so now steve the question, harkening back to that previous thread from several months ago, i realise the calculus of mass acceleration and force trade offs, and the momentum conservation.

but now im using 430 watt motors, traditional can-type, brushless. so can i use a reducion gear train? ( and so approximate the pancake motor) or is this botching the non-ideal system even further?

the problem is the pancake form factor motors are heavy and poor in overall power output. so i see some users making a tricopter with 6 motors, 3 pairs contra-rotating, six props. All this just to get the total lift value up.

The problem is you need 6 ESCs, 6 props, 6 copper wire bundles, 6 motors, and the aditional garbage starts piling up.

Patrick, Fri May 09 2014, 09:29PM

Steve Conner wrote ...

The pancake motor is larger diameter with lots of poles. That means it is designed for a higher torque and lower RPM than a traditional shaped motor. You would use it with a large diameter, slow turning prop to get lots of thrust at low speed, for efficient hovering.

ive not heard it so concisely stated, though ive heard what you say Steve, in drips and drabs from other sources, but i always like more opinions to avoid marketing propaganda.The pancake motor is larger diameter with lots of poles. That means it is designed for a higher torque and lower RPM than a traditional shaped motor. You would use it with a large diameter, slow turning prop to get lots of thrust at low speed, for efficient hovering.

this means im outside the effciancy curve im trying to aim for.

so now steve the question, harkening back to that previous thread from several months ago, i realise the calculus of mass acceleration and force trade offs, and the momentum conservation.

but now im using 430 watt motors, traditional can-type, brushless. so can i use a reducion gear train? ( and so approximate the pancake motor) or is this botching the non-ideal system even further?

the problem is the pancake form factor motors are heavy and poor in overall power output. so i see some users making a tricopter with 6 motors, 3 pairs contra-rotating, six props. All this just to get the total lift value up.

The problem is you need 6 ESCs, 6 props, 6 copper wire bundles, 6 motors, and the aditional garbage starts piling up.

Re: Novel flying machines

Steve Conner, Fri May 09 2014, 09:53PM

Sounds like time for a dyno experiment comparing the efficiency of a pancake motor against a regular shaped motor with a reduction gear. The gear train also adds weight and wastes some power, so I wouldn't care to say which would come out on top.

Steve Conner, Fri May 09 2014, 09:53PM

Sounds like time for a dyno experiment comparing the efficiency of a pancake motor against a regular shaped motor with a reduction gear. The gear train also adds weight and wastes some power, so I wouldn't care to say which would come out on top.

Re: Novel flying machines

Patrick, Fri May 09 2014, 10:03PM

Should i make a water-brake like load for a dynometer?

Patrick, Fri May 09 2014, 10:03PM

Steve Conner wrote ...

Sounds like time for a dyno experiment comparing the efficiency of a pancake motor against a regular shaped motor with a reduction gear. The gear train also adds weight and wastes some power, so I wouldn't care to say which would come out on top.

ok, so im already building a thrust stand.Sounds like time for a dyno experiment comparing the efficiency of a pancake motor against a regular shaped motor with a reduction gear. The gear train also adds weight and wastes some power, so I wouldn't care to say which would come out on top.

Should i make a water-brake like load for a dynometer?

Re: Novel flying machines

Steve Conner, Fri May 09 2014, 10:20PM

Probably not worth the bother, you can compare motors by measuring thrust vs. electrical power input with the same prop.

Steve Conner, Fri May 09 2014, 10:20PM

Probably not worth the bother, you can compare motors by measuring thrust vs. electrical power input with the same prop.

Re: Novel flying machines

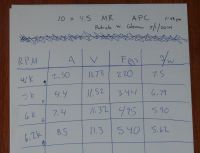

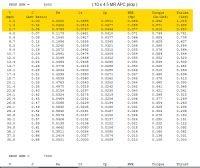

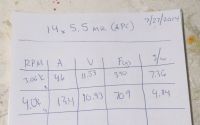

Patrick, Fri May 09 2014, 10:28PM

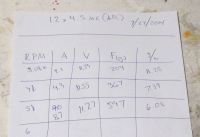

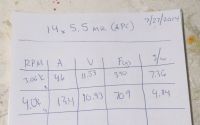

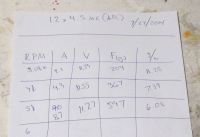

-Tacho

-Voltage

-Current

-Force/ thrust

-Temp via IR

-Anemometer

-White flour for thrust colunm pics.

VPP links:

Patrick, Fri May 09 2014, 10:28PM

Steve Conner wrote ...

Probably not worth the bother, you can compare motors by measuring thrust vs. electrical power input with the same prop.

excellent, ill make a really good thrust stand, then load it with instruments.Probably not worth the bother, you can compare motors by measuring thrust vs. electrical power input with the same prop.

-Tacho

-Voltage

-Current

-Force/ thrust

-Temp via IR

-Anemometer

-White flour for thrust colunm pics.

VPP links:

Re: Novel flying machines

Dr. Slack, Sat May 10 2014, 08:08AM

I'm really dubious about going doing the VPP route (which sounds rich as it's on the grounds of complexity, like my first post wasn't complex, but I' allowed to change my mind as I think through things).

A real benefit in flying machines is mechanical simplicity, less to buy, less to set up and keep in adjustment, less to replace when you crash. You know you have a good design when there's nothing left to take away.

VPP might have a small benefit over fixed pitch (like hand crafted assembler can usually be got to work faster than compiled code). But the weight of a machine will be more or less constant, or nearly so if it's consuming fuel, and as the thrust varies as the square of the prop speed, the best speed will vary over only a small range. The max efficiency band for motors, glow and electric, is not a spike but a bit of a pudding. You'd need more speed for a fast climb, and might run slightly less efficiently after dropping your Amazon parcel, but both of those are tractable costs of the simpler approach.

What I'm saying is, a VPP on a fast motor with a gearbox might be slightly more efficient than a 22 pole pancake on a fixed rotor. You can measure cost/benefit of $ and kg and minutes, but you can't measure the cost/benefit of complexity so easily. Does that mean you will ignore complexity as part of your thinking? A mantra oft repeated in the engineering circles I move in is 'a component that's not fitted is one that's guaranteed not to fail'. This affects the lifetime cost of the project, time to design, time to debug, warranty costs, unfortunately all very intangible.

Dr. Slack, Sat May 10 2014, 08:08AM

I'm really dubious about going doing the VPP route (which sounds rich as it's on the grounds of complexity, like my first post wasn't complex, but I' allowed to change my mind as I think through things).

A real benefit in flying machines is mechanical simplicity, less to buy, less to set up and keep in adjustment, less to replace when you crash. You know you have a good design when there's nothing left to take away.

VPP might have a small benefit over fixed pitch (like hand crafted assembler can usually be got to work faster than compiled code). But the weight of a machine will be more or less constant, or nearly so if it's consuming fuel, and as the thrust varies as the square of the prop speed, the best speed will vary over only a small range. The max efficiency band for motors, glow and electric, is not a spike but a bit of a pudding. You'd need more speed for a fast climb, and might run slightly less efficiently after dropping your Amazon parcel, but both of those are tractable costs of the simpler approach.

What I'm saying is, a VPP on a fast motor with a gearbox might be slightly more efficient than a 22 pole pancake on a fixed rotor. You can measure cost/benefit of $ and kg and minutes, but you can't measure the cost/benefit of complexity so easily. Does that mean you will ignore complexity as part of your thinking? A mantra oft repeated in the engineering circles I move in is 'a component that's not fitted is one that's guaranteed not to fail'. This affects the lifetime cost of the project, time to design, time to debug, warranty costs, unfortunately all very intangible.

Re: Novel flying machines

Ash Small, Sat May 10 2014, 11:21AM

The actual 'variable pitch prop' bit is easy to do. The 'swash plate' bit is the 'slightly tricky' bit. I've thought it through and you do need four servo's for a swashplate (possibly three, but tricky), you only need one for 'variable pitch'.

EDIT: I'll post a sketch or two if anyone's interested ( I'm away this weekend though)

Ash Small, Sat May 10 2014, 11:21AM

The actual 'variable pitch prop' bit is easy to do. The 'swash plate' bit is the 'slightly tricky' bit. I've thought it through and you do need four servo's for a swashplate (possibly three, but tricky), you only need one for 'variable pitch'.

EDIT: I'll post a sketch or two if anyone's interested ( I'm away this weekend though)

Re: Novel flying machines

Dr. Slack, Sat May 10 2014, 03:58PM

pic

That looks really cool, but at what cost?

Rotating the forward motors costs a control channel, the servo and rotator weight, and the fact that the prop pitch, size and power is a compromise between low pitch high power for hover and high pitch low power for forward flight.

What if he used two big low pitch fixed counter rotating lift props ahead of the wings, with the ESC programmed to stop them in the low drag fore-aft position, and a single fixed high pitch prop in the nose for forward flight? The servo channel becomes the forward channel, the weight of the rotator becomes the weight of the forward prop, so no significant change in weight or control channels. However, each prop is now more efficient as better matched to its job, and the mechanics are simpler with no rotator.

Now, additionally, what if control were completely split with forward flight motor and control surfaces on one radio, and vertical services on the other radio? Result total parallel get you home survivability so can land vertically, or like a plane, or glide in on receiver batteries only, if there's a malfunction with one set of controls. The cost at the vehicle being the weight of a second receiver and control battery. Is it worth the weight for a much more survivable plane?

Dr. Slack, Sat May 10 2014, 03:58PM

pic

That looks really cool, but at what cost?

Rotating the forward motors costs a control channel, the servo and rotator weight, and the fact that the prop pitch, size and power is a compromise between low pitch high power for hover and high pitch low power for forward flight.

What if he used two big low pitch fixed counter rotating lift props ahead of the wings, with the ESC programmed to stop them in the low drag fore-aft position, and a single fixed high pitch prop in the nose for forward flight? The servo channel becomes the forward channel, the weight of the rotator becomes the weight of the forward prop, so no significant change in weight or control channels. However, each prop is now more efficient as better matched to its job, and the mechanics are simpler with no rotator.

Now, additionally, what if control were completely split with forward flight motor and control surfaces on one radio, and vertical services on the other radio? Result total parallel get you home survivability so can land vertically, or like a plane, or glide in on receiver batteries only, if there's a malfunction with one set of controls. The cost at the vehicle being the weight of a second receiver and control battery. Is it worth the weight for a much more survivable plane?

Re: Novel flying machines

Patrick, Sat May 10 2014, 04:47PM

you make compelling points Dr. Slack. based on good engineering philosophy, rarely taught in college couses.

and ash small, id rather not have the swash plate at all, might as well go to a full heli then.

i want collective equivlent only, cyclic is uselessly complicated. (unless this tail rotor is what you menat) ->

ok then let me do some more thinking, and ty to get the machine flying today.

Patrick, Sat May 10 2014, 04:47PM

you make compelling points Dr. Slack. based on good engineering philosophy, rarely taught in college couses.

and ash small, id rather not have the swash plate at all, might as well go to a full heli then.

i want collective equivlent only, cyclic is uselessly complicated. (unless this tail rotor is what you menat) ->

ok then let me do some more thinking, and ty to get the machine flying today.

Re: Novel flying machines

Ash Small, Sun May 11 2014, 04:57PM

I don't agree. It can be accomplished easily with four servo's. The only other thing required over 'normal' variable pitch is a spherical bearing, which isn't subjected to rotational motion (EDIT: there is an element of rotational motion, depending on 'cyclical' stuff, but I'm sure this can be dealt with) and so can therefore be quite simple. You could either adapt something like a self-aligning bearing or get something machined out of nylon 66, or similar. I'd get this machined with some form of spline on the inside so it will slide on the prop shaft thus serving the variable pitch function at the same time. The only difference between the two systems is one extra spherical bearing and three servos, but they can each be much smaller than the single one required for VPP as they share the load.

EDIT: You still need a couple of taper-roller bearings, or something similar, (along with the blade carriers and pushrods) but you need all this for VPP anyway, unless I'm missing something.

EDIT: You need a bit of extra software too, but software doesn't weigh much

Ash Small, Sun May 11 2014, 04:57PM

Patrick wrote ...

cyclic is uselessly complicated.

cyclic is uselessly complicated.

I don't agree. It can be accomplished easily with four servo's. The only other thing required over 'normal' variable pitch is a spherical bearing, which isn't subjected to rotational motion (EDIT: there is an element of rotational motion, depending on 'cyclical' stuff, but I'm sure this can be dealt with) and so can therefore be quite simple. You could either adapt something like a self-aligning bearing or get something machined out of nylon 66, or similar. I'd get this machined with some form of spline on the inside so it will slide on the prop shaft thus serving the variable pitch function at the same time. The only difference between the two systems is one extra spherical bearing and three servos, but they can each be much smaller than the single one required for VPP as they share the load.

EDIT: You still need a couple of taper-roller bearings, or something similar, (along with the blade carriers and pushrods) but you need all this for VPP anyway, unless I'm missing something.

EDIT: You need a bit of extra software too, but software doesn't weigh much

Re: Novel flying machines

Chip Fixes, Mon May 12 2014, 05:38AM

Just saw this on Hack A Day today:

Although, besides being able to hover for 19 hours, it really doesn't seem that novel.

Chip Fixes, Mon May 12 2014, 05:38AM

Just saw this on Hack A Day today:

Although, besides being able to hover for 19 hours, it really doesn't seem that novel.

Re: Novel flying machines

BigBad, Tue May 13 2014, 06:55PM

I think maybe VPPs are particularly good for variable mass vehicles.

For battery powered vehicles, you just optimise the prop for one speed (the one needed to hover), and you can deal with the differences in thrust by varying the speed somewhat, hopefully not running it too much off the optimum speed.

BigBad, Tue May 13 2014, 06:55PM

I think maybe VPPs are particularly good for variable mass vehicles.

For battery powered vehicles, you just optimise the prop for one speed (the one needed to hover), and you can deal with the differences in thrust by varying the speed somewhat, hopefully not running it too much off the optimum speed.

Re: Novel flying machines

Ash Small, Tue May 13 2014, 07:08PM

i agree, but once you start considering IC engines I think you have to consider VPP and swashplate, as swashplate doesn't contribute much mass compared to VPP (and is hardly any more complicated to implement). I'm assuming that a large percentage of 'take off' weight will be fuel, and most of the fuel will be consumed during flight, I think this is where the advantages of VPP really lie. Also, I think the torque characteristics of IC compared to electric would also favour this approach. I can't really see much advantage of using VPP with electric motors if the payload is reasonably constant.

EDIT: Although I can see advantages of using swashplate with electric, as it means you only need one motor, assuming the tail rotor is driven by gears, and one large prop is more efficient than several smaller ones.

EDIT: I think you'd only need VPP for the tail rotor. I can't see any advantage of using a swashplate there.

Ash Small, Tue May 13 2014, 07:08PM

BigBad wrote ...

I think maybe VPPs are particularly good for variable mass vehicles.

For battery powered vehicles, you just optimise the prop for one speed (the one needed to hover), and you can deal with the differences in thrust by varying the speed somewhat, hopefully not running it too much off the optimum speed.

I think maybe VPPs are particularly good for variable mass vehicles.

For battery powered vehicles, you just optimise the prop for one speed (the one needed to hover), and you can deal with the differences in thrust by varying the speed somewhat, hopefully not running it too much off the optimum speed.

i agree, but once you start considering IC engines I think you have to consider VPP and swashplate, as swashplate doesn't contribute much mass compared to VPP (and is hardly any more complicated to implement). I'm assuming that a large percentage of 'take off' weight will be fuel, and most of the fuel will be consumed during flight, I think this is where the advantages of VPP really lie. Also, I think the torque characteristics of IC compared to electric would also favour this approach. I can't really see much advantage of using VPP with electric motors if the payload is reasonably constant.

EDIT: Although I can see advantages of using swashplate with electric, as it means you only need one motor, assuming the tail rotor is driven by gears, and one large prop is more efficient than several smaller ones.

EDIT: I think you'd only need VPP for the tail rotor. I can't see any advantage of using a swashplate there.

Re: Novel flying machines

Patrick, Wed May 14 2014, 12:47AM

i shoud have said this sooner, but the real problem with a traditional heli swashplate is that when you have a prop strike, youll bend all theose precision pieces. And if i want a commercial product to eventually come of this, ill need reliability and repairabilty.

Patrick, Wed May 14 2014, 12:47AM

i shoud have said this sooner, but the real problem with a traditional heli swashplate is that when you have a prop strike, youll bend all theose precision pieces. And if i want a commercial product to eventually come of this, ill need reliability and repairabilty.

Re: Novel flying machines

Steve Conner, Wed May 14 2014, 09:30AM

Hence see Dr. Slack's earlier comments about complexity.

My favourite design right now is the RCExplorer tricopter. The frame is a couple of softwood battens from the hardware store, and the motors are held on with cable ties so they will come loose in a crash before the shaft bends. I expect the average crash would cost about $7 and take 15 minutes to fix.

Steve Conner, Wed May 14 2014, 09:30AM

Hence see Dr. Slack's earlier comments about complexity.

My favourite design right now is the RCExplorer tricopter. The frame is a couple of softwood battens from the hardware store, and the motors are held on with cable ties so they will come loose in a crash before the shaft bends. I expect the average crash would cost about $7 and take 15 minutes to fix.

Re: Novel flying machines

BigBad, Wed May 14 2014, 02:19PM

If we're talking mechanical simplicity I quite like the sycamore seed type design where you spin the whole vehicle as a wing and then control it exclusively on cyclic and thrust. Maybe use an airjet at the tip and a compressor in the central hub. You could probably synchronise the rotation with a magnetic compass.

If you put a camera on it, you get 360 degree vision for free.

BigBad, Wed May 14 2014, 02:19PM

If we're talking mechanical simplicity I quite like the sycamore seed type design where you spin the whole vehicle as a wing and then control it exclusively on cyclic and thrust. Maybe use an airjet at the tip and a compressor in the central hub. You could probably synchronise the rotation with a magnetic compass.

If you put a camera on it, you get 360 degree vision for free.

Re: Novel flying machines

Patrick, Wed May 14 2014, 03:19PM

Patrick, Wed May 14 2014, 03:19PM

BigBad wrote ...

If we're talking mechanical simplicity I quite like the sycamore seed type design where you spin the whole vehicle as a wing and then control it exclusively on cyclic and thrust. Maybe use an airjet at the tip and a compressor in the central hub. You could probably synchronise the rotation with a magnetic compass.

If you put a camera on it, you get 360 degree vision for free.

i saw the embry riddel team demonstrate this at our academic competition in north dakota, it was really cool.If we're talking mechanical simplicity I quite like the sycamore seed type design where you spin the whole vehicle as a wing and then control it exclusively on cyclic and thrust. Maybe use an airjet at the tip and a compressor in the central hub. You could probably synchronise the rotation with a magnetic compass.

If you put a camera on it, you get 360 degree vision for free.

Re: Novel flying machines

Ash Small, Tue May 20 2014, 11:08PM

Ok, this is a hypothesis, and is not proven.

Following on from my comments in Dr Spark's 'big bird' thread, Here is a 'concept heptacopter'.

The image represents the ducts and framework. The props are mounted centrally in the ducts. I think it's easy to see that the central propeller doesn't suffer from the same peripheral losses that a single prop would experience, hence greatly improving efficiency. The efficiency of the surrounding props is also increased.

Assuning 13.5 inch props, length is around one metre.

Efficiency could be further increased by adding another six props, increasing length to around 1.5M, but I'm not sure how much this would weigh. There are regulations applying to these things.

I don't know if other factors are involved, most hexacopters have their props placed far apart. This improves manouverability, but is this at the cost of efficiency (read 'flight time') or are there other factors I've not considered?

EDIT: I calculate the rduction in peripheral losses with the above design to be ~43%, compared to a design with the rotors spaced further apart.

Ash Small, Tue May 20 2014, 11:08PM

Ok, this is a hypothesis, and is not proven.

Following on from my comments in Dr Spark's 'big bird' thread, Here is a 'concept heptacopter'.

The image represents the ducts and framework. The props are mounted centrally in the ducts. I think it's easy to see that the central propeller doesn't suffer from the same peripheral losses that a single prop would experience, hence greatly improving efficiency. The efficiency of the surrounding props is also increased.

Assuning 13.5 inch props, length is around one metre.

Efficiency could be further increased by adding another six props, increasing length to around 1.5M, but I'm not sure how much this would weigh. There are regulations applying to these things.

I don't know if other factors are involved, most hexacopters have their props placed far apart. This improves manouverability, but is this at the cost of efficiency (read 'flight time') or are there other factors I've not considered?

EDIT: I calculate the rduction in peripheral losses with the above design to be ~43%, compared to a design with the rotors spaced further apart.

Re: Novel flying machines

Carbon_Rod, Wed May 21 2014, 04:42PM

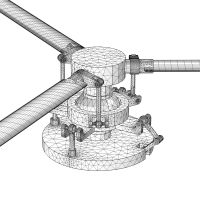

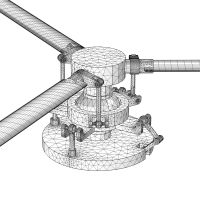

For those interested in a variable pitch aerial quad:

kit $800:

These are not a complicated build project.

Carbon_Rod, Wed May 21 2014, 04:42PM

For those interested in a variable pitch aerial quad:

kit $800:

These are not a complicated build project.

Re: Novel flying machines

Ash Small, Wed May 21 2014, 05:39PM

Now I'd argue that a single rotor craft with swash plate is simpler than this quad. You do need four servos for a swashplate, but he has four on this quad anyway.

The efficiency gained by using a single rotor and swashplate would be considerable in this instance.

EDIT: you could use a similar belt drive system as used here to drive the tail rotor, though, and you will need a fifth servo for the variable pitch tail rotor.

You could also use the system depected here in the 'concept heptacopter' design I posted above, with a single motor and belt drive, but you'd need a separate servo for each prop.

Ash Small, Wed May 21 2014, 05:39PM

Carbon_Rod wrote ...

For those interested in a variable pitch aerial quad:

kit $800:

These are not a complicated build project.

For those interested in a variable pitch aerial quad:

kit $800:

These are not a complicated build project.

Now I'd argue that a single rotor craft with swash plate is simpler than this quad. You do need four servos for a swashplate, but he has four on this quad anyway.

The efficiency gained by using a single rotor and swashplate would be considerable in this instance.

EDIT: you could use a similar belt drive system as used here to drive the tail rotor, though, and you will need a fifth servo for the variable pitch tail rotor.