Spark Discharge Anodizing, PEO, MAO, Keronite. Resources and Questions inside.

Storken, Wed Apr 23 2014, 04:19PMPlasma Electrolytic Oxide (PEO), Microarc (MAO), Keronite and Spark Discharge Anodizing all are names of the same process.

First, some videos to spark your interest.

Sites with info:

Cambridge PEO resource page.

Keronite titanium PP-slides. Nice introduction to the process. Explains how the ceramic is formed.

Keronite homepage. Applications etc. "Advertizing"-vibe. Does not go in-depth, "Contact us and we'll do it".

Lighter Bikes, one of the Keronite application ads.

Wikipedia: Plasma Electolytic Oxide. Good introduction.

Plasma Electrolytic Oxidation of Valve Metals. A good overview of some of the techniques used.

I would like to read more about this technology, I'm looking for a suitable book now. I want to use this technology to prepare (electically isolate) heatsinks for power transistors.

I will build a full-bridge power supply (bipolar capable) and a simple spectrum analyzer. The latter one to quantify the temperature of the sparks - a vital process parameter.

Any hints and tips, other experiences or similar, are warmly welcome :)

Re: Spark Discharge Anodizing, PEO, MAO, Keronite. Resources and Questions inside.

Sulaiman, Wed Apr 23 2014, 05:25PM

nice videos

I doubt that a book will help compared to internet resources.

Often the most useful resources are manufacturers data, instructions, application notes etc.

as they want their customers to succed.

If I understand correctly,

a porous layer will be formed which would not guarantee electrical isolation if moisture is present

so use as insulation for heatsinks may not be reliable

especially if the protective layer is scratched during installation.

If you watch the second video,

even after the protective layer has formed small nebulous discharges can still be seen

which implies to me that the protective layer is not ideal.

Sulaiman, Wed Apr 23 2014, 05:25PM

nice videos

I doubt that a book will help compared to internet resources.

Often the most useful resources are manufacturers data, instructions, application notes etc.

as they want their customers to succed.

If I understand correctly,

a porous layer will be formed which would not guarantee electrical isolation if moisture is present

so use as insulation for heatsinks may not be reliable

especially if the protective layer is scratched during installation.

If you watch the second video,

even after the protective layer has formed small nebulous discharges can still be seen

which implies to me that the protective layer is not ideal.

Re: Spark Discharge Anodizing, PEO, MAO, Keronite. Resources and Questions inside.

Proud Mary, Wed Apr 23 2014, 07:33PM

Google variations around these three searches "self-organized porous alumina nanoholes array" "anodic porous alumina" "alumina nanoholes"

You can even put a carbon nanotube inside an alumina nanohole if you know how.

Proud Mary, Wed Apr 23 2014, 07:33PM

Google variations around these three searches "self-organized porous alumina nanoholes array" "anodic porous alumina" "alumina nanoholes"

You can even put a carbon nanotube inside an alumina nanohole if you know how.

Re: Spark Discharge Anodizing, PEO, MAO, Keronite. Resources and Questions inside.

Ash Small, Wed Apr 23 2014, 07:52PM

There are also the old 'wet chemistry' anodizing methods as well, some of which can build up quite thick layers of oxide. These are generally porous as well, allowing them to hold a 'dye'. I just mention this as there 'may' be alternatives to 'plasma processing' that might achieve similar results.

Ash Small, Wed Apr 23 2014, 07:52PM

There are also the old 'wet chemistry' anodizing methods as well, some of which can build up quite thick layers of oxide. These are generally porous as well, allowing them to hold a 'dye'. I just mention this as there 'may' be alternatives to 'plasma processing' that might achieve similar results.

Re: Spark Discharge Anodizing, PEO, MAO, Keronite. Resources and Questions inside.

Storken, Thu Apr 24 2014, 07:21AM

@Sulaiman

I continued the search for good internet resources, found one more.

Applications for PEO, by naain

More on PEO technology, by naain

Still, process parameters are not discussed wrt heatsinks. Same as Keronite. They know how to protect and profit from their immaterial findings.

As the surface is very hard (from 1000 HV to 2000 HV), I don't think scratching is a problem during installation. Post installation ohmic test will quickly tell if the insulation is good or not. I've dabbed some with anodizing, some heatsinks are perfect with GOhms of resistance, others come in at low kOhms.

@Ash. The main pro with this method is the lack of sulfuric acid. It corrodes everything around it. But yes, hard anodizing are absolutely suitable for heatsink insulation.

Storken, Thu Apr 24 2014, 07:21AM

@Sulaiman

I continued the search for good internet resources, found one more.

Applications for PEO, by naain

More on PEO technology, by naain

Still, process parameters are not discussed wrt heatsinks. Same as Keronite. They know how to protect and profit from their immaterial findings.

As the surface is very hard (from 1000 HV to 2000 HV), I don't think scratching is a problem during installation. Post installation ohmic test will quickly tell if the insulation is good or not. I've dabbed some with anodizing, some heatsinks are perfect with GOhms of resistance, others come in at low kOhms.

@Ash. The main pro with this method is the lack of sulfuric acid. It corrodes everything around it. But yes, hard anodizing are absolutely suitable for heatsink insulation.

Re: Spark Discharge Anodizing, PEO, MAO, Keronite. Resources and Questions inside.

Ash Small, Thu Apr 24 2014, 07:42AM

It's a while since I looked into this myself, that's why I've not posted any details, but I do remember that there are loads of different 'recipes', some just use sodium bicarbonate, if I remember correctly (although this doesn't give 'hard' anodizing). I imagine there will be some 'hard anodizing' recipes that don't use sulphuric, although I'm not certain, I'd have to refresh my memory.

EDIT: just looked on Wikipedia, and it says anodizing with borate or tartrate produces a non-porous coating:

"Borate and tartrate baths

Anodizing can also be performed in borate or tartrate baths in which aluminium oxide is insoluble. In these processes, the coating growth stops when the part is fully covered, and the thickness is linearly related to the voltage applied. These coatings are free of pores, relative to the sulfuric and chromic acid processes. This type of coating is widely used to make electrolytic capacitors, because the thin aluminium films (typically less than 0.5 μm) would risk being pierced by acidic processes."

If it's used for capacitors it 'may' be suitable for your application, although it doesn't say how hard it is, but thickness is voltage dependant.

I'm currently reading through this:

]taleb_kaled_h_x.pdf[/file]

Ash Small, Thu Apr 24 2014, 07:42AM

Storken wrote ...

@Ash. The main pro with this method is the lack of sulfuric acid. It corrodes everything around it. But yes, hard anodizing are absolutely suitable for heatsink insulation.

@Ash. The main pro with this method is the lack of sulfuric acid. It corrodes everything around it. But yes, hard anodizing are absolutely suitable for heatsink insulation.

It's a while since I looked into this myself, that's why I've not posted any details, but I do remember that there are loads of different 'recipes', some just use sodium bicarbonate, if I remember correctly (although this doesn't give 'hard' anodizing). I imagine there will be some 'hard anodizing' recipes that don't use sulphuric, although I'm not certain, I'd have to refresh my memory.

EDIT: just looked on Wikipedia, and it says anodizing with borate or tartrate produces a non-porous coating:

"Borate and tartrate baths

Anodizing can also be performed in borate or tartrate baths in which aluminium oxide is insoluble. In these processes, the coating growth stops when the part is fully covered, and the thickness is linearly related to the voltage applied. These coatings are free of pores, relative to the sulfuric and chromic acid processes. This type of coating is widely used to make electrolytic capacitors, because the thin aluminium films (typically less than 0.5 μm) would risk being pierced by acidic processes."

If it's used for capacitors it 'may' be suitable for your application, although it doesn't say how hard it is, but thickness is voltage dependant.

I'm currently reading through this:

]taleb_kaled_h_x.pdf[/file]

Re: Spark Discharge Anodizing, PEO, MAO, Keronite. Resources and Questions inside.

Conundrum, Thu Apr 24 2014, 05:39PM

Interesting, thanks for sharing!

-A

Conundrum Drive page:-

Conundrum, Thu Apr 24 2014, 05:39PM

Interesting, thanks for sharing!

-A

Conundrum Drive page:-

Re: Spark Discharge Anodizing, PEO, MAO, Keronite. Resources and Questions inside.

Patrick, Thu Apr 24 2014, 07:26PM

Is any of this easier and cheaper than using the normal stick'em thermal pads. Or mica?

Patrick, Thu Apr 24 2014, 07:26PM

Is any of this easier and cheaper than using the normal stick'em thermal pads. Or mica?

Re: Spark Discharge Anodizing, PEO, MAO, Keronite. Resources and Questions inside.

Ash Small, Thu Apr 24 2014, 07:56PM

I'm guessing the idea is that it should conduct more heat than thermal pads, but I'm only guessing here. Whether or not it works out any cheaper would probably depend on quantity, but I'm only guessing again. The process I've linked to and which is described in the pdf I posted doesn't look that difficult, although preparation and cleanliness, as with most electrochemical processes is vital.

I'm interested enough to try this myself, pharmaceutical grade boric acid and borax are easy enough to get hold of.

I've not looked to deeply into what's involved in the plasma process that Storken posted, though.

Ash Small, Thu Apr 24 2014, 07:56PM

Patrick wrote ...

Is any of this easier and cheaper than using the normal stick'em thermal pads. Or mica?

Is any of this easier and cheaper than using the normal stick'em thermal pads. Or mica?

I'm guessing the idea is that it should conduct more heat than thermal pads, but I'm only guessing here. Whether or not it works out any cheaper would probably depend on quantity, but I'm only guessing again. The process I've linked to and which is described in the pdf I posted doesn't look that difficult, although preparation and cleanliness, as with most electrochemical processes is vital.

I'm interested enough to try this myself, pharmaceutical grade boric acid and borax are easy enough to get hold of.

I've not looked to deeply into what's involved in the plasma process that Storken posted, though.

Re: Spark Discharge Anodizing, PEO, MAO, Keronite. Resources and Questions inside.

Patrick, Thu Apr 24 2014, 09:15PM

im going out on a limb here, but going to say that spark/plasma forming l must be more difficult than electrolytic deposition (like capacitor plates, as others mentioned.) and more difficult to quality control.

just my opinion, but the aqueous-electrolytic method looks easier and more reliable. and youll still get to choose the shape of the deposition area.

Patrick, Thu Apr 24 2014, 09:15PM

im going out on a limb here, but going to say that spark/plasma forming l must be more difficult than electrolytic deposition (like capacitor plates, as others mentioned.) and more difficult to quality control.

just my opinion, but the aqueous-electrolytic method looks easier and more reliable. and youll still get to choose the shape of the deposition area.

Re: Spark Discharge Anodizing, PEO, MAO, Keronite. Resources and Questions inside.

Ash Small, Thu Apr 24 2014, 10:11PM

I've only read the wikipedia page on the plasma process, but it looks like it is still a 'wet chemistry' process that uses a higher voltage (sparks are involved). It produces a thicker coating which isn't porous although I suspect that a thinner layer may conduct heat better. The boric acid process produces a much thinner layer which is also not porous, although I don't know how hardness compares. Personally, I'm tempted to try the boric acid process myself.

Wikipedia article on the plasma process here:

Boric acid process is described in the pdf I posted earlier.

EDIT: I will read through the links that Storken provided, but I'll wait until I'm sober

Ash Small, Thu Apr 24 2014, 10:11PM

I've only read the wikipedia page on the plasma process, but it looks like it is still a 'wet chemistry' process that uses a higher voltage (sparks are involved). It produces a thicker coating which isn't porous although I suspect that a thinner layer may conduct heat better. The boric acid process produces a much thinner layer which is also not porous, although I don't know how hardness compares. Personally, I'm tempted to try the boric acid process myself.

Wikipedia article on the plasma process here:

Boric acid process is described in the pdf I posted earlier.

EDIT: I will read through the links that Storken provided, but I'll wait until I'm sober

Re: Spark Discharge Anodizing, PEO, MAO, Keronite. Resources and Questions inside.

Patrick, Thu Apr 24 2014, 10:48PM

if it lays down a non-prous layer, will he know it doesnt carry micro cracks across the whole surface area?

Patrick, Thu Apr 24 2014, 10:48PM

if it lays down a non-prous layer, will he know it doesnt carry micro cracks across the whole surface area?

Re: Spark Discharge Anodizing, PEO, MAO, Keronite. Resources and Questions inside.

Dago, Fri Apr 25 2014, 06:51AM

Seems like an interesting coating! Might be fun to try on aluminum. Would just need to figure out the electrolyte.

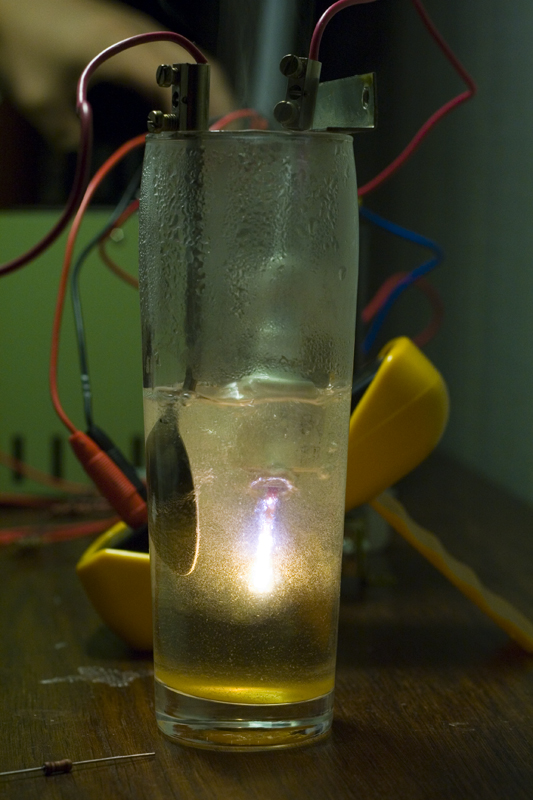

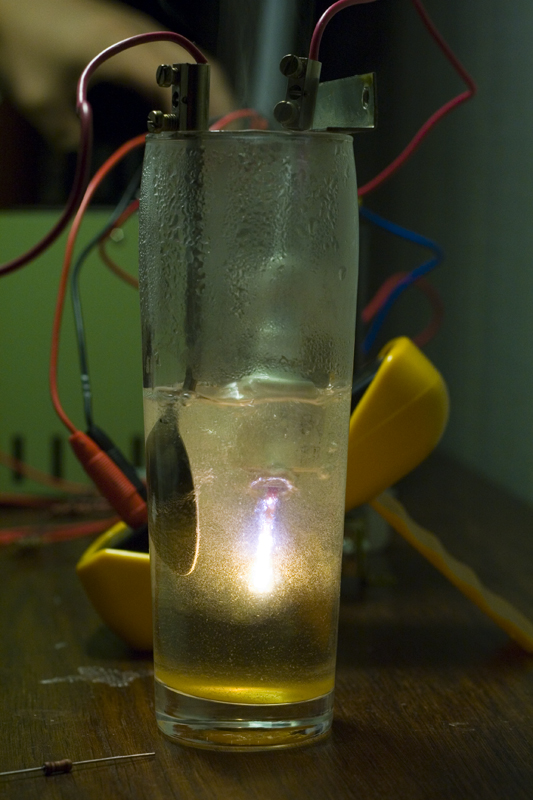

Kinda related, here is a picture of mine with a tungsten electrode in water:

Dago, Fri Apr 25 2014, 06:51AM

Seems like an interesting coating! Might be fun to try on aluminum. Would just need to figure out the electrolyte.

Kinda related, here is a picture of mine with a tungsten electrode in water:

Re: Spark Discharge Anodizing, PEO, MAO, Keronite. Resources and Questions inside.

Ash Small, Fri Apr 25 2014, 09:49AM

"The part to be coated is immersed in a bath of electrolyte which usually consists of a dilute alkaline solution such as KOH. It is electrically connected, so as to become one of the electrodes in the electrochemical cell, with the other "counter-electrode" typically being made from an inert material such as stainless steel, and often consisting of the wall of the bath itself.

Potentials of over 200 V are applied between these two electrodes. These may be continuous or pulsed direct current (DC) (in which case the part is simply an anode in DC operation), or alternating pulses (alternating current or "pulsed bi-polar" operation) where the stainless steel counter electrode might just be earthed."

From the Wikipedia link I posted above, although as I mentioned earlier, a thinner coating like the one using borate as described in the pdf above 'may' conduct heat better, although whether it's as hard a coating as the plasma process provides is probably unlikely. I'm planning on reading up some more on this later.

EDIT: this pdf linked to by Storken has a few 'recipes' in it:

]41307.pdf[/file]

Ash Small, Fri Apr 25 2014, 09:49AM

Dago wrote ...

Would just need to figure out the electrolyte.

Would just need to figure out the electrolyte.

"The part to be coated is immersed in a bath of electrolyte which usually consists of a dilute alkaline solution such as KOH. It is electrically connected, so as to become one of the electrodes in the electrochemical cell, with the other "counter-electrode" typically being made from an inert material such as stainless steel, and often consisting of the wall of the bath itself.

Potentials of over 200 V are applied between these two electrodes. These may be continuous or pulsed direct current (DC) (in which case the part is simply an anode in DC operation), or alternating pulses (alternating current or "pulsed bi-polar" operation) where the stainless steel counter electrode might just be earthed."

From the Wikipedia link I posted above, although as I mentioned earlier, a thinner coating like the one using borate as described in the pdf above 'may' conduct heat better, although whether it's as hard a coating as the plasma process provides is probably unlikely. I'm planning on reading up some more on this later.

EDIT: this pdf linked to by Storken has a few 'recipes' in it:

]41307.pdf[/file]

Print this page