Small CNC Mill - mechanics finished

Dr. H., Sat Nov 23 2013, 07:37AMGood day guys

It's been a while since I've posted something (or done anything interesting in that matter) but I finally found some time to start a new project. It is a small "precision" cnc mill. Some of you might remember this thread:

The old machine is big , pain in the ass to move and not really worth doing small stuff (not very precise).. but has been serving faithfully

. So it was finally a time to start on that small "tabletop" machine I've been dreaming about. This time it will use ball lead screws and better linear guides. The thing will be driven with servo motors (X, Y) and a stepper for the Z. Here is a crappy picture of most of the linear components:

. So it was finally a time to start on that small "tabletop" machine I've been dreaming about. This time it will use ball lead screws and better linear guides. The thing will be driven with servo motors (X, Y) and a stepper for the Z. Here is a crappy picture of most of the linear components:

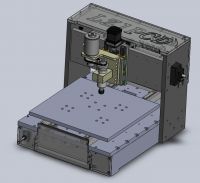

After about two months of fiddling here is the "final" 3D assembly of the CNC:

Re: Small CNC Mill - mechanics finished

Dr. H., Tue Nov 26 2013, 09:12PM

Hi guys

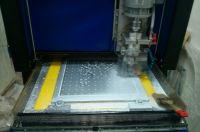

I've started cutting some parts. As the big machine hasn't been running for quite a while I've decided to start with something small. So here are the first plexi parts

Dr. H., Tue Nov 26 2013, 09:12PM

Hi guys

I've started cutting some parts. As the big machine hasn't been running for quite a while I've decided to start with something small. So here are the first plexi parts

Re: Small CNC Mill - mechanics finished

Dr. H., Wed Nov 27 2013, 06:16PM

Hi guys

few more parts for the mill. Also the power supply arrived today. It is a 24V 20A Mean Well SMPS. Of course the first thing to do was to take it apart

Cheers

Dr. H., Wed Nov 27 2013, 06:16PM

Hi guys

few more parts for the mill. Also the power supply arrived today. It is a 24V 20A Mean Well SMPS. Of course the first thing to do was to take it apart

Cheers

Re: Small CNC Mill - mechanics finished

Patrick, Wed Nov 27 2013, 11:25PM

How much did that SMPS cost ? Where did you get it?

I have my bridge frame mill pics somewhere here on the forum...

Patrick, Wed Nov 27 2013, 11:25PM

How much did that SMPS cost ? Where did you get it?

I have my bridge frame mill pics somewhere here on the forum...

Re: Small CNC Mill - mechanics finished

Dr. H., Sat Nov 30 2013, 08:16PM

Hi guys. Few new parts cut today.

Hi Patrick - the power supply is from a local dealer of Mean Well. It costs about 180$ including taxes.

Cheers

Dr. H., Sat Nov 30 2013, 08:16PM

Hi guys. Few new parts cut today.

Hi Patrick - the power supply is from a local dealer of Mean Well. It costs about 180$ including taxes.

Cheers

Re: Small CNC Mill - mechanics finished

Dr. H., Sun Dec 01 2013, 06:27PM

Hi guys - some new parts today - motor couplers and small shaft holders. I've cut them from ertacetal - first time working with this material and it is great - really easy to cut and in the meantime strong and a bit flexible.

Cheers

Dr. H., Sun Dec 01 2013, 06:27PM

Hi guys - some new parts today - motor couplers and small shaft holders. I've cut them from ertacetal - first time working with this material and it is great - really easy to cut and in the meantime strong and a bit flexible.

Cheers

Re: Small CNC Mill - mechanics finished

woodchuck, Mon Dec 02 2013, 04:35AM

Great looking parts! Who needs a 3D printer if you can crank them out like that!?

woodchuck, Mon Dec 02 2013, 04:35AM

Great looking parts! Who needs a 3D printer if you can crank them out like that!?

Re: Small CNC Mill - mechanics finished

Dr. H., Wed Dec 04 2013, 08:22PM

Hi guys

few more plexy parts. With those most of the "soft" parts are done. Time to start cutting that aluminum. About 3D printing - I've seen a professional 3D printer and the stuff produced by it - it can do amazing stuff

Dr. H., Wed Dec 04 2013, 08:22PM

Hi guys

few more plexy parts. With those most of the "soft" parts are done. Time to start cutting that aluminum. About 3D printing - I've seen a professional 3D printer and the stuff produced by it - it can do amazing stuff

Re: Small CNC Mill - mechanics finished

dingo27, Mon Dec 09 2013, 12:28PM

Interesting to see, maybe i will look for some ideas in my projects :)

It looks quite easy to build if you can produce your own parts

I keep my fingers crossed, keep up with good work

dingo27, Mon Dec 09 2013, 12:28PM

Interesting to see, maybe i will look for some ideas in my projects :)

It looks quite easy to build if you can produce your own parts

I keep my fingers crossed, keep up with good work

Re: Small CNC Mill - mechanics finished

Carbon_Rod, Tue Dec 10 2013, 01:40AM

@Dr. H.

The mini mill we have is based on a rebuilt Taig, and runs off the same PC power supply for LinuxCNC (EMC). For a little XYZ system like yours, HeeksCNC would handle most of the gcode CAM for you..

We also have a Prusa calibrated for ABS or PLA, and it does parts even the 5-axis would find impossible. For example, we've printed the Tesla valve-conduit as a single piece for fun. Note too, there are people who simply added extruder chucks (4th-axis A drive) to their mills, and indeed Slic3r will export gcode for EMC in “general†settings....

Some people 3D print in PLA, as the starch based plastic burns out of a sand mold. Then take the rough cast shapes to mill to tolerances on the CNC. However, uttering tolerances in the same breath as plastic or aluminum mills is a bit of a joke.

I have to try 3D printing a solder mask next....

Rod

Carbon_Rod, Tue Dec 10 2013, 01:40AM

@Dr. H.

The mini mill we have is based on a rebuilt Taig, and runs off the same PC power supply for LinuxCNC (EMC). For a little XYZ system like yours, HeeksCNC would handle most of the gcode CAM for you..

We also have a Prusa calibrated for ABS or PLA, and it does parts even the 5-axis would find impossible. For example, we've printed the Tesla valve-conduit as a single piece for fun. Note too, there are people who simply added extruder chucks (4th-axis A drive) to their mills, and indeed Slic3r will export gcode for EMC in “general†settings....

Some people 3D print in PLA, as the starch based plastic burns out of a sand mold. Then take the rough cast shapes to mill to tolerances on the CNC. However, uttering tolerances in the same breath as plastic or aluminum mills is a bit of a joke.

I have to try 3D printing a solder mask next....

Rod

Re: Small CNC Mill - mechanics finished

Dr. H., Sat Dec 14 2013, 06:52PM

Hi guys

not everything is going to plan ... A cheap chinese transformer went crazy and burnt some of the electronics in the old mill... some repairs were needed .... darn it ... Back and running now but with almost a week delay ....

A cheap chinese transformer went crazy and burnt some of the electronics in the old mill... some repairs were needed .... darn it ... Back and running now but with almost a week delay ....

Nice software Carbon Rod, thanks for shearing I am planning to play with some 3d printing in the not so near future ... but only plans for now.

I am planning to play with some 3d printing in the not so near future ... but only plans for now.

Cheers

Dr. H., Sat Dec 14 2013, 06:52PM

Hi guys

not everything is going to plan ...

A cheap chinese transformer went crazy and burnt some of the electronics in the old mill... some repairs were needed .... darn it ... Back and running now but with almost a week delay ....

A cheap chinese transformer went crazy and burnt some of the electronics in the old mill... some repairs were needed .... darn it ... Back and running now but with almost a week delay ....Nice software Carbon Rod, thanks for shearing

I am planning to play with some 3d printing in the not so near future ... but only plans for now.

I am planning to play with some 3d printing in the not so near future ... but only plans for now.Cheers

Re: Small CNC Mill - mechanics finished

Dr. H., Sun Dec 22 2013, 08:14PM

Hi guys

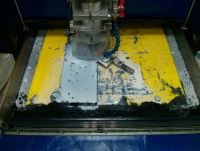

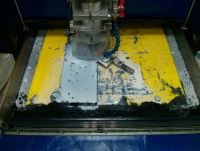

moving forward on the project - most of the ALU parts have been cut. I will be getting home for Christmas soon so till then I hope to have all parts to start assembling .

Cheers

Dr. H., Sun Dec 22 2013, 08:14PM

Hi guys

moving forward on the project - most of the ALU parts have been cut. I will be getting home for Christmas soon so till then I hope to have all parts to start assembling .

Cheers

Re: Small CNC Mill - mechanics finished

Dr. H., Sat Dec 28 2013, 08:51PM

Hi guys

I am back in the good old big workshop . All of the parts are cut - time to start the assembly.

. All of the parts are cut - time to start the assembly.

P.S. Hmm I didn't imagine soo many parts

Cheers

Dr. H., Sat Dec 28 2013, 08:51PM

Hi guys

I am back in the good old big workshop

. All of the parts are cut - time to start the assembly.

. All of the parts are cut - time to start the assembly. P.S. Hmm I didn't imagine soo many parts

Cheers

Re: Small CNC Mill - mechanics finished

Dr. H., Tue Dec 31 2013, 06:03PM

Hi guys

moving forward on the project. The mill is starting to take shape. Cheers and happy new year

Dr. H., Tue Dec 31 2013, 06:03PM

Hi guys

moving forward on the project. The mill is starting to take shape. Cheers and happy new year

Re: Small CNC Mill - mechanics finished

Shrad, Wed Jan 01 2014, 08:55AM

advice for power supplies...

use server power supplies like IBM or HP power supplies... they deliver 12V or 24V at the 50A level, plus other voltages at useful powers like5V 20A, 3V3 10A or things like this

main thing is they are sturdy, deliver top current without sagging, are reliable and have parameter monitoring through SPI, plus their PFC and almost 90% efficiency for the better ones

the latest I had a look for were 12V 50A supplies plus other voltages (600W total) for 6€ without shipping!

and the form factor is pleasant too... 5*5*30cm :)

Shrad, Wed Jan 01 2014, 08:55AM

advice for power supplies...

use server power supplies like IBM or HP power supplies... they deliver 12V or 24V at the 50A level, plus other voltages at useful powers like5V 20A, 3V3 10A or things like this

main thing is they are sturdy, deliver top current without sagging, are reliable and have parameter monitoring through SPI, plus their PFC and almost 90% efficiency for the better ones

the latest I had a look for were 12V 50A supplies plus other voltages (600W total) for 6€ without shipping!

and the form factor is pleasant too... 5*5*30cm :)

Re: Small CNC Mill - mechanics finished

Dr. H., Mon Jan 06 2014, 06:40PM

Hi guys

Shrad - this is a good suggestion. I've spent quite a lot of time looking for a power supply second hand but didn't find anything that worked fine for me and this is why I opted for this one. I've tried a 24V 350W SMPS from a medical equipment but was just too big to fit in the base of the machine. Good idea about the server supplies

To update the project - the X and Z are fully complete (except for the servo shaft extender and pulley - hope to make them tomorrow). Those little things sure take forever (end switches, optical sensors, cable guide ...)

I've done some speed tests and it seems the machine will be able to move in the 4000mm/min range witch is really nice

Cheers

Dr. H., Mon Jan 06 2014, 06:40PM

Hi guys

Shrad - this is a good suggestion. I've spent quite a lot of time looking for a power supply second hand but didn't find anything that worked fine for me and this is why I opted for this one. I've tried a 24V 350W SMPS from a medical equipment but was just too big to fit in the base of the machine. Good idea about the server supplies

To update the project - the X and Z are fully complete (except for the servo shaft extender and pulley - hope to make them tomorrow). Those little things sure take forever (end switches, optical sensors, cable guide ...)

I've done some speed tests and it seems the machine will be able to move in the 4000mm/min range witch is really nice

Cheers

Re: Small CNC Mill - mechanics finished

Dr. H., Thu Jan 09 2014, 08:28PM

Hi guys

The base is almost finished. One of the trickiest part remains - the protective cover for the guides and scew. Will be fighting with it tomorrow and after that final assembly of the mechanics.

Cheers

Dr. H., Thu Jan 09 2014, 08:28PM

Hi guys

The base is almost finished. One of the trickiest part remains - the protective cover for the guides and scew. Will be fighting with it tomorrow and after that final assembly of the mechanics.

Cheers

Re: Small CNC Mill - mechanics finished

Mads Barnkob, Thu Jan 09 2014, 09:37PM

That is some top quality do it yourself right there, I am impressed :)

I have some slide bearings for round rods with a flat side for screw mounting to a plate, I saved those for a possible DIY CNC project. There is 12 of them, so I have for xyz. They are around 40mm long and for a Ø20mm rod, (similar type: ) I fear that a rod only fixed in the ends can vibrate too much compared to a linear that is fixed along the axis with multiple screws, do you think there are stable enough compared to a linear bearing?

) I fear that a rod only fixed in the ends can vibrate too much compared to a linear that is fixed along the axis with multiple screws, do you think there are stable enough compared to a linear bearing?

Mads Barnkob, Thu Jan 09 2014, 09:37PM

That is some top quality do it yourself right there, I am impressed :)

I have some slide bearings for round rods with a flat side for screw mounting to a plate, I saved those for a possible DIY CNC project. There is 12 of them, so I have for xyz. They are around 40mm long and for a Ø20mm rod, (similar type:

) I fear that a rod only fixed in the ends can vibrate too much compared to a linear that is fixed along the axis with multiple screws, do you think there are stable enough compared to a linear bearing?

) I fear that a rod only fixed in the ends can vibrate too much compared to a linear that is fixed along the axis with multiple screws, do you think there are stable enough compared to a linear bearing?Re: Small CNC Mill - mechanics finished

Dr. H., Sun Jan 12 2014, 06:29PM

Hi guys

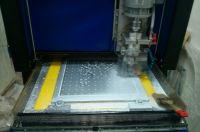

the mill is mechanically fully complete now . Time to start on the electronics.

. Time to start on the electronics.

Hi Mads - thanks for the kind words. Yes those round rails are really prone to bending and vibration. It all depends what you intend to do with the mill, but 20mm is suitable for small travels (and loads). My big mill uses 40mm rails and the travel is about 50cm (full lenght is about 70cm between supports) and it bends really bad. If you want some rigidity and don't want to spend too much money the supported round rails are a relatively good choice. Much better than the unsupported.

Cheers.

Dr. H., Sun Jan 12 2014, 06:29PM

Hi guys

the mill is mechanically fully complete now

. Time to start on the electronics.

. Time to start on the electronics. Hi Mads - thanks for the kind words. Yes those round rails are really prone to bending and vibration. It all depends what you intend to do with the mill, but 20mm is suitable for small travels (and loads). My big mill uses 40mm rails and the travel is about 50cm (full lenght is about 70cm between supports) and it bends really bad. If you want some rigidity and don't want to spend too much money the supported round rails are a relatively good choice. Much better than the unsupported.

Cheers.

Re: Small CNC Mill - mechanics finished

Patrick, Wed Jan 22 2014, 09:05PM

Masterful, just masterful build.

is that transformer device with heat sinks in the lower left of the pics, your power supply for this machine?

Patrick, Wed Jan 22 2014, 09:05PM

Masterful, just masterful build.

is that transformer device with heat sinks in the lower left of the pics, your power supply for this machine?

Re: Small CNC Mill - mechanics finished

Dr. H., Fri Jan 31 2014, 07:16AM

Hi Patrick

no that is a very old lab power supply. Actually this was the very first electronics project I ever did (more than 8 years ago .... wow time sure flies quick). The power supply for the mill is in the base (you can see it few posts above - it is a MW SMPS).

I've slowed (actually stopped) on the project due to a health problems. I am planning to resume work soon though.

Cheers

Dr. H., Fri Jan 31 2014, 07:16AM

Hi Patrick

no that is a very old lab power supply. Actually this was the very first electronics project I ever did (more than 8 years ago .... wow time sure flies quick). The power supply for the mill is in the base (you can see it few posts above - it is a MW SMPS).

I've slowed (actually stopped) on the project due to a health problems. I am planning to resume work soon though.

Cheers

Re: Small CNC Mill - mechanics finished

Proud Mary, Fri Jan 31 2014, 10:22AM

You are a fine engineer and craftsman, Dr H, an example to us all.

Proud Mary, Fri Jan 31 2014, 10:22AM

You are a fine engineer and craftsman, Dr H, an example to us all.

Re: Small CNC Mill - mechanics finished

Patrick, Fri Feb 14 2014, 02:36AM

Dr H, from where did you get your lead screw? and related pieces?

Patrick, Fri Feb 14 2014, 02:36AM

Dr H, from where did you get your lead screw? and related pieces?

Print this page