1.4kJ electrothermal gun

Wizzup, Fri Mar 01 2013, 09:14PMMrFlatox got me interested in electrothermal guns so I decided to make one:

In the video it shoots a 0.25g 6mm plastic airsoft round through 12mm thick plywood, the power is really good in my opinion, I didnt expect anything near that power. I dont have a chrony so I dont know the exact speed but I would say it is for sure over 500m/s because of the damage it makes, that would be 30J+ kinetic energy.

I will post some pictures tomorrow of my setup but for now ill just tell you the specs:

Capacitor bank: 3x 4700uF 450V inverter grade electrolytic caps, 22mOhm ESR each, so in parallel about 7mOhm.

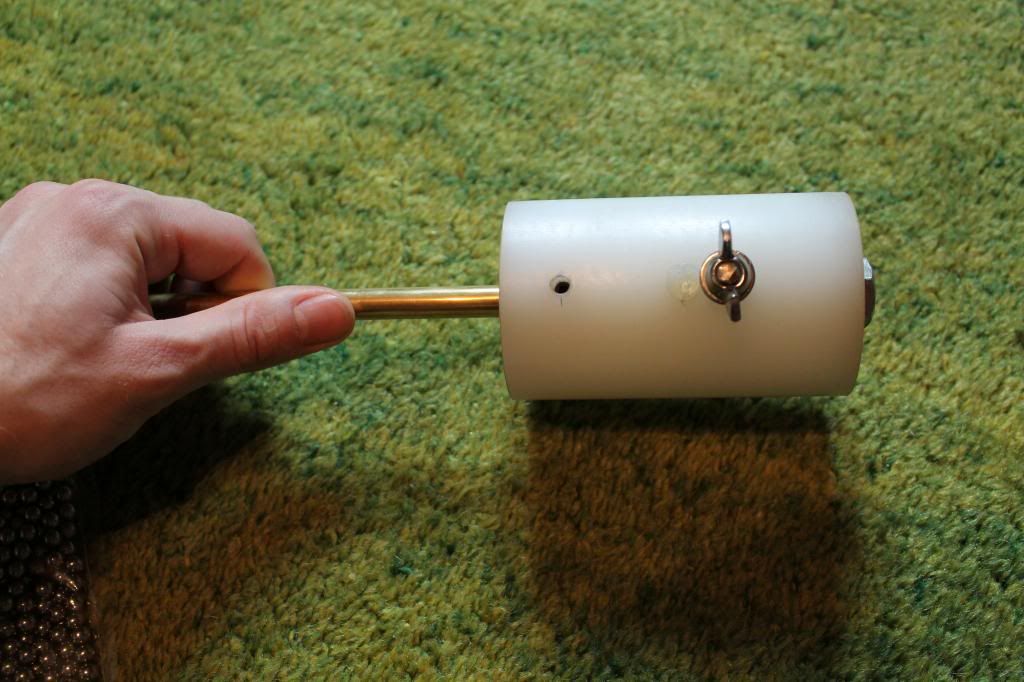

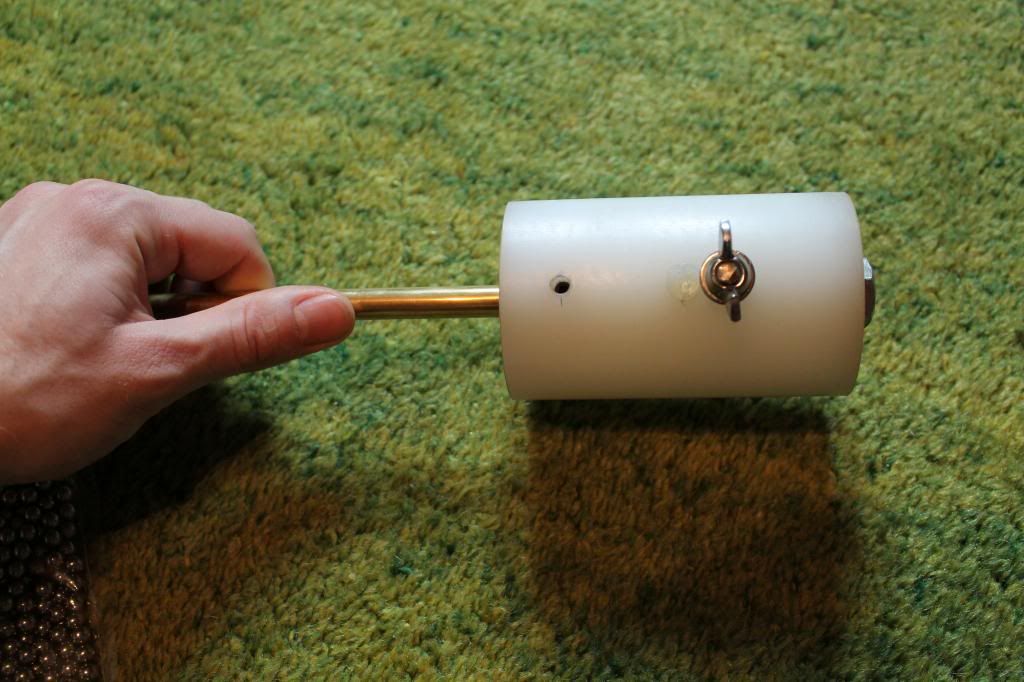

Chamber: 31mm diameter nylon rod, electrodes are two 6mm diameter threaded rods.

Switch: homemade spring loaded mechanical switch

I use some water in the chamber with a piece of aluminum foil, without the water the shot has only about half of its power than what it has with water.

Okay I took a new video this morning and some pictures:

The aluminum plate is 2mm thick. After the shot I found a small 6mm diameter aluminum "bowl" that the projectile had ripped out of the plate. Also the hole in the plate is 7mm in diameter, that is 1mm larger than the projectile originally. I have to make some improvements on the barrel attachment as the force is so big that it flies off.

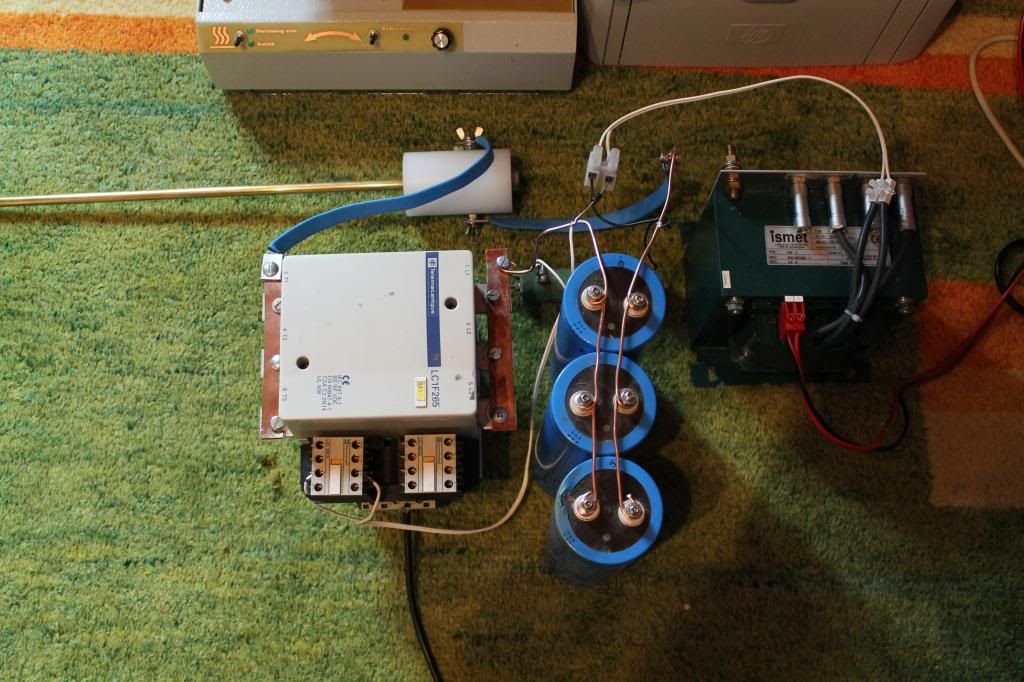

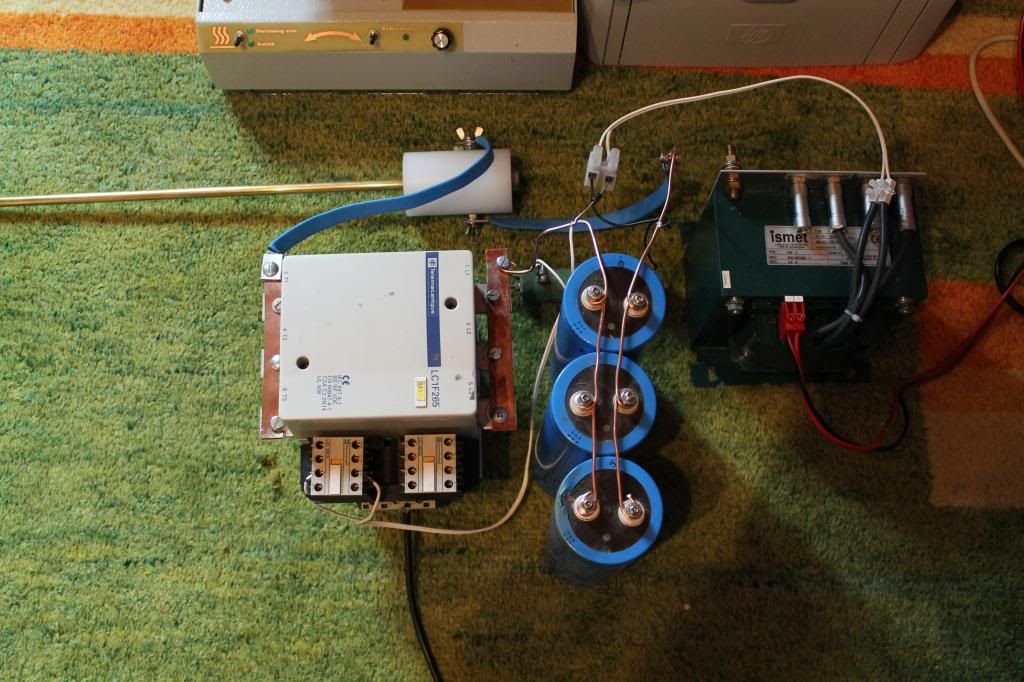

Overview of the whole etg:

Projectile:

just a regular plastic airsoft round, not aluminum

just a regular plastic airsoft round, not aluminumChamber overview:

Chamber inside:

UPDATE: New video using the new chamber:

It fires a 6mm diameter 9mm long steel projectile

into some wooden blocks that are 4cm thick, about 6cm total penetration. There was a bad connection on another one of the electrodes where the cable is attached, you can see the sparks in the video, so I lost some power there. Sorry for the camera shaking so much, I had some adrenaline in my blood that time :D I will fix that connection and then I will probably try a longer projectile and see if I can get even more power out of this.

into some wooden blocks that are 4cm thick, about 6cm total penetration. There was a bad connection on another one of the electrodes where the cable is attached, you can see the sparks in the video, so I lost some power there. Sorry for the camera shaking so much, I had some adrenaline in my blood that time :D I will fix that connection and then I will probably try a longer projectile and see if I can get even more power out of this.Re: 1.4kJ electrothermal gun

Maxwell, Fri Mar 01 2013, 10:00PM

I have a strong feeling we're going to be seeing a lot of ETG's on this forum in the coming months.

Very nice shot there...

We should really attempt measure some quantitative efficiency or energy conversion output.

Maxwell, Fri Mar 01 2013, 10:00PM

I have a strong feeling we're going to be seeing a lot of ETG's on this forum in the coming months.

Very nice shot there...

We should really attempt measure some quantitative efficiency or energy conversion output.

Re: 1.4kJ electrothermal gun

Ash Small, Fri Mar 01 2013, 10:08PM

Nice one

I was thinking myself that water in the chamber should improve performance considerably.

I've also been thinking, as E=1/2CV^2, does it make more sense to connect capacitors in series, rather than in parallel? (more voltage, but less charge, but energy is a factor of V^2)

Ash Small, Fri Mar 01 2013, 10:08PM

Nice one

I was thinking myself that water in the chamber should improve performance considerably.

I've also been thinking, as E=1/2CV^2, does it make more sense to connect capacitors in series, rather than in parallel? (more voltage, but less charge, but energy is a factor of V^2)

Re: 1.4kJ electrothermal gun

Yandersen, Fri Mar 01 2013, 10:30PM

Wizzup, I can't believe that plastic bullet can damage a plywood - I would expect it to smash over it in a little cloud of plastic dust. Maybe it was an aluminum ball?

I keep trying the pure air discharge increasing energy up to 70J already. I lost hope in air-operating ETG - plastic 6mm bullet can't go through the beer can - nonsense. So don't waste time - aluminum foil rules. Still I wouldn't recommend water as electrodes will not survive for long then.

Yandersen, Fri Mar 01 2013, 10:30PM

Wizzup, I can't believe that plastic bullet can damage a plywood - I would expect it to smash over it in a little cloud of plastic dust. Maybe it was an aluminum ball?

I keep trying the pure air discharge increasing energy up to 70J already. I lost hope in air-operating ETG - plastic 6mm bullet can't go through the beer can - nonsense. So don't waste time - aluminum foil rules. Still I wouldn't recommend water as electrodes will not survive for long then.

Re: 1.4kJ electrothermal gun

Thomas W, Sat Mar 02 2013, 12:01AM

theres a video of someone shooting a candle though a wood door

so i would think that a plastic ball could get though with enough force behind it

Thomas W, Sat Mar 02 2013, 12:01AM

Yandersen wrote ...

Wizzup, I can't believe that plastic bullet can damage a plywood - I would expect it to smash over it in a little cloud of plastic dust. Maybe it was an aluminum ball?

I keep trying the pure air discharge increasing energy up to 70J already. I lost hope in air-operating ETG - plastic 6mm bullet can't go through the beer can - nonsense. So don't waste time - aluminum foil rules. Still I wouldn't recommend water as electrodes will not survive for long then.

Wizzup, I can't believe that plastic bullet can damage a plywood - I would expect it to smash over it in a little cloud of plastic dust. Maybe it was an aluminum ball?

I keep trying the pure air discharge increasing energy up to 70J already. I lost hope in air-operating ETG - plastic 6mm bullet can't go through the beer can - nonsense. So don't waste time - aluminum foil rules. Still I wouldn't recommend water as electrodes will not survive for long then.

theres a video of someone shooting a candle though a wood door

so i would think that a plastic ball could get though with enough force behind it

Re: 1.4kJ electrothermal gun

Maxwell, Sat Mar 02 2013, 04:49AM

You typically get more bang for your buck as you increase your voltage rating.... but the capacitance quickly drops off. In CG's, the higher voltage, lower capacitance, faster pulses. In these ETG's, if a longer pulse is beneficial, greater capacitance is needed.

Maxwell, Sat Mar 02 2013, 04:49AM

Ash Small wrote ...

I've also been thinking, as E=1/2CV^2, does it make more sense to connect capacitors in series, rather than in parallel? (more voltage, but less charge, but energy is a factor of V^2)

I've also been thinking, as E=1/2CV^2, does it make more sense to connect capacitors in series, rather than in parallel? (more voltage, but less charge, but energy is a factor of V^2)

You typically get more bang for your buck as you increase your voltage rating.... but the capacitance quickly drops off. In CG's, the higher voltage, lower capacitance, faster pulses. In these ETG's, if a longer pulse is beneficial, greater capacitance is needed.

Re: 1.4kJ electrothermal gun

Wizzup, Sat Mar 02 2013, 08:28AM

First post updated with new video and pictures.

I think that I would not get much more power out of this if I had my capacitors in series, because I tried how it will fire at 300V charge and the sound was pretty much nothing, just a small puff. I think that my barrel length is pretty good for my current energy level, because with 300V the pulse is not long enough to push the projectile all the way out of the barrel before it ends so I guess that I would get worse performance with even shorter pulse.

Yandersen: The projectile is plastic, not aluminum. After the shot I find lots of small white plastic pieces that are parts of the projectile.

Wizzup, Sat Mar 02 2013, 08:28AM

First post updated with new video and pictures.

I think that I would not get much more power out of this if I had my capacitors in series, because I tried how it will fire at 300V charge and the sound was pretty much nothing, just a small puff. I think that my barrel length is pretty good for my current energy level, because with 300V the pulse is not long enough to push the projectile all the way out of the barrel before it ends so I guess that I would get worse performance with even shorter pulse.

Yandersen: The projectile is plastic, not aluminum. After the shot I find lots of small white plastic pieces that are parts of the projectile.

Re: 1.4kJ electrothermal gun

MrFlatox, Sat Mar 02 2013, 02:28PM

Very nice ETG ! I am glad to see that my presentation inspired some ideas !

It would indeed be very nice to see how it performs with figures, I would like to know how does the efficiency looks like on this one, but it should be pretty good judging from the damages you get. I am supposing something in the range of 4-5% range might be a good guess.

Keep up the good work !

MrFlatox, Sat Mar 02 2013, 02:28PM

Very nice ETG ! I am glad to see that my presentation inspired some ideas !

It would indeed be very nice to see how it performs with figures, I would like to know how does the efficiency looks like on this one, but it should be pretty good judging from the damages you get. I am supposing something in the range of 4-5% range might be a good guess.

Keep up the good work !

Re: 1.4kJ electrothermal gun

Wizzup, Sat Mar 02 2013, 03:53PM

I made a test shot with a 6mm diameter 10mm long steel projectile, the kinetic energy with it is a lot more than with a plastic airsoft round, and I used just 250V in the shot. It went through the plywood and sunk 0.5cm into my wooden backstop, that is about the same power as I have with an airsoft round at 400V. Only negative thing is that it broke my chamber, I found a crack going on the side of the chamber from top to bottom so I have to make a new one from some other material. I guess I dont have many other choices than steel because the old nylon chamber had over 1cm wall thickness and it is pretty strong material.

Wizzup, Sat Mar 02 2013, 03:53PM

I made a test shot with a 6mm diameter 10mm long steel projectile, the kinetic energy with it is a lot more than with a plastic airsoft round, and I used just 250V in the shot. It went through the plywood and sunk 0.5cm into my wooden backstop, that is about the same power as I have with an airsoft round at 400V. Only negative thing is that it broke my chamber, I found a crack going on the side of the chamber from top to bottom so I have to make a new one from some other material. I guess I dont have many other choices than steel because the old nylon chamber had over 1cm wall thickness and it is pretty strong material.

Re: 1.4kJ electrothermal gun

RateReducer, Sat Mar 02 2013, 05:02PM

This thing is unbelievable Wizzup!

2mm Aluminum with soft-air projectiles - just awesome! :)

How are you going to construct your new chamber?

RateReducer, Sat Mar 02 2013, 05:02PM

This thing is unbelievable Wizzup!

2mm Aluminum with soft-air projectiles - just awesome! :)

How are you going to construct your new chamber?

Re: 1.4kJ electrothermal gun

klugesmith, Sat Mar 02 2013, 08:22PM

The capacitance, resistance, and inductance between the bank terminals change by a factor of N^2. One configuration or the other might be a much better match for a particular ETG bridge or coilgun coil.

It's hard to argue against experimental results.

klugesmith, Sat Mar 02 2013, 08:22PM

Ash Small wrote ...

...I've also been thinking, as E=1/2CV^2, does it make more sense to connect capacitors in series, rather than in parallel? (more voltage, but less charge, but energy is a factor of V^2)

Ash, you ought to know better. The stored energy in a capacitor bank is not changed by converting from parallel to series connections, and neither is the maximum power output....I've also been thinking, as E=1/2CV^2, does it make more sense to connect capacitors in series, rather than in parallel? (more voltage, but less charge, but energy is a factor of V^2)

The capacitance, resistance, and inductance between the bank terminals change by a factor of N^2. One configuration or the other might be a much better match for a particular ETG bridge or coilgun coil.

It's hard to argue against experimental results.

Re: 1.4kJ electrothermal gun

Ash Small, Sat Mar 02 2013, 10:06PM

Well, I know that 1/Ct=1/C1+1/C2+1/C3.....+1/Cn, and the equation I quoted above contains a V^2 function, and I did find it puzzling that energy is a function of V^2. I also assume that the 'C' in the equation I quoted stands for charge (C=Coulombs). I'll have to look into this in more detail.

Ash Small, Sat Mar 02 2013, 10:06PM

klugesmith wrote ...

The capacitance, resistance, and inductance between the bank terminals change by a factor of N^2. One configuration or the other might be a much better match for a particular ETG bridge or coilgun coil.

It's hard to argue against experimental results.

Ash Small wrote ...

...I've also been thinking, as E=1/2CV^2, does it make more sense to connect capacitors in series, rather than in parallel? (more voltage, but less charge, but energy is a factor of V^2)

Ash, you ought to know better. The stored energy in a capacitor bank is not changed by converting from parallel to series connections, and neither is the maximum power output....I've also been thinking, as E=1/2CV^2, does it make more sense to connect capacitors in series, rather than in parallel? (more voltage, but less charge, but energy is a factor of V^2)

The capacitance, resistance, and inductance between the bank terminals change by a factor of N^2. One configuration or the other might be a much better match for a particular ETG bridge or coilgun coil.

It's hard to argue against experimental results.

Well, I know that 1/Ct=1/C1+1/C2+1/C3.....+1/Cn, and the equation I quoted above contains a V^2 function, and I did find it puzzling that energy is a function of V^2. I also assume that the 'C' in the equation I quoted stands for charge (C=Coulombs). I'll have to look into this in more detail.

Re: 1.4kJ electrothermal gun

Hanzie, Sat Mar 02 2013, 11:04PM

I believe the 'C' stands for the capacitance in Farad. Could be wrong though.

Hanzie, Sat Mar 02 2013, 11:04PM

I believe the 'C' stands for the capacitance in Farad. Could be wrong though.

Re: 1.4kJ electrothermal gun

Ash Small, Sun Mar 03 2013, 12:11AM

You could be right, but conventionaly, capacitance is expressed in terms of 'F'.

'C' generally stands for Coulombs, from what I remember.

EDIT: In the example I gave in my previous post, 'C' stands for capacitor (C1, C2, etc.).

Ash Small, Sun Mar 03 2013, 12:11AM

Hanzie wrote ...

I believe the 'C' stands for the capacitance in Farad. Could be wrong though.

I believe the 'C' stands for the capacitance in Farad. Could be wrong though.

You could be right, but conventionaly, capacitance is expressed in terms of 'F'.

'C' generally stands for Coulombs, from what I remember.

EDIT: In the example I gave in my previous post, 'C' stands for capacitor (C1, C2, etc.).

Re: 1.4kJ electrothermal gun

Ash Small, Sun Mar 03 2013, 12:57AM

You could be right, but conventionaly, capacitance is expressed in terms of 'F'.

'C' generally stands for Coulombs, from what I remember.

EDIT: In the example I gave in my previous post, 'C' stands for capacitor (C1, C2, etc.).

EDIT: Mods, Please sort out double post. Not sure how it happened.

Ash Small, Sun Mar 03 2013, 12:57AM

Ash Small wrote ...

Hanzie wrote ...

I believe the 'C' stands for the capacitance in Farad. Could be wrong though.

I believe the 'C' stands for the capacitance in Farad. Could be wrong though.

You could be right, but conventionaly, capacitance is expressed in terms of 'F'.

'C' generally stands for Coulombs, from what I remember.

EDIT: In the example I gave in my previous post, 'C' stands for capacitor (C1, C2, etc.).

EDIT: Mods, Please sort out double post. Not sure how it happened.

Re: 1.4kJ electrothermal gun

Maxwell, Sun Mar 03 2013, 02:02AM

C is most definitely capacitance in:

energy=1/2*C*V^2

C is used in electrical schematics to denote a capacitor.

Maxwell, Sun Mar 03 2013, 02:02AM

C is most definitely capacitance in:

energy=1/2*C*V^2

C is used in electrical schematics to denote a capacitor.

Re: 1.4kJ electrothermal gun

DerAlbi, Sun Mar 03 2013, 04:13AM

We need seven posts so clarify that you cant charge capacitors in parallel, then wire them in series and end up with more energy than before -.-

great job.

Does someone to accompany me? I take a walk - cant stop crying about this -.-

DerAlbi, Sun Mar 03 2013, 04:13AM

We need seven posts so clarify that you cant charge capacitors in parallel, then wire them in series and end up with more energy than before -.-

great job.

Does someone to accompany me? I take a walk - cant stop crying about this -.-

Re: 1.4kJ electrothermal gun

Yandersen, Sun Mar 03 2013, 06:18AM

Yeah, those guys need to pay a visit to school one day...

Energy of capacitor is

E=C*U*U/2,

where C is a capacitance in Farads.

The charge capacitor holds is expressed in Coloumbs:

q=C*U

When two caps are connected in series, the charge each one holds does not change - the effective capacitance becomes two times smaller. So as chain holds doubled voltage, the capacitance is halved.

Addition for curious ones:

q=C*U=I*t,

where I is a current and t is a time. I found that derivative very useful:

dU = I*dt / C

It shows for how much volts (dU) cap's voltage will change for some period of time (dt) if cap is being charged with a constant current (I).

Yandersen, Sun Mar 03 2013, 06:18AM

Yeah, those guys need to pay a visit to school one day...

Energy of capacitor is

E=C*U*U/2,

where C is a capacitance in Farads.

The charge capacitor holds is expressed in Coloumbs:

q=C*U

When two caps are connected in series, the charge each one holds does not change - the effective capacitance becomes two times smaller. So as chain holds doubled voltage, the capacitance is halved.

Addition for curious ones:

q=C*U=I*t,

where I is a current and t is a time. I found that derivative very useful:

dU = I*dt / C

It shows for how much volts (dU) cap's voltage will change for some period of time (dt) if cap is being charged with a constant current (I).

Re: 1.4kJ electrothermal gun

Wizzup, Sun Mar 03 2013, 10:30AM

I will build a new chamber with a similar design than the old one but I will use iron rod instead of nylon, 5mm wall thickness should hold inside anything I put in there. I will post pictures and a diagram of its structure when its ready and a video of it shooting a steel projectile through some stuff :)

Wizzup, Sun Mar 03 2013, 10:30AM

I will build a new chamber with a similar design than the old one but I will use iron rod instead of nylon, 5mm wall thickness should hold inside anything I put in there. I will post pictures and a diagram of its structure when its ready and a video of it shooting a steel projectile through some stuff :)

Re: 1.4kJ electrothermal gun

Ash Small, Sun Mar 03 2013, 11:17AM

Sorry about the mix up. As I said, according to international convention, F stands for capacitance (Farads) and C stands for charge (Coulombs).

C=F*V

Ash Small, Sun Mar 03 2013, 11:17AM

Sorry about the mix up. As I said, according to international convention, F stands for capacitance (Farads) and C stands for charge (Coulombs).

C=F*V

Re: 1.4kJ electrothermal gun

Thomas W, Sun Mar 03 2013, 01:29PM

Very nice, when i get a very big SCR i may try this.

Thomas W, Sun Mar 03 2013, 01:29PM

Very nice, when i get a very big SCR i may try this.

Re: 1.4kJ electrothermal gun

klugesmith, Sun Mar 03 2013, 04:39PM

Everyone: This is a good example of confusion caused when one

casually replaces the names/symbols of constants or variables,

with the names/symbols of their units of measurement.

Discussed at 4hv.org not long ago:

"Are 250 and 6-8 LeBron James's pounds and feet and inches, or his weight and height?

Are 98.6 and 37 our normal body degrees F and degrees C?

We say "current = 10 kA", not "kA = 10". One appears naturally when working out a formula; the other does not. I have tried to make a good example in this spreadsheet:

Unfortunately, there is one near-exception that can lead newbies astray.

Today it's popular, in fact practically universal, to use the word voltage (and symbol v or V) for the thing that is measured in volts (V)."

At least in English, since E (for electromotive force) fell out of favor in the last century.

European documents often symbolize voltage (Spannung) as U (Unterschied), which avoids the confusion. Wouldn't've worked in the Roman Empire era.

Everyone agrees that V is the SI symbol for the SI unit volt.

Someone else brought up the prefix letters in circuit diagram component reference designators.

For basic passive elements R, C, and L, they match the symbol of the variable provided by that component. Two out of three happen to match the name of the component type.

I think it stops there. Q1 is a transistor, not a charge element. U1 is an I.C.

klugesmith, Sun Mar 03 2013, 04:39PM

Ash Small wrote ...

Sorry about the mix up. As I said, according to international convention, F stands for capacitance (Farads) and C stands for charge (Coulombs).

C=F*V

That's like stating Ohm's law as Ω=V/A instead of R=V/I (or R=U/I; see below)Sorry about the mix up. As I said, according to international convention, F stands for capacitance (Farads) and C stands for charge (Coulombs).

C=F*V

Everyone: This is a good example of confusion caused when one

casually replaces the names/symbols of constants or variables,

with the names/symbols of their units of measurement.

Discussed at 4hv.org not long ago:

"Are 250 and 6-8 LeBron James's pounds and feet and inches, or his weight and height?

Are 98.6 and 37 our normal body degrees F and degrees C?

We say "current = 10 kA", not "kA = 10". One appears naturally when working out a formula; the other does not. I have tried to make a good example in this spreadsheet:

Unfortunately, there is one near-exception that can lead newbies astray.

Today it's popular, in fact practically universal, to use the word voltage (and symbol v or V) for the thing that is measured in volts (V)."

At least in English, since E (for electromotive force) fell out of favor in the last century.

European documents often symbolize voltage (Spannung) as U (Unterschied), which avoids the confusion. Wouldn't've worked in the Roman Empire era.

Everyone agrees that V is the SI symbol for the SI unit volt.

Someone else brought up the prefix letters in circuit diagram component reference designators.

For basic passive elements R, C, and L, they match the symbol of the variable provided by that component. Two out of three happen to match the name of the component type.

I think it stops there. Q1 is a transistor, not a charge element. U1 is an I.C.

Re: 1.4kJ electrothermal gun

Wizzup, Sun Mar 03 2013, 07:24PM

New chamber ready! I worked today the whole day on it and it looks pretty good in my opinion:

overview:

back:

top:

front:

I didnt take a video of the first test shot but I made a 0.25g airsoft round penetrate 3.5cm into wood.

Still needs some work but I guess I can get a video of it in action tomorrow.

Wizzup, Sun Mar 03 2013, 07:24PM

New chamber ready! I worked today the whole day on it and it looks pretty good in my opinion:

overview:

back:

top:

front:

I didnt take a video of the first test shot but I made a 0.25g airsoft round penetrate 3.5cm into wood.

Still needs some work but I guess I can get a video of it in action tomorrow.

Re: 1.4kJ electrothermal gun

Ash Small, Sun Mar 03 2013, 07:53PM

That's pretty amazing. How many coil guns of equivalent power are that destructive?

Can't wait to see the videos.

It is certainly partly that. I think it's also me not fully understanding 'charge' and 'capacitance', charge being capacitance multiplied by volts, and capacitance being charge divided by volts. The symbol for capacitance being 'C', and the symbol for units of charge being 'C'.

I don't recall ever using 'Q' for charge. I've always thought of charge as coulombs, 'C', and capacitance, 'C', as 'the charge stored in a capacitor'.

I thought 'Q' was a property of resonant circuits.

I know one coulomb is one amp for one second, and energy is a function of coulombs multiplied by volts (kW hour or joule, etc.).

Energy is also a function of capacitance multiplied by volts squared.

This is where I thought I'd found some 'extra' energy. (I didn't think it was 'free', I just thought it must 'store' more energy.)

My mistake. I've learned something today.

Ash Small, Sun Mar 03 2013, 07:53PM

Wizzup wrote ...

I didnt take a video of the first test shot but I made a 0.25g airsoft round penetrate 3.5cm into wood.

Still needs some work but I guess I can get a video of it in action tomorrow.

I didnt take a video of the first test shot but I made a 0.25g airsoft round penetrate 3.5cm into wood.

Still needs some work but I guess I can get a video of it in action tomorrow.

That's pretty amazing. How many coil guns of equivalent power are that destructive?

Can't wait to see the videos.

klugesmith wrote ...

Everyone: This is a good example of confusion caused when one

casually replaces the names/symbols of constants or variables,

with the names/symbols of their units of measurement.

Everyone: This is a good example of confusion caused when one

casually replaces the names/symbols of constants or variables,

with the names/symbols of their units of measurement.

It is certainly partly that. I think it's also me not fully understanding 'charge' and 'capacitance', charge being capacitance multiplied by volts, and capacitance being charge divided by volts. The symbol for capacitance being 'C', and the symbol for units of charge being 'C'.

I don't recall ever using 'Q' for charge. I've always thought of charge as coulombs, 'C', and capacitance, 'C', as 'the charge stored in a capacitor'.

I thought 'Q' was a property of resonant circuits.

I know one coulomb is one amp for one second, and energy is a function of coulombs multiplied by volts (kW hour or joule, etc.).

Energy is also a function of capacitance multiplied by volts squared.

This is where I thought I'd found some 'extra' energy. (I didn't think it was 'free', I just thought it must 'store' more energy.)

My mistake. I've learned something today.

Re: 1.4kJ electrothermal gun

Yandersen, Sun Mar 03 2013, 08:17PM

Ash, we don't care, really. Just relax.

Yandersen, Sun Mar 03 2013, 08:17PM

Ash, we don't care, really. Just relax.

Re: 1.4kJ electrothermal gun

Adrenaline, Mon Mar 04 2013, 02:31PM

Impressive results for your ETG. You definitely need a chrono, I'm curious as to the efficiency. What about making a ballistic pendulum?

For the OT conversation:

Its seems there is a confusion of units and variables...

C is the units of coulombs

F is the units Farads

What is L? Liters or inductance?

When used as a variable (in an equation), C is capacitance, q is charge, f is frequency.

f=1/2*pi*sqrt(L*C)

What about e=1/2 m*v^2

is m meters or mass?

You can see where this is going...

Adrenaline, Mon Mar 04 2013, 02:31PM

Impressive results for your ETG. You definitely need a chrono, I'm curious as to the efficiency. What about making a ballistic pendulum?

For the OT conversation:

Its seems there is a confusion of units and variables...

C is the units of coulombs

F is the units Farads

What is L? Liters or inductance?

When used as a variable (in an equation), C is capacitance, q is charge, f is frequency.

f=1/2*pi*sqrt(L*C)

What about e=1/2 m*v^2

is m meters or mass?

You can see where this is going...

Re: 1.4kJ electrothermal gun

Wizzup, Mon Mar 04 2013, 04:05PM

First post updated with a new video :)

Wizzup, Mon Mar 04 2013, 04:05PM

First post updated with a new video :)

Re: 1.4kJ electrothermal gun

Ash Small, Mon Mar 04 2013, 04:09PM

As I pointed out, it wasn't just that, it was also me not understanding the charge in a capacitor, which is capacitance multiplied by voltage, and energy being capacitance multiplied by voltage squared. The mistake I made was thinking that energy was charge multiplied by voltage squared, thanks to me not understanding/mis-reading an equation.

Probably a pretty basic mistake, but I now have a much better understanding of capacitors, thanks to this forum.

I think we can probably drop this subject now, and leave this thread to it's intended purpose.

Ash Small, Mon Mar 04 2013, 04:09PM

Adrenaline wrote ...

For the OT conversation:

Its seems there is a confusion of units and variables...

For the OT conversation:

Its seems there is a confusion of units and variables...

As I pointed out, it wasn't just that, it was also me not understanding the charge in a capacitor, which is capacitance multiplied by voltage, and energy being capacitance multiplied by voltage squared. The mistake I made was thinking that energy was charge multiplied by voltage squared, thanks to me not understanding/mis-reading an equation.

Probably a pretty basic mistake, but I now have a much better understanding of capacitors, thanks to this forum.

I think we can probably drop this subject now, and leave this thread to it's intended purpose.

Re: 1.4kJ electrothermal gun

Wizzup, Mon Mar 04 2013, 06:23PM

Seems like I have to design my chamber all over again... The nylon parts inside the chamber that work as insulators cant take the pressure created when firing heavier projectiles. I will spend more time designing this next chamber and I will probably start constructing it next weekend.

Wizzup, Mon Mar 04 2013, 06:23PM

Seems like I have to design my chamber all over again... The nylon parts inside the chamber that work as insulators cant take the pressure created when firing heavier projectiles. I will spend more time designing this next chamber and I will probably start constructing it next weekend.

Re: 1.4kJ electrothermal gun

Yandersen, Mon Mar 04 2013, 08:34PM

Wizzup, how about making the device safer and more durable?

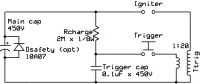

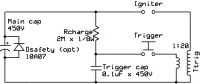

My considerations here: Aluminum foil around both of electrodes, but with 1mm air gap between those (or a paper insulator to ensure the right distance); triggering transformer on a ferrite ring with 1:20 turn ratio and non-polar 0.1uF x 450V cap to connect to primary to trigger the spark between aluminum pieces? Here is the schematic I stick to in my air gap discharges (so it is proved to work well):

Diode is not necessary unless you have an inductor in circuit and you have positive voltage left after shoot, but still preferable, as IF, due to some magic circumstances, cap bank get repolarized, your charger will blow.

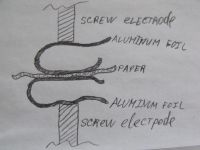

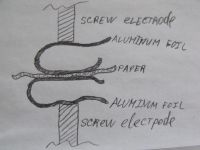

And here is an example of an ignition material for your chamber:

Still I would recommend two copper rods going along the barrel, but distance between those should be less than distance between any of them and a barrel (if it is made of conductive material). MrFlatox was right about using an epoxy fill to fasten electrodes at the end of a barrel - it is hard, non-conductive and can kinda sustain high temperatures.

You can try the following chamber construction:

copper pipe as a barrel and external electrode of the discharge chamber;

copper rode as another electrode going axially in center of the copper pipe - second electrode;

the roll of two aluminum foil tapes insulated by a paper tape as an ignition material: make two thin tapes of aluminum, put a paper between those and roll it in a aluminum cap way; ensure one "electrode" contacts with barrel and another "electrode" contacts wit central copper electrode.

Yandersen, Mon Mar 04 2013, 08:34PM

Wizzup, how about making the device safer and more durable?

My considerations here: Aluminum foil around both of electrodes, but with 1mm air gap between those (or a paper insulator to ensure the right distance); triggering transformer on a ferrite ring with 1:20 turn ratio and non-polar 0.1uF x 450V cap to connect to primary to trigger the spark between aluminum pieces? Here is the schematic I stick to in my air gap discharges (so it is proved to work well):

Diode is not necessary unless you have an inductor in circuit and you have positive voltage left after shoot, but still preferable, as IF, due to some magic circumstances, cap bank get repolarized, your charger will blow.

And here is an example of an ignition material for your chamber:

Still I would recommend two copper rods going along the barrel, but distance between those should be less than distance between any of them and a barrel (if it is made of conductive material). MrFlatox was right about using an epoxy fill to fasten electrodes at the end of a barrel - it is hard, non-conductive and can kinda sustain high temperatures.

You can try the following chamber construction:

copper pipe as a barrel and external electrode of the discharge chamber;

copper rode as another electrode going axially in center of the copper pipe - second electrode;

the roll of two aluminum foil tapes insulated by a paper tape as an ignition material: make two thin tapes of aluminum, put a paper between those and roll it in a aluminum cap way; ensure one "electrode" contacts with barrel and another "electrode" contacts wit central copper electrode.

Re: 1.4kJ electrothermal gun

Yandersen, Mon Mar 04 2013, 08:46PM

Please delete this doubled post.

Yandersen, Mon Mar 04 2013, 08:46PM

Please delete this doubled post.

Re: 1.4kJ electrothermal gun

Ash Small, Mon Mar 04 2013, 10:14PM

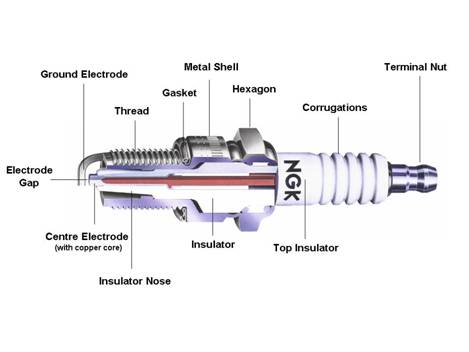

The idea I've come up with to tackle this problem is to use modified automotive spark plugs. You'd probably want un-suppressed ones (eg Ford model 'T', or similar). Grind off the 'earth' electrode, and the part that protrudes past the end of the threads, leaving the centre electrode intact. You can buy taps for tapping spark plug threads.

This is the method I'll use when I build one.

You could weld them in, but threading will probably be stronger and welding could damage the porcelain insulation.

Ash Small, Mon Mar 04 2013, 10:14PM

Wizzup wrote ...

Seems like I have to design my chamber all over again... The nylon parts inside the chamber that work as insulators cant take the pressure created when firing heavier projectiles. I will spend more time designing this next chamber and I will probably start constructing it next weekend.

Seems like I have to design my chamber all over again... The nylon parts inside the chamber that work as insulators cant take the pressure created when firing heavier projectiles. I will spend more time designing this next chamber and I will probably start constructing it next weekend.

The idea I've come up with to tackle this problem is to use modified automotive spark plugs. You'd probably want un-suppressed ones (eg Ford model 'T', or similar). Grind off the 'earth' electrode, and the part that protrudes past the end of the threads, leaving the centre electrode intact. You can buy taps for tapping spark plug threads.

This is the method I'll use when I build one.

You could weld them in, but threading will probably be stronger and welding could damage the porcelain insulation.

Re: 1.4kJ electrothermal gun

MrFlatox, Tue Mar 05 2013, 01:20PM

I did try automotive sparks plug in the first attempt, even before the actual setup. But as you mentioned, I did even thought taht spark plugs could have internal resistance so my design gave... nothing. I found out that using a cylindrical electrode at the end of the chamber sealed with epoxy between groove I made on the electrode and threads of the chamber to enable mor contact surface and more strenght. I do not know if this is understandable... This has not failed yet, and does not show any sign of wear. However I do not know how this would behave under higher imput energies.

MrFlatox, Tue Mar 05 2013, 01:20PM

I did try automotive sparks plug in the first attempt, even before the actual setup. But as you mentioned, I did even thought taht spark plugs could have internal resistance so my design gave... nothing. I found out that using a cylindrical electrode at the end of the chamber sealed with epoxy between groove I made on the electrode and threads of the chamber to enable mor contact surface and more strenght. I do not know if this is understandable... This has not failed yet, and does not show any sign of wear. However I do not know how this would behave under higher imput energies.

Re: 1.4kJ electrothermal gun

Wizzup, Sat Mar 16 2013, 09:46PM

I am currently waiting for some parts to arrive so that I can finish my chamber...

In the meantime I checked how many pulse caps there are for sale in ebay and found this one: its values look very good except for the pulse current rating, just 2kA? I thought that pulse rated caps with this voltage rating could do like atleast 10kA, or is this just a bad capacitor model for pulse discharge use? Or can the capacitor do more than that but can blow up on higher values or something? My knowledge on these type of capacitors is very limited, what type of capacitors are generally the best suited for this type of use? With the capacitor type I mean like foil, paper and so on what different types there are.

its values look very good except for the pulse current rating, just 2kA? I thought that pulse rated caps with this voltage rating could do like atleast 10kA, or is this just a bad capacitor model for pulse discharge use? Or can the capacitor do more than that but can blow up on higher values or something? My knowledge on these type of capacitors is very limited, what type of capacitors are generally the best suited for this type of use? With the capacitor type I mean like foil, paper and so on what different types there are.

Also if you know any other places than ebay where to look for this type of stuff it would be great if you can post it here. I tried googling "energy storage capacitor" and similar keywords and couldnt really find any sites that sold those other than those 20kJ+ monsters.

I will first make this thing fully working with my current capacitors and then look if I will find a pulse cap somewhere to get shorter pulse time.

Wizzup, Sat Mar 16 2013, 09:46PM

I am currently waiting for some parts to arrive so that I can finish my chamber...

In the meantime I checked how many pulse caps there are for sale in ebay and found this one:

its values look very good except for the pulse current rating, just 2kA? I thought that pulse rated caps with this voltage rating could do like atleast 10kA, or is this just a bad capacitor model for pulse discharge use? Or can the capacitor do more than that but can blow up on higher values or something? My knowledge on these type of capacitors is very limited, what type of capacitors are generally the best suited for this type of use? With the capacitor type I mean like foil, paper and so on what different types there are.

its values look very good except for the pulse current rating, just 2kA? I thought that pulse rated caps with this voltage rating could do like atleast 10kA, or is this just a bad capacitor model for pulse discharge use? Or can the capacitor do more than that but can blow up on higher values or something? My knowledge on these type of capacitors is very limited, what type of capacitors are generally the best suited for this type of use? With the capacitor type I mean like foil, paper and so on what different types there are.Also if you know any other places than ebay where to look for this type of stuff it would be great if you can post it here. I tried googling "energy storage capacitor" and similar keywords and couldnt really find any sites that sold those other than those 20kJ+ monsters.

I will first make this thing fully working with my current capacitors and then look if I will find a pulse cap somewhere to get shorter pulse time.

Re: 1.4kJ electrothermal gun

Yandersen, Sun Mar 17 2013, 03:42PM

As far as I know russian traditions, they put halved numbers as official parameters for max ratings and x10 values for parasitic parameters comparing to real values. Make sure this cap is not an old timer from sixties - you don't want cracked dielectric.

Still, I would just recommend any polypropylene stacked caps - with negligible ESL the only thing that may limit current in those caps is a resistance of the terminal wires, so look for screw-mount types. Usually those caps are called surge or surge-suppressing caps or pulse caps. They are box-shaped, not cylinder. The one you linked is the perfect example, but I wouldn't play with 4kV - look for higher capacitance and <1kV rating - you still can survive a 1kV shock if any accident happen, but 4kV will probably kill you. :)

Yandersen, Sun Mar 17 2013, 03:42PM

As far as I know russian traditions, they put halved numbers as official parameters for max ratings and x10 values for parasitic parameters comparing to real values. Make sure this cap is not an old timer from sixties - you don't want cracked dielectric.

Still, I would just recommend any polypropylene stacked caps - with negligible ESL the only thing that may limit current in those caps is a resistance of the terminal wires, so look for screw-mount types. Usually those caps are called surge or surge-suppressing caps or pulse caps. They are box-shaped, not cylinder. The one you linked is the perfect example, but I wouldn't play with 4kV - look for higher capacitance and <1kV rating - you still can survive a 1kV shock if any accident happen, but 4kV will probably kill you. :)

Re: 1.4kJ electrothermal gun

Wizzup, Fri Apr 19 2013, 12:20PM

Long time since i last posted here... most of the time i have waited for parts to arrive. I made a new chamber from aluminum and it should be strong enough that i cant break it with the current energy levels.

First a video of the new design:

I have two new barrels made from steel, 4mm and 6mm ID, the one used in this video is the 4mm one. It shot a 15mm long 4mm sharpened steel rod through about 11cm of wood and then it hit a pile of glass panels that were behind that wooden box, shattered few of them to small pieces and stopped to the bow target that is the grey thing behind the box. I didnt think it would go through all that wood so it was a surprise for me also. The "raining" sound right after the shot is pieces of glass dropping on the floor and table. I stopped filming on the plywood because i thought it didnt go through it but found out the real damages later.

Also the new barrels are attached to the aluminum chamber with threads so there is no longer need for any difficult attachment things like i had with the softair gun barrel.

EDIT: I made another shot with the 4mm barrel, this time with a 30mm long projectile and 10mm thick aluminum plate as a target:

EDIT2: I tested the 6mm barrel, made a 40mm long 6mm diameter steel rod almost through 10mm aluminum:

I will also get a chrony in a few weeks so then i will be able to say how much kinetic energy the projectile has and what is the effiency :) With it I can also adjust the projectile lengths and so on to get the most energy out.

Also no one has anything to comment?

Wizzup, Fri Apr 19 2013, 12:20PM

Long time since i last posted here... most of the time i have waited for parts to arrive. I made a new chamber from aluminum and it should be strong enough that i cant break it with the current energy levels.

First a video of the new design:

I have two new barrels made from steel, 4mm and 6mm ID, the one used in this video is the 4mm one. It shot a 15mm long 4mm sharpened steel rod through about 11cm of wood and then it hit a pile of glass panels that were behind that wooden box, shattered few of them to small pieces and stopped to the bow target that is the grey thing behind the box. I didnt think it would go through all that wood so it was a surprise for me also. The "raining" sound right after the shot is pieces of glass dropping on the floor and table. I stopped filming on the plywood because i thought it didnt go through it but found out the real damages later.

Also the new barrels are attached to the aluminum chamber with threads so there is no longer need for any difficult attachment things like i had with the softair gun barrel.

EDIT: I made another shot with the 4mm barrel, this time with a 30mm long projectile and 10mm thick aluminum plate as a target:

EDIT2: I tested the 6mm barrel, made a 40mm long 6mm diameter steel rod almost through 10mm aluminum:

I will also get a chrony in a few weeks so then i will be able to say how much kinetic energy the projectile has and what is the effiency :) With it I can also adjust the projectile lengths and so on to get the most energy out.

Also no one has anything to comment?

Re: 1.4kJ electrothermal gun

Maxwell, Mon Apr 22 2013, 11:42PM

@Wizzup,

I'm very impressed with your above tests. Can you provide a few more pictures of your setup?

Caps? Trigger? Voltage?

Maxwell, Mon Apr 22 2013, 11:42PM

@Wizzup,

I'm very impressed with your above tests. Can you provide a few more pictures of your setup?

Caps? Trigger? Voltage?

Re: 1.4kJ electrothermal gun

Wizzup, Tue Apr 23 2013, 01:13PM

I can get some more pictures later today but you can find all the specs in the video describtion in youtube.

Caps: 3x 4700uF 450V inverter grade electrolytics in parallel.

Switch is a homemade spring loaded switch with flattened coper pipe as contacts. Voltage is in the range of 400-420V in the shots.

EDIT: Also I found a guy who sells these capacitors:

The terminals and the capacitors size look sturdy enough that it should be able to take the "short out" on an ETG with no problems and an ETG is not fired that often either so it would probably survive well in my usage. I wouldnt shoot any heavy steel projectiles etc with those because the pressures would be massive but i should be able to get a airsoft round going well over 1000m/s with one or two of those. They also cost very little as they are used, i dont know yet where they have been used but i sent the seller a message about them. I would expect a capacitor like that to discharge fully in under 50µs so it would for sure be fast enough to discharge fully before an airsoft round leaves the barrel. And yes, i know these capacitors are WAY more dangerous than my current electrolytic ones so i will be super careful if i will buy some of these.

Wizzup, Tue Apr 23 2013, 01:13PM

I can get some more pictures later today but you can find all the specs in the video describtion in youtube.

Caps: 3x 4700uF 450V inverter grade electrolytics in parallel.

Switch is a homemade spring loaded switch with flattened coper pipe as contacts. Voltage is in the range of 400-420V in the shots.

EDIT: Also I found a guy who sells these capacitors:

The terminals and the capacitors size look sturdy enough that it should be able to take the "short out" on an ETG with no problems and an ETG is not fired that often either so it would probably survive well in my usage. I wouldnt shoot any heavy steel projectiles etc with those because the pressures would be massive but i should be able to get a airsoft round going well over 1000m/s with one or two of those. They also cost very little as they are used, i dont know yet where they have been used but i sent the seller a message about them. I would expect a capacitor like that to discharge fully in under 50µs so it would for sure be fast enough to discharge fully before an airsoft round leaves the barrel. And yes, i know these capacitors are WAY more dangerous than my current electrolytic ones so i will be super careful if i will buy some of these.

Re: 1.4kJ electrothermal gun

radhoo, Wed Jun 12 2013, 07:27PM

amazing stuff. did you have the chance to make any additional progress on this?

I'd also like to see more pics and vids with your project

radhoo, Wed Jun 12 2013, 07:27PM

amazing stuff. did you have the chance to make any additional progress on this?

I'd also like to see more pics and vids with your project

Re: 1.4kJ electrothermal gun

Wizzup, Wed Jun 12 2013, 09:10PM

I am currently waiting for some mosfets to arrive for a zvs driver for the charger so that the charging would be a lot faster and then I will be able to charge them a bit higher voltage than about 410V that is the maximum with the current driver to get about 250J more energy. The mosfets should arrive this week so I will shoot a new video of it + a shot with a bit higher energy after it is working.

I also got some 6mm 440 SS ball bearings to shoot with this thing, I am waiting to get to shoot them at some steel plates and that 10mm thick aluminum plate.

Wizzup, Wed Jun 12 2013, 09:10PM

I am currently waiting for some mosfets to arrive for a zvs driver for the charger so that the charging would be a lot faster and then I will be able to charge them a bit higher voltage than about 410V that is the maximum with the current driver to get about 250J more energy. The mosfets should arrive this week so I will shoot a new video of it + a shot with a bit higher energy after it is working.

I also got some 6mm 440 SS ball bearings to shoot with this thing, I am waiting to get to shoot them at some steel plates and that 10mm thick aluminum plate.

Re: 1.4kJ electrothermal gun

Wizzup, Wed Jun 12 2013, 09:42PM

-- doubled post --

Wizzup, Wed Jun 12 2013, 09:42PM

-- doubled post --

Re: 1.4kJ electrothermal gun

radhoo, Thu Jun 13 2013, 10:00AM

Where did you find those ball bearings?

And would be nice to know more on the amount of water you've used, the shape of the inside electrodes, size of the chamber, the type of aluminum you've used as a "fuel", and so on. Can you perhaps draw these details by hand and post it here?

radhoo, Thu Jun 13 2013, 10:00AM

Where did you find those ball bearings?

And would be nice to know more on the amount of water you've used, the shape of the inside electrodes, size of the chamber, the type of aluminum you've used as a "fuel", and so on. Can you perhaps draw these details by hand and post it here?

Re: 1.4kJ electrothermal gun

Ash Small, Thu Jun 13 2013, 10:25AM

There are some here: (Other sellers are available.)

Ash Small, Thu Jun 13 2013, 10:25AM

radhoo wrote ...

Where did you find those ball bearings?

Where did you find those ball bearings?

There are some here: (Other sellers are available.)

Re: 1.4kJ electrothermal gun

Wizzup, Thu Jun 13 2013, 02:57PM

Yep I got the bearings from that exact same seller Ash posted, i bought a pack of 50.

The mosfets arrived today morning and I assembled the driver and it is working well but I found out that the core I was using for the flyback is not suitable for that kind of operation or something. I get a small arc from it that i can stretch to about 5mm but the output power is only a couple of watts and it won't draw more than 0.35A at 12V so there is obviously something wrong.

I am pretty sure that the problem is the flyback's core as it is not taken from a real flyback, i ordered it from some russian webstore. If I take the core out completely it draws many amps so I guess ill try to find an old TV somewhere and take a real flyback out of it.

Here is a quick diagram of the ETG:

Barrel ID is 6mm

The copper electrode ID is 8mm, OD 10mm, length 7mm

The insulator is M12 threaded nylon rod with a hole in the middle for the positive electrode

Positive electrode is 6mm steel threaded rod with the head filed to 4mm (basically just threads removed), the filed tip is about 3-4mm long, it varies a bit.

The negative wire from the cap bank is connected to the aluminum and the positive wire is connected to the center electrode. I can't say the exact amount of water because I usually just put a little water in there, shake it and then tap the excess water out so there is a bit water on the bottom but its not nearly full. After putting the water in I take about 1cm x 3cm piece of regular aluminum foil and push it between the copper and center electrodes using a small screw driver.

The copper electrode is just a piece of 10mm copper pipe gently hammered in place, it is there just so that when the shots melt and corrode the surfaces I can just easily take the copper out and clean it or just replace it with a new one.

Wizzup, Thu Jun 13 2013, 02:57PM

Yep I got the bearings from that exact same seller Ash posted, i bought a pack of 50.

The mosfets arrived today morning and I assembled the driver and it is working well but I found out that the core I was using for the flyback is not suitable for that kind of operation or something. I get a small arc from it that i can stretch to about 5mm but the output power is only a couple of watts and it won't draw more than 0.35A at 12V so there is obviously something wrong.

I am pretty sure that the problem is the flyback's core as it is not taken from a real flyback, i ordered it from some russian webstore. If I take the core out completely it draws many amps so I guess ill try to find an old TV somewhere and take a real flyback out of it.

Here is a quick diagram of the ETG:

Barrel ID is 6mm

The copper electrode ID is 8mm, OD 10mm, length 7mm

The insulator is M12 threaded nylon rod with a hole in the middle for the positive electrode

Positive electrode is 6mm steel threaded rod with the head filed to 4mm (basically just threads removed), the filed tip is about 3-4mm long, it varies a bit.

The negative wire from the cap bank is connected to the aluminum and the positive wire is connected to the center electrode. I can't say the exact amount of water because I usually just put a little water in there, shake it and then tap the excess water out so there is a bit water on the bottom but its not nearly full. After putting the water in I take about 1cm x 3cm piece of regular aluminum foil and push it between the copper and center electrodes using a small screw driver.

The copper electrode is just a piece of 10mm copper pipe gently hammered in place, it is there just so that when the shots melt and corrode the surfaces I can just easily take the copper out and clean it or just replace it with a new one.

Re: 1.4kJ electrothermal gun

radhoo, Thu Jun 13 2013, 04:28PM

excellent details, thank you.

What are your results on using the etg only with air (no aluminum, no water)?

What about using it only with water?

radhoo, Thu Jun 13 2013, 04:28PM

excellent details, thank you.

What are your results on using the etg only with air (no aluminum, no water)?

What about using it only with water?

Re: 1.4kJ electrothermal gun

Wizzup, Thu Jun 13 2013, 05:41PM

You're welcome. I have not tested using just air because my bank voltage is just 400V and making a HV "ignition" system is not that easy to make and I don't have much interest anymore on trying it. I tried using just salt water (the salt is to increase water's conductivity) but my bank voltage is too low for that also, what it did was discharge the bank to it in like 5 seconds and create lots of green bubbly cream like stuff.

Also I got my flyback working properly now, the reason it didnt work good earlier today was that the core halves had a little gap between them because the secondary winding was a bit too wide so I grinded about 0.5mm of the winding holding pipe off of both sides so they fit together.

Here is a video of it in action:

EDIT: I also ordered a 3.3uF cap for the driver as I read from uzzors2k's site that if I lower the frequency the charging power will rise a lot. With a 0.68uF cap I get like 10W output, it depends on the bank voltage but he gets about 50W out with a 4.2uF cap. Ill put the new cap and my current one in parallel to get about 4uF, that should improve the charging speed.

Wizzup, Thu Jun 13 2013, 05:41PM

You're welcome. I have not tested using just air because my bank voltage is just 400V and making a HV "ignition" system is not that easy to make and I don't have much interest anymore on trying it. I tried using just salt water (the salt is to increase water's conductivity) but my bank voltage is too low for that also, what it did was discharge the bank to it in like 5 seconds and create lots of green bubbly cream like stuff.

Also I got my flyback working properly now, the reason it didnt work good earlier today was that the core halves had a little gap between them because the secondary winding was a bit too wide so I grinded about 0.5mm of the winding holding pipe off of both sides so they fit together.

Here is a video of it in action:

EDIT: I also ordered a 3.3uF cap for the driver as I read from uzzors2k's site that if I lower the frequency the charging power will rise a lot. With a 0.68uF cap I get like 10W output, it depends on the bank voltage but he gets about 50W out with a 4.2uF cap. Ill put the new cap and my current one in parallel to get about 4uF, that should improve the charging speed.

Re: 1.4kJ electrothermal gun

radhoo, Mon Jun 17 2013, 02:01PM

sure, you can do that. a few more questions if you don't mind. I was actually impressed by the penetration test of that tick 1cm aluminum sheet. Have you done longer range tests (outside)? If not could you try that and post some videos?

radhoo, Mon Jun 17 2013, 02:01PM

sure, you can do that. a few more questions if you don't mind. I was actually impressed by the penetration test of that tick 1cm aluminum sheet. Have you done longer range tests (outside)? If not could you try that and post some videos?

Re: 1.4kJ electrothermal gun

Wizzup, Mon Jun 17 2013, 06:35PM

No I have not done any longer range tests, Ill see if I will do some someday when its good weather. Also I found a guy in ebay that sells some capacitors with exact same values than the ones I am using now, so I thought I might buy 3 of them to double my bank. The caps are little used so they are pretty cheap also. I would wire them 2 in series and then 3 of those in parallel to get 7050uF and 900V.

I am on my summer holiday atm but I got a 2 week job so I will get some money to buy the caps and stuff. After the 2 week job I will still have about one month holiday left so good time to work on this.

Wizzup, Mon Jun 17 2013, 06:35PM

No I have not done any longer range tests, Ill see if I will do some someday when its good weather. Also I found a guy in ebay that sells some capacitors with exact same values than the ones I am using now, so I thought I might buy 3 of them to double my bank. The caps are little used so they are pretty cheap also. I would wire them 2 in series and then 3 of those in parallel to get 7050uF and 900V.

I am on my summer holiday atm but I got a 2 week job so I will get some money to buy the caps and stuff. After the 2 week job I will still have about one month holiday left so good time to work on this.

Re: 1.4kJ electrothermal gun

Wizzup, Wed Jun 26 2013, 01:16PM

My new resonant capacitor for the ZVS arrived today, the power difference is huge! Compare this to the video I posted previously:

The current in the arc is much larger and the arc is much fatter than what it was so I am really happy with it now, and this is just 12v. With 24v or 36v the arcs would be huge.

EDIT: I cleaned up the desk to get some more space and I cleaned up all the connections on the capacitors and ETG and wired the charger to the capacitors and tested its power. It charged the bank to about 360V in 15s so that is about 60W of charging power.

EDIT2: I didnt want to do a triple post so ill just edit some new stuff here. I organized my setup a bit so it is much cleaner now. I also built a wooden mount for the chamber so it is easier to attach it to the table, here are some pics of the new setup: ,

,  ,

,

Here is a video of a shot with a steel bearing vs aluminum plate:

EDIT3: radhoo requested a longer range shot so here you go:

It is not very long range but much longer than the earlier ones... Aiming this thing accurately is not easy so I wouldnt have hit even that large piece of wood if the range had been greater. Also notice the jet of plasma coming out of the barrel, it looks very cool:

Wizzup, Wed Jun 26 2013, 01:16PM

My new resonant capacitor for the ZVS arrived today, the power difference is huge! Compare this to the video I posted previously:

The current in the arc is much larger and the arc is much fatter than what it was so I am really happy with it now, and this is just 12v. With 24v or 36v the arcs would be huge.

EDIT: I cleaned up the desk to get some more space and I cleaned up all the connections on the capacitors and ETG and wired the charger to the capacitors and tested its power. It charged the bank to about 360V in 15s so that is about 60W of charging power.

EDIT2: I didnt want to do a triple post so ill just edit some new stuff here. I organized my setup a bit so it is much cleaner now. I also built a wooden mount for the chamber so it is easier to attach it to the table, here are some pics of the new setup:

,

,  ,

,

Here is a video of a shot with a steel bearing vs aluminum plate:

EDIT3: radhoo requested a longer range shot so here you go:

It is not very long range but much longer than the earlier ones... Aiming this thing accurately is not easy so I wouldnt have hit even that large piece of wood if the range had been greater. Also notice the jet of plasma coming out of the barrel, it looks very cool:

Re: 1.4kJ electrothermal gun

radhoo, Sun Jun 30 2013, 02:11PM

impressive results, thanks for making the outside video.

radhoo, Sun Jun 30 2013, 02:11PM

impressive results, thanks for making the outside video.

Re: 1.4kJ electrothermal gun

Wizzup, Sun Jun 30 2013, 02:14PM

Thanks, I just uploaded a video of another outside shooting with a much larger projectile:

Wizzup, Sun Jun 30 2013, 02:14PM

Thanks, I just uploaded a video of another outside shooting with a much larger projectile:

Re: 1.4kJ electrothermal gun

radhoo, Sun Jun 30 2013, 02:18PM

I watched both, nice! How is the barrel attached to the discharge chamber presented in one of the pics ?

?

radhoo, Sun Jun 30 2013, 02:18PM

I watched both, nice! How is the barrel attached to the discharge chamber presented in one of the pics

?

?Re: 1.4kJ electrothermal gun

Wizzup, Sun Jun 30 2013, 02:21PM

The barrel and the chamber have M10x1.5mm threads on them so I just put some PTFE tape on the barrel threads and screw it in.

Also I wrote it already in the video describtion but I bought 6 pieces capacitors from ebay today, they have same stats as my current ones so I will wire them for a bank of 4700uF at 1350V, thats about 4.3kJ. The new setup should discharge in the same time as the current one but will deliver 3x the energy. I cant wait for them to arrive so I can start building it.

Wizzup, Sun Jun 30 2013, 02:21PM

The barrel and the chamber have M10x1.5mm threads on them so I just put some PTFE tape on the barrel threads and screw it in.

Also I wrote it already in the video describtion but I bought 6 pieces capacitors from ebay today, they have same stats as my current ones so I will wire them for a bank of 4700uF at 1350V, thats about 4.3kJ. The new setup should discharge in the same time as the current one but will deliver 3x the energy. I cant wait for them to arrive so I can start building it.

Re: 1.4kJ electrothermal gun

Wizzup, Thu Jul 04 2013, 04:47PM

The new capacitors arrived today, I tested all of them and they work well. 6 pieces of them, 4700uF 450V each. I will get some copper pipe tomorrow that I will flatten for busbars and connect the caps for a nice bank.

EDIT: I will put a 47k bleeding resistor for each row of 3 caps in parallel so they will keep the bank discharged when not used and they also act as balancing resistors. I will not trust only those resistors to keep every row at balance but I will also put 3 separate voltmeters in place to measure the voltage of each row so that I can stop charging if one row is going near 450V.

Wizzup, Thu Jul 04 2013, 04:47PM

The new capacitors arrived today, I tested all of them and they work well. 6 pieces of them, 4700uF 450V each. I will get some copper pipe tomorrow that I will flatten for busbars and connect the caps for a nice bank.

EDIT: I will put a 47k bleeding resistor for each row of 3 caps in parallel so they will keep the bank discharged when not used and they also act as balancing resistors. I will not trust only those resistors to keep every row at balance but I will also put 3 separate voltmeters in place to measure the voltage of each row so that I can stop charging if one row is going near 450V.

Re: 1.4kJ electrothermal gun

radhoo, Thu Jul 04 2013, 05:27PM

I would use a regulated power supply to charge them, instead of measuring the voltage and stopping the loading process manually, the power supply should be capable of providing the selected voltage, and not more. Nevertheless these are `minor` details, looking forward to your new test! :)

radhoo, Thu Jul 04 2013, 05:27PM

I would use a regulated power supply to charge them, instead of measuring the voltage and stopping the loading process manually, the power supply should be capable of providing the selected voltage, and not more. Nevertheless these are `minor` details, looking forward to your new test! :)

Re: 1.4kJ electrothermal gun

Wizzup, Thu Jul 04 2013, 05:39PM

I know that a regulated power supply would be good but I don't really see a need for one right now, my charger is not that powerful and my bank is pretty big compared to it so the voltage won't rise that fast.

EDIT: Capacitors are now connected, I got some 1.5mm thick copper sheet from a local shop instead of flattened copper pipe and it became very nice in my opinion: The new capacitors have attachment bolts on their bottom so the bank is attached to the wood under the capacitors so it is very sturdy. I will build a new switch tomorrow maybe because I dont really like the current one.

The new capacitors have attachment bolts on their bottom so the bank is attached to the wood under the capacitors so it is very sturdy. I will build a new switch tomorrow maybe because I dont really like the current one.

EDIT2: I got 30k bleeding resistors instead of 47k, I made them by connecting 2 15k 5W resistors in series and I have extra ones so I can change them to 45k if needed. I made a new switch that works in a different way than the old one and is much sturdier design. Also I put double cables everywhere to decrease the resistance and replaced many aluminum connections with copper.

Here are some pictures about the new setup:

bleeding resistors

bleeding resistors

bleeding resistor closeup

bleeding resistor closeup

new switch

new switch

switch surfaces

switch surfaces

switch surfaces top view

switch surfaces top view

trigger

trigger

overview

overview

side overview

side overview

chamber front

chamber front

chamber back

chamber back

If you want more pictures from some specific spots don't be afraid to ask.

I still need to make a safety discharge thing to this because the old one that just shorts the terminals isn't very good. I thought about a light bulb but I would need like 4 of those in series to prevent them from blowing up as my bank's max voltage is 1350V. Ofcourse the bleeding resistors will discharge the bank but it will take several minutes, I would like to have a better option than just waiting.

I did the first firing of the thing at 900V ~1.9kJ with a 6mm steel bearing, the result was very much like my previous shot on the aluminum but the crater was a little larger in diameter. I will have to wait for my 10M resistor to arrive so I can charge past 1000V as that is the max of my multimeter.

EDIT3: I made nice casings for the bank and charger from wood and lexan, they are now easier to handle and much safer. Now I dont have to worry too much if a diode or something blows up. Also for the safe discharge system, I ordered 2x 100W 15k resistors that I will put in parallel and discharge the bank through those. I dont know yet how I will switch the discharge system but Ill come up with something.

Here are some pics:

bank front panel

bank front panel

bank overview

bank overview

charger front panel

charger front panel

charger overview

charger overview

Wizzup, Thu Jul 04 2013, 05:39PM

I know that a regulated power supply would be good but I don't really see a need for one right now, my charger is not that powerful and my bank is pretty big compared to it so the voltage won't rise that fast.

EDIT: Capacitors are now connected, I got some 1.5mm thick copper sheet from a local shop instead of flattened copper pipe and it became very nice in my opinion:

The new capacitors have attachment bolts on their bottom so the bank is attached to the wood under the capacitors so it is very sturdy. I will build a new switch tomorrow maybe because I dont really like the current one.

The new capacitors have attachment bolts on their bottom so the bank is attached to the wood under the capacitors so it is very sturdy. I will build a new switch tomorrow maybe because I dont really like the current one.EDIT2: I got 30k bleeding resistors instead of 47k, I made them by connecting 2 15k 5W resistors in series and I have extra ones so I can change them to 45k if needed. I made a new switch that works in a different way than the old one and is much sturdier design. Also I put double cables everywhere to decrease the resistance and replaced many aluminum connections with copper.

Here are some pictures about the new setup:

bleeding resistors

bleeding resistors bleeding resistor closeup

bleeding resistor closeup new switch

new switch switch surfaces

switch surfaces switch surfaces top view

switch surfaces top view trigger

trigger overview

overview side overview

side overview chamber front

chamber front chamber back

chamber backIf you want more pictures from some specific spots don't be afraid to ask.

I still need to make a safety discharge thing to this because the old one that just shorts the terminals isn't very good. I thought about a light bulb but I would need like 4 of those in series to prevent them from blowing up as my bank's max voltage is 1350V. Ofcourse the bleeding resistors will discharge the bank but it will take several minutes, I would like to have a better option than just waiting.

I did the first firing of the thing at 900V ~1.9kJ with a 6mm steel bearing, the result was very much like my previous shot on the aluminum but the crater was a little larger in diameter. I will have to wait for my 10M resistor to arrive so I can charge past 1000V as that is the max of my multimeter.

EDIT3: I made nice casings for the bank and charger from wood and lexan, they are now easier to handle and much safer. Now I dont have to worry too much if a diode or something blows up. Also for the safe discharge system, I ordered 2x 100W 15k resistors that I will put in parallel and discharge the bank through those. I dont know yet how I will switch the discharge system but Ill come up with something.

Here are some pics:

bank front panel

bank front panel bank overview

bank overview charger front panel

charger front panel charger overview

charger overviewRe: 1.4kJ electrothermal gun

Wizzup, Sat Jul 20 2013, 04:02PM

I fired this thing with 3.3kJ energy and the chamber's nylon insulator couldn't take the pressure so it ripped out the nylon threads and the electrode hit the brick behind the ETG with some serious force...

Here is a video of the shot:

Even though the insulator blew out the projectile was accelerated to 225.7m/s regarding to the chrony so that is about 215J kinetic energy and about 6.5% effiency. That is pretty good in my opinion when you take into account that a lot of gas was wasted because of the insulator...

I will have to make a new chamber with longer threads for the insulator or make some kind of extra attachment thing for the current one to prevent it from blowing out.

I am considering buying a mini lathe, with it I could easily make a much better chamber and projectiles and lots of other stuff for other projects.

Wizzup, Sat Jul 20 2013, 04:02PM

I fired this thing with 3.3kJ energy and the chamber's nylon insulator couldn't take the pressure so it ripped out the nylon threads and the electrode hit the brick behind the ETG with some serious force...

Here is a video of the shot:

Even though the insulator blew out the projectile was accelerated to 225.7m/s regarding to the chrony so that is about 215J kinetic energy and about 6.5% effiency. That is pretty good in my opinion when you take into account that a lot of gas was wasted because of the insulator...

I will have to make a new chamber with longer threads for the insulator or make some kind of extra attachment thing for the current one to prevent it from blowing out.

I am considering buying a mini lathe, with it I could easily make a much better chamber and projectiles and lots of other stuff for other projects.

Re: 1.4kJ electrothermal gun

Goodchild, Thu Aug 15 2013, 08:56PM

Wosa, how did I get over here? I frequent the Tesla coil forum the most but this has got my attention. Partly because I love electronics and also because I love real firearms in general.

What catches my interest is that even with your failed chamber you managed to get a projectile energy of nearly double what is seen with stock .22LR. (~160J) I imagine that you could approach 500J with a properly designed chamber and slightly more Q. This is entering the realm of 9mm pistol muzzle energies (~520J).

I can honestly say that this is the first hobby built electro style gun (that I have seen) that actually approaches the world of real firearms!

I may just have to build something like this in the near future. Great work, can’t wait to see more!

Goodchild, Thu Aug 15 2013, 08:56PM

Wosa, how did I get over here? I frequent the Tesla coil forum the most but this has got my attention. Partly because I love electronics and also because I love real firearms in general.

What catches my interest is that even with your failed chamber you managed to get a projectile energy of nearly double what is seen with stock .22LR. (~160J) I imagine that you could approach 500J with a properly designed chamber and slightly more Q. This is entering the realm of 9mm pistol muzzle energies (~520J).

I can honestly say that this is the first hobby built electro style gun (that I have seen) that actually approaches the world of real firearms!

I may just have to build something like this in the near future. Great work, can’t wait to see more!

Re: 1.4kJ electrothermal gun

Kizmo, Thu Aug 22 2013, 10:11AM

I shot 8mm projectile through 4mm steel plate ;)

Wizzup: if you ever need more capacitors or parts for your ETG just contact me, i have huge stash of 3300µF caps and i can machine pretty much anything.

Kizmo, Thu Aug 22 2013, 10:11AM

I shot 8mm projectile through 4mm steel plate ;)

Wizzup: if you ever need more capacitors or parts for your ETG just contact me, i have huge stash of 3300µF caps and i can machine pretty much anything.

Re: 1.4kJ electrothermal gun

Wizzup, Thu Aug 22 2013, 02:09PM

Very nice shot :) What was the capacitor configuration in that shot? I tried shooting a 2mm steel plate with the old 1.4kJ bank but my projectile tip just crushed and made a large dent on the plate, I guess I need to use harder steel to make it penetrate steel.

Before getting any more capacitors I need a new chamber that can hold the current pressures without blowing up so I have been looking for a small lathe to do the parts for my cannons, I am considering this one as the working space of the lathe is 550mm long so I can do small and medium size parts with it and have some space to work. In Finland that same model costs about 1400 euros but just 900 euros if I buy it from Netherlands. You have experience with machining equipment Kizmo so do you think it is a good price for the machine or should I maybe look for an older used machine? I would use it to machine small parts such as ETG chambers and similar size parts from aluminum and steel and sometimes maybe a bit larger parts too.