Why not steel as projectile?

Pinkamena, Thu Mar 01 2012, 10:14PMHey.

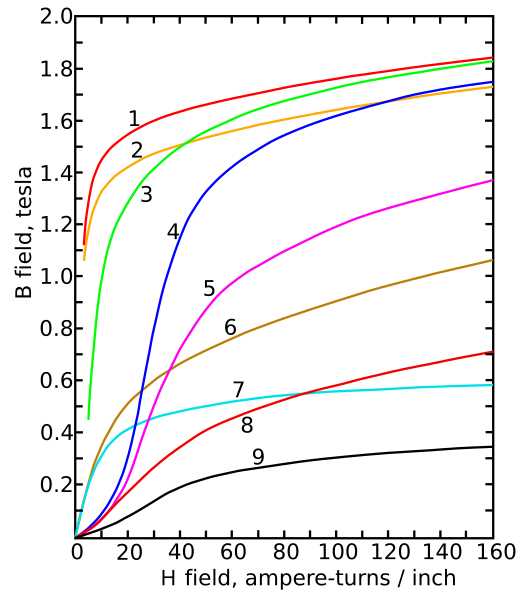

Looking at these magnetization curves, I can't understand why coilgun makers always say that one should use iron instead of steel for your projectile. Anyone care to shed some light on this? Not only do steel have a higher saturation level, it gets to this level at much lower H-field strengths as well.

Numer 6 is cast iron, number 1 is sheet steel.

Re: Why not steel as projectile?

Forty, Thu Mar 01 2012, 11:36PM

I think most people do use steel actually.

(printers are full of nice steel bars)

I dunno. but here's some more curves!

looks like iron gets an extra bump of B field at sufficient H.

I use two sets of projectiles at the moment: one nickel cobalt plated steel and the other silicon steel.

The problem with all conductive projectiles is the eddy current losses. That's what the powdered iron's for. I guess you could use powdered steel just the same, but you'll probably have to make it yourself (the powder, not the steel)

Forty, Thu Mar 01 2012, 11:36PM

I think most people do use steel actually.

(printers are full of nice steel bars)

I dunno. but here's some more curves!

looks like iron gets an extra bump of B field at sufficient H.

I use two sets of projectiles at the moment: one nickel cobalt plated steel and the other silicon steel.

The problem with all conductive projectiles is the eddy current losses. That's what the powdered iron's for. I guess you could use powdered steel just the same, but you'll probably have to make it yourself (the powder, not the steel)

Re: Why not steel as projectile?

Pinkamena, Fri Mar 02 2012, 12:34AM

Yay curves! Strangely, those curves does not make steel look as good as the curve I posted. And I trust them more than a drawing from Wikipedia!

I guess I'll just stick to iron.

Oh, and another question. I have written a program that calculates the current through a coil, and the H-field it puts up. As you can see, the H-field completely breaks my scale, which goes all the way up to 50 000 A/m!

Looking at the magnetization curves, the H-field is in magnitudes of houndreds of A/m. So either I have completely misunderstood something, or the coil I am simulating will be way, way too strong.

I have tried decreasing the simulated H-field by changing the only things I have control over (which is inner and outer radius of the coil), but doing so doesn't do much good. I could of course have decreased the current by decreasing the voltage, but I want this to stay at 280V which is what I'll charge my cap bank to.

EDIT: The way I am calculating the H-field is by this equation:

H=(number of turns*current)/length of coil

This might be wrong, I don't know.

Pinkamena, Fri Mar 02 2012, 12:34AM

Yay curves! Strangely, those curves does not make steel look as good as the curve I posted. And I trust them more than a drawing from Wikipedia!

I guess I'll just stick to iron.

Oh, and another question. I have written a program that calculates the current through a coil, and the H-field it puts up. As you can see, the H-field completely breaks my scale, which goes all the way up to 50 000 A/m!

Looking at the magnetization curves, the H-field is in magnitudes of houndreds of A/m. So either I have completely misunderstood something, or the coil I am simulating will be way, way too strong.

I have tried decreasing the simulated H-field by changing the only things I have control over (which is inner and outer radius of the coil), but doing so doesn't do much good. I could of course have decreased the current by decreasing the voltage, but I want this to stay at 280V which is what I'll charge my cap bank to.

EDIT: The way I am calculating the H-field is by this equation:

H=(number of turns*current)/length of coil

This might be wrong, I don't know.

Re: Why not steel as projectile?

2Spoons, Fri Mar 02 2012, 12:55AM

Cast iron and pure iron are not the same thing at all. Cast iron has a lot of carbon in it - way more than steel.

2Spoons, Fri Mar 02 2012, 12:55AM

Cast iron and pure iron are not the same thing at all. Cast iron has a lot of carbon in it - way more than steel.

Re: Why not steel as projectile?

klugesmith, Fri Mar 02 2012, 02:10AM

P and F: thank you for posting the curves!

Yes to what 2spoons said. When talking metallurgy, need to use use a metal engineer's vocabulary.

Pure elemental iron (Fe) is a laboratory curiosity, and still its magnetic properties will depend on its grain structure (temperature and strain history).

"cast iron" is a pretty sloppy term. Do you mean a gray cast iron? a white cast iron?

"steel" is even sloppier as a technical name. Rods from printers are generally "mild steel", but the part fabrication drawing will call out something more specific. For example, CRS, or even C1018, perhaps nickel-plated to resist corrosion.

Transformers generally use a silicon steel. As far as I know, the Si has no particular benefit to the mechanical properties. But it cost-effectively increases the electrical resistivity, to directly reduce eddy currents, with a relatively small negative effect on the magnetic properties.

Maybe ordinary cast iron is better than ordinary steel in a coilgun, because of its higher resistivity.

One practical discovery by the great Francis Bitter was the magnetic anisotropy of rolled steel sheets.

You will discover that coilgun performance may depend significantly on the saturation B values, but is pretty insensitive to orders-of-magnitude differences in the required H values. IMHO. Read on!

[edit] Pinky:

Want to approximate the H field along a magnetic field loop that encircles some turns of a finite solenoid, with no ferrous core? Divide the encircled ampere turns by the length of the field loop,

which generally runs along the inside of the coil and returns on the outside.

The H values will still be enormous compared to the magnetizing force of ferrous materials.

Compare your H values with those from the reference I cited in this thread:

When a core is in place, there will be a large B and relatively small H inside the core.

At the place where a flux line leaves the core, B is continuous while H jumps to the value for that B in air. 50,000 A/m gives you only 0.062 teslas in air, for a maximum attraction of 0.23 psi (1.6 kPa) if I computed correctly. You need 800 kA/m to get 1 tesla in any air gap, but that can give you 60 psi (4 bar) since it's a B*H/2 product thing.

If you integrate H around the entire flux loop, relatively few ampere-turns are going to magnetize the metal. Almost all the ampere-turns go to "magnetize" the return path, even if it's just a small air gap in an otherwise closed core. It's easy to visualize that if you are playing with the FEMM field solver program, and chart B or H along some linear path in the model.

Keep up the good work. And please holler if I'm wasting time being pedantic!

klugesmith, Fri Mar 02 2012, 02:10AM

P and F: thank you for posting the curves!

Yes to what 2spoons said. When talking metallurgy, need to use use a metal engineer's vocabulary.

Pure elemental iron (Fe) is a laboratory curiosity, and still its magnetic properties will depend on its grain structure (temperature and strain history).

"cast iron" is a pretty sloppy term. Do you mean a gray cast iron? a white cast iron?

"steel" is even sloppier as a technical name. Rods from printers are generally "mild steel", but the part fabrication drawing will call out something more specific. For example, CRS, or even C1018, perhaps nickel-plated to resist corrosion.

Transformers generally use a silicon steel. As far as I know, the Si has no particular benefit to the mechanical properties. But it cost-effectively increases the electrical resistivity, to directly reduce eddy currents, with a relatively small negative effect on the magnetic properties.

Maybe ordinary cast iron is better than ordinary steel in a coilgun, because of its higher resistivity.

One practical discovery by the great Francis Bitter was the magnetic anisotropy of rolled steel sheets.

You will discover that coilgun performance may depend significantly on the saturation B values, but is pretty insensitive to orders-of-magnitude differences in the required H values. IMHO. Read on!

[edit] Pinky:

Want to approximate the H field along a magnetic field loop that encircles some turns of a finite solenoid, with no ferrous core? Divide the encircled ampere turns by the length of the field loop,

which generally runs along the inside of the coil and returns on the outside.

The H values will still be enormous compared to the magnetizing force of ferrous materials.

Compare your H values with those from the reference I cited in this thread:

When a core is in place, there will be a large B and relatively small H inside the core.

At the place where a flux line leaves the core, B is continuous while H jumps to the value for that B in air. 50,000 A/m gives you only 0.062 teslas in air, for a maximum attraction of 0.23 psi (1.6 kPa) if I computed correctly. You need 800 kA/m to get 1 tesla in any air gap, but that can give you 60 psi (4 bar) since it's a B*H/2 product thing.

If you integrate H around the entire flux loop, relatively few ampere-turns are going to magnetize the metal. Almost all the ampere-turns go to "magnetize" the return path, even if it's just a small air gap in an otherwise closed core. It's easy to visualize that if you are playing with the FEMM field solver program, and chart B or H along some linear path in the model.

Keep up the good work. And please holler if I'm wasting time being pedantic!

Re: Why not steel as projectile?

Pinkamena, Fri Mar 02 2012, 02:36PM

Thanks for the detailed reply, kluge! Much appreciated.

I have decided that I want to go for powdered iron/resin for my projectile, in order to eliminate those pesky eddy currents. I am going to read up on the subject though, to see if they can be effectively removed by slotting the projectile, and if eddy currents in the barrel can be removed by slotting that as well. If not, I'll probably use carbon fiber for the barrel.

I am still worried about wasting a lot of energy in the coils by having a too strong H-field. Is it true that if I enclose the coil in metal, the H-field will be much lower, because it has all been "used" to induce a B-field in the metal housing? I can imagine that would drastically improve efficiency as well as give the projectile a much higher acceleration.

Pinkamena, Fri Mar 02 2012, 02:36PM

Thanks for the detailed reply, kluge! Much appreciated.

I have decided that I want to go for powdered iron/resin for my projectile, in order to eliminate those pesky eddy currents. I am going to read up on the subject though, to see if they can be effectively removed by slotting the projectile, and if eddy currents in the barrel can be removed by slotting that as well. If not, I'll probably use carbon fiber for the barrel.

I am still worried about wasting a lot of energy in the coils by having a too strong H-field. Is it true that if I enclose the coil in metal, the H-field will be much lower, because it has all been "used" to induce a B-field in the metal housing? I can imagine that would drastically improve efficiency as well as give the projectile a much higher acceleration.

Print this page