Secondary Coil Terminations

Wilson, Tue Jul 04 2006, 01:48PMI've been wondering about this for a week now, and i haven't been able to find an answer out there on the web:

Do you guys usually terminate the secondary winding by leading the wire along the outer surface of the secondary former, and to some sort of attachment, ie a screw, at the base/top? OR

Drill a small hole in the secondary former, and lead the wire through the centre of the former, to some form of connection?

Is there any difference between the two? [Note: I've found in a test SSTC that a kink in the secondary wire near where it terminates leads to promoted streamer formation in that area when no topload is used]

Also, is there a stark difference in performance if the secondary wire makes a poor electrical connection to the topload or RF ground? ie. the magnet wire hasn't been "stripped" and just wrapped around a bolt?

Thanks,

Wilson

Re: Secondary Coil Terminations

Marko, Tue Jul 04 2006, 02:31PM

I usually drill a small hole and stick the wire trough it.

Sometimes two holes can be drilled, so wire goes inside and out wich makes a very good connection.

When winding I usually put a small piece of doble-sided sticky tape for first few turns, wich eases things a lot.

I even tought if it could be used on entire secondary length ( with thicker gauges, it would be visible with thin wires) in order to prevent unwinding/overlaping of wire if secondary isn't immediately warnished ( exscept myselfI saw this happening to Steve Conner and TDU, very frustrating experience ).

).

Regarding poor electrical connections:

I had such one on my class E SSTC secondary.

To make things worse Secondary was filled with poliester goop to prevent melting of former at enormous frequecies. Top wire of secondary was soldered onto a brass bolt, and it looked pretty good when I put everything in.

After poliester dried I measured it and figured out it shows infinite resistance , god knows what happened. (wire tripped, bad solder?) I saw it arcing and smoking a bit under poliester but I could do nothing at that time.I used ping-pong ball as topload, and continuous arcing finally created enough carbon to weaken the contact to topload too.

, god knows what happened. (wire tripped, bad solder?) I saw it arcing and smoking a bit under poliester but I could do nothing at that time.I used ping-pong ball as topload, and continuous arcing finally created enough carbon to weaken the contact to topload too.

Arcs finally ignitedvery flammable celluloid ball, wich burned with low presence of air under the foil and exploded into a cloud of smoke. It stunk out terribly the whole room.

Fortunately wire seems to have welded itself to bolt under the poliester and this saved the secondary for now.

I strongly reccomend any high-voltage connections to be best possible, adviseably soldered and checked using ohmmeter.

PS. with bad contats spark difference usually isn't visible, until you eventually set something to fire..

Marko, Tue Jul 04 2006, 02:31PM

I usually drill a small hole and stick the wire trough it.

Sometimes two holes can be drilled, so wire goes inside and out wich makes a very good connection.

When winding I usually put a small piece of doble-sided sticky tape for first few turns, wich eases things a lot.

I even tought if it could be used on entire secondary length ( with thicker gauges, it would be visible with thin wires) in order to prevent unwinding/overlaping of wire if secondary isn't immediately warnished ( exscept myselfI saw this happening to Steve Conner and TDU, very frustrating experience

).

).Regarding poor electrical connections:

I had such one on my class E SSTC secondary.

To make things worse Secondary was filled with poliester goop to prevent melting of former at enormous frequecies. Top wire of secondary was soldered onto a brass bolt, and it looked pretty good when I put everything in.

After poliester dried I measured it and figured out it shows infinite resistance

, god knows what happened. (wire tripped, bad solder?) I saw it arcing and smoking a bit under poliester but I could do nothing at that time.I used ping-pong ball as topload, and continuous arcing finally created enough carbon to weaken the contact to topload too.

, god knows what happened. (wire tripped, bad solder?) I saw it arcing and smoking a bit under poliester but I could do nothing at that time.I used ping-pong ball as topload, and continuous arcing finally created enough carbon to weaken the contact to topload too.Arcs finally ignitedvery flammable celluloid ball, wich burned with low presence of air under the foil and exploded into a cloud of smoke. It stunk out terribly the whole room.

Fortunately wire seems to have welded itself to bolt under the poliester and this saved the secondary for now.

I strongly reccomend any high-voltage connections to be best possible, adviseably soldered and checked using ohmmeter.

PS. with bad contats spark difference usually isn't visible, until you eventually set something to fire..

Re: Secondary Coil Terminations

Avalanche, Tue Jul 04 2006, 02:51PM

I keep the secondary wire on the outside of the former now. The trick is to not bend it too sharply towards the topload, so I kind of spiral it towards a bolt sticking up from the centre of the former, and trap it under there. On small coils, I have started to cut the secondary wire right at the last turn, and solder on a thicker piece of insulated wire. Also make sure the topload is sheilding the top windings with its electric field, this helps a lot.

Avalanche, Tue Jul 04 2006, 02:51PM

I keep the secondary wire on the outside of the former now. The trick is to not bend it too sharply towards the topload, so I kind of spiral it towards a bolt sticking up from the centre of the former, and trap it under there. On small coils, I have started to cut the secondary wire right at the last turn, and solder on a thicker piece of insulated wire. Also make sure the topload is sheilding the top windings with its electric field, this helps a lot.

Re: Secondary Coil Terminations

HV Enthusiast, Tue Jul 04 2006, 07:51PM

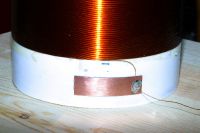

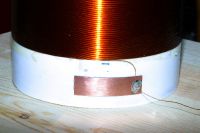

I simply take a rectangular piece of thin copper sheet (say 0.5" x 2") and glue to the PVC directly (clamping overnight) at the base of the coil. Use some type of superglue. make sure to scratch the surface beforehand.

HV Enthusiast, Tue Jul 04 2006, 07:51PM

I simply take a rectangular piece of thin copper sheet (say 0.5" x 2") and glue to the PVC directly (clamping overnight) at the base of the coil. Use some type of superglue. make sure to scratch the surface beforehand.

Re: Secondary Coil Terminations

GimpyJoe, Tue Jul 04 2006, 07:59PM

Never ever run the secondary wire inside the former. With small sstc's you may be fine but with drsstc's and sgtc's where spark length exceeds secondary length you can get sparks tracking along the inside of your former and burning carbon tracks that ruin your secondary. I find the best way to terminate the secondary winding is to wrap a few layers of electrical tape over the last few turns and cut the former right where the tape ends. Then make a corona ring for the top, the best way I have found is with a foam floral wreath ring covered in aluminum foil. Strip the wire leading from the top of the secondary and secure this to your corona ring by wrapping strips of aluminum tape around it and the ring to hold it tight. Then glue your ring right to the top of your secondary. I always make my toroid supports from PVC couplings wrapped in aluminum tape and set them on top of the corona ring so I get good contact.

GimpyJoe, Tue Jul 04 2006, 07:59PM

Never ever run the secondary wire inside the former. With small sstc's you may be fine but with drsstc's and sgtc's where spark length exceeds secondary length you can get sparks tracking along the inside of your former and burning carbon tracks that ruin your secondary. I find the best way to terminate the secondary winding is to wrap a few layers of electrical tape over the last few turns and cut the former right where the tape ends. Then make a corona ring for the top, the best way I have found is with a foam floral wreath ring covered in aluminum foil. Strip the wire leading from the top of the secondary and secure this to your corona ring by wrapping strips of aluminum tape around it and the ring to hold it tight. Then glue your ring right to the top of your secondary. I always make my toroid supports from PVC couplings wrapped in aluminum tape and set them on top of the corona ring so I get good contact.

Re: Secondary Coil Terminations

Marko, Tue Jul 04 2006, 08:30PM

Wire can be safely ran inside as long as it doesn't fall under top turn/hang too high from bottom turn of the secondary. If wire is nicely placed it usually won't be more than few cm long and this isn't a big deal.

It's anyway just for fixing purposes.

Marko, Tue Jul 04 2006, 08:30PM

Wire can be safely ran inside as long as it doesn't fall under top turn/hang too high from bottom turn of the secondary. If wire is nicely placed it usually won't be more than few cm long and this isn't a big deal.

It's anyway just for fixing purposes.

Re: Secondary Coil Terminations

Hazmatt_(The Underdog), Wed Jul 05 2006, 02:48AM

I'm using the copper pad at the bottom, but with a bonus. We have a pair of 6-32 nylon screws threaded through from inside to outside acting as studs. These studs have knurled nuts that snug a forked terminal against the copper pad for termination.

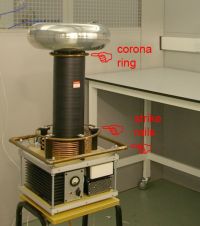

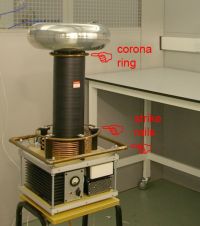

The top lead is terminated to a corona ring supported by ceramic supports. The corona ring serves as a termination and corona suppression. This helps when the system operates without a toroid, I like the crazy streamers with and without. So the ring helps in the sense that you don't cause a lot of stress to that last turn on top.

I'll have some pics soon so you can see what I'm referring to.

Hazmatt_(The Underdog), Wed Jul 05 2006, 02:48AM

I'm using the copper pad at the bottom, but with a bonus. We have a pair of 6-32 nylon screws threaded through from inside to outside acting as studs. These studs have knurled nuts that snug a forked terminal against the copper pad for termination.

The top lead is terminated to a corona ring supported by ceramic supports. The corona ring serves as a termination and corona suppression. This helps when the system operates without a toroid, I like the crazy streamers with and without. So the ring helps in the sense that you don't cause a lot of stress to that last turn on top.

I'll have some pics soon so you can see what I'm referring to.

Re: Secondary Coil Terminations

Wilson, Wed Jul 05 2006, 12:38PM

Pictures would be greatly appreciated :) I'm particularly interested in this corona ring. Is it just as simple as a ring of copper tubing?

Also, are there any effects of having ferrous objects in close proximity to the coil, ie, for the screw connections at the top and bottom? I imagine it might lower the resonant freq. somewhat and can cause some losses by induction, but any other negative effects? [Not that i'll be using iron in my coil of course ]

]

Wilson, Wed Jul 05 2006, 12:38PM

Pictures would be greatly appreciated :) I'm particularly interested in this corona ring. Is it just as simple as a ring of copper tubing?

Also, are there any effects of having ferrous objects in close proximity to the coil, ie, for the screw connections at the top and bottom? I imagine it might lower the resonant freq. somewhat and can cause some losses by induction, but any other negative effects? [Not that i'll be using iron in my coil of course

]

]Re: Secondary Coil Terminations

Steve Conner, Wed Jul 05 2006, 01:21PM

I think the only bad thing you can do is passing the wire through a hole in the former. The presence of the hole shortens the tracking distance down the inside of the secondary, and the sharp bend in the wire makes corona start early. Everything else is OK, although I think the little glued-on squares of copper sheet lower the flashover voltage compared to corona rings. I had a secondary made with these glued-on squares top and bottom, and it always flashed over between the squares.

My DRSSTC secondary has the square of sheet at the bottom (though it's glued to the bottom flange, not the tube itself) and a corona ring at the top, and has made sparks 4.4 times its own length. Having said that, when used without a breakout point, it flashes over from the top turn to the bottom turn. The spark breaks out from the bottom turn, tracks over the bottom of the tube, up the inside, out the top, and back to the top turn. I guess I should have left more unwound length at the ends. >_<

Metal hardware is :-/ IMO. I've used steel bolts to mount toroids on coils, and steel woodscrews to screw the secondary mounting flange to the baseboard. They never seemed to induction heat noticeably. But I do try not to use metal hardware in any area where the E-field is high, in case it starts corona. So I make sure nuts and bolts are hidden inside toroids, corona rings, or under the primary or whatever.

I just make corona rings out of 3/8" soft copper pipe that I bend into a circle. I leave a gap in the ends to stop them being shorted turns.

You should make the effort to strip the enamel off the wire and make a good connection. It'll probably not make any difference at high power, but if you're trying to tune it with a signal generator or whatever, it could make a huge difference.

Steve Conner, Wed Jul 05 2006, 01:21PM

I think the only bad thing you can do is passing the wire through a hole in the former. The presence of the hole shortens the tracking distance down the inside of the secondary, and the sharp bend in the wire makes corona start early. Everything else is OK, although I think the little glued-on squares of copper sheet lower the flashover voltage compared to corona rings. I had a secondary made with these glued-on squares top and bottom, and it always flashed over between the squares.

My DRSSTC secondary has the square of sheet at the bottom (though it's glued to the bottom flange, not the tube itself) and a corona ring at the top, and has made sparks 4.4 times its own length. Having said that, when used without a breakout point, it flashes over from the top turn to the bottom turn. The spark breaks out from the bottom turn, tracks over the bottom of the tube, up the inside, out the top, and back to the top turn. I guess I should have left more unwound length at the ends. >_<

Metal hardware is :-/ IMO. I've used steel bolts to mount toroids on coils, and steel woodscrews to screw the secondary mounting flange to the baseboard. They never seemed to induction heat noticeably. But I do try not to use metal hardware in any area where the E-field is high, in case it starts corona. So I make sure nuts and bolts are hidden inside toroids, corona rings, or under the primary or whatever.

I just make corona rings out of 3/8" soft copper pipe that I bend into a circle. I leave a gap in the ends to stop them being shorted turns.

You should make the effort to strip the enamel off the wire and make a good connection. It'll probably not make any difference at high power, but if you're trying to tune it with a signal generator or whatever, it could make a huge difference.

Re: Secondary Coil Terminations

Terry Fritz, Thu Jul 06 2006, 12:37AM

Hi,

I am a bad boy since all my secondaries have holes and connection drilled through the form.

But my coils are not real voltage stressed like those ones that do 3 times the coil length streamers. I think I have one of the largest 12/60 coils out there )

)

But what you really have to consider are voltage stress plots like this:

The brighter the image the higher the stress and the more likely it is to arc. The strike rail near the bottom is hanging out there like a lighting rod trying to attract streamers. The secondary is the real arc producer with the toroid radius trying to make the arcs. The top wind of the secondary is always a "hot spot" but only in the "outward" direction, not inward. If we color enhance:

The punctures at the top and bottom "inside" of the coil just don't have anywhere to arc too. The voltage difference is just not real high. Teh bottom of the coil is real dead so no problem there. The top is a little more stressed but there is no place for the arc to find a big potential difference other than the free space capacitance inside the coil which is not very great.

Cool charts :o))

So if your coil is not a super high performer (like Dan's) then you are probably fine.

I would alwasy try to get the connections sound and tight with low resistance. There are a few amps in the secondary and that will burn up a poor joint over time. High voltage will arc over, but that is going to bite you sooner or latter. It is also an energy drain on the normally high Q secondary. These days, I ponder silver filled epoxy...

I am going to study this tonight or tomorrow. My new coil will have a lot of things under the primary fairly close. So I am going to set it put an measure the effects on teh primary inductance and Q. Remind me if I forget to report back..

I drill two holes two to wrap the end of the wire to get a solid locked end of wire point that won't come loose. You should try not to make a "bump" toward the outside of the secondary though.

It is far safer not to make holes and keep from making any sharp points. It is far easier to do the opposite, but you have to be a little careful.

Cheers,

Terry

Terry Fritz, Thu Jul 06 2006, 12:37AM

Hi,

I am a bad boy since all my secondaries have holes and connection drilled through the form.

But my coils are not real voltage stressed like those ones that do 3 times the coil length streamers. I think I have one of the largest 12/60 coils out there

)

)

But what you really have to consider are voltage stress plots like this:

The brighter the image the higher the stress and the more likely it is to arc. The strike rail near the bottom is hanging out there like a lighting rod trying to attract streamers. The secondary is the real arc producer with the toroid radius trying to make the arcs. The top wind of the secondary is always a "hot spot" but only in the "outward" direction, not inward. If we color enhance:

The punctures at the top and bottom "inside" of the coil just don't have anywhere to arc too. The voltage difference is just not real high. Teh bottom of the coil is real dead so no problem there. The top is a little more stressed but there is no place for the arc to find a big potential difference other than the free space capacitance inside the coil which is not very great.

Cool charts :o))

So if your coil is not a super high performer (like Dan's) then you are probably fine.

I would alwasy try to get the connections sound and tight with low resistance. There are a few amps in the secondary and that will burn up a poor joint over time. High voltage will arc over, but that is going to bite you sooner or latter. It is also an energy drain on the normally high Q secondary. These days, I ponder silver filled epoxy...

Also, are there any effects of having ferrous objects in close proximity to the coil, ie, for the screw connections at the top and bottom? I imagine it might lower the resonant freq. somewhat and can cause some losses by induction, but any other negative effects? [Not that i'll be using iron in my coil of course ]

I am going to study this tonight or tomorrow. My new coil will have a lot of things under the primary fairly close. So I am going to set it put an measure the effects on teh primary inductance and Q. Remind me if I forget to report back..

I usually drill a small hole and stick the wire trough it.

Sometimes two holes can be drilled, so wire goes inside and out wich makes a very good connection.

I drill two holes two to wrap the end of the wire to get a solid locked end of wire point that won't come loose. You should try not to make a "bump" toward the outside of the secondary though.

It is far safer not to make holes and keep from making any sharp points. It is far easier to do the opposite, but you have to be a little careful.

Cheers,

Terry

Re: Secondary Coil Terminations

Terry Fritz, Thu Jul 06 2006, 03:42AM

Hi,

Oh!! I am a "double" bad boy now

Not only do I drill through and terminate my primaries inside, but now I am double posting!! But I think I do have significant "new information to add" since this data has never shown up in Tesla coil stuff before

As to:

See tonight's testing!!! I never would have thought before that the "center of the primary" was where to put the MOT!!

The SISG is the "perfect gap" for this stuff since is it totally repeatable... Bwahahahha!!

Wild stuff!!! Someday, we must make a field mapper program for the primary coil.... I guess "below the center" of the primary is like a funnel with lower fieds...

Cheers,

Terry

Terry Fritz, Thu Jul 06 2006, 03:42AM

Hi,

Oh!! I am a "double" bad boy now

Not only do I drill through and terminate my primaries inside, but now I am double posting!! But I think I do have significant "new information to add" since this data has never shown up in Tesla coil stuff before

As to:

Also, are there any effects of having ferrous objects in close proximity to the coil, ie, for the screw connections at the top and bottom? I imagine it might lower the resonant freq. somewhat and can cause some losses by induction

See tonight's testing!!! I never would have thought before that the "center of the primary" was where to put the MOT!!

The SISG is the "perfect gap" for this stuff since is it totally repeatable... Bwahahahha!!

Wild stuff!!! Someday, we must make a field mapper program for the primary coil.... I guess "below the center" of the primary is like a funnel with lower fieds...

Cheers,

Terry

Re: Secondary Coil Terminations

Wilson, Thu Jul 06 2006, 09:15AM

Thanks for the pics Terry. The stress plots were very interesting indeed.

Seems like the best method for high power coils is to spiral the wire up the former, and into a notch perhaps, to smoothly bend the wire, which would then be attached to a corona ring.

Could someone post a pic of a corona ring please? I need a gauge of how large it should be and how high it should be raised.

Is there any difference between attaching the topload very close to the last turn, or further away? Does mounting it too close promote arcs to the secondary?

Thanks,

Wilson

Wilson, Thu Jul 06 2006, 09:15AM

Thanks for the pics Terry. The stress plots were very interesting indeed.

Seems like the best method for high power coils is to spiral the wire up the former, and into a notch perhaps, to smoothly bend the wire, which would then be attached to a corona ring.

Could someone post a pic of a corona ring please? I need a gauge of how large it should be and how high it should be raised.

Is there any difference between attaching the topload very close to the last turn, or further away? Does mounting it too close promote arcs to the secondary?

Thanks,

Wilson

Re: Secondary Coil Terminations

Steve Conner, Thu Jul 06 2006, 03:40PM

I had a look through my tesla photos and found these pics. TBH, I don't know if the corona ring is any use, but I thought it looked neat.

Steve Conner, Thu Jul 06 2006, 03:40PM

I had a look through my tesla photos and found these pics. TBH, I don't know if the corona ring is any use, but I thought it looked neat.

Re: Secondary Coil Terminations

Terry Fritz, Thu Jul 06 2006, 11:01PM

Hi,

I worked out the numbers for the "big iron" next to the primary thing.

MOT position Rac(Ohm) Lpri (uH) Power Loss (W (14Arms))

No MOT 0.14 3.19 0

MOT in worst position 0.20 3.25 11.76

MOT in expected build position 0.148 3.19 1.57

On a conventional lossy spark gap coil, even a very close MOT in a bad position would not be noticed. We often see coils with transformers and such under the primary. It might be the case that their added losses are not too great. But the open core MOT will reject eddy and shorted turn currents. That is not the case for say a NST cover.

But I just tried a sheet of copper under the postion I will build the coil to (about 2.5 inches below the secondary) The loss was insignificant. So I thihnk if you space the iron and metal stuff about say 1/2 the primary diameter away you will be fine. Only when you get really close (inches) does it mater. The fields must stay pretty close to the primary coil. MandK could probably calculate such distances too with some creativity.

So bottom line is you can put stuff pretty close, espicially with a spark gap coil.

More...

I put a piece of copper under the primary like this:

It hardly made any difference!!! The magnetic fields around the primary must stay very close the the coil!! I don't know if there are any magnetic field mapping programs out there that could show this?

But it appears you can put metal objects really near the primary!!

Cheers,

Terry

Terry Fritz, Thu Jul 06 2006, 11:01PM

Hi,

I worked out the numbers for the "big iron" next to the primary thing.

MOT position Rac(Ohm) Lpri (uH) Power Loss (W (14Arms))

No MOT 0.14 3.19 0

MOT in worst position 0.20 3.25 11.76

MOT in expected build position 0.148 3.19 1.57

On a conventional lossy spark gap coil, even a very close MOT in a bad position would not be noticed. We often see coils with transformers and such under the primary. It might be the case that their added losses are not too great. But the open core MOT will reject eddy and shorted turn currents. That is not the case for say a NST cover.

But I just tried a sheet of copper under the postion I will build the coil to (about 2.5 inches below the secondary) The loss was insignificant. So I thihnk if you space the iron and metal stuff about say 1/2 the primary diameter away you will be fine. Only when you get really close (inches) does it mater. The fields must stay pretty close to the primary coil. MandK could probably calculate such distances too with some creativity.

So bottom line is you can put stuff pretty close, espicially with a spark gap coil.

More...

I put a piece of copper under the primary like this:

It hardly made any difference!!! The magnetic fields around the primary must stay very close the the coil!! I don't know if there are any magnetic field mapping programs out there that could show this?

But it appears you can put metal objects really near the primary!!

Cheers,

Terry

Re: Secondary Coil Terminations

Steve Conner, Thu Jul 06 2006, 11:30PM

Hi Terry

I always assumed that you could put metal objects as near the primary as you liked, as long as they were good RF conductors like copper. That was what gave me the courage to park all the electronics for my DRSSTC (shielded in aluminium boxes) directly under the primary. I put the tank capacitor under there too because I figured it was mostly just a big brick of copper foil with some plastic mixed in.

I'd expect that good conducting objects would increase the resonant frequency but not lower the Q significantly, whereas lossy objects like the MOT would do pretty much what you measured.

My conception of things leads me to believe that if you put the MOT in the least favourable place, putting the copper plate on top of it should restore most of the Q that you lost. Did you try that?

On a related note, I once tried shorting the strike rail on my DRSSTC with a big alligator clip so that it formed a shorted turn. The spark output wasn't affected as far as I could see, but after a few seconds the alligator clip melted in a shower of sparks.

Steve Conner, Thu Jul 06 2006, 11:30PM

Hi Terry

I always assumed that you could put metal objects as near the primary as you liked, as long as they were good RF conductors like copper. That was what gave me the courage to park all the electronics for my DRSSTC (shielded in aluminium boxes) directly under the primary. I put the tank capacitor under there too because I figured it was mostly just a big brick of copper foil with some plastic mixed in.

I'd expect that good conducting objects would increase the resonant frequency but not lower the Q significantly, whereas lossy objects like the MOT would do pretty much what you measured.

My conception of things leads me to believe that if you put the MOT in the least favourable place, putting the copper plate on top of it should restore most of the Q that you lost. Did you try that?

On a related note, I once tried shorting the strike rail on my DRSSTC with a big alligator clip so that it formed a shorted turn. The spark output wasn't affected as far as I could see, but after a few seconds the alligator clip melted in a shower of sparks.

Re: Secondary Coil Terminations

Terry Fritz, Fri Jul 07 2006, 12:32AM

Hi Steve,

I tried a copper plate over the MOT in the bad postion (yellow) as compared to just the MOT (white):

It helped a tiny bit but the loss was still pretty high. But the copper only covered about 1/2 the coil so it was probably not a good low loss shield. So I tried a full sheet about 1.2 inches abouve the coil like this:

And got this:

Still fairly lossy. but for a conventional coil that 0.1 ohm of added primary resistance will not matter!! If a coil has say 15 amps of primary RMS current the heat in the copper would be 22.5 watts. If that were all in a lossy aligator clip, it could very easily burn it up.

My little coil's performance goes way down if it is on concrete (~1.5 inch spacing). But it is much wider too. I will try to find a field mapper which will probably explain a lot about the dimensions and sizes.

Cool stuff!!

Cheers,

Terry

Terry Fritz, Fri Jul 07 2006, 12:32AM

Hi Steve,

I tried a copper plate over the MOT in the bad postion (yellow) as compared to just the MOT (white):

It helped a tiny bit but the loss was still pretty high. But the copper only covered about 1/2 the coil so it was probably not a good low loss shield. So I tried a full sheet about 1.2 inches abouve the coil like this:

And got this:

Still fairly lossy. but for a conventional coil that 0.1 ohm of added primary resistance will not matter!! If a coil has say 15 amps of primary RMS current the heat in the copper would be 22.5 watts. If that were all in a lossy aligator clip, it could very easily burn it up.

My little coil's performance goes way down if it is on concrete (~1.5 inch spacing). But it is much wider too. I will try to find a field mapper which will probably explain a lot about the dimensions and sizes.

Cool stuff!!

Cheers,

Terry

Re: Secondary Coil Terminations

HV Enthusiast, Fri Jul 07 2006, 12:40AM

22 watts seems like quite a bit. I have a full sheet of copper underneath my DRSSTC III (only 1 inch below primary coil), and even after very long run times (20 minutes or more), the copper is not even noticeably warm.

Relatively conductive material, such as copper and aluminum, will not pose much of a problem as far as losses go and actually are the best materials for magnetic shielding for the frequency we usually see in our coils (few hundred kHz) Copper actually becomes superior for shielding above 200kHz for magnetic shielding even over steel.

On the otherhand, magnetically soft metals, such as Mu metal, are very poor at magnetic shielding for Tesla coil frequencies are pose MAJOR losses in the system if placed in the vicinity of the primary coil. (Mu metal should only be used for 60Hz or lower magetic fields)

I did some experiments awhile ago on shielding my control electronics on my DRSSTC III system since the control electronics were literally less than 1 inch from the base of my primary coil. For the hell of it, i put a sheet of Mu metal in there just for fun, and it got so hot it was glowing red and melted my PVC enclosure top! On the other hand, i put a copper sheet, again only about 1 inch lower than the primary, and it solved my noise problem, and at the same time didn't even get warm, even after long runs. The Mu metal glowed Red after about 30 seconds.

Dan

HV Enthusiast, Fri Jul 07 2006, 12:40AM

wrote ...

If a coil has say 15 amps of primary RMS current the heat in the copper would be 22.5 watts. If that were all in a lossy aligator clip, it could very easily burn it up.

If a coil has say 15 amps of primary RMS current the heat in the copper would be 22.5 watts. If that were all in a lossy aligator clip, it could very easily burn it up.

22 watts seems like quite a bit. I have a full sheet of copper underneath my DRSSTC III (only 1 inch below primary coil), and even after very long run times (20 minutes or more), the copper is not even noticeably warm.

Relatively conductive material, such as copper and aluminum, will not pose much of a problem as far as losses go and actually are the best materials for magnetic shielding for the frequency we usually see in our coils (few hundred kHz) Copper actually becomes superior for shielding above 200kHz for magnetic shielding even over steel.

On the otherhand, magnetically soft metals, such as Mu metal, are very poor at magnetic shielding for Tesla coil frequencies are pose MAJOR losses in the system if placed in the vicinity of the primary coil. (Mu metal should only be used for 60Hz or lower magetic fields)

I did some experiments awhile ago on shielding my control electronics on my DRSSTC III system since the control electronics were literally less than 1 inch from the base of my primary coil. For the hell of it, i put a sheet of Mu metal in there just for fun, and it got so hot it was glowing red and melted my PVC enclosure top! On the other hand, i put a copper sheet, again only about 1 inch lower than the primary, and it solved my noise problem, and at the same time didn't even get warm, even after long runs. The Mu metal glowed Red after about 30 seconds.

Dan

Re: Secondary Coil Terminations

Marko, Fri Jul 07 2006, 12:40AM

Omg d00d. And I had an iron plate just about 3cm, under entire primary.

I knew it was bad but now i see how bad really...

Im' reconfiguring that coil for a while now, since this is most probable reason of my low primary current.

Marko, Fri Jul 07 2006, 12:40AM

Omg d00d. And I had an iron plate just about 3cm, under entire primary.

I knew it was bad but now i see how bad really...

Im' reconfiguring that coil for a while now, since this is most probable reason of my low primary current.

Re: Secondary Coil Terminations

HV Enthusiast, Fri Jul 07 2006, 12:45AM

Yeah, iron is definitely not the way to go for Tesla coil frequencies.

Soft magnetic materials have a very high initial permeability, while conductive metals such as copper, aluminum, steel, have relatively low initial permeability. But, as you increase in frequency, the permeability of the soft magnetic materials drops off way way faster than the conductive metals and these curves eventually cross one another if you were to plot the permeabilities.

HV Enthusiast, Fri Jul 07 2006, 12:45AM

Yeah, iron is definitely not the way to go for Tesla coil frequencies.

Soft magnetic materials have a very high initial permeability, while conductive metals such as copper, aluminum, steel, have relatively low initial permeability. But, as you increase in frequency, the permeability of the soft magnetic materials drops off way way faster than the conductive metals and these curves eventually cross one another if you were to plot the permeabilities.

Re: Secondary Coil Terminations

Terry Fritz, Fri Jul 07 2006, 04:42AM

Hi,

For my little SISG coil, I got the Ansoft Maxwell 2D thing going:

Here are the flux lines of the coil set up with the MOT under the coil and a fan to the right side:

Very few flux lines make it up to the top terminal and the aluminum fan seems to be transparent to magnetic flux. The big iron transformer bends the lines around.

We then can look at the B field (in Teslas )

)

The transformer attracts some of this field and is energized by it slightly.

The plot of field energy is where the "power" is at:

The power stays "very close" to the primary coil turns. That is why those big metal things in the area of the primary do not affect things much. If we increase the sensitivity, we can see more detail:

The energy still clings very close to the primary but you can see it touching the secondary now. If we really turn up the magnification, you can see the transformer having a tiny effect:

Sort of cool!!

Two feet of copper surface (front and back) with fan cooling is not going to get warm :o)) But 1 inch seems "too" close to me... But the primary energy loss is probably not a big deal. If it fixes the noise problem that is the main thing there.

That might get warm :o)) but I see you are fixing it

Cheers,

Terry

Terry Fritz, Fri Jul 07 2006, 04:42AM

Hi,

For my little SISG coil, I got the Ansoft Maxwell 2D thing going:

Here are the flux lines of the coil set up with the MOT under the coil and a fan to the right side:

Very few flux lines make it up to the top terminal and the aluminum fan seems to be transparent to magnetic flux. The big iron transformer bends the lines around.

We then can look at the B field (in Teslas

)

)

The transformer attracts some of this field and is energized by it slightly.

The plot of field energy is where the "power" is at:

The power stays "very close" to the primary coil turns. That is why those big metal things in the area of the primary do not affect things much. If we increase the sensitivity, we can see more detail:

The energy still clings very close to the primary but you can see it touching the secondary now. If we really turn up the magnification, you can see the transformer having a tiny effect:

Sort of cool!!

22 watts seems like quite a bit. I have a full sheet of copper underneath my DRSSTC III (only 1 inch below primary coil), and even after very long run times (20 minutes or more), the copper is not even noticeably warm.

Two feet of copper surface (front and back) with fan cooling is not going to get warm :o)) But 1 inch seems "too" close to me... But the primary energy loss is probably not a big deal. If it fixes the noise problem that is the main thing there.

Omg d00d. And I had an iron plate just about 3cm, under entire primary.

That might get warm :o)) but I see you are fixing it

Cheers,

Terry

Re: Secondary Coil Terminations

Sulaiman, Fri Jul 07 2006, 05:57AM

Terry,

In your magnetic field/energy analysis,

I see no magnetic field component due to the secondary

which I imagine will be significant/extensive due to;

- the physical size of the secondary

- the resonant current

e.g. B= (Uo x N x I) / (L x2) at the end of the solenoid (from memory)

The relative phases of primary and secondary current will vary during ringup

causing primary and secondary fields to add in-phase for periods of time,

so for worst-case just add the two fields arithmetically.

Sulaiman, Fri Jul 07 2006, 05:57AM

Terry,

In your magnetic field/energy analysis,

I see no magnetic field component due to the secondary

which I imagine will be significant/extensive due to;

- the physical size of the secondary

- the resonant current

e.g. B= (Uo x N x I) / (L x2) at the end of the solenoid (from memory)

The relative phases of primary and secondary current will vary during ringup

causing primary and secondary fields to add in-phase for periods of time,

so for worst-case just add the two fields arithmetically.

Re: Secondary Coil Terminations

Terry Fritz, Fri Jul 07 2006, 08:53PM

Hi,

I did the same thing for a cone primary here:

But in these plots, the secondary is only air and just outlined for reference. I had only been using the program for ten minutes and I did not (and still don't) have any idea what I am doing

But here I did model in the windings as copper with zero current. When the primary is at maximum current the secondary is at zero current. This is what I got:

I don't see a way to set up a current gradient along the coil.

The program also does electrostatic fields too. It is not too hard to run just a bit awkward. Sort of cool and is free )

)

Cheers,

Terry

Terry Fritz, Fri Jul 07 2006, 08:53PM

Hi,

I did the same thing for a cone primary here:

But in these plots, the secondary is only air and just outlined for reference. I had only been using the program for ten minutes and I did not (and still don't) have any idea what I am doing

But here I did model in the windings as copper with zero current. When the primary is at maximum current the secondary is at zero current. This is what I got:

I don't see a way to set up a current gradient along the coil.

The program also does electrostatic fields too. It is not too hard to run just a bit awkward. Sort of cool and is free

)

)Cheers,

Terry

Print this page