Royer induction heater

Marko, Sat Aug 13 2011, 11:48PMHi guys

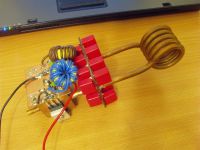

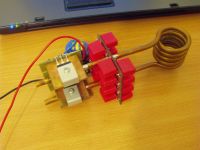

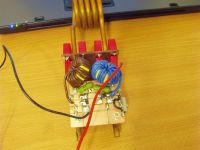

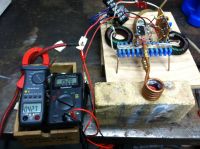

I remember a while ago some members complaining they can't find an easy to build and yet powerful enough IH to play with. This has been done before and I just reiterated it in my own way, built in one afternoon to see if it would work. To keep short here are some of the most important hints:

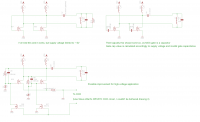

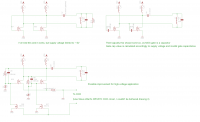

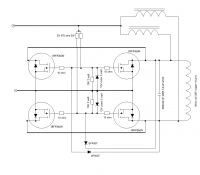

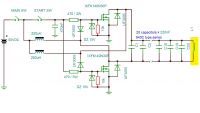

- The circuit is the very same as ZVS mazilli flyback driver (along with zeners and 470 ohm resistors), except it uses two inductors going from V+ to each end of the coil instead of one going to center of the coil.

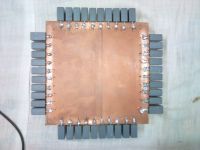

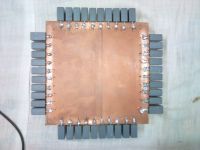

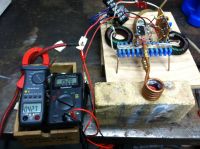

- Use water cooling. Your mosfet drains are electrically connected to each end of the coil and you can use this as an opportunity to cool them too without investing in big heatsinks. I soldered some pieces of copper to loose ends of the copper pipe and bolted mosfets to them - not the best waterblocks in existence but worked more than well enough.

- Use a MMC of many parallel FKP caps for your tank cap. If you want to push a lot of power you'll need a lot of capacitance. I used 16 * 270nF, total over 4uF. The MMC has to handle very large current so you can't save there.

- Don't push your supply voltage, 50-60V would be ideal along with IRFP260's. I used up to 30V and could push over 600 watts and melt aluminum and ignite steel coins quite fast. If I used bigger mosfets like IRFP260's and 60V input, I could do likely over 2kW. This would ruin the caps very quickly though as they get very hot and were a limiting factor in my design. If you want an industrial power IH prepare to buy hundreds of small caps of a conduction cooled cap (both might turn out costing about the same).

Here is a video for now showing melting a brass coin, melting/burning up a steel coin and melting a piece of aluminum heatsink (shown uncut), along with some additional aluminum re-melting.

It was fun and I'm thinking about building a bigger version, with an unique water-cooled MMC. I don't have a proper power source though, I feel sorry killing my only MOT to rewind it. I'll post schematics (if required at all?) after some interest shows up.

*Some pics and a schemo*

Re: Royer induction heater

jnbrex, Sun Aug 14 2011, 02:10AM

That thing is awesome! Some schematics would be great too. That is a very interesting project, but I think it looks a little too complicated for my novice soldering skills...

On another note, does the copper pipe that is the heater get hot? I thought that induction heaters worked through eddy currents produced on the object to be heated and didn't actually heat up themselves.

jnbrex, Sun Aug 14 2011, 02:10AM

That thing is awesome! Some schematics would be great too. That is a very interesting project, but I think it looks a little too complicated for my novice soldering skills...

On another note, does the copper pipe that is the heater get hot? I thought that induction heaters worked through eddy currents produced on the object to be heated and didn't actually heat up themselves.

Re: Royer induction heater

radhoo, Sun Aug 14 2011, 07:43AM

looks and works great!

a few months ago I built something similar, schematics and photos here:

radhoo, Sun Aug 14 2011, 07:43AM

looks and works great!

a few months ago I built something similar, schematics and photos here:

Re: Royer induction heater

Conundrum, Sun Aug 14 2011, 12:46PM

Its a shame you can't buy cheap magnetic solder (yet!)

Something like this would be great for emergency repairs etc and for people who aren't allowed to use a conventional soldering iron for safety reasons.

-A

Conundrum, Sun Aug 14 2011, 12:46PM

Its a shame you can't buy cheap magnetic solder (yet!)

Something like this would be great for emergency repairs etc and for people who aren't allowed to use a conventional soldering iron for safety reasons.

-A

Re: Royer induction heater

Gabriel35, Wed Aug 17 2011, 02:33AM

Incredible!

How do you got so much power from a simple Royer oscillator? I'm very very interested on the schematic *-*

I got some nice IGBT's and 30vDC Supplys here, and I can't wait to try this scheme out!

Can IGBT's be used instead of mosfets?

I have here a pair of IRFPG40 4.3A @ 1000v

and a Pair of IRFZ48N 64A @ 55v

Can some of them be used?

It's really the same mazilli's driver only with two inductors and strong caps?

Thank you!!

Gabriel35, Wed Aug 17 2011, 02:33AM

Incredible!

How do you got so much power from a simple Royer oscillator? I'm very very interested on the schematic *-*

I got some nice IGBT's and 30vDC Supplys here, and I can't wait to try this scheme out!

Can IGBT's be used instead of mosfets?

I have here a pair of IRFPG40 4.3A @ 1000v

and a Pair of IRFZ48N 64A @ 55v

Can some of them be used?

It's really the same mazilli's driver only with two inductors and strong caps?

Thank you!!

Re: Royer induction heater

Dr. ISOTOP, Wed Aug 17 2011, 03:13AM

Dr. ISOTOP, Wed Aug 17 2011, 03:13AM

Conundrum wrote ...

Its a shame you can't buy cheap magnetic solder (yet!)

Something like this would be great for emergency repairs etc and for people who aren't allowed to use a conventional soldering iron for safety reasons.

-A

Induction heaters will melt normal solder. It's a common misconception that they only heat ferrous objects.Its a shame you can't buy cheap magnetic solder (yet!)

Something like this would be great for emergency repairs etc and for people who aren't allowed to use a conventional soldering iron for safety reasons.

-A

Re: Royer induction heater

Gabriel35, Wed Aug 17 2011, 12:52PM

Can you post some photos of your circuit too?

Thank you!

I can't wait to buy some mosfets and try it out!

Gabriel35, Wed Aug 17 2011, 12:52PM

Can you post some photos of your circuit too?

Thank you!

I can't wait to buy some mosfets and try it out!

Re: Royer induction heater

Marko, Wed Aug 17 2011, 01:12PM

Yes it is, and if you wanted you could even center-tap the coil and use a single inductor if you wished. Another advantage of this would be that you could drive the water supply through both ends of the coil and having it exit through the center tap, removing the temperature difference that would normally be experienced between mosfets cooled with same water flow. But this didn't really matter at this power level and used only a tiny fraction of possible flow rate, so you can do as you wish I guess.

Regarding switches, I would still best recommend IRFP260's and a rewound MOT for the power supply.

Those IRFG40 high voltage mosfets are pretty useless for this circuit, you want low voltage mosfets with ON resistance of 50m ohms or less which is important for keeping the circuit stable. IGBT's, especially 1200V ones have high voltage drop which may again result in the circuit ceasing to oscillate and shorting out the power supply. You can try them but at your own risk, and they will probably not be as efficient as mosfets at such low voltages.

IRFZ44/48 or whatever are another extreme, with them you would be limited to like a 12-15V supply (car battery)? providing tens of amps, and you would have to put a step up transformer between your driver and the tank circuit, or use a 4x larger tank cap than I did which would be impractical.

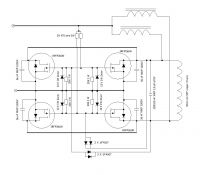

The radhoo's schematic which uses the transformer is wrong, the tank cap should go after the transformer and not before it by the way.

Marko, Wed Aug 17 2011, 01:12PM

Gabriel35 wrote ...

Incredible!

How do you got so much power from a simple Royer oscillator? I'm very very interested on the schematic *-*

I got some nice IGBT's and 30vDC Supplys here, and I can't wait to try this scheme out!

Can IGBT's be used instead of mosfets?

I have here a pair of IRFPG40 4.3A @ 1000v

and a Pair of IRFZ48N 64A @ 55v

Can some of them be used?

It's really the same mazilli's driver only with two inductors and strong caps?

Thank you!!

Incredible!

How do you got so much power from a simple Royer oscillator? I'm very very interested on the schematic *-*

I got some nice IGBT's and 30vDC Supplys here, and I can't wait to try this scheme out!

Can IGBT's be used instead of mosfets?

I have here a pair of IRFPG40 4.3A @ 1000v

and a Pair of IRFZ48N 64A @ 55v

Can some of them be used?

It's really the same mazilli's driver only with two inductors and strong caps?

Thank you!!

Yes it is, and if you wanted you could even center-tap the coil and use a single inductor if you wished. Another advantage of this would be that you could drive the water supply through both ends of the coil and having it exit through the center tap, removing the temperature difference that would normally be experienced between mosfets cooled with same water flow. But this didn't really matter at this power level and used only a tiny fraction of possible flow rate, so you can do as you wish I guess.

Regarding switches, I would still best recommend IRFP260's and a rewound MOT for the power supply.

Those IRFG40 high voltage mosfets are pretty useless for this circuit, you want low voltage mosfets with ON resistance of 50m ohms or less which is important for keeping the circuit stable. IGBT's, especially 1200V ones have high voltage drop which may again result in the circuit ceasing to oscillate and shorting out the power supply. You can try them but at your own risk, and they will probably not be as efficient as mosfets at such low voltages.

IRFZ44/48 or whatever are another extreme, with them you would be limited to like a 12-15V supply (car battery)? providing tens of amps, and you would have to put a step up transformer between your driver and the tank circuit, or use a 4x larger tank cap than I did which would be impractical.

The radhoo's schematic which uses the transformer is wrong, the tank cap should go after the transformer and not before it by the way.

Re: Royer induction heater

Gabriel35, Wed Aug 17 2011, 02:36PM

Ok!

So the secret of the huge power of the classic Royer Oscillator isn't the two inductors?

I have here a bank of 32x 0.068uF @ 630v - P612 w722 EPCOS Model (P6XX MKP capacitor)

Resulting a capacitance of 2.176uF. I can buy those IRFP260's and try it out!

I've experienced with Royer Oscillator a long time ago using two IRFP250 and a 36v Supply. But it was so weak, It was just capable of making a screwdriver redhot. I think that I still don't know what is the BIG difference between this circuit and the classic ones, like the one I've tryed... It is pretty incredible the power amout that you achieved on that video =O

What about the number of turns and diameter of work coil? are them important variables?

About the water? It's just to maintain the whole thing as cool as possible or it affects the Pratical Power of the circuit?

The capacitors? Can i use the ones mentioned? Do I need more capacitance?

I have a transformer here that is 24v. Rectified and with 8x 470uF capacitors it results in 36vDC, this tranformer is capable of 10~15amps. Can I use it?

About the Zeners, I plan to use 1N5349B 5w.

And the Fast Rectifiers, BYT11-1000

The 470 Ohm 5w Resistors, OK

And the 10K 0.5w too. =D

EDIT: I've found some IRF540N's here...VDSS = 100V RDS(on) = 44mΩ ID = 33A... Can I use them with 36vDC?

Thank you, and nice pics too!

Gabriel35, Wed Aug 17 2011, 02:36PM

Ok!

So the secret of the huge power of the classic Royer Oscillator isn't the two inductors?

I have here a bank of 32x 0.068uF @ 630v - P612 w722 EPCOS Model (P6XX MKP capacitor)

Resulting a capacitance of 2.176uF. I can buy those IRFP260's and try it out!

I've experienced with Royer Oscillator a long time ago using two IRFP250 and a 36v Supply. But it was so weak, It was just capable of making a screwdriver redhot. I think that I still don't know what is the BIG difference between this circuit and the classic ones, like the one I've tryed... It is pretty incredible the power amout that you achieved on that video =O

What about the number of turns and diameter of work coil? are them important variables?

About the water? It's just to maintain the whole thing as cool as possible or it affects the Pratical Power of the circuit?

The capacitors? Can i use the ones mentioned? Do I need more capacitance?

I have a transformer here that is 24v. Rectified and with 8x 470uF capacitors it results in 36vDC, this tranformer is capable of 10~15amps. Can I use it?

About the Zeners, I plan to use 1N5349B 5w.

And the Fast Rectifiers, BYT11-1000

The 470 Ohm 5w Resistors, OK

And the 10K 0.5w too. =D

EDIT: I've found some IRF540N's here...VDSS = 100V RDS(on) = 44mΩ ID = 33A... Can I use them with 36vDC?

Thank you, and nice pics too!

Re: Royer induction heater

Forty, Wed Aug 17 2011, 04:00PM

ah the pictures certainly help. I can close the paused youtube video tab now lol. I wonder how the dual inductor scheme would work with driving a flyback.

I imagine you formed your work coil around a pipe. Did you fill it with sand or anneal it to help with even bending? I've got the tubing sitting here, I just don't want to screw it all up by bending it improperly.

what do you guys think about fairchild's fdp2552

for zvs circuits like this? or should I finally give in and buy the proper irf's?

Forty, Wed Aug 17 2011, 04:00PM

ah the pictures certainly help. I can close the paused youtube video tab now lol. I wonder how the dual inductor scheme would work with driving a flyback.

I imagine you formed your work coil around a pipe. Did you fill it with sand or anneal it to help with even bending? I've got the tubing sitting here, I just don't want to screw it all up by bending it improperly.

what do you guys think about fairchild's fdp2552

for zvs circuits like this? or should I finally give in and buy the proper irf's?

Re: Royer induction heater

Inducktion, Wed Aug 17 2011, 05:17PM

When I made my induction heater's coil, I filled it up with sand to make sure it didn't bend. Make sure you have it full, with no pockets otherwise you'll end up ruining the pipe. (I have a few kinks in mine because of that, but it still works fine)

and, the dual inductor thing probably wouldn't help with a flyback, because the windings on the core are technically inductors/an inductor as well.

Inducktion, Wed Aug 17 2011, 05:17PM

When I made my induction heater's coil, I filled it up with sand to make sure it didn't bend. Make sure you have it full, with no pockets otherwise you'll end up ruining the pipe. (I have a few kinks in mine because of that, but it still works fine)

and, the dual inductor thing probably wouldn't help with a flyback, because the windings on the core are technically inductors/an inductor as well.

Re: Royer induction heater

Forty, Wed Aug 17 2011, 07:02PM

i wonder if filling it with water and freezing it would work the same as the sand (that's what they do for brass musical instruments, thanks "how it's made")

I didn't mean to improve the driving of a flyback, i just wondered if it would work equally as well as a single inductor. with less turns actually required on the core, I could use thicker wire with some of my smaller transformers.

Forty, Wed Aug 17 2011, 07:02PM

i wonder if filling it with water and freezing it would work the same as the sand (that's what they do for brass musical instruments, thanks "how it's made")

I didn't mean to improve the driving of a flyback, i just wondered if it would work equally as well as a single inductor. with less turns actually required on the core, I could use thicker wire with some of my smaller transformers.

Re: Royer induction heater

Marko, Wed Aug 17 2011, 11:58PM

Hy everyone,

Gabriel: It's important to use a large tank capacitance, 4uF in my case, if you keep 0.68uF or whatever was used for a mazzili driver the power output will likely be pathetic. Using higher supply voltage as well as a step-up isolation transformer also helps. On the other hand it's completely the same whether you use one DC link inductor or two!

Note that in this circuit the device has to be rated at least pi*supply voltage, hence 30V is pretty much the macimum for a 100V mosfet. Your supply voltage will probably sag under 30V even without workpiece, but I would use a variac anyway to bring the voltage up if it sags too much when you put the workpiece in. You would need a huge transformer with good regulation if you want to go without variac and drive the circuit to full power.

Also if you have only a 2uF tank cap, your power throughput might be somewhat disappointing if you don't get 200V mosfets. But your current ones should work for the first try.

Forty,Inducktion: Yes, FDB2552 looks great if you have some, although a 200V mosfet would be even better as I think.

I filled my coil with table salt before winding it, and blown it out (with some difficulty) with a compressor later. I didn't think of freezing the coil with water in it, it looks like even better idea actually.

Marko

Marko, Wed Aug 17 2011, 11:58PM

Hy everyone,

Gabriel: It's important to use a large tank capacitance, 4uF in my case, if you keep 0.68uF or whatever was used for a mazzili driver the power output will likely be pathetic. Using higher supply voltage as well as a step-up isolation transformer also helps. On the other hand it's completely the same whether you use one DC link inductor or two!

Note that in this circuit the device has to be rated at least pi*supply voltage, hence 30V is pretty much the macimum for a 100V mosfet. Your supply voltage will probably sag under 30V even without workpiece, but I would use a variac anyway to bring the voltage up if it sags too much when you put the workpiece in. You would need a huge transformer with good regulation if you want to go without variac and drive the circuit to full power.

Also if you have only a 2uF tank cap, your power throughput might be somewhat disappointing if you don't get 200V mosfets. But your current ones should work for the first try.

Forty,Inducktion: Yes, FDB2552 looks great if you have some, although a 200V mosfet would be even better as I think.

I filled my coil with table salt before winding it, and blown it out (with some difficulty) with a compressor later. I didn't think of freezing the coil with water in it, it looks like even better idea actually.

Marko

Re: Royer induction heater

Adam Munich, Thu Aug 18 2011, 12:27AM

Funny, I've built that same circuit in the past as an experiment. It worked, but my mosfets kept exploding so I didn't bother to post it.

Maybe I just used crappy mosfets, but good job for getting it working marko!

Adam Munich, Thu Aug 18 2011, 12:27AM

Marko wrote ...

Funny, I've built that same circuit in the past as an experiment. It worked, but my mosfets kept exploding so I didn't bother to post it.

Maybe I just used crappy mosfets, but good job for getting it working marko!

Re: Royer induction heater

Dr. ISOTOP, Thu Aug 18 2011, 12:56AM

The giant Eurofarad Snubbers on Ebay are excellent tank caps; I've run mine to 4KVA with only mild heating (cooled through the two large metal terminals).

This has got to be the most beautiful Royer project I've seen

Dr. ISOTOP, Thu Aug 18 2011, 12:56AM

The giant Eurofarad Snubbers on Ebay are excellent tank caps; I've run mine to 4KVA with only mild heating (cooled through the two large metal terminals).

This has got to be the most beautiful Royer project I've seen

Re: Royer induction heater

Marko, Thu Aug 18 2011, 02:00AM

Hey bwang, those caps you discovered do look superb for induction heaters, so depressing they don't ship them out of US. I see some of them have large flat terminals, are those designed to be conduction cooled? And by 4kVA I assume you mean apparent input power, not the reactive power handled by the cap

WIMA caps do surprisingly well though, I was very surprised to calculate that current in my work coil with no load is over 100A, all of which is handled by just 16 small paralleled caps! It's surprising they are surviving it at all without bulging up or showing decreased capacitance.

Grenadier, your circuit might have been unstable if you used high RDS-on mosfets like IRFP450's. That's the main reason why I enforced low voltages here.

marko

Marko, Thu Aug 18 2011, 02:00AM

Hey bwang, those caps you discovered do look superb for induction heaters, so depressing they don't ship them out of US. I see some of them have large flat terminals, are those designed to be conduction cooled? And by 4kVA I assume you mean apparent input power, not the reactive power handled by the cap

WIMA caps do surprisingly well though, I was very surprised to calculate that current in my work coil with no load is over 100A, all of which is handled by just 16 small paralleled caps! It's surprising they are surviving it at all without bulging up or showing decreased capacitance.

Grenadier, your circuit might have been unstable if you used high RDS-on mosfets like IRFP450's. That's the main reason why I enforced low voltages here.

marko

Re: Royer induction heater

radhoo, Thu Aug 18 2011, 03:48PM

The purpose of the ferrite core is as insulation transformer. It reduces stress on transistors and capacitor.

This approach can be used to power the original winding of flybacks as well, since we know that a concentric primary-secondary topology will put out more power.

Your current design is identical to my second variant, without the insulation transformer, just that you increased the power ratings with the bigger tank capacitor and work coil. Others willing to try this might want to look for mosfets with lower Rds instead, since keeping mosfets cool in this circuit is essential.

radhoo, Thu Aug 18 2011, 03:48PM

Marko wrote ...

The radhoo's schematic which uses the transformer is wrong, the tank cap should go after the transformer and not before it by the way.

I think you got it a little wrong. You can't move the capacitor as the oscillator will not work.The radhoo's schematic which uses the transformer is wrong, the tank cap should go after the transformer and not before it by the way.

The purpose of the ferrite core is as insulation transformer. It reduces stress on transistors and capacitor.

This approach can be used to power the original winding of flybacks as well, since we know that a concentric primary-secondary topology will put out more power.

Your current design is identical to my second variant, without the insulation transformer, just that you increased the power ratings with the bigger tank capacitor and work coil. Others willing to try this might want to look for mosfets with lower Rds instead, since keeping mosfets cool in this circuit is essential.

Re: Royer induction heater

Marko, Thu Aug 18 2011, 10:40PM

Hi radhoo,

the simple answer is, why would you want to have your transformer suffer all the reactive power in the tank circuit when you can have it handle only the real power instead? If I was to place a transformer in my circuit this way, it would need to handle the several tens of kVa present there, requiring a huge ferrite pole pig.

On the other hand having the transformer before the tank circuit it would only need to handle 600 watts of real power that are really going in, which could be done on a flyback core or similar.

I've used these transformers all the time, but on low power levels though (<100W). A 1:1 transformer produces absolutely no observable difference in operation, other than the output being isolated from the input. You can center tap the primary and use a single inductor instead of two and everything stays the same again!

If you use a step-up transformer, it will make the impedance of your tank circuit appear lower to the driver section, divided by square of sec/pri ratio: in other words, the oscillator will feel like you're using more capacitance and less inductance, with everything else staying the same.

I would still take care to minimize the leakage inductance on the transformer as much as possible, which may destabilize the oscillator but simply overloading it could do the same. If I slapped a 1:2 transformer to my circuit I'm pretty certain it would explode, but 1:1 should make no difference at all.

I actually wanted to try it out on this IH, but am unsure how to mount it to the existing configuration of the circuit, would have to isolate the mosfets from the work coil which is some trouble to do now :(

Still if you're going to use a 50Hz transformer like rewound MOT for a power supply it might make no sense to use an additional ferrite transformer - unless you have only very low voltage supply and low voltage mosfets like IRFZ44's and you want to push a lot of power.

Marko

Marko, Thu Aug 18 2011, 10:40PM

I think you got it a little wrong. You can't move the capacitor as the oscillator will not work.

The purpose of the ferrite core is as insulation transformer. It reduces stress on transistors and capacitor.

Hi radhoo,

the simple answer is, why would you want to have your transformer suffer all the reactive power in the tank circuit when you can have it handle only the real power instead? If I was to place a transformer in my circuit this way, it would need to handle the several tens of kVa present there, requiring a huge ferrite pole pig.

On the other hand having the transformer before the tank circuit it would only need to handle 600 watts of real power that are really going in, which could be done on a flyback core or similar.

I've used these transformers all the time, but on low power levels though (<100W). A 1:1 transformer produces absolutely no observable difference in operation, other than the output being isolated from the input. You can center tap the primary and use a single inductor instead of two and everything stays the same again!

If you use a step-up transformer, it will make the impedance of your tank circuit appear lower to the driver section, divided by square of sec/pri ratio: in other words, the oscillator will feel like you're using more capacitance and less inductance, with everything else staying the same.

I would still take care to minimize the leakage inductance on the transformer as much as possible, which may destabilize the oscillator but simply overloading it could do the same. If I slapped a 1:2 transformer to my circuit I'm pretty certain it would explode, but 1:1 should make no difference at all.

I actually wanted to try it out on this IH, but am unsure how to mount it to the existing configuration of the circuit, would have to isolate the mosfets from the work coil which is some trouble to do now :(

Still if you're going to use a 50Hz transformer like rewound MOT for a power supply it might make no sense to use an additional ferrite transformer - unless you have only very low voltage supply and low voltage mosfets like IRFZ44's and you want to push a lot of power.

Marko

Re: Royer induction heater

Gabriel35, Fri Aug 19 2011, 01:55PM

Hey Marko!

I'm experiencing with the circuit again.

I got some cheap as hell IRF540N's just to try out and but how you said, 36v seems to be so much for them to keep.

I'm waiting for my new IRFP260N's to arrive.

I have 8x 1uF 250 X2 Category Capacitors here.

can I use a capacitance of 8uF or something like that? How does it behave on the circuit?

Can you post a video of your oscillator melting a screw? and some photos of your Power Supply stage?

Can I use 13v Zeners instead of 12v ones?

Thank you!! =D

Gabriel35, Fri Aug 19 2011, 01:55PM

Hey Marko!

I'm experiencing with the circuit again.

I got some cheap as hell IRF540N's just to try out and but how you said, 36v seems to be so much for them to keep.

I'm waiting for my new IRFP260N's to arrive.

I have 8x 1uF 250 X2 Category Capacitors here.

can I use a capacitance of 8uF or something like that? How does it behave on the circuit?

Can you post a video of your oscillator melting a screw? and some photos of your Power Supply stage?

Can I use 13v Zeners instead of 12v ones?

Thank you!! =D

Re: Royer induction heater

Forty, Fri Aug 19 2011, 03:46PM

the 13v zeners should be just fine. I think his power supply is just a MOT with a rewound secondary and then a big rectifier and some smoothing lytics (unless that's what you meant that you wanted to see)

Forty, Fri Aug 19 2011, 03:46PM

the 13v zeners should be just fine. I think his power supply is just a MOT with a rewound secondary and then a big rectifier and some smoothing lytics (unless that's what you meant that you wanted to see)

Re: Royer induction heater

Marko, Fri Aug 19 2011, 04:52PM

Hi guys,

In the video I'm actually using two UPS transformers wired in reverse, in series - rectified and filtered with a bunch of caps. I have a MOT too but I don't want to hammer out it's secondary and I'm actually building a transformer now from some huge cores I had around from old dead OBIT's.

I suggested a MOT as an easy solution for a power supply for soemone who has acces to lots of MOT's.

Gabriel: I don't know what type your caps are so I can't tell whether they'll be good or not, but also their capacitance seems a bit too high individually, unless they can handle 20-30amps per cap I wouldn't use them. If they are polyester, which they most likely are, the circuit might not work at all or they may just burn out.

Marko

Marko, Fri Aug 19 2011, 04:52PM

Hi guys,

In the video I'm actually using two UPS transformers wired in reverse, in series - rectified and filtered with a bunch of caps. I have a MOT too but I don't want to hammer out it's secondary and I'm actually building a transformer now from some huge cores I had around from old dead OBIT's.

I suggested a MOT as an easy solution for a power supply for soemone who has acces to lots of MOT's.

Gabriel: I don't know what type your caps are so I can't tell whether they'll be good or not, but also their capacitance seems a bit too high individually, unless they can handle 20-30amps per cap I wouldn't use them. If they are polyester, which they most likely are, the circuit might not work at all or they may just burn out.

Marko

Re: Royer induction heater

Goodchild, Fri Aug 19 2011, 07:27PM

Beautiful construction, all your compact projects are great!

May I ask what the overall voltage and RMS current rating is of the MMC bank you are running? It must be rather high by the amount of power you are putting into it!

Goodchild, Fri Aug 19 2011, 07:27PM

Beautiful construction, all your compact projects are great!

May I ask what the overall voltage and RMS current rating is of the MMC bank you are running? It must be rather high by the amount of power you are putting into it!

Re: Royer induction heater

Nah, Fri Aug 19 2011, 08:39PM

I knew it was a good idea to get all those WIMA caps!

Also, would it be ok to use a back of caps with different values?

Thank you

Paul

Nah, Fri Aug 19 2011, 08:39PM

I knew it was a good idea to get all those WIMA caps!

Also, would it be ok to use a back of caps with different values?

Thank you

Paul

Re: Royer induction heater

Forty, Fri Aug 19 2011, 09:22PM

oh whoops. i thought by "I don't have a proper power source though, I feel sorry killing my only MOT to rewind it." you meant that you already had killed your mot and currently feel bad. sorry for responding incorrectly on your behalf.

i wonder too about using a bank of mismatched capacitors (i've got lots of salvaged mkp x2 box caps.) I suppose it would be fun to try it out and possibly explode a few.

anyone ever used an ac oil filled cap (like a MOC) in a high current tank circuit? i've got 3 10.5uf 520vac oil filled caps from a large ballast and no idea what to do with them.

Forty, Fri Aug 19 2011, 09:22PM

oh whoops. i thought by "I don't have a proper power source though, I feel sorry killing my only MOT to rewind it." you meant that you already had killed your mot and currently feel bad. sorry for responding incorrectly on your behalf.

i wonder too about using a bank of mismatched capacitors (i've got lots of salvaged mkp x2 box caps.) I suppose it would be fun to try it out and possibly explode a few.

anyone ever used an ac oil filled cap (like a MOC) in a high current tank circuit? i've got 3 10.5uf 520vac oil filled caps from a large ballast and no idea what to do with them.

Re: Royer induction heater

Gabriel35, Mon Aug 22 2011, 01:42AM

I Have the same doubt. about different cap values...

Thank you!

Gabriel35, Mon Aug 22 2011, 01:42AM

Nah wrote ...

I knew it was a good idea to get all those WIMA caps!

Also, would it be ok to use a back of caps with different values?

Thank you

Paul

I knew it was a good idea to get all those WIMA caps!

Also, would it be ok to use a back of caps with different values?

Thank you

Paul

I Have the same doubt. about different cap values...

Thank you!

Re: Royer induction heater

Dr. ISOTOP, Mon Aug 22 2011, 02:18AM

Don't use oil/paper/mylar caps in a tank circuit. You'll be real sad when it fails and spits boiling oil at you.

Dr. ISOTOP, Mon Aug 22 2011, 02:18AM

Forty wrote ...

oh whoops. i thought by "I don't have a proper power source though, I feel sorry killing my only MOT to rewind it." you meant that you already had killed your mot and currently feel bad. sorry for responding incorrectly on your behalf.

i wonder too about using a bank of mismatched capacitors (i've got lots of salvaged mkp x2 box caps.) I suppose it would be fun to try it out and possibly explode a few.

anyone ever used an ac oil filled cap (like a MOC) in a high current tank circuit? i've got 3 10.5uf 520vac oil filled caps from a large ballast and no idea what to do with them.

Different-valued caps will share current unequally, leading to possible failure of some of the capacitors.oh whoops. i thought by "I don't have a proper power source though, I feel sorry killing my only MOT to rewind it." you meant that you already had killed your mot and currently feel bad. sorry for responding incorrectly on your behalf.

i wonder too about using a bank of mismatched capacitors (i've got lots of salvaged mkp x2 box caps.) I suppose it would be fun to try it out and possibly explode a few.

anyone ever used an ac oil filled cap (like a MOC) in a high current tank circuit? i've got 3 10.5uf 520vac oil filled caps from a large ballast and no idea what to do with them.

Don't use oil/paper/mylar caps in a tank circuit. You'll be real sad when it fails and spits boiling oil at you.

Re: Royer induction heater

Marko, Mon Aug 22 2011, 03:17AM

hi guys,

If you have the caps from same manufacturer, of same technology and voltage rating but different capacitance I think they should do reasonably well when paralleled. Caps will form a current divider and all of them will share portions of current proportional to their capacitance.

The downside is that not all of the caps may be able to take the same power dissipation punishment due to surface area of their package. Due to square/cube law a lot of small, low-value caps are of benefit here,

So if you have caps that are like 0.27uF and 0.15uF mixing them should work fine, but you wouldn't be able to run 0.15's to their maximum without cooking the other ones. So I say mix them and have fun - just watch them not to overheat. The general rule for polypropylene caps seems to be, if they're too hot to touch, they're too hot, as I found out the hard way.

Goodchild:

I'm not sure what exactly is the current rating of the caps, but dividing the tank voltage with it's characteristic impedance yielded a current value of as much as 150A - and without water cooling the coil gets sizzling hot in seconds. I'm very surprised how well are the caps holding without blowing up so far.

They are 160V DC caps and I'm running them up to 70V AC,which seems to be about the limit considering they get quite hot.

Cheers,

Marko

Marko, Mon Aug 22 2011, 03:17AM

hi guys,

If you have the caps from same manufacturer, of same technology and voltage rating but different capacitance I think they should do reasonably well when paralleled. Caps will form a current divider and all of them will share portions of current proportional to their capacitance.

The downside is that not all of the caps may be able to take the same power dissipation punishment due to surface area of their package. Due to square/cube law a lot of small, low-value caps are of benefit here,

So if you have caps that are like 0.27uF and 0.15uF mixing them should work fine, but you wouldn't be able to run 0.15's to their maximum without cooking the other ones. So I say mix them and have fun - just watch them not to overheat. The general rule for polypropylene caps seems to be, if they're too hot to touch, they're too hot, as I found out the hard way.

Goodchild:

I'm not sure what exactly is the current rating of the caps, but dividing the tank voltage with it's characteristic impedance yielded a current value of as much as 150A - and without water cooling the coil gets sizzling hot in seconds. I'm very surprised how well are the caps holding without blowing up so far.

They are 160V DC caps and I'm running them up to 70V AC,which seems to be about the limit considering they get quite hot.

Cheers,

Marko

Re: Royer induction heater

Gabriel35, Mon Aug 22 2011, 02:58PM

Can you post a video of your oscillator melting a screw?

Or Something like that Marko?

It's so nice to see things melting and burning with it, and quite impressive too.

Hey guys! I'm back, and got my new IRFP's260N and everything is working nicely, but now i have one problem... Like Marko said, when the workpiece is introduced on the work coil, the voltage drops a lot, in my case, I got a transformer very simmilar to the one that appears on Marko's video. It's rated 24V AC, Rectified it becomes 36vDC, when i turn the circuit on, it drops to 31, and with work, it drops to 24vDC...

I've made some calculations here, I got 11.8A as maximum current draw, and when the workpiece meets curie point it starts droping and keeps at 9A, so, my power source drops down to 24vDC, it gives me a real power of ~276W and aproximately 230W when curie point is reached...

With only 276W i alredy got the screw to become RedHot and I'm pretty excited to get more power with it, I think something around 1200W

As for the supplys, whats the advantage on using a separate 12v supply for the mosfets gates and a higher voltage for the power stage?

Someone knows a way to avoid that and make the thing work at full power?

As Marko noted, I can go up to 60v, because I'm using IRFP260N as switches.

Thank you!

Gabriel35, Mon Aug 22 2011, 02:58PM

Can you post a video of your oscillator melting a screw?

Or Something like that Marko?

It's so nice to see things melting and burning with it, and quite impressive too.

Hey guys! I'm back, and got my new IRFP's260N and everything is working nicely, but now i have one problem... Like Marko said, when the workpiece is introduced on the work coil, the voltage drops a lot, in my case, I got a transformer very simmilar to the one that appears on Marko's video. It's rated 24V AC, Rectified it becomes 36vDC, when i turn the circuit on, it drops to 31, and with work, it drops to 24vDC...

I've made some calculations here, I got 11.8A as maximum current draw, and when the workpiece meets curie point it starts droping and keeps at 9A, so, my power source drops down to 24vDC, it gives me a real power of ~276W and aproximately 230W when curie point is reached...

With only 276W i alredy got the screw to become RedHot and I'm pretty excited to get more power with it, I think something around 1200W

As for the supplys, whats the advantage on using a separate 12v supply for the mosfets gates and a higher voltage for the power stage?

Someone knows a way to avoid that and make the thing work at full power?

As Marko noted, I can go up to 60v, because I'm using IRFP260N as switches.

Thank you!

Re: Royer induction heater

Arcstarter, Tue Aug 23 2011, 12:49AM

The 12v supply for the mosfet gates is a good idea. I doubt i will be making any more ZVSs without that kind of drive. With a 12v supply, the gate resistors have to drop less voltage, and thusly heat less. This means more efficiency and smaller resistors, i used a single 1/4 watt resistor for each gate and they remained well within their resistance tolerance range. However, i would probably use less than 500 ohms, because as the voltage drops, so does the speed the gates charge.

A big transformer is needed for the wattage you want, and even a MOT wound with too thin wire could be 50v output with no load and drop to 25v with 10 amp load. You can use ohm's law to calculate the amount of voltage that will be dropped across the resistance of the secondary, if you know the resistance of the secondary.

Arcstarter, Tue Aug 23 2011, 12:49AM

Gabriel35 wrote ...

Hey guys! I'm back, and got my new IRFP's260N and everything is working nicely, but now i have one problem... Like Marko said, when the workpiece is introduced on the work coil, the voltage drops a lot, in my case, I got a transformer very simmilar to the one that appears on Marko's video. It's rated 24V AC, Rectified it becomes 36vDC, when i turn the circuit on, it drops to 31, and with work, it drops to 24vDC...

I've made some calculations here, I got 11.8A as maximum current draw, and when the workpiece meets curie point it starts droping and keeps at 9A, so, my power source drops down to 24vDC, it gives me a real power of ~276W and aproximately 230W when curie point is reached...

With only 276W i alredy got the screw to become RedHot and I'm pretty excited to get more power with it, I think something around 1200W

As for the supplys, whats the advantage on using a separate 12v supply for the mosfets gates and a higher voltage for the power stage?

Someone knows a way to avoid that and make the thing work at full power?

As Marko noted, I can go up to 60v, because I'm using IRFP260N as switches.

Thank you!

To get more overall wattage, you can lower the inductance/resistance of the work coil for lower impedance which raises the current, or use more voltage which would also raise the current. Hey guys! I'm back, and got my new IRFP's260N and everything is working nicely, but now i have one problem... Like Marko said, when the workpiece is introduced on the work coil, the voltage drops a lot, in my case, I got a transformer very simmilar to the one that appears on Marko's video. It's rated 24V AC, Rectified it becomes 36vDC, when i turn the circuit on, it drops to 31, and with work, it drops to 24vDC...

I've made some calculations here, I got 11.8A as maximum current draw, and when the workpiece meets curie point it starts droping and keeps at 9A, so, my power source drops down to 24vDC, it gives me a real power of ~276W and aproximately 230W when curie point is reached...

With only 276W i alredy got the screw to become RedHot and I'm pretty excited to get more power with it, I think something around 1200W

As for the supplys, whats the advantage on using a separate 12v supply for the mosfets gates and a higher voltage for the power stage?

Someone knows a way to avoid that and make the thing work at full power?

As Marko noted, I can go up to 60v, because I'm using IRFP260N as switches.

Thank you!

The 12v supply for the mosfet gates is a good idea. I doubt i will be making any more ZVSs without that kind of drive. With a 12v supply, the gate resistors have to drop less voltage, and thusly heat less. This means more efficiency and smaller resistors, i used a single 1/4 watt resistor for each gate and they remained well within their resistance tolerance range. However, i would probably use less than 500 ohms, because as the voltage drops, so does the speed the gates charge.

A big transformer is needed for the wattage you want, and even a MOT wound with too thin wire could be 50v output with no load and drop to 25v with 10 amp load. You can use ohm's law to calculate the amount of voltage that will be dropped across the resistance of the secondary, if you know the resistance of the secondary.

Re: Royer induction heater

Gabriel35, Tue Aug 23 2011, 02:05AM

And about the two inductors noted 45~200uH , if I lower their inductance, will the current raise?

Gabriel35, Tue Aug 23 2011, 02:05AM

And about the two inductors noted 45~200uH , if I lower their inductance, will the current raise?

Re: Royer induction heater

Inducktion, Tue Aug 23 2011, 02:38AM

Your frequency may change...

Inducktion, Tue Aug 23 2011, 02:38AM

Your frequency may change...

Re: Royer induction heater

Gabriel35, Tue Aug 23 2011, 04:02PM

Hey guys I'm back with some news...

I got a transformer that gives me 30vAC, properly rectified and filtered it results in 43vDC.

I've tested the circuit with it and the power of it raised a little. I've measured the current and it was at 12,8A at peak. But the voltage drop was giant, When the current was 12.8 the voltage was 28,00v

so it gave me aproximately 360w of power...

So the question is: what do I need to change on the circuit to get more current flowing?

The parts are:

IRFP260N

13v Zeners

BYV26E Ultra fast rectifiers Maximum trr of 75ns

The tank capacitor consists of 27x 0.068uF MKP + 3x 0.47uF + 1x 0.22uF + 2x 0.1uF , resulting in:

3.666uF (all MKP)

Thanks!

Gabriel35, Tue Aug 23 2011, 04:02PM

Hey guys I'm back with some news...

I got a transformer that gives me 30vAC, properly rectified and filtered it results in 43vDC.

I've tested the circuit with it and the power of it raised a little. I've measured the current and it was at 12,8A at peak. But the voltage drop was giant, When the current was 12.8 the voltage was 28,00v

so it gave me aproximately 360w of power...

So the question is: what do I need to change on the circuit to get more current flowing?

The parts are:

IRFP260N

13v Zeners

BYV26E Ultra fast rectifiers Maximum trr of 75ns

The tank capacitor consists of 27x 0.068uF MKP + 3x 0.47uF + 1x 0.22uF + 2x 0.1uF , resulting in:

3.666uF (all MKP)

Thanks!

Re: Royer induction heater

Marko, Tue Aug 23 2011, 04:55PM

Hi gabriel,

well most importantly, what is the power rating of your transformer? And if you don't know it, what is the approximate area of it's core? It might just be too small for what you want, and buying a new transformer of the required power would be very expensive, hence I recommended a rewound MOT. The little transformers I used didn't have much more guts than yours did, I could get full 30V only when I cranked the variac to 11.

If you're sure your circuit is working well you could even consider using a welding supply if you have one, on lowest voltage setting you can get from it.

Marko

Marko, Tue Aug 23 2011, 04:55PM

Hi gabriel,

well most importantly, what is the power rating of your transformer? And if you don't know it, what is the approximate area of it's core? It might just be too small for what you want, and buying a new transformer of the required power would be very expensive, hence I recommended a rewound MOT. The little transformers I used didn't have much more guts than yours did, I could get full 30V only when I cranked the variac to 11.

If you're sure your circuit is working well you could even consider using a welding supply if you have one, on lowest voltage setting you can get from it.

Marko

Re: Royer induction heater

Gabriel35, Tue Aug 23 2011, 05:02PM

Hey Marko! Thank you for the fast reply!

I don't have a welding supply here =//

The area of the transoformer is aproximately:

11.4cm X 10cm X 6,8cm

It's pretty huge but i Know that it's Power rating is low, because it is a multi tapped transformer...

So, do you thing that whats limiting the current flow of the circuit is the transformer only?

changing the inductors inductance and the work coil's inductance are good ideas? or not?

What about 3,666uF it's good?

A good ideia is getting a transformer capable of 36v and about 22A of current isn't it? or a variac... Or a MOT, but i've never experienced with it, and I don't know how to rewind it...

My rectifier bridge is rated 50A.

Thanks!

Gabriel35, Tue Aug 23 2011, 05:02PM

Hey Marko! Thank you for the fast reply!

I don't have a welding supply here =//

The area of the transoformer is aproximately:

11.4cm X 10cm X 6,8cm

It's pretty huge but i Know that it's Power rating is low, because it is a multi tapped transformer...

So, do you thing that whats limiting the current flow of the circuit is the transformer only?

changing the inductors inductance and the work coil's inductance are good ideas? or not?

What about 3,666uF it's good?

A good ideia is getting a transformer capable of 36v and about 22A of current isn't it? or a variac... Or a MOT, but i've never experienced with it, and I don't know how to rewind it...

My rectifier bridge is rated 50A.

Thanks!

Re: Royer induction heater

Forty, Wed Aug 24 2011, 12:55AM

for mot rewinding info.

for mot rewinding info.

variacs for that kind of current are pretty expensive. audio amplifiers and subwoofer supplies usually have big transformers too (as long as they're not switch mode supplies)

Forty, Wed Aug 24 2011, 12:55AM

for mot rewinding info.

for mot rewinding info.variacs for that kind of current are pretty expensive. audio amplifiers and subwoofer supplies usually have big transformers too (as long as they're not switch mode supplies)

Re: Royer induction heater

Gabriel35, Wed Aug 24 2011, 02:39AM

Thank you for the information on MOTs.

I have one doubt, help me understanding the following:

For example, I Get 2 transformers, both rated 36v output, one of them is capable of 300VA and the other 700VA...

That means that the 300VA one is capable of 8,33A and the 700VA one is capable of 19.44A

So, the transformer limits the current drain of the whole circuit, or the circuit will take as many amps as It deserve? In other words... Can a transformer be overloaded and start to heat due to high current consumption from the circuit? or it will only work within it's limits, giving only the current that it's projected to give?

Thanks!

Gabriel35, Wed Aug 24 2011, 02:39AM

Thank you for the information on MOTs.

I have one doubt, help me understanding the following:

For example, I Get 2 transformers, both rated 36v output, one of them is capable of 300VA and the other 700VA...

That means that the 300VA one is capable of 8,33A and the 700VA one is capable of 19.44A

So, the transformer limits the current drain of the whole circuit, or the circuit will take as many amps as It deserve? In other words... Can a transformer be overloaded and start to heat due to high current consumption from the circuit? or it will only work within it's limits, giving only the current that it's projected to give?

Thanks!

Re: Royer induction heater

Dr. ISOTOP, Wed Aug 24 2011, 06:05AM

It will _not_ work beyond its voltage ratings (it'll saturate )

)

Dr. ISOTOP, Wed Aug 24 2011, 06:05AM

Gabriel35 wrote ...

Thank you for the information on MOTs.

I have one doubt, help me understanding the following:

For example, I Get 2 transformers, both rated 36v output, one of them is capable of 300VA and the other 700VA...

That means that the 300VA one is capable of 8,33A and the 700VA one is capable of 19.44A

So, the transformer limits the current drain of the whole circuit, or the circuit will take as many amps as It deserve? In other words... Can a transformer be overloaded and start to heat due to high current consumption from the circuit? or it will only work within it's limits, giving only the current that it's projected to give?

Thanks!

A transformer will work beyond its current ratings for short duty cycle.Thank you for the information on MOTs.

I have one doubt, help me understanding the following:

For example, I Get 2 transformers, both rated 36v output, one of them is capable of 300VA and the other 700VA...

That means that the 300VA one is capable of 8,33A and the 700VA one is capable of 19.44A

So, the transformer limits the current drain of the whole circuit, or the circuit will take as many amps as It deserve? In other words... Can a transformer be overloaded and start to heat due to high current consumption from the circuit? or it will only work within it's limits, giving only the current that it's projected to give?

Thanks!

It will _not_ work beyond its voltage ratings (it'll saturate

)

)Re: Royer induction heater

Marko, Wed Aug 24 2011, 01:09PM

Hi guys,

gabriel, I'm sorry that I didn't clarify that it's cross-sectional area of the core that is required, or whatever it's called (width*length of the centre leg).

Anyway if that's your 700VA transformer it looks like it has more than enough power for this circuit, but if it is the multi-taped transformer you mentioned then it might just have too much resistance in the particular winding you're using.

Oh, and changing your DC link inductors will do pretty much nothing as long as they are not too small, at which the circuit will most likely go into latchup and die.

It looks to me like you just need a bigger power supply.

I think someone mentioned that it's advantageous to use a separate 12V supply for the gates - I used to do it all the time when I tried to conserve every mW of power for wireless power circuits. But now here not only that this is a negligible loss, but I also suspect that big value of gate resistance with high voltage supply actually helps improve stability of the circuit. I'm not sure why is that so, but the circuit seems to like it's gate pullups act more like high impedance current source than a low impedance voltage source. Using discrete gate divers for amplification always turned out a disaster for me.

And yet with this circuit which is the only I've built by bastardly copying the original mazzili schematic, is by far the most stable of them all. It starts up nicely even when I bring the supply voltage up slowly by a variac, a feat unseen before in a royer world.

Cheers,

Marko

Marko, Wed Aug 24 2011, 01:09PM

Hi guys,

gabriel, I'm sorry that I didn't clarify that it's cross-sectional area of the core that is required, or whatever it's called (width*length of the centre leg).

Anyway if that's your 700VA transformer it looks like it has more than enough power for this circuit, but if it is the multi-taped transformer you mentioned then it might just have too much resistance in the particular winding you're using.

Oh, and changing your DC link inductors will do pretty much nothing as long as they are not too small, at which the circuit will most likely go into latchup and die.

It looks to me like you just need a bigger power supply.

I think someone mentioned that it's advantageous to use a separate 12V supply for the gates - I used to do it all the time when I tried to conserve every mW of power for wireless power circuits. But now here not only that this is a negligible loss, but I also suspect that big value of gate resistance with high voltage supply actually helps improve stability of the circuit. I'm not sure why is that so, but the circuit seems to like it's gate pullups act more like high impedance current source than a low impedance voltage source. Using discrete gate divers for amplification always turned out a disaster for me.

And yet with this circuit which is the only I've built by bastardly copying the original mazzili schematic, is by far the most stable of them all. It starts up nicely even when I bring the supply voltage up slowly by a variac, a feat unseen before in a royer world.

Cheers,

Marko

Re: Royer induction heater

Gabriel35, Wed Aug 24 2011, 03:01PM

I Agree Marko!

I've experienced with some variations of the Mazzili's driver too , and the most stable one is this, with just one power supply, and using mosfets like IRFP250 & 260N (This secon one, is even better, because of the lower RDS on and higher current capabilty.

So... I think its time to get some MOTs here... But... I'm sacred about how it sags... I hope that the rewinded MOTs don't sag too much... Because if everything works, I pretend to apply something near 60v and see how much power the old and good Royer driver can deliver...

EDIT: Got some photos...

Cheers.

Gabriel35, Wed Aug 24 2011, 03:01PM

I Agree Marko!

I've experienced with some variations of the Mazzili's driver too , and the most stable one is this, with just one power supply, and using mosfets like IRFP250 & 260N (This secon one, is even better, because of the lower RDS on and higher current capabilty.

So... I think its time to get some MOTs here... But... I'm sacred about how it sags... I hope that the rewinded MOTs don't sag too much... Because if everything works, I pretend to apply something near 60v and see how much power the old and good Royer driver can deliver...

EDIT: Got some photos...

Cheers.

Re: Royer induction heater

Marko, Wed Aug 24 2011, 05:39PM

Hi gabriel... probably a good time to start using water cooling, as your coil looks quite like a roast to me?

I also don't think your mosfets are going to last long once you push 20A through them continuously with their current heatsink.

I used simple pieces of 2mm copper as cooling blocks with pipe soldered underneath which worked well enough, but if you truly wished to be a bastard you could even solder the mosfet backs directly to the pipe... you'd need to have confidence not to have to replace them too often that way, though.

I've also heard some people (including Celem cap manufacturers) complain about the specific arrangement of caps you use, with all of them in a long line from a work coil. I suspect the problem might be in the all extra inductance the cap furthest away from the coil sees, which may be comparable to the work coil inductance - this inductance in turn cancels a portion of the faraway cap's capacitance, making them appear smaller and causing those closest to the work coil to hog current.

I see you placed some of your largest caps on the far end though, which may cancel out this effect to some extent, but I would consider it for future.

If you use double sided PCB for your interconnections, inductance is low enough that you can orient the caps a more relaxed way.

Or you can use another common approach, with one work coil end going around the cap bank and connecting to it from back (some extra copper pipe usage).

Regarding the MOT: I've never rewound a MOT, so I don't know what it's voltage regulation characteristics are, but due do separation of primary and secondary I presume they are poor. Make sure to knock out the magnetic shunts from the mot too along with the secondary, and if it heats up a lot with no load add a 10-20 more primary turns to it somehow.

You could pull more juice if you wound the transformer for a bit high voltage, but just enough that it sags to 60V with royer unloaded. It would sag further when you put a workpiece in, but there's little you can do about that. Note that this way you would have to power your monster up and down from the mains side, to avoid slamming it with too high voltage from overcharged bus caps - and this is in contradiction with royer circuit's inherent desire to latch up and explode when it's supply voltage rises too slowly, as with charging bus caps after turn-on. I don't think it will be a problem in this case though, I couldn't force my circuit to latch up yet no matter what I did :)

Cheers,

Marko

Marko, Wed Aug 24 2011, 05:39PM

Hi gabriel... probably a good time to start using water cooling, as your coil looks quite like a roast to me?

I also don't think your mosfets are going to last long once you push 20A through them continuously with their current heatsink.

I used simple pieces of 2mm copper as cooling blocks with pipe soldered underneath which worked well enough, but if you truly wished to be a bastard you could even solder the mosfet backs directly to the pipe... you'd need to have confidence not to have to replace them too often that way, though.

I've also heard some people (including Celem cap manufacturers) complain about the specific arrangement of caps you use, with all of them in a long line from a work coil. I suspect the problem might be in the all extra inductance the cap furthest away from the coil sees, which may be comparable to the work coil inductance - this inductance in turn cancels a portion of the faraway cap's capacitance, making them appear smaller and causing those closest to the work coil to hog current.

I see you placed some of your largest caps on the far end though, which may cancel out this effect to some extent, but I would consider it for future.

If you use double sided PCB for your interconnections, inductance is low enough that you can orient the caps a more relaxed way.

Or you can use another common approach, with one work coil end going around the cap bank and connecting to it from back (some extra copper pipe usage).

Regarding the MOT: I've never rewound a MOT, so I don't know what it's voltage regulation characteristics are, but due do separation of primary and secondary I presume they are poor. Make sure to knock out the magnetic shunts from the mot too along with the secondary, and if it heats up a lot with no load add a 10-20 more primary turns to it somehow.

You could pull more juice if you wound the transformer for a bit high voltage, but just enough that it sags to 60V with royer unloaded. It would sag further when you put a workpiece in, but there's little you can do about that. Note that this way you would have to power your monster up and down from the mains side, to avoid slamming it with too high voltage from overcharged bus caps - and this is in contradiction with royer circuit's inherent desire to latch up and explode when it's supply voltage rises too slowly, as with charging bus caps after turn-on. I don't think it will be a problem in this case though, I couldn't force my circuit to latch up yet no matter what I did :)

Cheers,

Marko

Re: Royer induction heater

Gabriel35, Wed Aug 24 2011, 07:18PM

The work coil used, is from a previous Half bridge IGBT Induction heater, and is a little roasted because of that.

I think this heat sink is pretty large, is larger than my hand, and with 13A it stays very cool.

About the capacitors, I need to get some equally rated caps to make a better arrangement.

This thing is getting complicated... Since I don't have proper caps and proper Supply...

I have that two huge transformers here, and I doubt that a rewound MOT will be much powerful than theese ones.

Does someone knows something about turning two transformers in series to raise thye overall voltage?

I was wondering what happens if i take a big ferrite toroid and wound 5 turns of wire to the driver side and about 15 turns for the tank capacitors side? Its a little hard to find MOTs where I Live... so, using a toroid step up transformer between the driver and the resonant tank could be an option to increase the power? Or I need a flyback ferrite without gaps?

Thanks!

Gabriel35, Wed Aug 24 2011, 07:18PM

The work coil used, is from a previous Half bridge IGBT Induction heater, and is a little roasted because of that.

I think this heat sink is pretty large, is larger than my hand, and with 13A it stays very cool.

About the capacitors, I need to get some equally rated caps to make a better arrangement.

This thing is getting complicated... Since I don't have proper caps and proper Supply...

I have that two huge transformers here, and I doubt that a rewound MOT will be much powerful than theese ones.

Does someone knows something about turning two transformers in series to raise thye overall voltage?

I was wondering what happens if i take a big ferrite toroid and wound 5 turns of wire to the driver side and about 15 turns for the tank capacitors side? Its a little hard to find MOTs where I Live... so, using a toroid step up transformer between the driver and the resonant tank could be an option to increase the power? Or I need a flyback ferrite without gaps?

Thanks!

Re: Royer induction heater

Forty, Wed Aug 24 2011, 09:08PM

for a transformer between the driver and tank, you'd need a ferrite transformer anyway, as an iron one would eventually start to glow.

for the voltage sag on the supply side, maybe you could use a high current relay to switch power to the driver once the voltage on the smoothing caps reaches a certain level, thus avoiding the slow climb problem. MOT's are usually rated upwards of 1kW, so they're a bit more powerful than your transformer, but yours should be sufficient.

Forty, Wed Aug 24 2011, 09:08PM

for a transformer between the driver and tank, you'd need a ferrite transformer anyway, as an iron one would eventually start to glow.

for the voltage sag on the supply side, maybe you could use a high current relay to switch power to the driver once the voltage on the smoothing caps reaches a certain level, thus avoiding the slow climb problem. MOT's are usually rated upwards of 1kW, so they're a bit more powerful than your transformer, but yours should be sufficient.

Re: Royer induction heater

Gabriel35, Thu Aug 25 2011, 01:46AM

So the idea of the ferrite toroid between the driver and tank side is good? Can it be a BIG toroid or i need a flyback ferrite?

Can i achieve more power using it?

I was thinking.... how to amplify the voltage of the transformer's output (the same one that I already have here) Wouldn't be a nice idea to use a voltage doubler circuit?

Gabriel35, Thu Aug 25 2011, 01:46AM

So the idea of the ferrite toroid between the driver and tank side is good? Can it be a BIG toroid or i need a flyback ferrite?

Can i achieve more power using it?

I was thinking.... how to amplify the voltage of the transformer's output (the same one that I already have here) Wouldn't be a nice idea to use a voltage doubler circuit?

Re: Royer induction heater

Marko, Thu Aug 25 2011, 02:45AM

Hi gabriel,

Once the voltage on your transformer has sagged to half of it's initial value, it's putting out it's maximum power and there's nothing you can do about it.

700VA transformer should do plenty for this circuit, probably over 1.5kW for short durations. I think it sucks for you because you're using a tiny auxiliary winding which can't support all the current you need.

Your probably only hope is to either find a more useful winding on this transformer, dismantle it and rewind it or rewind a MOT.

If you find a more useful, but lower voltage winding on this transformer you could try the matching transformer approach. Smaller mosfets would then be in order though, like IRFZ44 or IRF1010 for up to 20V supply. I'd wind a 1:2 transformer tightly on your toroid and see what happens. Make sure to give it a sane number of volts/turn for the core crossection area of the toroid. You can also center tap the transformer and get rid of one inductor. Heck, you could even try supplying it with a car battery if you had one around.

Also, don't be fooled by your heatsink feeling cold, as those mosfets seem to be mounted onto a thin fin on it's edge instead of the base, also with sil pads and poor mounting pressure.. I would expect the dies to cook very quickly at 20A +. I can't see your sil-pads by the way, are they trimmed to size of mosfet packages?

Marko

Marko, Thu Aug 25 2011, 02:45AM

Hi gabriel,

Once the voltage on your transformer has sagged to half of it's initial value, it's putting out it's maximum power and there's nothing you can do about it.

700VA transformer should do plenty for this circuit, probably over 1.5kW for short durations. I think it sucks for you because you're using a tiny auxiliary winding which can't support all the current you need.

Your probably only hope is to either find a more useful winding on this transformer, dismantle it and rewind it or rewind a MOT.

If you find a more useful, but lower voltage winding on this transformer you could try the matching transformer approach. Smaller mosfets would then be in order though, like IRFZ44 or IRF1010 for up to 20V supply. I'd wind a 1:2 transformer tightly on your toroid and see what happens. Make sure to give it a sane number of volts/turn for the core crossection area of the toroid. You can also center tap the transformer and get rid of one inductor. Heck, you could even try supplying it with a car battery if you had one around.

Also, don't be fooled by your heatsink feeling cold, as those mosfets seem to be mounted onto a thin fin on it's edge instead of the base, also with sil pads and poor mounting pressure.. I would expect the dies to cook very quickly at 20A +. I can't see your sil-pads by the way, are they trimmed to size of mosfet packages?

Marko

Re: Royer induction heater

Gabriel35, Thu Aug 25 2011, 01:44PM

Yes, I'm using sil Pads... I have many other heatsinks here, i'll try to change them...

I was thinking yesterday and I got a possible solution...

I have here 2 300VA 24v transformers...

Can I plug their primaries together on the wall and their secondaries in series, giving me 48v AC or in parallel giving me same 24v but with more current capability?

I'm a little scared to turn the circuit on with 48v AC, what means something around 70vDC (rectified) It will sag i know... but the range for IRFP260N isn't 60v

What do you think?

What are the risks of everything explode using a 1:2 toroidal step up transformer between tank and driver?

EDIT> I think that I'm still missing something here... I made an association of a 6v tap of the huge transformer, with the other 24v transformer, I've measured the voltage and current when the workpiece was inside the coil and it gave me 32vDC and 14,9A, giving a theorical output of 480W... and I'm pretty away form melting the steel bolt with it, It just became red...

Gabriel35, Thu Aug 25 2011, 01:44PM

Yes, I'm using sil Pads... I have many other heatsinks here, i'll try to change them...

I was thinking yesterday and I got a possible solution...

I have here 2 300VA 24v transformers...

Can I plug their primaries together on the wall and their secondaries in series, giving me 48v AC or in parallel giving me same 24v but with more current capability?

I'm a little scared to turn the circuit on with 48v AC, what means something around 70vDC (rectified) It will sag i know... but the range for IRFP260N isn't 60v

What do you think?

What are the risks of everything explode using a 1:2 toroidal step up transformer between tank and driver?

EDIT> I think that I'm still missing something here... I made an association of a 6v tap of the huge transformer, with the other 24v transformer, I've measured the voltage and current when the workpiece was inside the coil and it gave me 32vDC and 14,9A, giving a theorical output of 480W... and I'm pretty away form melting the steel bolt with it, It just became red...

Re: Royer induction heater

Marko, Thu Aug 25 2011, 03:17PM

Hi gabriel,

Your current configuration of the circuit looks pretty much like mine, apart from your work coil being somewhat wider. Note that a jump from 30 to 60V is actually a really big one, if the circuit behaved linearly then my IH would jump in consumption (with same workpiece in) from 600W to 2400W for example.

You'll have to decide whether you want to run at 60V, in which case you'll have to remove a fair bit of caps, I'd go down to 2uF or less.

I think you're safe to plug the circuit straight to rectified and filtered 48V AC, just switch the transformers on and off on primary side (and put a breaker or fuse in series with DC output perhaps).

Or you could try using your transformers in parallel first and see what happens, in which case you can leave the circuit mostly as is. I'd recommend you a bit narrower work coil though, I can't tell exactly from the pics but yours looks like 5-6cm wide while mine is just about 3. Smaller coil will have a better coupling to the workpiece.

Regarding melting a steel bolt, it mostly depends on how big it is, 500W isn't really much power so I'd start with a M4 or M5 bolt. I'll try and see what bolt size can I melt after I finish my new power supply.

I'd recommend you to start some water cooling as soon as possible though, at 500W everything got super hot in seconds in my circuit, and I was afraid that all the emitted heat from the copper tube could cook the caps. You don't really see it at first, you just see decrease in performance as their capacitance drops, after which they bulge up and burst in flames :(

Marko

Marko, Thu Aug 25 2011, 03:17PM

Hi gabriel,

Your current configuration of the circuit looks pretty much like mine, apart from your work coil being somewhat wider. Note that a jump from 30 to 60V is actually a really big one, if the circuit behaved linearly then my IH would jump in consumption (with same workpiece in) from 600W to 2400W for example.

You'll have to decide whether you want to run at 60V, in which case you'll have to remove a fair bit of caps, I'd go down to 2uF or less.

I think you're safe to plug the circuit straight to rectified and filtered 48V AC, just switch the transformers on and off on primary side (and put a breaker or fuse in series with DC output perhaps).

Or you could try using your transformers in parallel first and see what happens, in which case you can leave the circuit mostly as is. I'd recommend you a bit narrower work coil though, I can't tell exactly from the pics but yours looks like 5-6cm wide while mine is just about 3. Smaller coil will have a better coupling to the workpiece.

Regarding melting a steel bolt, it mostly depends on how big it is, 500W isn't really much power so I'd start with a M4 or M5 bolt. I'll try and see what bolt size can I melt after I finish my new power supply.

I'd recommend you to start some water cooling as soon as possible though, at 500W everything got super hot in seconds in my circuit, and I was afraid that all the emitted heat from the copper tube could cook the caps. You don't really see it at first, you just see decrease in performance as their capacitance drops, after which they bulge up and burst in flames :(

Marko

Re: Royer induction heater

Gabriel35, Thu Aug 25 2011, 04:00PM

My work coil is small as yours, it is 3cm wide too.

Why do i need to take caps out and decrease the capacitance with more power?

I was wondering to use my 8x 1uF bank to see if the power levels become higher but now i don't know...

Thanks!

Gabriel35, Thu Aug 25 2011, 04:00PM

My work coil is small as yours, it is 3cm wide too.

Why do i need to take caps out and decrease the capacitance with more power?

I was wondering to use my 8x 1uF bank to see if the power levels become higher but now i don't know...

Thanks!

Re: Royer induction heater

Nah, Thu Aug 25 2011, 04:15PM

Marco,

Would submersing the capacitors in oil help them cool?

Nah, Thu Aug 25 2011, 04:15PM

Marco,

Would submersing the capacitors in oil help them cool?

Re: Royer induction heater

Marko, Thu Aug 25 2011, 04:49PM

Hi guys,

Gabriel, you need to remove the caps in order to get a better impedance match to the transformers. You want your IH to draw much less current (about 4 times) at 30V in order not to overlaod the supply at 60V.

Nah, I'm actually already building a MMC that is cooled by water flow around the caps. Transformer oil is hard to get here and would require heat exchangers and mess.

By the way, I challenge anyone of you guys to attempt an offline IH of this type with 1200V IGBT's and insulation transformer, as I don't ahve any suitable igbt's around myself. It would be quite challenging, as far as I know there have ben few attempts but their stability is questionable.

I would start by using a 30-40V supply for the gates, and use 470 ohm resistors and zeners much like original mazzili circuit.

Then if this is not stable enough, I have another secret little improvement that I'll only tell about if someone attempts it :)

Cheers,

Marko

Marko, Thu Aug 25 2011, 04:49PM

Hi guys,

Gabriel, you need to remove the caps in order to get a better impedance match to the transformers. You want your IH to draw much less current (about 4 times) at 30V in order not to overlaod the supply at 60V.

Nah, I'm actually already building a MMC that is cooled by water flow around the caps. Transformer oil is hard to get here and would require heat exchangers and mess.

By the way, I challenge anyone of you guys to attempt an offline IH of this type with 1200V IGBT's and insulation transformer, as I don't ahve any suitable igbt's around myself. It would be quite challenging, as far as I know there have ben few attempts but their stability is questionable.