OLTC project

Jrz126, Sun Jun 18 2006, 02:51PMSo I have one of these IGBT's here and I want to make an OLTC.

Now I need to figure out how to drive it and whatnot... I've been reading up on it at Steve Conner's site. I was going to use 20V for my gate voltage (or should I over drive it?). So at Vge=20, the gate charge is 6500nc. Steve mentioned that you want a turn on time of 0.5uS, is this determined by the igbt or just a good rule of thumb to use?

oh yeah, and how do I determine the best coil size and whatnot?

I appologize for all of the noob-ish questions, but we all have to start somewhere...

Re: OLTC project

Dr. Shark, Sun Jun 18 2006, 06:23PM

That's a big brick, you might want to gather some experience from "cheaper" silicon before you give that one a shot.

If you intend to drive the brick within spec, you will be fine with the 20V on the gate, it is only if you want to push higher currents that a higher gate voltage helps.

The 0.5us is basically a funcion of your resonance frequency. IF you build a tiny high frequency coil, you want 100ns, whereas a huge beast might get away with 1us.

Best Coil-size fol OLTCs traditionally is: The lower the resonant frequency, the better, so you want 2000 turns of fine wire, and make it as big as you like. The IGBT you got should be in for several kW of power.

Dr. Shark, Sun Jun 18 2006, 06:23PM

That's a big brick, you might want to gather some experience from "cheaper" silicon before you give that one a shot.

If you intend to drive the brick within spec, you will be fine with the 20V on the gate, it is only if you want to push higher currents that a higher gate voltage helps.

The 0.5us is basically a funcion of your resonance frequency. IF you build a tiny high frequency coil, you want 100ns, whereas a huge beast might get away with 1us.

Best Coil-size fol OLTCs traditionally is: The lower the resonant frequency, the better, so you want 2000 turns of fine wire, and make it as big as you like. The IGBT you got should be in for several kW of power.

Re: OLTC project

Extreme Electronics, Sun Jun 18 2006, 08:41PM

Hi,

Thats a really nice brick !! but its be a shame to blow it...

I really suggest you start with a smaller OLTC first. to get the "feel" of OLTC's

You can build a nice OLTC with a single small $10 IGBT that will give 1' sparks and wont cost you the earth when you kill it.. take a look at 4pf50's tha are well proven in OLTC service.

take a look at

the "on" time is dependant on your quenching time, which is dependant on your coils frequency and coupling. Basically the IGBT needs to be on for as long as it takes to transfer all of your primary power to your secondary, and no longer to prevent over heating.

You Will need to overdrive even a small IGBT in OLTC service, a small OLTC can easilly have 400A primary current. Fortunatly IGBT's can be overdriven to around 2x their pulse rating with 25V gate drive. so a single 4pf50 can take a pulse of 400A.

Bigger OLTCs get much more complecated, as Steves site will show you, but most of that electronics is to protect the brick from over voltage & over current.

for a guide to coil sizes etc take a look at my OLTC calculatior I cant claim its accuracy, but its will give good ball-park figures.

I cant claim its accuracy, but its will give good ball-park figures.

Derek

Extreme Electronics, Sun Jun 18 2006, 08:41PM

Hi,

Thats a really nice brick !! but its be a shame to blow it...

I really suggest you start with a smaller OLTC first. to get the "feel" of OLTC's

You can build a nice OLTC with a single small $10 IGBT that will give 1' sparks and wont cost you the earth when you kill it.. take a look at 4pf50's tha are well proven in OLTC service.

take a look at

the "on" time is dependant on your quenching time, which is dependant on your coils frequency and coupling. Basically the IGBT needs to be on for as long as it takes to transfer all of your primary power to your secondary, and no longer to prevent over heating.

You Will need to overdrive even a small IGBT in OLTC service, a small OLTC can easilly have 400A primary current. Fortunatly IGBT's can be overdriven to around 2x their pulse rating with 25V gate drive. so a single 4pf50 can take a pulse of 400A.

Bigger OLTCs get much more complecated, as Steves site will show you, but most of that electronics is to protect the brick from over voltage & over current.

for a guide to coil sizes etc take a look at my OLTC calculatior

I cant claim its accuracy, but its will give good ball-park figures.

I cant claim its accuracy, but its will give good ball-park figures.Derek

Re: OLTC project

Jrz126, Tue Jun 20 2006, 12:01PM

I was thinking about building a smaller oltc, but I was thinking that it would be alot harder to blow this brick compared to a smaller TO-220 type igbt.

I've been reading up on how to use the IGBT bricks here Looks like there is quite a bit of good information there

Now for the secondary, do I want to keep the 4/1 H/W ratio? and whats a good resonant frequency to shoot for? I'm also planning on using 26 gauge (.404mm) wire, and probably an 8" cardboard concrete form.

Jrz126, Tue Jun 20 2006, 12:01PM

I was thinking about building a smaller oltc, but I was thinking that it would be alot harder to blow this brick compared to a smaller TO-220 type igbt.

I've been reading up on how to use the IGBT bricks here Looks like there is quite a bit of good information there

Now for the secondary, do I want to keep the 4/1 H/W ratio? and whats a good resonant frequency to shoot for? I'm also planning on using 26 gauge (.404mm) wire, and probably an 8" cardboard concrete form.

Re: OLTC project

Dr. Shark, Tue Jun 20 2006, 12:24PM

Blowing big IGBTs can be very easy. E.g. if the gate is not protected properly, and switching with too high dI/dt causes a voltage spike, it is dead. Get some TO247 devices to play with, they are a good compromise.

Short and fat would be a good idea for an OLTC, even something like 2:1 ratio. .4mm wire would give you almost 2000T, so it sounds good.

Dr. Shark, Tue Jun 20 2006, 12:24PM

Blowing big IGBTs can be very easy. E.g. if the gate is not protected properly, and switching with too high dI/dt causes a voltage spike, it is dead. Get some TO247 devices to play with, they are a good compromise.

Short and fat would be a good idea for an OLTC, even something like 2:1 ratio. .4mm wire would give you almost 2000T, so it sounds good.

Re: OLTC project

Steve Conner, Tue Jun 20 2006, 01:37PM

Meh. Calling a certain kind of Tesla coil obsolete doesn't really achieve anything. They're all variations on a 100 year old theme as far as I'm concerned, and hardly going to net you a Nobel Prize. Having said that, I admit the OLTC doesn't perform as well as the DRSSTC.

Steve Conner, Tue Jun 20 2006, 01:37PM

Meh. Calling a certain kind of Tesla coil obsolete doesn't really achieve anything. They're all variations on a 100 year old theme as far as I'm concerned, and hardly going to net you a Nobel Prize. Having said that, I admit the OLTC doesn't perform as well as the DRSSTC.

Re: OLTC project

Jrz126, Tue Jun 20 2006, 05:56PM

Well, I've only got one of these bricks, so it kinda limits my options.

If I use the 26 gauge wire, I'd need a height of 34" to get ~2000T. Should I make the coil diameter pretty wide? (they also had 12" concrete forms).

Is cardboard a good material to use?

In general, do I want to shoot for a lower or higher resonant freq?

Jrz126, Tue Jun 20 2006, 05:56PM

Well, I've only got one of these bricks, so it kinda limits my options.

If I use the 26 gauge wire, I'd need a height of 34" to get ~2000T. Should I make the coil diameter pretty wide? (they also had 12" concrete forms).

Is cardboard a good material to use?

In general, do I want to shoot for a lower or higher resonant freq?

Re: OLTC project

Dr. Shark, Tue Jun 20 2006, 06:46PM

Don't let Dan discourage you, I think he is joking. With the recent interest in Terrys Solid State Spark Gap, I think OLTCs are better than ever. Of course you can buy longer sparks with a DRSSTC, but it is a hell of a lot more complicated!

Making the coil diameter wider is going to give you more inductance per foot of wire, so you want to make it pretty wide. The lower the frequency, the better, as it allows you to use a bigger primary capacitor for more bang energy.

Dr. Shark, Tue Jun 20 2006, 06:46PM

Don't let Dan discourage you, I think he is joking. With the recent interest in Terrys Solid State Spark Gap, I think OLTCs are better than ever. Of course you can buy longer sparks with a DRSSTC, but it is a hell of a lot more complicated!

Making the coil diameter wider is going to give you more inductance per foot of wire, so you want to make it pretty wide. The lower the frequency, the better, as it allows you to use a bigger primary capacitor for more bang energy.

Re: OLTC project

Terry Fritz, Tue Jun 20 2006, 08:14PM

Hi,

Sweet!!! 20V should be fine on the gate unless you want to drive like 10,000 amps thorugh it, then go to 25 volts

0.5uS is fine. Mostly determined buy the resonant frequency of your coil and how fast the initial current will rise. You don't want to turn on "too fast" or the Ccg capacitance could over voltage the gate. But put a big 30V TVS across the gate to emitter anyway.

You want a big primary cap and small primary inductance. It is hard to get less than 1uH for the primary inductor so the biggest cap you can get. That usually drives down the secondary frequency making a secondary coil with lots of turns for high inductance. Be careful not to make the secondary coil too lossy though!! My 'first' OLTC suffered from high secondary losses since I got too carried away trying to make it 120BPS at 300V. You could go to like 900 to 1000V pretty much solving all that if you have the power supply to get that voltage. Or was your IGBT 2400V... if so you can really go to a higher voltage!

Everything begining with OLTC here:

Is about my 'first' one. But Steve's and latter ones or all modern with more of the details and problems figured out. But you can quickly click through the about just to check.

I don't think you "can" blow that brick. But start out running at lower voltage just to get everything tuned in before running at high power. Low break rates (like once every few seconds) also help setting up.

Sounds fine! Probably in the 50 - 100kHz range. See this for formulas and the JAVA on-line tool:

You wants lots of secondary peak voltage and lots of capacitor stored energy (1/2CV^2). Higher voltage really helps stored energy so you can use a smaller cap for higher resonant frequency and a more normal secondary.

I never thought about it till now, but the SISG drive circuit could run the single big high current brick OLTC too!!! In that case, you don't need nothin for a drive circuit )

)

You may want to check this out:

I hate to recommend something "new and never tried" to a new coiler though. But I think you are an engineer so you know the usual electronic details. The SISG drive is probably far more reliable and easy than any conventional OLTC drive. We won't even mention the complexity of DRSSTC's Newer DF-DRSSTC and SISG circuits will probably make them obsolete

Newer DF-DRSSTC and SISG circuits will probably make them obsolete  And the OLTC will always be the "daddy"

And the OLTC will always be the "daddy"  But the DRSSTC is definitly the "thinking man's" machine!!! Once one has mastered the DRSSTC, everything else is "simple"...

But the DRSSTC is definitly the "thinking man's" machine!!! Once one has mastered the DRSSTC, everything else is "simple"...

If the SISG drive does not work, you are only out like $5 and 15 minutes of work But it should work fine. I guess it would be a SISGOLTC

But it should work fine. I guess it would be a SISGOLTC  It would be the simplest "big" coil out there in that case with only "one" SISG section.

It would be the simplest "big" coil out there in that case with only "one" SISG section.

Be sure to use a minimum of copper too!! A "ten foot" length of 1/4 inch tubing is running $16 here!!!!

Cheers,

Terry

Terry Fritz, Tue Jun 20 2006, 08:14PM

Hi,

So I have one of these IGBT's here and I want to make an OLTC.

Sweet!!! 20V should be fine on the gate unless you want to drive like 10,000 amps thorugh it, then go to 25 volts

0.5uS is fine. Mostly determined buy the resonant frequency of your coil and how fast the initial current will rise. You don't want to turn on "too fast" or the Ccg capacitance could over voltage the gate. But put a big 30V TVS across the gate to emitter anyway.

You want a big primary cap and small primary inductance. It is hard to get less than 1uH for the primary inductor so the biggest cap you can get. That usually drives down the secondary frequency making a secondary coil with lots of turns for high inductance. Be careful not to make the secondary coil too lossy though!! My 'first' OLTC suffered from high secondary losses since I got too carried away trying to make it 120BPS at 300V. You could go to like 900 to 1000V pretty much solving all that if you have the power supply to get that voltage. Or was your IGBT 2400V... if so you can really go to a higher voltage!

Everything begining with OLTC here:

Is about my 'first' one. But Steve's and latter ones or all modern with more of the details and problems figured out. But you can quickly click through the about just to check.

I don't think you "can" blow that brick. But start out running at lower voltage just to get everything tuned in before running at high power. Low break rates (like once every few seconds) also help setting up.

Now for the secondary, do I want to keep the 4/1 H/W ratio? and whats a good resonant frequency to shoot for? I'm also planning on using 26 gauge (.404mm) wire, and probably an 8" cardboard concrete form.

Sounds fine! Probably in the 50 - 100kHz range. See this for formulas and the JAVA on-line tool:

You wants lots of secondary peak voltage and lots of capacitor stored energy (1/2CV^2). Higher voltage really helps stored energy so you can use a smaller cap for higher resonant frequency and a more normal secondary.

I never thought about it till now, but the SISG drive circuit could run the single big high current brick OLTC too!!! In that case, you don't need nothin for a drive circuit

)

)You may want to check this out:

I hate to recommend something "new and never tried" to a new coiler though. But I think you are an engineer so you know the usual electronic details. The SISG drive is probably far more reliable and easy than any conventional OLTC drive. We won't even mention the complexity of DRSSTC's

Newer DF-DRSSTC and SISG circuits will probably make them obsolete

Newer DF-DRSSTC and SISG circuits will probably make them obsolete  And the OLTC will always be the "daddy"

And the OLTC will always be the "daddy"  But the DRSSTC is definitly the "thinking man's" machine!!! Once one has mastered the DRSSTC, everything else is "simple"...

But the DRSSTC is definitly the "thinking man's" machine!!! Once one has mastered the DRSSTC, everything else is "simple"...

If the SISG drive does not work, you are only out like $5 and 15 minutes of work

But it should work fine. I guess it would be a SISGOLTC

But it should work fine. I guess it would be a SISGOLTC  It would be the simplest "big" coil out there in that case with only "one" SISG section.

It would be the simplest "big" coil out there in that case with only "one" SISG section.Be sure to use a minimum of copper too!! A "ten foot" length of 1/4 inch tubing is running $16 here!!!!

Cheers,

Terry

Re: OLTC project

Marko, Tue Jun 20 2006, 08:17PM

OK you mean steve.. ? :)

Actually it seems that oltc's are indeed quite outperformed by DRSSTC's.

Looking at steve conner's OLTC 1 and 2 small one barely outsparks it's secondary length in the end.

If you are building an OLTC I guess you should make it huge. You want lowest possible Fres for biggest possible bang energy with single primary turn.

Conner's big one made 6 foot sparks(if I remember) with whole mess of toroids, from the pic it seems somewhat more than 2 secondary lenghts.

Ward's DRSSTC1 makes equal sparks that look much more impressive from many times smaller coil.

That brick will make a quite good OLTC since you already have it, but then you will figure out that people make longer sparks with DRSSTC's based on some 40N60's, even if you draw out 'maximum' of that IGBT and the coil itself.

I guess that's what Steve wanted to say...

2500V IGBT also adds room for bigger sparks, if you jump from 1000 to 2000V cap voltage you get four times more stored bang energy.

Good luck with your coil...

Marko, Tue Jun 20 2006, 08:17PM

Don't let Dan discourage you

OK you mean steve.. ? :)

Actually it seems that oltc's are indeed quite outperformed by DRSSTC's.

Looking at steve conner's OLTC 1 and 2 small one barely outsparks it's secondary length in the end.

If you are building an OLTC I guess you should make it huge. You want lowest possible Fres for biggest possible bang energy with single primary turn.

Conner's big one made 6 foot sparks(if I remember) with whole mess of toroids, from the pic it seems somewhat more than 2 secondary lenghts.

Ward's DRSSTC1 makes equal sparks that look much more impressive from many times smaller coil.

That brick will make a quite good OLTC since you already have it, but then you will figure out that people make longer sparks with DRSSTC's based on some 40N60's, even if you draw out 'maximum' of that IGBT and the coil itself.

I guess that's what Steve wanted to say...

2500V IGBT also adds room for bigger sparks, if you jump from 1000 to 2000V cap voltage you get four times more stored bang energy.

Good luck with your coil...

Re: OLTC project

Steve Conner, Tue Jun 20 2006, 09:32PM

In the end the best I got was 81" from a 30" tall resonator, and it needed over 4kW of power input to do that. The OLTC is quite limited in its bang energy, and delivers it in one short wallop. The DRSSTC can achieve a much bigger energy, and delivers it more slowly, so it can grow long sparks from a short coil without flashing it over. My OLTC 2was flashing over the whole length of the resonator towards the end, although the sparks weren't that long.

To explain: An OLTC or conventional coil dumps all the energy into the secondary as fast as possible to minimize primary circuit losses. The streamers then form and suck it out. A properly tuned DRSSTC seems to deliver the power just as fast as the streamers can eat it and no more, so there's no harsh spike of voltage that would aggravate flashovers or racing sparks. In practice, we can slow the energy transfer in a conventional coil by loosening the coupling, but an OLTC can't tolerate the low coupling because of its high primary losses, so it ends up with this wham-bam energy transfer.

I think that giant 2500V IGBT has got to do something spectacular, though You should get twice the spark length of my OLTC 2 (which had a 1200A 1200V switch)

You should get twice the spark length of my OLTC 2 (which had a 1200A 1200V switch)

When I think about it, I get kind of depressed that I lost the "Battle Of The Giant SSTCs". I guess if it weren't for me, we wouldn't know that OLTCs sucked, so it wasn't all wasted effort :-/

Steve Conner, Tue Jun 20 2006, 09:32PM

In the end the best I got was 81" from a 30" tall resonator, and it needed over 4kW of power input to do that. The OLTC is quite limited in its bang energy, and delivers it in one short wallop. The DRSSTC can achieve a much bigger energy, and delivers it more slowly, so it can grow long sparks from a short coil without flashing it over. My OLTC 2was flashing over the whole length of the resonator towards the end, although the sparks weren't that long.

To explain: An OLTC or conventional coil dumps all the energy into the secondary as fast as possible to minimize primary circuit losses. The streamers then form and suck it out. A properly tuned DRSSTC seems to deliver the power just as fast as the streamers can eat it and no more, so there's no harsh spike of voltage that would aggravate flashovers or racing sparks. In practice, we can slow the energy transfer in a conventional coil by loosening the coupling, but an OLTC can't tolerate the low coupling because of its high primary losses, so it ends up with this wham-bam energy transfer.

I think that giant 2500V IGBT has got to do something spectacular, though

You should get twice the spark length of my OLTC 2 (which had a 1200A 1200V switch)

You should get twice the spark length of my OLTC 2 (which had a 1200A 1200V switch)When I think about it, I get kind of depressed that I lost the "Battle Of The Giant SSTCs". I guess if it weren't for me, we wouldn't know that OLTCs sucked, so it wasn't all wasted effort :-/

Re: OLTC project

Marko, Tue Jun 20 2006, 10:09PM

Yeah, but I don't think you should 'quit' TC's and everything because of 'frustrations' , funds etc.

You don't need to beat any of world records but for me such claims and putting 'wtf d00d' page over there seems boring.

For jrz126, I think he should try to make secondary as small as posible with tiny wire (winding 110mm or bigger tube with 0.1mm etc. wire could be an interesting battle) and then find ways to move breakout avay from it to avoid flashovers.

Maybe to leave some empty space between toroid and top secondary winding, or, who says that toroid needs to be at top of secondary anyway?

(small corona ring is now needed to remove danger of top-turn breakout)

Maybe with few more ideas you could make a pretty good coil in the end. Conner and Terry Fritz will probably help you the most in this area.

Marko, Tue Jun 20 2006, 10:09PM

When I think about it, I get kind of depressed that I lost the "Battle Of The Giant SSTCs". I guess if it weren't for me, we wouldn't know that OLTCs sucked, so it wasn't all wasted effort :-/

Yeah, but I don't think you should 'quit' TC's and everything because of 'frustrations' , funds etc.

You don't need to beat any of world records but for me such claims and putting 'wtf d00d' page over there seems boring.

For jrz126, I think he should try to make secondary as small as posible with tiny wire (winding 110mm or bigger tube with 0.1mm etc. wire could be an interesting battle) and then find ways to move breakout avay from it to avoid flashovers.

Maybe to leave some empty space between toroid and top secondary winding, or, who says that toroid needs to be at top of secondary anyway?

(small corona ring is now needed to remove danger of top-turn breakout)

Maybe with few more ideas you could make a pretty good coil in the end. Conner and Terry Fritz will probably help you the most in this area.

Re: OLTC project

Jrz126, Tue Jun 20 2006, 10:12PM

Thanks a bunch Terry, finally someone with some info :)

I’m going to read up on those SISG’s…I think I might already have all of the parts I need to build one. How would I set it up to fire off of 120Vac and 220Vac? Using a voltage doubler...I could probably figure it out on my own, but I figure I might as well ask.

That IGBT is rated for 2500V, and as of right now I am limited to a 220V outlet. I’m also going to use some snubber caps (1000VDC 0.56uf KPF type). I’ve got a total of 24 to use.

Jrz126, Tue Jun 20 2006, 10:12PM

Thanks a bunch Terry, finally someone with some info :)

I’m going to read up on those SISG’s…I think I might already have all of the parts I need to build one. How would I set it up to fire off of 120Vac and 220Vac? Using a voltage doubler...I could probably figure it out on my own, but I figure I might as well ask.

That IGBT is rated for 2500V, and as of right now I am limited to a 220V outlet. I’m also going to use some snubber caps (1000VDC 0.56uf KPF type). I’ve got a total of 24 to use.

Re: OLTC project

Terry Fritz, Tue Jun 20 2006, 11:43PM

Hi Jeff,

I just realized it was "you"

I "think" voltage doublers will charge in 1/60th of a second so the BPS would "always" be 60 BPS max? So we end up with either 300V at 120 BPS or 600V at 60BPS.... I am thinking the 600V would be better. Maybe there is a simple way to switch between them? I really think you want to use the 220VAC but you could use the 120VAC too for testing like me. Make the input power stuff real "flexible". At 300V we might be able to run at 240 BPS too which seems to have odd advantages... Wysock and Parisse love 240 BPS and their coils spark super good!! My new test coil will look into that, but it is a few weeks out.... We are now learning MUCH about streamer and how to make them long

I used resonate charging but that was sort of a complex thing requiering a pretty finicy inductor. I would avoid that even though it "could" do wonderful things.

I "think" a voltage doubled 220VAC thing would give the best bang for the buck. Maybe others would know better? If you have a 220V variac that could go to 256.7 VAC that would be perfect? Do you have a variac and if so what kind?

I think OLTCs are hurt a little by secondary losses so we need to be careful of that. I think Bart's program does Rac of the secondary prediction but I have always used MandK since that matches measurements for me. Paul has a ton of great data about Rac and how to keep it low. Coupling is also an area where I really had no choice on my OLTC. But maybe ScanTesla can show us a better approach. It can itterate though all the variables looking for the "best" configuration. It works fine for OLTCs too

We should study Steve's coil too that he says sucks to see if there are any areas that could be improved.

I have not played with the OLTC other than my original one. The goal then was just get it to work "at all".... But we know so much more now...

SISG firing voltage is controlled by the number and value of the SIDACs used. You can set it for anything...

SISG don't quench on like the first notch "yet"... So tht is a bit of an issue but my OLTC did not perform that much better anyway with first notch quenching and I think Steve found that too... I really see "no" reason not to make it an SISG... The firing system I had needed current taps off the line and all for sync... That all seems usless now with the SISG...

The OLTC may not be the best performing coil on earth, but it is the "simplest" in many ways. The SISG combined with the OLTC might make it the simplest "period"...

Cheers,

Terry

Terry Fritz, Tue Jun 20 2006, 11:43PM

Hi Jeff,

I just realized it was "you"

I "think" voltage doublers will charge in 1/60th of a second so the BPS would "always" be 60 BPS max? So we end up with either 300V at 120 BPS or 600V at 60BPS.... I am thinking the 600V would be better. Maybe there is a simple way to switch between them? I really think you want to use the 220VAC but you could use the 120VAC too for testing like me. Make the input power stuff real "flexible". At 300V we might be able to run at 240 BPS too which seems to have odd advantages... Wysock and Parisse love 240 BPS and their coils spark super good!! My new test coil will look into that, but it is a few weeks out.... We are now learning MUCH about streamer and how to make them long

I used resonate charging but that was sort of a complex thing requiering a pretty finicy inductor. I would avoid that even though it "could" do wonderful things.

I "think" a voltage doubled 220VAC thing would give the best bang for the buck. Maybe others would know better? If you have a 220V variac that could go to 256.7 VAC that would be perfect? Do you have a variac and if so what kind?

I think OLTCs are hurt a little by secondary losses so we need to be careful of that. I think Bart's program does Rac of the secondary prediction but I have always used MandK since that matches measurements for me. Paul has a ton of great data about Rac and how to keep it low. Coupling is also an area where I really had no choice on my OLTC. But maybe ScanTesla can show us a better approach. It can itterate though all the variables looking for the "best" configuration. It works fine for OLTCs too

We should study Steve's coil too that he says sucks to see if there are any areas that could be improved.

I have not played with the OLTC other than my original one. The goal then was just get it to work "at all".... But we know so much more now...

SISG firing voltage is controlled by the number and value of the SIDACs used. You can set it for anything...

SISG don't quench on like the first notch "yet"... So tht is a bit of an issue but my OLTC did not perform that much better anyway with first notch quenching and I think Steve found that too... I really see "no" reason not to make it an SISG... The firing system I had needed current taps off the line and all for sync... That all seems usless now with the SISG...

The OLTC may not be the best performing coil on earth, but it is the "simplest" in many ways. The SISG combined with the OLTC might make it the simplest "period"...

Cheers,

Terry

Re: OLTC project

Jrz126, Wed Jun 21 2006, 01:14AM

Yeah, it's "me"...kinda sounds like you recognize me from somewhere?

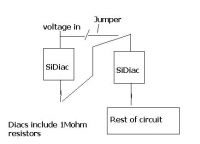

Could I set the SISG up so that I can control the breakdown voltage by using a jumper? Lemme see if I can get a schematic...the girlfriend only has dial up, so its quite slow...well I made a quick sketch...

well that can always be an upgrade I suppose...

Well I better get going, the girlfriend is giving me the evil eye right now, and saying something about a "joining a 'my boyfriend is an electrical engineer' support group".

Oh yeah, I noticed steve used some flexable cable to connect his primary to the bricks. What should I look for in this cable?

Jrz126, Wed Jun 21 2006, 01:14AM

Terry Fritz wrote ...

Hi Jeff,

I just realized it was "you"

Hi Jeff,

I just realized it was "you"

Yeah, it's "me"...kinda sounds like you recognize me from somewhere?

I "think" voltage doublers will charge in 1/60th of a second so the BPS would "always" be 60 BPS max? So we end up with either 300V at 120 BPS or 600V at 60BPS.... I am thinking the 600V would be better. Maybe there is a simple way to switch between them? I really think you want to use the 220VAC but you could use the 120VAC too for testing like me.

Could I set the SISG up so that I can control the breakdown voltage by using a jumper? Lemme see if I can get a schematic...the girlfriend only has dial up, so its quite slow...well I made a quick sketch...

I used resonate charging but that was sort of a complex thing requiering a pretty finicy inductor. I would avoid that even though it "could" do wonderful things.

well that can always be an upgrade I suppose...

I "think" a voltage doubled 220VAC thing would give the best bang for the buck. Maybe others would know better? If you have a 220V variac that could go to 256.7 VAC that would be perfect? Do you have a variac and if so what kind?I have only have a 10 amp 120V variac :(

Well I better get going, the girlfriend is giving me the evil eye right now, and saying something about a "joining a 'my boyfriend is an electrical engineer' support group".

Oh yeah, I noticed steve used some flexable cable to connect his primary to the bricks. What should I look for in this cable?

Re: OLTC project

Terry Fritz, Wed Jun 21 2006, 03:00AM

The only one I know to get "another" DF-DRSSTC working )

)

Yep!! You got keep all the "nodes" "open" for "modification"... Nobody knows what really to do, so you have to be able to do it "all"...

"If it ain't RG-8, it can't be toooo great" )) Radio Shack# 278-980.

)) Radio Shack# 278-980.

Cheers,

Terry

Terry Fritz, Wed Jun 21 2006, 03:00AM

Yeah, it's "me"...kinda sounds like you recognize me from somewhere?

The only one I know to get "another" DF-DRSSTC working

)

)Could I set the SISG up so that I can control the breakdown voltage by using a jumper? Lemme see if I can get a schematic...

Yep!! You got keep all the "nodes" "open" for "modification"... Nobody knows what really to do, so you have to be able to do it "all"...

Oh yeah, I noticed steve used some flexable cable to connect his primary to the bricks. What should I look for in this cable?

"If it ain't RG-8, it can't be toooo great"

)) Radio Shack# 278-980.

)) Radio Shack# 278-980.Cheers,

Terry

Re: OLTC project

Steve Conner, Wed Jun 21 2006, 10:11AM

The cable I used is coaxial speaker cable for PA systems. It has about 12AWG worth of wire crammed into it.

To drive that brick off 220v you probably want a voltage tripler or quadrupler to get you up to 1kV DC bus voltage

Firkragg, I just changed the wtf d00d page to something a bit less "dum". I was ill and real depressed when I wrote it

In response to the original question about gate charge, I found that my new gate driver design with discrete MOSFETs rated 12A@60V can drive a 600A brick fine. What affects the turn-on and turn-off times the most seems to be the stray inductance of the wiring between driver board and brick: not the choice of MOSFETs or whatever.

Most big bricks seem to have gate resistors built into them that limit how fast you can turn the thing on. I believe the popular CM600HA-24H has 0.8 ohm worth of resistance in there, so if a gate driver for these bricks goes to 20V, there's no point in designing it to deliver more than 25A.

Steve Conner, Wed Jun 21 2006, 10:11AM

The cable I used is coaxial speaker cable for PA systems. It has about 12AWG worth of wire crammed into it.

To drive that brick off 220v you probably want a voltage tripler or quadrupler to get you up to 1kV DC bus voltage

Firkragg, I just changed the wtf d00d page to something a bit less "dum". I was ill and real depressed when I wrote it

In response to the original question about gate charge, I found that my new gate driver design with discrete MOSFETs rated 12A@60V can drive a 600A brick fine. What affects the turn-on and turn-off times the most seems to be the stray inductance of the wiring between driver board and brick: not the choice of MOSFETs or whatever.

Most big bricks seem to have gate resistors built into them that limit how fast you can turn the thing on. I believe the popular CM600HA-24H has 0.8 ohm worth of resistance in there, so if a gate driver for these bricks goes to 20V, there's no point in designing it to deliver more than 25A.

Re: OLTC project

Jrz126, Wed Jun 21 2006, 12:11PM

Well I just put in an order to Digikey...so it will hopefully be here Monday or Tuesday. That will give me some time to get the brick ready to go.

A voltage Tripler?...I didnt know they existed.

I should probably figure out what voltage I am going to run at...My Cap bank is going to be somewhat difficult to connect up. They have the tabs, not the axial leads.

here's the datasheet. (1000VDC working volts and 0.56uF.)

So I'd prefer to not have to reconfigure it too much to run at a higher voltage.

Jrz126, Wed Jun 21 2006, 12:11PM

Well I just put in an order to Digikey...so it will hopefully be here Monday or Tuesday. That will give me some time to get the brick ready to go.

A voltage Tripler?...I didnt know they existed.

I should probably figure out what voltage I am going to run at...My Cap bank is going to be somewhat difficult to connect up. They have the tabs, not the axial leads.

here's the datasheet. (1000VDC working volts and 0.56uF.)

So I'd prefer to not have to reconfigure it too much to run at a higher voltage.

Re: OLTC project

Steve Conner, Wed Jun 21 2006, 12:53PM

Yup, you get voltage triplers, check out I believe they draw a DC component from the line however, which can be a real pain in some circumstances.

I believe they draw a DC component from the line however, which can be a real pain in some circumstances.

I would connect the cap bank for 2000V right from the word go. The extra voltage will give your coil a real kick in the back side, I wouldn't be surprised if it turned out the best performing OLTC ever.

Steve Conner, Wed Jun 21 2006, 12:53PM

Yup, you get voltage triplers, check out

I believe they draw a DC component from the line however, which can be a real pain in some circumstances.

I believe they draw a DC component from the line however, which can be a real pain in some circumstances.I would connect the cap bank for 2000V right from the word go. The extra voltage will give your coil a real kick in the back side, I wouldn't be surprised if it turned out the best performing OLTC ever.

Re: OLTC project

Jrz126, Wed Jun 21 2006, 03:23PM

Whats the benefit of using the coax cable? Is the coax cable just being used for the shielding conductor? Old Monitor cables had a steel braided sheilding over the cable, would that also work? I've got plenty of both lying around, but the braiding from the monitor cable would be much more flexible.

Also, how should I go about heatsinking this monster?

Jrz126, Wed Jun 21 2006, 03:23PM

Whats the benefit of using the coax cable? Is the coax cable just being used for the shielding conductor? Old Monitor cables had a steel braided sheilding over the cable, would that also work? I've got plenty of both lying around, but the braiding from the monitor cable would be much more flexible.

Also, how should I go about heatsinking this monster?

Re: OLTC project

Steve Ward, Wed Jun 21 2006, 05:35PM

The coax is to provide a low inductance line between the IGBTs and primary coil. This is very crucial because you want all of the inductance to be in the primary. You dont want stray inductance in the circuit for a few reasons: it lowers the overall coupling between the primary and secondary, and it increases your surge impedance unnecessarily so. Ideally the IGBTs would probably become part of the primary coil like Terry did in his first OLTC design. But, since you are dealing with a giant IGBT with a big heatsink, its not an easy way go to. The coax is the next best option, but you need to parallel enough of them to handle the currents.

Steve Ward, Wed Jun 21 2006, 05:35PM

The coax is to provide a low inductance line between the IGBTs and primary coil. This is very crucial because you want all of the inductance to be in the primary. You dont want stray inductance in the circuit for a few reasons: it lowers the overall coupling between the primary and secondary, and it increases your surge impedance unnecessarily so. Ideally the IGBTs would probably become part of the primary coil like Terry did in his first OLTC design. But, since you are dealing with a giant IGBT with a big heatsink, its not an easy way go to. The coax is the next best option, but you need to parallel enough of them to handle the currents.

Re: OLTC project

Jrz126, Wed Jun 21 2006, 08:17PM

So is the coax being used for the inner or outer conductor? I'm assuming outter due to the high current involved...so would the braided shielding work then?

Also, Are there any eaisly obtainable alternatives to using the cardboard form for the secondary? I can see that getting broken down the road.

Jrz126, Wed Jun 21 2006, 08:17PM

So is the coax being used for the inner or outer conductor? I'm assuming outter due to the high current involved...so would the braided shielding work then?

Also, Are there any eaisly obtainable alternatives to using the cardboard form for the secondary? I can see that getting broken down the road.

Re: OLTC project

Steve Ward, Wed Jun 21 2006, 08:53PM

No, the coax is used as coax (both conductors are used, and seperately). It is used for the send and return of the primary connections. You are basically reducing the loop area of the wiring, thus reducing the inductance.

Steve Ward, Wed Jun 21 2006, 08:53PM

No, the coax is used as coax (both conductors are used, and seperately). It is used for the send and return of the primary connections. You are basically reducing the loop area of the wiring, thus reducing the inductance.

Re: OLTC project

Terry Fritz, Thu Jun 22 2006, 12:30AM

Hi,

I had you confused with James Zimmerschied who is also "JRZ". I get confused easy #:-)

The Steve's

Thanks for explaining the Coax and how it is used to reduce wiring inductance!! I never realized what all that was about *:-) I might do that on my new coil where primary inductance needs to be rather low.

Must study the voltage doubler and trippler link! The DC SISG and MOT stuff is all new to me. Mark and some use resonant charging on them too...

Somedays, it is like I don't know anything 0:-)

For a durrable secondary form. I like cut to length polycarbonite from Mcmaster-Carr.

Cut-to-Length Length

Id OD P# Cost/foot

1" 1-1/4" 8585K15 $4.58

1-1/4" 1-1/2" 8585K16 5.32

1-3/8" 1-1/2" 8585K43 3.24

1-1/2" 1-3/4" 8585K17 6.51

1-3/4" 2" 8585K18 7.00

2" 2-1/4" 8585K46 8.19

2-1/4" 2-1/2" 8585K19 8.73

2-1/2" 2-3/4" 8585K34 10.01

2-3/4" 3" 8585K21 10.70

3-1/4" 3-1/2" 8585K33 13.25

3-3/4" 4" 8585K22 17.06

4-3/4" 5" 8585K45 24.38

5-3/4" 6" 8585K23 29.92

7-3/4" 8" 8585K48 33.36

But it costs a whole lot more that concrete tube!! Very nice for little coils though. You can also get sewer and drain pipe from a plumbing supply contractor type place but you usually have to get full lengths that are like 20 feet long... Or just hang out there and follow the guy that just bought 50 of them and see if he has any left over )) You can often call plumbing places and ask if they have an extra bit they would sell you too. Most contractors just throw the extra away. The trick is to be there at the right time.

)) You can often call plumbing places and ask if they have an extra bit they would sell you too. Most contractors just throw the extra away. The trick is to be there at the right time.

Cheers,

Terry

Terry Fritz, Thu Jun 22 2006, 12:30AM

Hi,

Yeah, it's "me"...kinda sounds like you recognize me from somewhere?

I had you confused with James Zimmerschied who is also "JRZ". I get confused easy #:-)

The Steve's

Thanks for explaining the Coax and how it is used to reduce wiring inductance!! I never realized what all that was about *:-) I might do that on my new coil where primary inductance needs to be rather low.

Must study the voltage doubler and trippler link! The DC SISG and MOT stuff is all new to me. Mark and some use resonant charging on them too...

Somedays, it is like I don't know anything 0:-)

For a durrable secondary form. I like cut to length polycarbonite from Mcmaster-Carr.

Cut-to-Length Length

Id OD P# Cost/foot

1" 1-1/4" 8585K15 $4.58

1-1/4" 1-1/2" 8585K16 5.32

1-3/8" 1-1/2" 8585K43 3.24

1-1/2" 1-3/4" 8585K17 6.51

1-3/4" 2" 8585K18 7.00

2" 2-1/4" 8585K46 8.19

2-1/4" 2-1/2" 8585K19 8.73

2-1/2" 2-3/4" 8585K34 10.01

2-3/4" 3" 8585K21 10.70

3-1/4" 3-1/2" 8585K33 13.25

3-3/4" 4" 8585K22 17.06

4-3/4" 5" 8585K45 24.38

5-3/4" 6" 8585K23 29.92

7-3/4" 8" 8585K48 33.36

But it costs a whole lot more that concrete tube!! Very nice for little coils though. You can also get sewer and drain pipe from a plumbing supply contractor type place but you usually have to get full lengths that are like 20 feet long... Or just hang out there and follow the guy that just bought 50 of them and see if he has any left over

)) You can often call plumbing places and ask if they have an extra bit they would sell you too. Most contractors just throw the extra away. The trick is to be there at the right time.

)) You can often call plumbing places and ask if they have an extra bit they would sell you too. Most contractors just throw the extra away. The trick is to be there at the right time.Cheers,

Terry

Re: OLTC project

Jrz126, Thu Jun 22 2006, 01:08AM

ouch. thats quite expensive.

I'm going to make some calls tomorrow and see if I can find some for cheap...If not, I'll probably just buy a concrete tube, plug the ends and fill it with expandable foam.

My dad has a 18.5" diameter piece of pvc, 48" long, left over from when we built our house...I think its alittle too big?

Jrz126, Thu Jun 22 2006, 01:08AM

ouch. thats quite expensive.

I'm going to make some calls tomorrow and see if I can find some for cheap...If not, I'll probably just buy a concrete tube, plug the ends and fill it with expandable foam.

My dad has a 18.5" diameter piece of pvc, 48" long, left over from when we built our house...I think its alittle too big?

Re: OLTC project

..., Thu Jun 22 2006, 01:33AM

What size are you looking for? Public Missiles Ltd has 48" pieces of phenolic tube for $40 for a 6" piece or $80 for a 12" diameter... If you only need 4" I would get the 'quantum tube', (it is that grey plastic tube that is shown at the top of the airframes section of the webstore) it isn't as strong (but still stronger than you need) but considerably easier to work with.

..., Thu Jun 22 2006, 01:33AM

What size are you looking for? Public Missiles Ltd has 48" pieces of phenolic tube for $40 for a 6" piece or $80 for a 12" diameter... If you only need 4" I would get the 'quantum tube', (it is that grey plastic tube that is shown at the top of the airframes section of the webstore) it isn't as strong (but still stronger than you need) but considerably easier to work with.

Re: OLTC project

Steve Conner, Thu Jun 22 2006, 11:10AM

When I was making my OLTC 2, I went to one of those plumbing supply places and spoke nicely to them, and they cut off a 3 foot piece of 10" HDPE pipe with 3/8" wall thickness for me. It cost about $35.

The secondary for my DRSSTC was another piece of smaller HDPE piping that I found lying in the road one day.

Steve Conner, Thu Jun 22 2006, 11:10AM

When I was making my OLTC 2, I went to one of those plumbing supply places and spoke nicely to them, and they cut off a 3 foot piece of 10" HDPE pipe with 3/8" wall thickness for me. It cost about $35.

The secondary for my DRSSTC was another piece of smaller HDPE piping that I found lying in the road one day.

Re: OLTC project

HV Enthusiast, Thu Jun 22 2006, 12:38PM

Check EBAY. There is a supplier there that sells acrylic tubes for dirt cheap. Although, i'm not sure what the largest diameter is.

HV Enthusiast, Thu Jun 22 2006, 12:38PM

wrote ...

Cut-to-Length Length

Id OD P# Cost/foot

1" 1-1/4" 8585K15 $4.58

1-1/4" 1-1/2" 8585K16 5.32

1-3/8" 1-1/2" 8585K43 3.24

1-1/2" 1-3/4" 8585K17 6.51

1-3/4" 2" 8585K18 7.00

2" 2-1/4" 8585K46 8.19

2-1/4" 2-1/2" 8585K19 8.73

2-1/2" 2-3/4" 8585K34 10.01

2-3/4" 3" 8585K21 10.70

3-1/4" 3-1/2" 8585K33 13.25

3-3/4" 4" 8585K22 17.06

4-3/4" 5" 8585K45 24.38

5-3/4" 6" 8585K23 29.92

7-3/4" 8" 8585K48 33.36

But it costs a whole lot more that concrete tube!! Very nice for little coils though. You can also get sewer and drain pipe from a plumbing supply contractor type place but you usually have to get full lengths that are like 20 feet long... Or just hang out there and follow the guy that just bought 50 of them and see if he has any left over )) You can often call plumbing places and ask if they have an extra bit they would sell you too. Most contractors just throw the extra away. The trick is to be there at the right time.

Cheers,

Terry

Cut-to-Length Length

Id OD P# Cost/foot

1" 1-1/4" 8585K15 $4.58

1-1/4" 1-1/2" 8585K16 5.32

1-3/8" 1-1/2" 8585K43 3.24

1-1/2" 1-3/4" 8585K17 6.51

1-3/4" 2" 8585K18 7.00

2" 2-1/4" 8585K46 8.19

2-1/4" 2-1/2" 8585K19 8.73

2-1/2" 2-3/4" 8585K34 10.01

2-3/4" 3" 8585K21 10.70

3-1/4" 3-1/2" 8585K33 13.25

3-3/4" 4" 8585K22 17.06

4-3/4" 5" 8585K45 24.38

5-3/4" 6" 8585K23 29.92

7-3/4" 8" 8585K48 33.36

But it costs a whole lot more that concrete tube!! Very nice for little coils though. You can also get sewer and drain pipe from a plumbing supply contractor type place but you usually have to get full lengths that are like 20 feet long... Or just hang out there and follow the guy that just bought 50 of them and see if he has any left over )) You can often call plumbing places and ask if they have an extra bit they would sell you too. Most contractors just throw the extra away. The trick is to be there at the right time.

Cheers,

Terry

Check EBAY. There is a supplier there that sells acrylic tubes for dirt cheap. Although, i'm not sure what the largest diameter is.

Re: OLTC project

J. Aaron Holmes, Thu Jun 22 2006, 06:35PM

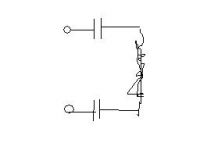

Now that we have the SISG in our toolboxes, what about using SISGs to create an "off line" Marx generator to power your OLTC? Take three 300V SISGs (one SIDAC each) and make a three-stage Marx that'll spit out 900V. Then attach TC primary. I'm told SIDACs are slow, so perhaps the rule would be that the output of the stack ought not to exceed the voltage of any single IGBT. Else the rise time might outpace the SIDACs after the first stage fired and you'd get deep-fried IGBT. But if you stay below the IGBT voltage, as in my example above, wouldn't that work?

Then you'd have the Sidac Igbt Spark Gap Marx Generator Tesla Coil (SISGMGTC)

...would be "interesting".

Regards,

Aaron, N7OE

PS: Yay! I'm finally signed up!

J. Aaron Holmes, Thu Jun 22 2006, 06:35PM

Now that we have the SISG in our toolboxes, what about using SISGs to create an "off line" Marx generator to power your OLTC? Take three 300V SISGs (one SIDAC each) and make a three-stage Marx that'll spit out 900V. Then attach TC primary. I'm told SIDACs are slow, so perhaps the rule would be that the output of the stack ought not to exceed the voltage of any single IGBT. Else the rise time might outpace the SIDACs after the first stage fired and you'd get deep-fried IGBT. But if you stay below the IGBT voltage, as in my example above, wouldn't that work?

Then you'd have the Sidac Igbt Spark Gap Marx Generator Tesla Coil (SISGMGTC)

...would be "interesting".

Regards,

Aaron, N7OE

PS: Yay! I'm finally signed up!

Re: OLTC project

J. Aaron Holmes, Thu Jun 22 2006, 07:31PM

(edit: Few more thoughts)

Basically, the schematic I had in mind was:

...where each SISG is set for 300V (one SIDAC).

Hmmm... Maybe the voltage doubler ought to be separated out with bigger caps for smoothing to allow for higher break rates, I don't know. Haven't thought enough about it. Add in DC resonant charging and higher-V IGBTs and you might really get something out

J. Aaron Holmes, Thu Jun 22 2006, 07:31PM

(edit: Few more thoughts)

Basically, the schematic I had in mind was:

...where each SISG is set for 300V (one SIDAC).

Hmmm... Maybe the voltage doubler ought to be separated out with bigger caps for smoothing to allow for higher break rates, I don't know. Haven't thought enough about it. Add in DC resonant charging and higher-V IGBTs and you might really get something out

Re: OLTC project

Jrz126, Thu Jun 22 2006, 08:39PM

So I think I'm going to go with the cardboard tube...(although, I think I might have enough 26# wire to do a 34" coil on that 18.5" diameter pipe that I have ). Will I have to coat the cardboard before I wind it?

). Will I have to coat the cardboard before I wind it?

My SISG parts wont arrive until Tuesday

Jrz126, Thu Jun 22 2006, 08:39PM

So I think I'm going to go with the cardboard tube...(although, I think I might have enough 26# wire to do a 34" coil on that 18.5" diameter pipe that I have

). Will I have to coat the cardboard before I wind it?

). Will I have to coat the cardboard before I wind it?My SISG parts wont arrive until Tuesday

Re: OLTC project

Jrz126, Fri Jun 23 2006, 07:16PM

Sweet! the fed ex package tracker dealy is way off. The parts are scheduled to be delivered today.

I have a 4.5" x 18" coil already wound, I think I'll set up a little test rig for now. I dont know if Ill be able to use the SiDac circuit, since it will only fire at 240-280V. I should have ordered some lower voltage ones.

I was reading up on how to drive these some more (see this ). on page 16,

Also, I was reading Steve's OLTC stuff and he mentioned something about secondary flashover...what is this exactly?

Jrz126, Fri Jun 23 2006, 07:16PM

Sweet! the fed ex package tracker dealy is way off. The parts are scheduled to be delivered today.

I have a 4.5" x 18" coil already wound, I think I'll set up a little test rig for now. I dont know if Ill be able to use the SiDac circuit, since it will only fire at 240-280V. I should have ordered some lower voltage ones.

I was reading up on how to drive these some more (see this ). on page 16,

An IGBT will be off when its gate voltage is zero. However, in order to ensure that the IGBT stays in its off state when dv/dt noise is present in the collector-emitter voltage an off bias must be used. Use of reverse bias also decreases turn off losses. The relationship between reverse bias voltage and switching losses is shown in Figure 4.45. For H-Series IGBTs an off bias of -5 to -15V is recommended.So does this mean my Gate Drive should be capable of going negative?

Also, I was reading Steve's OLTC stuff and he mentioned something about secondary flashover...what is this exactly?

Re: OLTC project

Marko, Fri Jun 23 2006, 08:43PM

Yes, It probably isn't that important here but it's main advantages are that it speeds up turn-off, and holds the gate strongly under zero.

Noise needs to be greater than this voltage (plus few volts) to accidently turn the IGBT on.

In high frequency bridge applications this is very important because miller (gate-drain capacitance) couples part of high supply voltage to the gate.

When IGBT closes shut voltage on it's drain quickly rises to supply voltage, and miller capacitance couples this dV/dt change to gate.

If gatedrive failed to hold off that 'spike', gate will turn on, IGBT will open when it was supposed to be closed, undergo shoot-trough with another IGBT in halfbridge, shorting the supply, and both die a horrid death.

In OLTC things are different, you have only one switch and switching is slow, so holding gate isn't necessary. As I figured out Steve Conner didn't use negative drive in his final design.

As steve explained, single turn primary and MMC, switched by IGBT, aren't actually a very good resonant circuit.

Since we are operating on low voltage we try to get the tank capacitance as big as possible, and we must cut down the primary to single turn if we want a reasonably high Fres.

Due to losses on Primary circuit it must be closely coupled to secondary, so the energy is transferred as fast as possible before it's lost.

Fast energy transfer causes secondary voltage to rise rapidly, wich leaves little time for streamers to 'grow' and secondary tends to flash over and make racing sparks. It's hard to get multi-secondary-length streamer 'growing' off the breakout point and miraculously not flashing ovver, like with DRSSTC and less-coupled SGTC's (where energy transfer is much slower, especially with DRSSTC).

Marko, Fri Jun 23 2006, 08:43PM

So does this mean my Gate Drive should be capable of going negative?

Yes, It probably isn't that important here but it's main advantages are that it speeds up turn-off, and holds the gate strongly under zero.

Noise needs to be greater than this voltage (plus few volts) to accidently turn the IGBT on.

In high frequency bridge applications this is very important because miller (gate-drain capacitance) couples part of high supply voltage to the gate.

When IGBT closes shut voltage on it's drain quickly rises to supply voltage, and miller capacitance couples this dV/dt change to gate.

If gatedrive failed to hold off that 'spike', gate will turn on, IGBT will open when it was supposed to be closed, undergo shoot-trough with another IGBT in halfbridge, shorting the supply, and both die a horrid death.

In OLTC things are different, you have only one switch and switching is slow, so holding gate isn't necessary. As I figured out Steve Conner didn't use negative drive in his final design.

Also, I was reading Steve's OLTC stuff and he mentioned something about secondary flashover...what is this exactly?

As steve explained, single turn primary and MMC, switched by IGBT, aren't actually a very good resonant circuit.

Since we are operating on low voltage we try to get the tank capacitance as big as possible, and we must cut down the primary to single turn if we want a reasonably high Fres.

Due to losses on Primary circuit it must be closely coupled to secondary, so the energy is transferred as fast as possible before it's lost.

Fast energy transfer causes secondary voltage to rise rapidly, wich leaves little time for streamers to 'grow' and secondary tends to flash over and make racing sparks. It's hard to get multi-secondary-length streamer 'growing' off the breakout point and miraculously not flashing ovver, like with DRSSTC and less-coupled SGTC's (where energy transfer is much slower, especially with DRSSTC).

Re: OLTC project

Jrz126, Sat Jun 24 2006, 03:32AM

I made a quick test setup... secondary + rig

the brick

closeup of the brick

Now all I need is a gate drive

Jrz126, Sat Jun 24 2006, 03:32AM

I made a quick test setup... secondary + rig

the brick

closeup of the brick

Now all I need is a gate drive

Re: OLTC project

Marko, Sat Jun 24 2006, 10:41AM

Your MMC and secondary look pretty small for that brick. (Hihg Fres).

But for quick lash-up we can say it's OK.

What wire thickness did you use for this secondary?

Marko, Sat Jun 24 2006, 10:41AM

Your MMC and secondary look pretty small for that brick. (Hihg Fres).

But for quick lash-up we can say it's OK.

What wire thickness did you use for this secondary?

Re: OLTC project

Jrz126, Sat Jun 24 2006, 10:53AM

I've got 24 of those caps to use.

I used 1/4" fridge tube.

I'll be working on it later tonight :)

Jrz126, Sat Jun 24 2006, 10:53AM

I've got 24 of those caps to use.

I used 1/4" fridge tube.

I'll be working on it later tonight :)

Re: OLTC project

Jrz126, Sat Jun 24 2006, 10:40PM

I'm designing my Gate drive right now, I'm going to use a IR21844 IC, a half bridge mosfet driver which has a programmable 'dead time' to prevent shoot through.

I'm going to use a 555 timer to trigger it. What duty cycle/on time do I want to use to drive my IGBT?

Jrz126, Sat Jun 24 2006, 10:40PM

I'm designing my Gate drive right now, I'm going to use a IR21844 IC, a half bridge mosfet driver which has a programmable 'dead time' to prevent shoot through.

I'm going to use a 555 timer to trigger it. What duty cycle/on time do I want to use to drive my IGBT?

Re: OLTC project

Marko, Sat Jun 24 2006, 11:13PM

Maybe we misunderstood?

I guess you meant to drive gatedrive-mosfets with this driver, and shoot-trough is not a danger there.

This is a high voltage driver for SMPS use, seems to be generally slow but you could use it if you really wish, for mosfet driving.

Look at Steve Conner's OLTC pages, you have lots of OLTC knowledge there.

You can use it but there are much simpler ways to do the same thing, and much faster.

I'd stick to Steve Conner's driver for the beggining, for a big OLTC improved version (with zero cross detection and crowbar) is very advisable.

NE555 and simple mosfet driver may be good for the beggining, at low power. Just take care not to blow up that nice IGBT.

Marko, Sat Jun 24 2006, 11:13PM

Maybe we misunderstood?

I guess you meant to drive gatedrive-mosfets with this driver, and shoot-trough is not a danger there.

This is a high voltage driver for SMPS use, seems to be generally slow but you could use it if you really wish, for mosfet driving.

Look at Steve Conner's OLTC pages, you have lots of OLTC knowledge there.

You can use it but there are much simpler ways to do the same thing, and much faster.

I'd stick to Steve Conner's driver for the beggining, for a big OLTC improved version (with zero cross detection and crowbar) is very advisable.

NE555 and simple mosfet driver may be good for the beggining, at low power. Just take care not to blow up that nice IGBT.

Re: OLTC project

Steve Conner, Sat Jun 24 2006, 11:21PM

Jrz and Aaron, 48 hours between double posts please If you want to add something in a hurry, edit your original post.

If you want to add something in a hurry, edit your original post.

Using the SISG as a power supply is pretty pointless. If you don't like voltage multipliers running off the 60Hz line, just go to an electrical salvage yard, get a 120 to 480v transformer, run it backwards, and rectify the 480V AC output. If you want to do something really 1337, make a boost converter power supply like Steve Ward's 7kW unit.

Steve Conner, Sat Jun 24 2006, 11:21PM

Jrz and Aaron, 48 hours between double posts please

If you want to add something in a hurry, edit your original post.

If you want to add something in a hurry, edit your original post.Using the SISG as a power supply is pretty pointless. If you don't like voltage multipliers running off the 60Hz line, just go to an electrical salvage yard, get a 120 to 480v transformer, run it backwards, and rectify the 480V AC output. If you want to do something really 1337, make a boost converter power supply like Steve Ward's 7kW unit.

Re: OLTC project

Terry Fritz, Sat Jun 24 2006, 11:30PM

Hi,

I looked into the voltage doubler and trippler stuff. Pretty cool!! But the caps have to be pretty darn big and all!! In general, I would think one would be better off just using a MOT. Of course, maybe some folks like the voltage doublers and tripplers so more "power" to them ))) But a very simple MOT run at low voltage off a variac can kick some pretty big arcs too

))) But a very simple MOT run at low voltage off a variac can kick some pretty big arcs too  )

)

Cheers,

Terry

Terry Fritz, Sat Jun 24 2006, 11:30PM

Hi,

I looked into the voltage doubler and trippler stuff. Pretty cool!! But the caps have to be pretty darn big and all!! In general, I would think one would be better off just using a MOT. Of course, maybe some folks like the voltage doublers and tripplers so more "power" to them

))) But a very simple MOT run at low voltage off a variac can kick some pretty big arcs too

))) But a very simple MOT run at low voltage off a variac can kick some pretty big arcs too  )

)Cheers,

Terry

Re: OLTC project

Marko, Sat Jun 24 2006, 11:45PM

With 2500V IGBT one needs to lower the input voltage of a mot just a little.

To get 2 kilovolts it would take a pretty big voltage multiplier to get enough power ($$$ caps)

Marko, Sat Jun 24 2006, 11:45PM

With 2500V IGBT one needs to lower the input voltage of a mot just a little.

To get 2 kilovolts it would take a pretty big voltage multiplier to get enough power ($$$ caps)

Re: OLTC project

Steve Conner, Sun Jun 25 2006, 01:04AM

You only need 1kV since DC resonant charging automatically doubles it for you. My OLTC 2 used a 600V DC bus made by voltage doubling the 240V AC supply.

Steve Conner, Sun Jun 25 2006, 01:04AM

You only need 1kV since DC resonant charging automatically doubles it for you. My OLTC 2 used a 600V DC bus made by voltage doubling the 240V AC supply.

Re: OLTC project

Jrz126, Sun Jun 25 2006, 11:37PM

I calcuated the resonant freq of my testing secondary to be 189.95 khz. Now how do I determine what frequency to drive my IGBT at?

Jrz126, Sun Jun 25 2006, 11:37PM

I calcuated the resonant freq of my testing secondary to be 189.95 khz. Now how do I determine what frequency to drive my IGBT at?

Re: OLTC project

Steve Conner, Sun Jun 25 2006, 11:43PM

The OLTC isn't like other SSTCs where you drive the switches around the resonant frequency. If you want 120 sparks per second, you feed 120 pulses per second to the IGBT, so you could say you're driving it at 120Hz.

However, the length of the pulse for best performance is related to the resonant frequency of the coils and the coupling between them. You want the pulse to end when the primary current reaches its first notch, usually after 3-4 cycles of the resonant frequency.

Since OLTCs lacked bang energy, we ended up operating them at insane breakrates to try and make the sparks bigger. I never ran my OLTC 2 at breakrates higher than 600Hz because the power supply couldn't take it, but I've seen other people use well over 1000Hz.

Steve Conner, Sun Jun 25 2006, 11:43PM

The OLTC isn't like other SSTCs where you drive the switches around the resonant frequency. If you want 120 sparks per second, you feed 120 pulses per second to the IGBT, so you could say you're driving it at 120Hz.

However, the length of the pulse for best performance is related to the resonant frequency of the coils and the coupling between them. You want the pulse to end when the primary current reaches its first notch, usually after 3-4 cycles of the resonant frequency.

Since OLTCs lacked bang energy, we ended up operating them at insane breakrates to try and make the sparks bigger. I never ran my OLTC 2 at breakrates higher than 600Hz because the power supply couldn't take it, but I've seen other people use well over 1000Hz.

Re: OLTC project

GimpyJoe, Mon Jun 26 2006, 12:40AM

You can eliminate the need for a variac by simply making a new tap point on your MOT secondary. Just do a cut off turns and re-solder when you have the output voltage you want.

GimpyJoe, Mon Jun 26 2006, 12:40AM

Firkragg wrote ...

With 2500V IGBT one needs to lower the input voltage of a mot just a little.

To get 2 kilovolts it would take a pretty big voltage multiplier to get enough power ($$$ caps)

With 2500V IGBT one needs to lower the input voltage of a mot just a little.

To get 2 kilovolts it would take a pretty big voltage multiplier to get enough power ($$$ caps)

You can eliminate the need for a variac by simply making a new tap point on your MOT secondary. Just do a cut off turns and re-solder when you have the output voltage you want.

Re: OLTC project

Marko, Mon Jun 26 2006, 11:57AM

Maybe, if MOT likes unwinding.

Problem is that this involves sawing the core in half, and resonant charging with doubler or etc. is a less pain than that.

Marko, Mon Jun 26 2006, 11:57AM

Maybe, if MOT likes unwinding.

Problem is that this involves sawing the core in half, and resonant charging with doubler or etc. is a less pain than that.

Re: OLTC project

Steve Ward, Mon Jun 26 2006, 04:28PM

Re: Cardboard forms: I use a cardboard form on my largest coil. The cardboard performs just fine at standing off the voltages, but you must properly prep the form. Make sure you have a dry tube, not something thats been sitting outside. First thing you have to do is take a knife and "score" (shallow cut) along the seam of where the paper wrapping overlaps (its a spiral around the tube). This should allow you to remove the outer paper easily with careful peeling. Once you get rid of that outer layer of paper (you want it gone cause it has black, conductive, ink), you are ready to begin the process of coating and sanding. Coat the tube with your typical polyurethane varnish, then give it a light sanding. Repeat this process about 3 times or more, until you have a suitably smooth surface to wind your coil on. After winding the coil, seal it again with 3 or more coats of the varnish. You may also wish to coat the ends (the edges) as well as the inside of the tube with varnish to keep it from absorbing any more water. So far my coil has withstood 144" sparks from an 8" diameter 45" long winding. I used the concrete form tube from menards, but the stuff from home-depot has worked fine too. I think its all pretty much the same, as ive heard other successes with cardboard too.

Steve Ward, Mon Jun 26 2006, 04:28PM

Re: Cardboard forms: I use a cardboard form on my largest coil. The cardboard performs just fine at standing off the voltages, but you must properly prep the form. Make sure you have a dry tube, not something thats been sitting outside. First thing you have to do is take a knife and "score" (shallow cut) along the seam of where the paper wrapping overlaps (its a spiral around the tube). This should allow you to remove the outer paper easily with careful peeling. Once you get rid of that outer layer of paper (you want it gone cause it has black, conductive, ink), you are ready to begin the process of coating and sanding. Coat the tube with your typical polyurethane varnish, then give it a light sanding. Repeat this process about 3 times or more, until you have a suitably smooth surface to wind your coil on. After winding the coil, seal it again with 3 or more coats of the varnish. You may also wish to coat the ends (the edges) as well as the inside of the tube with varnish to keep it from absorbing any more water. So far my coil has withstood 144" sparks from an 8" diameter 45" long winding. I used the concrete form tube from menards, but the stuff from home-depot has worked fine too. I think its all pretty much the same, as ive heard other successes with cardboard too.

Re: OLTC project

Dr. Drone, Mon Jun 26 2006, 07:21PM

Dr. Drone, Mon Jun 26 2006, 07:21PM

Re: OLTC project

Jrz126, Mon Jun 26 2006, 11:38PM

Thank you all for the info...

I found a 555 circuit that allows me to vary the duty cycle with a pot. I had the on time set to about 50usec. with 144 bps. It ran pretty good off of a car battery charger, pulling about 4-8 amps. When I use my variac, it hums like mad...Am I drawing too much current through it? how do I make sure I dont pull too much current from the wall outlet?

Jrz126, Mon Jun 26 2006, 11:38PM

Thank you all for the info...

I found a 555 circuit that allows me to vary the duty cycle with a pot. I had the on time set to about 50usec. with 144 bps. It ran pretty good off of a car battery charger, pulling about 4-8 amps. When I use my variac, it hums like mad...Am I drawing too much current through it? how do I make sure I dont pull too much current from the wall outlet?

Re: OLTC project

HV Enthusiast, Tue Jun 27 2006, 01:08AM

i use cardboard sonotubes for a number of coils also. i don't bother removing the outer layer though. i think the entire tube, being considerably hygroscopic, will have a higher conductivity than a little black ink. if it makes you feel better, then by all means remove it, but i don't think its necessary.

HV Enthusiast, Tue Jun 27 2006, 01:08AM

i use cardboard sonotubes for a number of coils also. i don't bother removing the outer layer though. i think the entire tube, being considerably hygroscopic, will have a higher conductivity than a little black ink. if it makes you feel better, then by all means remove it, but i don't think its necessary.

Re: OLTC project

Jrz126, Wed Jun 28 2006, 08:55PM

I've started work on my winding jig. I'll try to have some pics up later tonight.

I've got a few questions, first off, how much polyurethane did you guys use? I'd prefer to not buy the 1 gallon can if I dont have to.

I also ordered parts to build a gate drive similar to Steve Conner's. How is the Rogowski coil implemented? I'm mostly looking for the position with respect to the primary, and I assume I'll need to use shielded cable?

Well thats all for now, hopefully I'll be able to get some work done tonight

Jrz126, Wed Jun 28 2006, 08:55PM

I've started work on my winding jig. I'll try to have some pics up later tonight.

I've got a few questions, first off, how much polyurethane did you guys use? I'd prefer to not buy the 1 gallon can if I dont have to.

I also ordered parts to build a gate drive similar to Steve Conner's. How is the Rogowski coil implemented? I'm mostly looking for the position with respect to the primary, and I assume I'll need to use shielded cable?

Well thats all for now, hopefully I'll be able to get some work done tonight

Re: OLTC project

Steve Ward, Thu Jun 29 2006, 01:15AM

1 quart of varnish was plenty for my 8"x48" coil. I wouldnt get the really small can though.

Steve Ward, Thu Jun 29 2006, 01:15AM

1 quart of varnish was plenty for my 8"x48" coil. I wouldnt get the really small can though.

Re: OLTC project

Steve Conner, Thu Jun 29 2006, 08:58AM

Hi jrz

The Rogowski coil is a toroidal air cored current transformer. I made mine by wrapping some left-over secondary wire round a 6" length of plastic hose (about 3/8" diameter) and then bending the hose round into a donut shape and joining the ends with tape.

I put it round a conductor of the primary circuit so that the full primary current flows through the middle of it. The whole point of the Rogowski coil is that it only detects currents that pass through the donut hole. To avoid the single turn effect and help improve the cancellation, I passed the wire from the far end back down the middle of the hose.

Steve Conner, Thu Jun 29 2006, 08:58AM

Hi jrz

The Rogowski coil is a toroidal air cored current transformer. I made mine by wrapping some left-over secondary wire round a 6" length of plastic hose (about 3/8" diameter) and then bending the hose round into a donut shape and joining the ends with tape.

I put it round a conductor of the primary circuit so that the full primary current flows through the middle of it. The whole point of the Rogowski coil is that it only detects currents that pass through the donut hole. To avoid the single turn effect and help improve the cancellation, I passed the wire from the far end back down the middle of the hose.

Re: OLTC project

Jrz126, Tue Jul 04 2006, 08:37PM

I've got my winding jig ready to go and I put 4 coats of poly. on the bare form. I'm just about ready to start winding it. It was suggested previously in this thread to use about 2000 turns and a 2:1 ratio. Now do I want to stick to the 2:1 ratio or 2000 turns?

If I stick with the 2000 turns, I'll end up with a 2.7:1 ratio. and if I stick to the 2:1 ratio, I'll end up with 1400 turns.

Jrz126, Tue Jul 04 2006, 08:37PM

I've got my winding jig ready to go and I put 4 coats of poly. on the bare form. I'm just about ready to start winding it. It was suggested previously in this thread to use about 2000 turns and a 2:1 ratio. Now do I want to stick to the 2:1 ratio or 2000 turns?

If I stick with the 2000 turns, I'll end up with a 2.7:1 ratio. and if I stick to the 2:1 ratio, I'll end up with 1400 turns.

Re: OLTC project

Steve Ward, Tue Jul 04 2006, 10:32PM

I see no reason at all for a 2:1 ratio. By all means, use a longer winding and get the lowest operating frequency you can. Even a 3:1 ratio is a little "fat" in my experience. I typically go with 4:1. But really, winding ratio isnt as crucial as some might say it is. Getting a lower Fr so you can use more bang energy *is* crucial.

Steve Ward, Tue Jul 04 2006, 10:32PM

I see no reason at all for a 2:1 ratio. By all means, use a longer winding and get the lowest operating frequency you can. Even a 3:1 ratio is a little "fat" in my experience. I typically go with 4:1. But really, winding ratio isnt as crucial as some might say it is. Getting a lower Fr so you can use more bang energy *is* crucial.

Re: OLTC project

Steve Conner, Wed Jul 05 2006, 02:59PM

I'd go with the 2.7:1 and 2000 turns. The reason for a "Stubby" secondary is that it allows higher coupling, but the OLTC isn't so demanding of coupling as the DRSSTC. I got plenty coupling on the OLTC 2 with its 3:1 (30" x 10") secondary.

Steve Conner, Wed Jul 05 2006, 02:59PM

I'd go with the 2.7:1 and 2000 turns. The reason for a "Stubby" secondary is that it allows higher coupling, but the OLTC isn't so demanding of coupling as the DRSSTC. I got plenty coupling on the OLTC 2 with its 3:1 (30" x 10") secondary.

Re: OLTC project

Jrz126, Thu Jul 06 2006, 01:50PM

There is a seam in the cardboard that is exposed now from when I removed the yellow paper. How should I fill it in? I put a piece of masking tape over it, but its still alittle flimsy. Should I put some Poly. over the masking tape?

So should I put more than 2000 turns on it? Is it possible to have a resonant frequency that is too low?

I ordered a bunch of parts last wednesday, hopefully they will be here shortly.

Jrz126, Thu Jul 06 2006, 01:50PM

There is a seam in the cardboard that is exposed now from when I removed the yellow paper. How should I fill it in? I put a piece of masking tape over it, but its still alittle flimsy. Should I put some Poly. over the masking tape?

So should I put more than 2000 turns on it? Is it possible to have a resonant frequency that is too low?

I ordered a bunch of parts last wednesday, hopefully they will be here shortly.

Re: OLTC project

Steve Ward, Thu Jul 06 2006, 04:18PM

Is there a deep grove left? The seam in my tube just left a bit if a bump, so i just wound over it.