Alternative high voltage coupling - sparkgap to solid state.

3l3ctrici7y, Fri Feb 11 2011, 07:49PMI am working to build a high frequency arc starter.

See here, here, here, here.

The first one is a terrible example, but has a nice picutre of the basic thing. The youtube vids, I think were based on the first link; running the capacitor discharge thru the mains ground.

Such devices are basically a spark gap Tesla coil, but with a very small number of secondary turns. In my case, I have 6 primary turns and 18 secondary turns with a ferrite core. It does work, but is very erratic and tends to lose performance as it is used. I don't think the capacitor is up to the task. After killing two doorknobs I made my own, and killed that too. The writing on the wall; it has been seen. While simple, it just doesn't work, and there are no prizes for the simplest failure.

Mine is based on a GM HEI ignition coil driven with a 555 and FET gate driver driving the gate on an IGBT to switch the iggy. I have a 100 or so nF cap on the iggy primary (this makes a huge difference on the output). The output is in series with four spark gaps in series at .008" each. The spark gaps are in series with the doorknob capacitor, a 5 (or so) ohm resistor, and the primary of the HF transformer where the primary is 6 turns and the secondary is 18 turns with a ferrite core.

Going to plan "B", I was thinking about some sort of a solid state Tesla coil version of this. Perhaps drive it using the ZVS FBT driver circuit. Ultimately the secondary is formed using thick welding wire with 4-6+mm diameter; so having a large number of turns is impractical.

I don't really have a specific question, other than being interested in whatever sage wisdom anyone would like to offer.

Thanks.

Re: Alternative high voltage coupling - sparkgap to solid state.

Conundrum, Fri Feb 11 2011, 07:55PM

homemade litz wire?

Tools required:- One drill, a large room and about 200 feet of 30 gauge wire would back and forth to make a 15 wire bundle.

-A

Conundrum, Fri Feb 11 2011, 07:55PM

homemade litz wire?

Tools required:- One drill, a large room and about 200 feet of 30 gauge wire would back and forth to make a 15 wire bundle.

-A

Re: Alternative high voltage coupling - sparkgap to solid state.

3l3ctrici7y, Fri Feb 11 2011, 07:58PM

litz wire?? What is litz wire?

Oh, I see.. Wiki has the answer.

I get the idea I must be doing something wrong and litz wire will help me.

What is that??

Well, I assume it would be used on the primary since the secondary is what it is.

At the moment, I am using 16 or 14 gage stranded copper wire for the primary.

Is the skin effect causing problems for me here?

According to powerstream, the frequency for solid wire is between 6 and 11 kHz. I am not sure how much the stranding will change that. But that is far lower than the hundreds of kHz or few MHz that I expect this is oscillating at.

3l3ctrici7y, Fri Feb 11 2011, 07:58PM

litz wire?? What is litz wire?

Oh, I see.. Wiki has the answer.

I get the idea I must be doing something wrong and litz wire will help me.

What is that??

Well, I assume it would be used on the primary since the secondary is what it is.

At the moment, I am using 16 or 14 gage stranded copper wire for the primary.

Is the skin effect causing problems for me here?

According to powerstream, the frequency for solid wire is between 6 and 11 kHz. I am not sure how much the stranding will change that. But that is far lower than the hundreds of kHz or few MHz that I expect this is oscillating at.

Re: Alternative high voltage coupling - sparkgap to solid state.

Ash Small, Fri Feb 11 2011, 08:10PM

I built one using a single transistor flyback circuit, homemade caps, a spark gap tank circuit, and ten turns primary and secondary. It works really well.

You need to choke the HF off from getting back into the buzzbox, though, I used a core from a 50 Hz toriodal transformer (has to be large enough to take the thick diameter welding flex) and some home made caps (about 200nF total).

Ash Small, Fri Feb 11 2011, 08:10PM

3l3ctrici7y wrote ...

I am working to build a high frequency arc starter.

.

I am working to build a high frequency arc starter.

.

I built one using a single transistor flyback circuit, homemade caps, a spark gap tank circuit, and ten turns primary and secondary. It works really well.

You need to choke the HF off from getting back into the buzzbox, though, I used a core from a 50 Hz toriodal transformer (has to be large enough to take the thick diameter welding flex) and some home made caps (about 200nF total).

Re: Alternative high voltage coupling - sparkgap to solid state.

3l3ctrici7y, Fri Feb 11 2011, 08:18PM

That's interesting. What I have seen done, and what was planning on doing, is using a large AC capacitor across the "buzz box" to allow the HF to bypass it.

What kind of capacitor did you use for your HF unit?

3l3ctrici7y, Fri Feb 11 2011, 08:18PM

That's interesting. What I have seen done, and what was planning on doing, is using a large AC capacitor across the "buzz box" to allow the HF to bypass it.

What kind of capacitor did you use for your HF unit?

Re: Alternative high voltage coupling - sparkgap to solid state.

Ash Small, Fri Feb 11 2011, 09:10PM

The cap across the buzz box will probably work on it's own, I just added the choke for extra protection. I think it was ten turns for each cable, wound so they oppose each other.

I used a home made cap for the HF tank circuit, 20nF if I remember correctly. I didn't really do any maths as I couldn't measure the inductance of the primary. I was going to do a bit of 'trial and error', but it worked so well I left it as it was.

I wound the air core transformer on a polypropylene tube that effervescent vitamin C tablets come in, after removing the paint with scotchbrite or wire wool (It was ten years ago so I can't remember which). I used multi-stranded wire for the primary, and welding cable for the secondary.

Polypropylene is supposed to be the best stuff for HF air core transformers.

Ash Small, Fri Feb 11 2011, 09:10PM

3l3ctrici7y wrote ...

That's interesting. What I have seen done, and what was planning on doing, is using a large AC capacitor across the "buzz box" to allow the HF to bypass it.

What kind of capacitor did you use for your HF unit?

That's interesting. What I have seen done, and what was planning on doing, is using a large AC capacitor across the "buzz box" to allow the HF to bypass it.

What kind of capacitor did you use for your HF unit?

The cap across the buzz box will probably work on it's own, I just added the choke for extra protection. I think it was ten turns for each cable, wound so they oppose each other.

I used a home made cap for the HF tank circuit, 20nF if I remember correctly. I didn't really do any maths as I couldn't measure the inductance of the primary. I was going to do a bit of 'trial and error', but it worked so well I left it as it was.

I wound the air core transformer on a polypropylene tube that effervescent vitamin C tablets come in, after removing the paint with scotchbrite or wire wool (It was ten years ago so I can't remember which). I used multi-stranded wire for the primary, and welding cable for the secondary.

Polypropylene is supposed to be the best stuff for HF air core transformers.

Re: Alternative high voltage coupling - sparkgap to solid state.

3l3ctrici7y, Fri Feb 11 2011, 10:21PM

Interesting :)

That was kind of my approach also; I chose the 4700pF since I was getting two I could put them in series to get half that, or in parallel for double, and I had seen something where 4700pF was used for this.

20nF huh? That's huge. The first link I posted uses 500pF, and the second uses 2500pF. I did have it working with 4700pF until the cap died (or so I presume)

If I try building a cap again or getting another doorknob, I think I am going to go smaller. The iggy runs out of breath and cannot charge 4700pF and break down four gaps at .008". It can only break two reliably. But hey, it stopped working all together as the caps died, so who knows.

On that page I read a while back where a 4700pF cap was used, the author said that two spark gaps are much better than one. This is my experience also. Those two projects I posted both use four gaps. As I have come to realize from reading, multi smaller gaps will quench sooner than a single equivalent gap and this causes a steeper dI/dt in the primary and thus a greater voltage spike. So using a smaller cap should (I hope) allow me to use all four gaps and perhaps increase the dI/dt and get better output. I can always crank up the drive frequency so whatever energy I lose using a smaller cap, I can make up for in frequency.

Here are a couple of youtube videos showing some impressive HF output.

The second one even has corona when it's not arcing :)

3l3ctrici7y, Fri Feb 11 2011, 10:21PM

Interesting :)

That was kind of my approach also; I chose the 4700pF since I was getting two I could put them in series to get half that, or in parallel for double, and I had seen something where 4700pF was used for this.

20nF huh? That's huge. The first link I posted uses 500pF, and the second uses 2500pF. I did have it working with 4700pF until the cap died (or so I presume)

If I try building a cap again or getting another doorknob, I think I am going to go smaller. The iggy runs out of breath and cannot charge 4700pF and break down four gaps at .008". It can only break two reliably. But hey, it stopped working all together as the caps died, so who knows.

On that page I read a while back where a 4700pF cap was used, the author said that two spark gaps are much better than one. This is my experience also. Those two projects I posted both use four gaps. As I have come to realize from reading, multi smaller gaps will quench sooner than a single equivalent gap and this causes a steeper dI/dt in the primary and thus a greater voltage spike. So using a smaller cap should (I hope) allow me to use all four gaps and perhaps increase the dI/dt and get better output. I can always crank up the drive frequency so whatever energy I lose using a smaller cap, I can make up for in frequency.

Here are a couple of youtube videos showing some impressive HF output.

The second one even has corona when it's not arcing :)

Re: Alternative high voltage coupling - sparkgap to solid state.

Ash Small, Fri Feb 11 2011, 10:45PM

Yes, I realise that 20nF is large, but I thought bigger was better (more charge). It worked so I left it as it was.

I can't be certain that it worked as it is supposed to, and that the secondary isn't just running at the same frequency as the flyback, but the spark across the spark gap is much brighter than the arc from the flyback was during testing, so I assume that the tank circuit is resonating as expected.

I only used one spark gap, an unsuppressed spark plug (eg model T ford)

I think the bigger cap is more robust, I still plan to try different values but haven't got round to it yet.

I tried experimenting with multiple gaps but found one gave better results. I assume this is because my tank circuit oscillates at a lower frequency so quenching time isn't a problem. (I understand a bit more about this now than I did ten years ago)

I've not watched the videos as I'm on a mobile ISP that charges by the gigabyte.

Ash Small, Fri Feb 11 2011, 10:45PM

Yes, I realise that 20nF is large, but I thought bigger was better (more charge). It worked so I left it as it was.

I can't be certain that it worked as it is supposed to, and that the secondary isn't just running at the same frequency as the flyback, but the spark across the spark gap is much brighter than the arc from the flyback was during testing, so I assume that the tank circuit is resonating as expected.

I only used one spark gap, an unsuppressed spark plug (eg model T ford)

I think the bigger cap is more robust, I still plan to try different values but haven't got round to it yet.

I tried experimenting with multiple gaps but found one gave better results. I assume this is because my tank circuit oscillates at a lower frequency so quenching time isn't a problem. (I understand a bit more about this now than I did ten years ago)

I've not watched the videos as I'm on a mobile ISP that charges by the gigabyte.

Re: Alternative high voltage coupling - sparkgap to solid state.

3l3ctrici7y, Fri Feb 11 2011, 11:27PM

I have some nice BC Components caps floating around that i had thought of making an MMC out of, but I thought that it would still be too much capacitance, but since 20nF is working along with a single gap, then maybe it's worth a try.

Also, in the first set of youtube vids I linked to, at least in the final version, it looks like he has the cap in across with the iggy rather than the single spark gap. I've seen this topology before, but it seemed improper, so I put the gap across the iggy. I wonder what effects this would have. He also used a ferrite yoke.

3l3ctrici7y, Fri Feb 11 2011, 11:27PM

I have some nice BC Components caps floating around that i had thought of making an MMC out of, but I thought that it would still be too much capacitance, but since 20nF is working along with a single gap, then maybe it's worth a try.

Also, in the first set of youtube vids I linked to, at least in the final version, it looks like he has the cap in across with the iggy rather than the single spark gap. I've seen this topology before, but it seemed improper, so I put the gap across the iggy. I wonder what effects this would have. He also used a ferrite yoke.

Re: Alternative high voltage coupling - sparkgap to solid state.

Ash Small, Fri Feb 11 2011, 11:51PM

I had the cap across the flyback, with a resistor between the output of the flyback and the tank circuit. I can't remember the value offhand, but it was 33 something (approx) Either 33 k ohm, 330 k ohm, or 33 M ohm. I used about 12" of suppressed spark plug lead, (the carbon cored stuff) so that's a guide. (I think it was 33 k ohm)

I agree that 20 nF seems a bit high, but my reasoning was that it would be more robust than a smaller cap. I was planning to experiment, but it worked so I left it.

What was the ferrite yoke used for?

Ash Small, Fri Feb 11 2011, 11:51PM

I had the cap across the flyback, with a resistor between the output of the flyback and the tank circuit. I can't remember the value offhand, but it was 33 something (approx) Either 33 k ohm, 330 k ohm, or 33 M ohm. I used about 12" of suppressed spark plug lead, (the carbon cored stuff) so that's a guide. (I think it was 33 k ohm)

I agree that 20 nF seems a bit high, but my reasoning was that it would be more robust than a smaller cap. I was planning to experiment, but it worked so I left it.

What was the ferrite yoke used for?

Re: Alternative high voltage coupling - sparkgap to solid state.

3l3ctrici7y, Sat Feb 12 2011, 12:09AM

Oh, sorry; he used it for the coupling transformer. He has about 4 turns (I cannot see for sure) for the primary, and 9 for the secondary. Also included is a can style iggy, light dimmer, and motor run cap. A door knob across the iggy, and a single spark gap consisting of a pair of bolts across a small PVC tube. It looks like he is using a doorknob for the HF bypass capacitor.

Using a yoke was on my list of things to try, but a little past the bottom of the list, because I have no good place to get a yoke. Maybe once I have it working, I will try removing the ferrite and see how it does as a pure air core. Well not "pure" air.. but at least nothing-metallic-core.

3l3ctrici7y, Sat Feb 12 2011, 12:09AM

Oh, sorry; he used it for the coupling transformer. He has about 4 turns (I cannot see for sure) for the primary, and 9 for the secondary. Also included is a can style iggy, light dimmer, and motor run cap. A door knob across the iggy, and a single spark gap consisting of a pair of bolts across a small PVC tube. It looks like he is using a doorknob for the HF bypass capacitor.

Using a yoke was on my list of things to try, but a little past the bottom of the list, because I have no good place to get a yoke. Maybe once I have it working, I will try removing the ferrite and see how it does as a pure air core. Well not "pure" air.. but at least nothing-metallic-core.

Re: Alternative high voltage coupling - sparkgap to solid state.

Ash Small, Sat Feb 12 2011, 12:47AM

I'm wondering if the ferrite core isn't part of your problem. The inductance will be much greater than an air core xformer, and could be contributing to your problem of blowing caps (I'm not sure here, just a gut feeling)

I used a polypropylene former (see above)

I also used a 1:1 ratio for the primary/secondary. You don't need a huge voltage because the HF arc is under argon.

I was unable to measure much but I assume the output from the flyback is around 15kv, due to the length of the arcs obtained during testing. What voltage were your caps rated for?

Some iggy coils put out 30-40kV (ones from electronic ignition vehicles, depending on the operating voltage) Older ones put out around 20kV on 12 V input.

I've described my caps elsewhere on the forum, but basically, they are polyethylene rubble sacks and kitchen foil on plastic waterpipe formers.

Ash Small, Sat Feb 12 2011, 12:47AM

I'm wondering if the ferrite core isn't part of your problem. The inductance will be much greater than an air core xformer, and could be contributing to your problem of blowing caps (I'm not sure here, just a gut feeling)

I used a polypropylene former (see above)

I also used a 1:1 ratio for the primary/secondary. You don't need a huge voltage because the HF arc is under argon.

I was unable to measure much but I assume the output from the flyback is around 15kv, due to the length of the arcs obtained during testing. What voltage were your caps rated for?

Some iggy coils put out 30-40kV (ones from electronic ignition vehicles, depending on the operating voltage) Older ones put out around 20kV on 12 V input.

I've described my caps elsewhere on the forum, but basically, they are polyethylene rubble sacks and kitchen foil on plastic waterpipe formers.

Re: Alternative high voltage coupling - sparkgap to solid state.

3l3ctrici7y, Sat Feb 12 2011, 01:47AM

I have read various descriptions of HF arc starters, and most but not all used ferrite cores. I would be very happy if I could avoid it (one less part :) I was loosely copying this one because it seemed to be the most well thought out and detailed of those I had to look at.

I am planning on building another cap and I will try it with and without the ferrite and see what happens.

Currently my former is PVC, but I could hunt down some PP and try that.

Funny you mention the voltage necessary, I am currently just using some 16ga wire in place of the welding cable (for testing) and had the two ends of the secondary close. I was not getting any sparks, so I bring the TIG torch over and blow argon over the gap, and lo, it starts sparking.

What was really strange was that it also sparked to the TIG torch, which wasn't even hooked to anything, let alone any of the wires involved in the HF transformer. HF/HV is strange stuff.

The doorknob caps I purchased are supposedly rated for 20kV.

The iggy was originally driven by some sort of solid state ignition module. It will easily make strong arcs/sparks across 20-25mm, possibly more. But if shorten it to maybe 8-10mm and fiddle with the drive frequency and pulse width and the arc will get really hot. I am not clamping iggy's primary in any way. I am driving it with a 1200V IGBT, and have a 200nF (or so) capacitor across the primary. This capacitor makes a huge difference in output.

The capacitor I built was made out of a zip top kitchen freezer bag and some baking aluminium foil.

Two plates are maybe 7cm by 15cm. I was amazed how well it worked... until it blew :(

All I did was connect it across the spark gap, but the spark in the gap got fairly bright and loud (very comparable to using the doorknob). I was mightily impressed considering what I used to make the cap and how long it took. I guess next time around I will use a little more dielectric to keep it from blowing.

3l3ctrici7y, Sat Feb 12 2011, 01:47AM

I have read various descriptions of HF arc starters, and most but not all used ferrite cores. I would be very happy if I could avoid it (one less part :) I was loosely copying this one because it seemed to be the most well thought out and detailed of those I had to look at.

I am planning on building another cap and I will try it with and without the ferrite and see what happens.

Currently my former is PVC, but I could hunt down some PP and try that.

Funny you mention the voltage necessary, I am currently just using some 16ga wire in place of the welding cable (for testing) and had the two ends of the secondary close. I was not getting any sparks, so I bring the TIG torch over and blow argon over the gap, and lo, it starts sparking.

What was really strange was that it also sparked to the TIG torch, which wasn't even hooked to anything, let alone any of the wires involved in the HF transformer. HF/HV is strange stuff.

The doorknob caps I purchased are supposedly rated for 20kV.

The iggy was originally driven by some sort of solid state ignition module. It will easily make strong arcs/sparks across 20-25mm, possibly more. But if shorten it to maybe 8-10mm and fiddle with the drive frequency and pulse width and the arc will get really hot. I am not clamping iggy's primary in any way. I am driving it with a 1200V IGBT, and have a 200nF (or so) capacitor across the primary. This capacitor makes a huge difference in output.

The capacitor I built was made out of a zip top kitchen freezer bag and some baking aluminium foil.

Two plates are maybe 7cm by 15cm. I was amazed how well it worked... until it blew :(

All I did was connect it across the spark gap, but the spark in the gap got fairly bright and loud (very comparable to using the doorknob). I was mightily impressed considering what I used to make the cap and how long it took. I guess next time around I will use a little more dielectric to keep it from blowing.

Re: Alternative high voltage coupling - sparkgap to solid state.

Ash Small, Sat Feb 12 2011, 02:27AM

I'm pretty certain the iggy is putting out a lot more than 20kV.

I was driving my flyback with a 2N3055.

Try some thicker dielectric for the caps.

Ash Small, Sat Feb 12 2011, 02:27AM

I'm pretty certain the iggy is putting out a lot more than 20kV.

I was driving my flyback with a 2N3055.

Try some thicker dielectric for the caps.

Re: Alternative high voltage coupling - sparkgap to solid state.

Steve Conner, Sat Feb 12 2011, 09:06AM

Presumably the secret of success is that Ash used a DC flyback, one with a built-in diode. This allows it to charge a much bigger capacitor than an ignition coil could, because it can pump up the charge over multiple cycles. If the ignition coil can't do it in one cycle, it won't do it at all.

Might be worth trying to rectify the ignition coil output with some microwave oven diodes, but be sure to get the polarity right, it generates much more voltage in one polarity than the other, and will just blow the diodes if you get it wrong.

A good capacitor also helps. You can't necessarily trust some random doorknob capacitor to be pulse rated, and home-made caps are notoriously hit-or-miss too.

Steve Conner, Sat Feb 12 2011, 09:06AM

Presumably the secret of success is that Ash used a DC flyback, one with a built-in diode. This allows it to charge a much bigger capacitor than an ignition coil could, because it can pump up the charge over multiple cycles. If the ignition coil can't do it in one cycle, it won't do it at all.

Might be worth trying to rectify the ignition coil output with some microwave oven diodes, but be sure to get the polarity right, it generates much more voltage in one polarity than the other, and will just blow the diodes if you get it wrong.

A good capacitor also helps. You can't necessarily trust some random doorknob capacitor to be pulse rated, and home-made caps are notoriously hit-or-miss too.

Re: Alternative high voltage coupling - sparkgap to solid state.

Ash Small, Thu Feb 17 2011, 12:06AM

That explains a lot Steve. When I built it ten years ago (before 4HV) the best explanation I could find was that the coil charges the cap on one cycle, then the circuit oscillates, then the coil charges the cap again. Your explanation makes a lot more sense (once the cap is sufficiently charged to jump the spark gap, the circuit oscillates, and the coil keeps the tank 'topped up', losses being in the gap, the coil,(primary to secondary coupling) and the capacitor.).

There were some errors in the circuit diagram that I used as a guide as well, took me weeks to sort those out.

Ash Small, Thu Feb 17 2011, 12:06AM

Steve McConner wrote ...

Presumably the secret of success is that Ash used a DC flyback, one with a built-in diode. This allows it to charge a much bigger capacitor than an ignition coil could, because it can pump up the charge over multiple cycles. If the ignition coil can't do it in one cycle, it won't do it at all.

.

Presumably the secret of success is that Ash used a DC flyback, one with a built-in diode. This allows it to charge a much bigger capacitor than an ignition coil could, because it can pump up the charge over multiple cycles. If the ignition coil can't do it in one cycle, it won't do it at all.

.

That explains a lot Steve. When I built it ten years ago (before 4HV) the best explanation I could find was that the coil charges the cap on one cycle, then the circuit oscillates, then the coil charges the cap again. Your explanation makes a lot more sense (once the cap is sufficiently charged to jump the spark gap, the circuit oscillates, and the coil keeps the tank 'topped up', losses being in the gap, the coil,(primary to secondary coupling) and the capacitor.).

There were some errors in the circuit diagram that I used as a guide as well, took me weeks to sort those out.

Re: Alternative high voltage coupling - sparkgap to solid state.

3l3ctrici7y, Thu Feb 17 2011, 01:19AM

Thank you all for the replies. I am sorry for the long delay; I just now got back to the project.

I built another cap using 11 mil PET with two plates and an overlap area of about 25 square inches. According to my calculations, that should have yielded something around 1.5nF (1500pF). It worked quite well for pulse discharge across the spark gap even at a very high frequency. The output was hot and loud as compared to no capacitor. Regrettably, using this capacitor did not produce any HF output (sparks) at all; ferrite or no ferrite.

Am I giving up, or am I reading the writing on the wall about having been beaten? I am going to say that I've been beaten.... the Visigoths have arrived :(

3l3ctrici7y, Thu Feb 17 2011, 01:19AM

Thank you all for the replies. I am sorry for the long delay; I just now got back to the project.

I built another cap using 11 mil PET with two plates and an overlap area of about 25 square inches. According to my calculations, that should have yielded something around 1.5nF (1500pF). It worked quite well for pulse discharge across the spark gap even at a very high frequency. The output was hot and loud as compared to no capacitor. Regrettably, using this capacitor did not produce any HF output (sparks) at all; ferrite or no ferrite.

Am I giving up, or am I reading the writing on the wall about having been beaten? I am going to say that I've been beaten.... the Visigoths have arrived :(

Re: Alternative high voltage coupling - sparkgap to solid state.

Ash Small, Thu Feb 17 2011, 01:56AM

Follow Steve's advice and try adding some diodes....or try a DC flyback.

Ash Small, Thu Feb 17 2011, 01:56AM

Follow Steve's advice and try adding some diodes....or try a DC flyback.

Re: Alternative high voltage coupling - sparkgap to solid state.

Newton Brawn, Sat Feb 19 2011, 04:07AM

Hi Ash, Hi 3l3 !

Im realy interested in what you have done. I have working in welding machines repair for some time.

The caps that shunt the buzzboz output high current terminals are normally paper-foil 400-600V. Polyester or polypropylrene METALIZED caps are not suitable. Some manufacturers use of 0.02uF. Other (Miller, Esab, etc) use caps up to 10uF.

0.02uF is enough to avoid the hv enter in the secondary coil or buzzbox diodes .

Also 2uF in series with 10 ohm 2w CARBON resistor bridges the hi current work terminal to the ground. This is the way to rf grounding the buzzbox secondary.

Some time ago I have noticed in the 4HV.ORG forum that the schematic is wrong. The 10 turns primary coil to be in series with the spark gaps, See the post made by Newton Brawn on October 10 2010.

Other interesting point is that for proper arc start, just one pulse of 10 kV 0.5 microsecond is required. this pulse tobe at each 8.333ms, for a 60Hz buzbox. Using only one pulse close the zero voltage passage a lot of energy is saved, reducing the size and ratings of conponents.

The ignition coil may be replaced for homemade pulse tranformer. 24turns in primary 400 turns at secondary, ferrite core from flyback. insulation 0.2 polyester between layers. No more 20 turns per layer.

Glass capacitors 1000uuF, 10kV proper handymade are reliable.

I have more info to share, for next time

Regards

Newton

Newton Brawn, Sat Feb 19 2011, 04:07AM

Hi Ash, Hi 3l3 !

Im realy interested in what you have done. I have working in welding machines repair for some time.

The caps that shunt the buzzboz output high current terminals are normally paper-foil 400-600V. Polyester or polypropylrene METALIZED caps are not suitable. Some manufacturers use of 0.02uF. Other (Miller, Esab, etc) use caps up to 10uF.

0.02uF is enough to avoid the hv enter in the secondary coil or buzzbox diodes .

Also 2uF in series with 10 ohm 2w CARBON resistor bridges the hi current work terminal to the ground. This is the way to rf grounding the buzzbox secondary.

Some time ago I have noticed in the 4HV.ORG forum that the schematic is wrong. The 10 turns primary coil to be in series with the spark gaps, See the post made by Newton Brawn on October 10 2010.

Other interesting point is that for proper arc start, just one pulse of 10 kV 0.5 microsecond is required. this pulse tobe at each 8.333ms, for a 60Hz buzbox. Using only one pulse close the zero voltage passage a lot of energy is saved, reducing the size and ratings of conponents.

The ignition coil may be replaced for homemade pulse tranformer. 24turns in primary 400 turns at secondary, ferrite core from flyback. insulation 0.2 polyester between layers. No more 20 turns per layer.

Glass capacitors 1000uuF, 10kV proper handymade are reliable.

I have more info to share, for next time

Regards

Newton

Re: Alternative high voltage coupling - sparkgap to solid state.

Newton Brawn, Sat Feb 19 2011, 04:16AM

Sorry for the copy and paste duplication in my reply. Someone can fix it?

Newton

Newton Brawn, Sat Feb 19 2011, 04:16AM

Sorry for the copy and paste duplication in my reply. Someone can fix it?

Newton

Re: Alternative high voltage coupling - sparkgap to solid state.

Ash Small, Sat Feb 19 2011, 04:19AM

Newton, can you please explain why this is required?

Thanks.

EDIT: I've looked at the circuit diagram that you mention, and it is quite a bit different to my circuit. My tank circuit looks completely different. I think I've described it above.

Ash Small, Sat Feb 19 2011, 04:19AM

Newton Brawn wrote ...

.Also 2uF in series with 10 ohm 2w CARBON resistor bridges the hi current work terminal to the ground. This is the way to rf grounding the buzzbox secondary.

..

.Also 2uF in series with 10 ohm 2w CARBON resistor bridges the hi current work terminal to the ground. This is the way to rf grounding the buzzbox secondary.

..

Newton, can you please explain why this is required?

Thanks.

EDIT: I've looked at the circuit diagram that you mention, and it is quite a bit different to my circuit. My tank circuit looks completely different. I think I've described it above.

Re: Alternative high voltage coupling - sparkgap to solid state.

3l3ctrici7y, Sun Feb 20 2011, 06:16AM

Hi Newton. Welcome :)

Ash, the diagram you looked at that Newton mentioned, is it one of the ones I posed, or a different one?

If different, could you post a link?

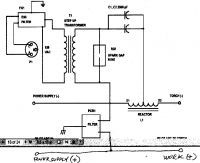

I never really made it clear what I did, so here is a drawing of it.

I intermittently had a resistor between the cap and the HF primary, as well as testing with and without the ferrite core (chunks of ferrite reasonably centered inside the former.)

It is interesting that Newton mentions an RF ground. The manual for the welder I finally broke down and ordered shows a screw on the back for RF grounding. It appears to be just screwed into the case, but I will have to look at it when I get the machine. The manual says NOT to connect that to the electrical ground... but rather a grounding rod in moist soil. It will be interesting to see where the electrical ground is connected and what the screw screws into.

I knew that Tesla coils needed an RF ground, but I assumed that it was because you wanted to play the capacitance of the top load off of that of the Earth through the RF ground. My assumption was that since the goal was to create an arc between the ends of the RF secondary, a ground would not be necessary. I suppose the difference is that with one side grounded, one end of the RF transformer will be held at ground potential and the other will swing wildly, and without a ground, both ends will swing wildly. I can see where even when the goal is to arc between the ends, having one at a constant potential could have a positive effect.

This all leads me to recall something interesting. I mentioned this before, but I will reiterate.

During one of the tests, I used the TIG torch to blow argon onto the short gap of the RF secondary. It immediately started arcing, both between the two ends of the secondary and to the tungsten in the torch. What makes it so interesting is that the torch cable was not connected to anything; it was just coiled up on the bench. My guess is that it has something to do with the capacitance in the torch cable relative to HF secondary. I am thinking a capacitor where one side is to your circuit and the other is to free space. This makes me wonder if my circuit would have worked better if I had grounded or at least had a large capacitance on one side of the secondary.

Newton, click the middle icon/button on the top right of your post and you can edit the post.

The capacitor across the iggy's primary says

3l3ctrici7y, Sun Feb 20 2011, 06:16AM

Hi Newton. Welcome :)

Ash, the diagram you looked at that Newton mentioned, is it one of the ones I posed, or a different one?

If different, could you post a link?

I never really made it clear what I did, so here is a drawing of it.

I intermittently had a resistor between the cap and the HF primary, as well as testing with and without the ferrite core (chunks of ferrite reasonably centered inside the former.)

It is interesting that Newton mentions an RF ground. The manual for the welder I finally broke down and ordered shows a screw on the back for RF grounding. It appears to be just screwed into the case, but I will have to look at it when I get the machine. The manual says NOT to connect that to the electrical ground... but rather a grounding rod in moist soil. It will be interesting to see where the electrical ground is connected and what the screw screws into.

I knew that Tesla coils needed an RF ground, but I assumed that it was because you wanted to play the capacitance of the top load off of that of the Earth through the RF ground. My assumption was that since the goal was to create an arc between the ends of the RF secondary, a ground would not be necessary. I suppose the difference is that with one side grounded, one end of the RF transformer will be held at ground potential and the other will swing wildly, and without a ground, both ends will swing wildly. I can see where even when the goal is to arc between the ends, having one at a constant potential could have a positive effect.

This all leads me to recall something interesting. I mentioned this before, but I will reiterate.

During one of the tests, I used the TIG torch to blow argon onto the short gap of the RF secondary. It immediately started arcing, both between the two ends of the secondary and to the tungsten in the torch. What makes it so interesting is that the torch cable was not connected to anything; it was just coiled up on the bench. My guess is that it has something to do with the capacitance in the torch cable relative to HF secondary. I am thinking a capacitor where one side is to your circuit and the other is to free space. This makes me wonder if my circuit would have worked better if I had grounded or at least had a large capacitance on one side of the secondary.

Newton, click the middle icon/button on the top right of your post and you can edit the post.

+12v +-----+ 1500-7400pF ||O-----+

| | |----+------||------+ ||O |

+------+------+------+-----| GM | | | ||O |

| | | | HEI | \/ +-O||O \/

| Gate +--||--+-----|iggy | gap ~= .032" O||O .2"?

555----Drive | | | /\ +-O||O /\

| Chip---------igbt | | | 6t/18t | ||O |

| | | | |----+--------------+ ||O |

+------+------------GND +-----+ ||O-----+The capacitor across the iggy's primary says

225P400V 224K 0138Maybe .22uF, or maybe 2.2uF and 400V.. I am not sure.. but that's what it says. Just ahead of the 225P, there is a small 2 with a circle around it. The whole thing is the same size as the 2 in 225P

Re: Alternative high voltage coupling - sparkgap to solid state.

Ash Small, Sun Feb 20 2011, 05:06PM

The circuit that Newton mentioned is here:

My tank circuit is the same as yours in the post above except that the capacitor and gap are switched, ie, my cap is across the coil and my gap is in series with the coil (air core transformer). This just seems to make more sense to me, the cap can be charged without the primary of the air core transformer being in series (remember, the whole point of the flyback/iggy is to charge the cap). Also I have a high value resistor between the output of the flyback and the tank circuit, 330 k Ohm, If I remember correctly.

I don't have an RF ground and it works fine. I just wondered if it was there for safety, or why it is there. My circuit doesn't need it in order to work.

Ash Small, Sun Feb 20 2011, 05:06PM

The circuit that Newton mentioned is here:

My tank circuit is the same as yours in the post above except that the capacitor and gap are switched, ie, my cap is across the coil and my gap is in series with the coil (air core transformer). This just seems to make more sense to me, the cap can be charged without the primary of the air core transformer being in series (remember, the whole point of the flyback/iggy is to charge the cap). Also I have a high value resistor between the output of the flyback and the tank circuit, 330 k Ohm, If I remember correctly.

I don't have an RF ground and it works fine. I just wondered if it was there for safety, or why it is there. My circuit doesn't need it in order to work.

Re: Alternative high voltage coupling - sparkgap to solid state.

3l3ctrici7y, Sun Feb 20 2011, 06:43PM

Thanks.

Yea, that is one of the ones I posted. A while back, someone here was building off that diagram and I wrote a lengthy post explaining what all is wrong with it. Most obviously, the ground circuit of the mains is in series with the HF circuit.

Also a while back, I was reading about Tesla coils and the two topologies were mentioned, where the HV transformer was across the gap or the cap. Both work. With what I did, the disadvantage is that the primary is in series with the cap for charging (as you mentioned), and it is also shorted out when the gap fires. With having the HV transformer across the cap for direct charging, it is exposed to the high frequency AC that the cap and primary produce. I did it the way I did because that is what I have most often seen done.

I am glad to hear that the RF ground does not seem to be necessary; that is most consistent with what I would expect.

3l3ctrici7y, Sun Feb 20 2011, 06:43PM

Thanks.

Yea, that is one of the ones I posted. A while back, someone here was building off that diagram and I wrote a lengthy post explaining what all is wrong with it. Most obviously, the ground circuit of the mains is in series with the HF circuit.

Also a while back, I was reading about Tesla coils and the two topologies were mentioned, where the HV transformer was across the gap or the cap. Both work. With what I did, the disadvantage is that the primary is in series with the cap for charging (as you mentioned), and it is also shorted out when the gap fires. With having the HV transformer across the cap for direct charging, it is exposed to the high frequency AC that the cap and primary produce. I did it the way I did because that is what I have most often seen done.

I am glad to hear that the RF ground does not seem to be necessary; that is most consistent with what I would expect.

Re: Alternative high voltage coupling - sparkgap to solid state.

Ash Small, Sun Feb 20 2011, 08:42PM

It's only just occured to me the significance of what you said about the secondary arcing when you placed it under argon.

This means that your circuit works, but it doesn't seem to work when connected to the buzzbox/capacitor.

What value cap are you using? (mine is 200 nano farads), Maybe it's worth adding a choke as well?

EDIT: the resistor in my circuit is there to block the HF from getting back to the flyback (at least, that's the theory). I really can't remember the value, but it was 330 something. I think it was 330 k Ohm, but it could have been anything from 330 Ohms to 330 meggohms. It was made from about 12 inches of carbon cored automotive ignition lead (mayby 18 inches).

Ash Small, Sun Feb 20 2011, 08:42PM

It's only just occured to me the significance of what you said about the secondary arcing when you placed it under argon.

This means that your circuit works, but it doesn't seem to work when connected to the buzzbox/capacitor.

What value cap are you using? (mine is 200 nano farads), Maybe it's worth adding a choke as well?

EDIT: the resistor in my circuit is there to block the HF from getting back to the flyback (at least, that's the theory). I really can't remember the value, but it was 330 something. I think it was 330 k Ohm, but it could have been anything from 330 Ohms to 330 meggohms. It was made from about 12 inches of carbon cored automotive ignition lead (mayby 18 inches).

Re: Alternative high voltage coupling - sparkgap to solid state.

3l3ctrici7y, Mon Feb 21 2011, 01:36AM

Ash, I don't quite follow what you're saying about it working but not when connected to the buzzbox/capacitor.

Please see my revised diagram in the above post. In the first version, I forgot to show the capacitor across the iggy's primary. I have fixed that mistake. As I noted, I am not sure what it is, but probably .22 uF or 2.2 uF. I had originally thought it was 200n or so, but that is probably way off.

The capacitor I was using in series with the spark gap stared out as being a 4700pF doorknob and after two of those burned out, I built my own capacitor, that burned out, and I rebuilt it more robustly and based on the dimensions, it should have been around 1500 pF, I did not roll it quite tight enough, so it could have been 750 pF or less.

3l3ctrici7y, Mon Feb 21 2011, 01:36AM

Ash, I don't quite follow what you're saying about it working but not when connected to the buzzbox/capacitor.

Please see my revised diagram in the above post. In the first version, I forgot to show the capacitor across the iggy's primary. I have fixed that mistake. As I noted, I am not sure what it is, but probably .22 uF or 2.2 uF. I had originally thought it was 200n or so, but that is probably way off.

The capacitor I was using in series with the spark gap stared out as being a 4700pF doorknob and after two of those burned out, I built my own capacitor, that burned out, and I rebuilt it more robustly and based on the dimensions, it should have been around 1500 pF, I did not roll it quite tight enough, so it could have been 750 pF or less.

Re: Alternative high voltage coupling - sparkgap to solid state.

Ash Small, Mon Feb 21 2011, 02:26AM

You said the output of the HF coil arced under argon. This means that the circuit works. The problem seems to be when you connect the buzzbox and blocking capacitor, or did I misunderstand you?

I don't know enough about transistor driven iggy circuits to know if it's right or wrong. I'd expect it to go across the transistor, but I don't know. 0.22 uF is around 200 nF (1000nF=1uF).

4700pF is 4.7 nF. Mine is 20 nF, not a lot bigger (4X). I think you really need to get a cheap DMM to measure the capacitance of your home made caps.

Ash Small, Mon Feb 21 2011, 02:26AM

3l3ctrici7y wrote ...

Ash, I don't quite follow what you're saying about it working but not when connected to the buzzbox/capacitor.

Ash, I don't quite follow what you're saying about it working but not when connected to the buzzbox/capacitor.

You said the output of the HF coil arced under argon. This means that the circuit works. The problem seems to be when you connect the buzzbox and blocking capacitor, or did I misunderstand you?

3l3ctrici7y wrote ...

Please see my revised diagram in the above post. In the first version, I forgot to show the capacitor across the iggy's primary. I have fixed that mistake. As I noted, I am not sure what it is, but probably .22 uF or 2.2 uF. I had originally thought it was 200n or so, but that is probably way off.

Please see my revised diagram in the above post. In the first version, I forgot to show the capacitor across the iggy's primary. I have fixed that mistake. As I noted, I am not sure what it is, but probably .22 uF or 2.2 uF. I had originally thought it was 200n or so, but that is probably way off.

I don't know enough about transistor driven iggy circuits to know if it's right or wrong. I'd expect it to go across the transistor, but I don't know. 0.22 uF is around 200 nF (1000nF=1uF).

3l3ctrici7y wrote ...

The capacitor I was using in series with the spark gap stared out as being a 4700pF doorknob and after two of those burned out, I built my own capacitor, that burned out, and I rebuilt it more robustly and based on the dimensions, it should have been around 1500 pF, I did not roll it quite tight enough, so it could have been 750 pF or less.

The capacitor I was using in series with the spark gap stared out as being a 4700pF doorknob and after two of those burned out, I built my own capacitor, that burned out, and I rebuilt it more robustly and based on the dimensions, it should have been around 1500 pF, I did not roll it quite tight enough, so it could have been 750 pF or less.

4700pF is 4.7 nF. Mine is 20 nF, not a lot bigger (4X). I think you really need to get a cheap DMM to measure the capacitance of your home made caps.

Re: Alternative high voltage coupling - sparkgap to solid state.

3l3ctrici7y, Mon Feb 21 2011, 04:54AM

Oh, that's it :)

I never had it connected to anything. I just had some wire wrapped around the former in place of the welding cable as the secondary of the HF transformer. I had the two ends of the wire bent so that they were close. There were no sparks between the two ends of the wire when in air, but blew argon over the two ends of the wire, then it started sparking. At some points it did spark in air, but it was the time that I blew argon over it and it jumped to the tig torch that I thought was most interesting.

Placing the cap across the iggy is just what I seem to recall being recommended in something I read long ago. As I think about it now, I think the only real difference between having the cap across the switch or the iggy itself is whether or not the voltage source is in series or not. For a battery, it probably won't matter. I'm not sure about what the reactance formula would be for a battery, but I imagine it has very low reactance.

Great, my brain gave out on me, and I forgot the order of the metric prefixes. When I looked at the numbers and came up with .22uF, I thought wow that's A LOT more than the 200 nF that I had thought it was. Whoops! My bad.

Yea, I have been wanting to get a LCR meter for a while, but just never managed to pull the trigger. I agree with you about what Steve said, that the DC output of the FBT allows it to charge a larger capacitor; and that just cannot hurt in these situations.

One of the reasons I called it quits on this project was that I only occasionally got it to spark at all, and lacking any experience with commercial units, I don't know what sort of level of performance would be necessary to be reliable. Having seen that YouTube video, I thought that that might be what I would have to accomplish.

Since you're on a pay per bandwidth connection, I took two screen caps of the impressive HF output.

Corona, and Strong HF arc. The video.

3l3ctrici7y, Mon Feb 21 2011, 04:54AM

Oh, that's it :)

I never had it connected to anything. I just had some wire wrapped around the former in place of the welding cable as the secondary of the HF transformer. I had the two ends of the wire bent so that they were close. There were no sparks between the two ends of the wire when in air, but blew argon over the two ends of the wire, then it started sparking. At some points it did spark in air, but it was the time that I blew argon over it and it jumped to the tig torch that I thought was most interesting.

Placing the cap across the iggy is just what I seem to recall being recommended in something I read long ago. As I think about it now, I think the only real difference between having the cap across the switch or the iggy itself is whether or not the voltage source is in series or not. For a battery, it probably won't matter. I'm not sure about what the reactance formula would be for a battery, but I imagine it has very low reactance.

Great, my brain gave out on me, and I forgot the order of the metric prefixes. When I looked at the numbers and came up with .22uF, I thought wow that's A LOT more than the 200 nF that I had thought it was. Whoops! My bad.

Yea, I have been wanting to get a LCR meter for a while, but just never managed to pull the trigger. I agree with you about what Steve said, that the DC output of the FBT allows it to charge a larger capacitor; and that just cannot hurt in these situations.

One of the reasons I called it quits on this project was that I only occasionally got it to spark at all, and lacking any experience with commercial units, I don't know what sort of level of performance would be necessary to be reliable. Having seen that YouTube video, I thought that that might be what I would have to accomplish.

Since you're on a pay per bandwidth connection, I took two screen caps of the impressive HF output.

Corona, and Strong HF arc. The video.

Re: Alternative high voltage coupling - sparkgap to solid state.

Ash Small, Mon Feb 21 2011, 05:30AM

Is it just occasional sparks you were getting, or an arc?

Some articles say you only need a spark to initiate the welding arc, but mine looks like arc in the second picture.

It seems the only real difference between your circuit and mine is the diodes and resistance between the HV (iggy) coil and the tank circuit, apart from the choke on the output of my buzzbox.

Ash Small, Mon Feb 21 2011, 05:30AM

3l3ctrici7y wrote ...

Oh, that's it :)

I never had it connected to anything. I just had some wire wrapped around the former in place of the welding cable as the secondary of the HF transformer. I had the two ends of the wire bent so that they were close. There were no sparks between the two ends of the wire when in air, but blew argon over the two ends of the wire, then it started sparking. At some points it did spark in air, but it was the time that I blew argon over it and it jumped to the tig torch that I thought was most interesting.

.

Oh, that's it :)

I never had it connected to anything. I just had some wire wrapped around the former in place of the welding cable as the secondary of the HF transformer. I had the two ends of the wire bent so that they were close. There were no sparks between the two ends of the wire when in air, but blew argon over the two ends of the wire, then it started sparking. At some points it did spark in air, but it was the time that I blew argon over it and it jumped to the tig torch that I thought was most interesting.

.

Is it just occasional sparks you were getting, or an arc?

Some articles say you only need a spark to initiate the welding arc, but mine looks like arc in the second picture.

It seems the only real difference between your circuit and mine is the diodes and resistance between the HV (iggy) coil and the tank circuit, apart from the choke on the output of my buzzbox.

Re: Alternative high voltage coupling - sparkgap to solid state.

3l3ctrici7y, Mon Feb 21 2011, 06:04AM

Sometimes it was an occasional spark here or there and other times it would spark/arc too rapidly to distinguish one from the next, but usually nothing at all.

With the apparent similarity between yours, mine, and the one I was basing mine on, and my failure to accomplish the goal; I think there must be some subtle but critical thing I was doing wrong.

As a perhaps interesting aside, here is a page about getting huge voltages out of an HEI coil by removing the iron E-core and treating it as a Tesla coil.

There is a definite mystique about simple traditional designs (spark gap TC), but I think if I ever revisit this HF arc starter, I will try to make it out of a ZVS and see if I can get favorable results. Maybe weld aluminum foil using the HF alone. That would be so awesome, but totally impossible.

uzzors2k said that with his ZVS the wires start to glow, so perhaps welding with the HF isn't so far fetched ;)

3l3ctrici7y, Mon Feb 21 2011, 06:04AM

Sometimes it was an occasional spark here or there and other times it would spark/arc too rapidly to distinguish one from the next, but usually nothing at all.

With the apparent similarity between yours, mine, and the one I was basing mine on, and my failure to accomplish the goal; I think there must be some subtle but critical thing I was doing wrong.

As a perhaps interesting aside, here is a page about getting huge voltages out of an HEI coil by removing the iron E-core and treating it as a Tesla coil.

There is a definite mystique about simple traditional designs (spark gap TC), but I think if I ever revisit this HF arc starter, I will try to make it out of a ZVS and see if I can get favorable results. Maybe weld aluminum foil using the HF alone. That would be so awesome, but totally impossible.

uzzors2k said that with his ZVS the wires start to glow, so perhaps welding with the HF isn't so far fetched ;)

Re: Alternative high voltage coupling - sparkgap to solid state.

Ash Small, Mon Feb 21 2011, 06:44AM

After I built mine I was looking into constructing a Non-Transferred Arc Inert Gas Plasma Torch (Micro-Torch). These work on a similar principle, but the arc is struck in the torch and the plasma is blown out to the workpiece by the gas. They run at very low currents and are used for welding thin foils, etc. The most significant difference is that the welding current is at 220 volts, as this gives a more stable arc at low currents. The same principle could probably be used for TIG welding.

The other method for welding thin fiols is Electron Beam Welding, but that requires a vacuum chamber.

I don't see why a Mazilli/ZVS circuit wouldn't work, you wouldn't require a very high voltage to get an arc under argon so you would have even more current available for welding. I might try this myself.

(My present circuit just uses the single transistor flyback driver, you can't get much simpler than a 2N3055, two resistors and an old TV flyback to charge the tank circuit.)

Ash Small, Mon Feb 21 2011, 06:44AM

3l3ctrici7y wrote ...

Sometimes it was an occasional spark here or there and other times it would spark/arc too rapidly to distinguish one from the next, but usually nothing at all.

With the apparent similarity between yours, mine, and the one I was basing mine on, and my failure to accomplish the goal; I think there must be some subtle but critical thing I was doing wrong.

As a perhaps interesting aside, here is a page about getting huge voltages out of an HEI coil by removing the iron E-core and treating it as a Tesla coil.

There is a definite mystique about simple traditional designs (spark gap TC), but I think if I ever revisit this HF arc starter, I will try to make it out of a ZVS and see if I can get favorable results. Maybe weld aluminum foil using the HF alone. That would be so awesome, but totally impossible.

uzzors2k said that with his ZVS the wires start to glow, so perhaps welding with the HF isn't so far fetched ;)

Sometimes it was an occasional spark here or there and other times it would spark/arc too rapidly to distinguish one from the next, but usually nothing at all.

With the apparent similarity between yours, mine, and the one I was basing mine on, and my failure to accomplish the goal; I think there must be some subtle but critical thing I was doing wrong.

As a perhaps interesting aside, here is a page about getting huge voltages out of an HEI coil by removing the iron E-core and treating it as a Tesla coil.

There is a definite mystique about simple traditional designs (spark gap TC), but I think if I ever revisit this HF arc starter, I will try to make it out of a ZVS and see if I can get favorable results. Maybe weld aluminum foil using the HF alone. That would be so awesome, but totally impossible.

uzzors2k said that with his ZVS the wires start to glow, so perhaps welding with the HF isn't so far fetched ;)

After I built mine I was looking into constructing a Non-Transferred Arc Inert Gas Plasma Torch (Micro-Torch). These work on a similar principle, but the arc is struck in the torch and the plasma is blown out to the workpiece by the gas. They run at very low currents and are used for welding thin foils, etc. The most significant difference is that the welding current is at 220 volts, as this gives a more stable arc at low currents. The same principle could probably be used for TIG welding.

The other method for welding thin fiols is Electron Beam Welding, but that requires a vacuum chamber.

I don't see why a Mazilli/ZVS circuit wouldn't work, you wouldn't require a very high voltage to get an arc under argon so you would have even more current available for welding. I might try this myself.

(My present circuit just uses the single transistor flyback driver, you can't get much simpler than a 2N3055, two resistors and an old TV flyback to charge the tank circuit.)

Re: Alternative high voltage coupling - sparkgap to solid state.

3l3ctrici7y, Mon Feb 21 2011, 07:51AM

Wah-hoo! My thread made it to two pages :)

The Micro-Torch sounds interesting; maybe a lot like the non-transfered version of plasma arc welding.

The biggest thing I see about home-brewing a torch is the water cooled nozzle. Staring off with an existing tig or pac torch seems like a good thing.. then "just" build the nozzle. I supposed it might be fairly straight forward if one had a lathe.

220v.. Good thing it's inside the torch. I have seen "designs" for cheap DIY plasma cutters that used rectified mains voltages. The electrical safety people chime in loudly after such things are posted. I like the non-transfered mode of operation, because then the weldment does not need to be grounded, or fight with a ground clamp. Sadly, I don't think it's practical at higher currents. I have seen some plasma cutters that have HF internal to the torch.. so you can push the button and it will spray plasma out the nozzle even without having a work piece under it.

I couldn't quite work it out in my head and convince myself that a ZVS would work with such a small number of turns on the secondary. There are complexities related to the total number of turns and the core material that I do not understand. I guess that with an FBT, it has a large number of turns and will produce a long arc in air.. but we only really need a 6-10mm under argon.

3l3ctrici7y, Mon Feb 21 2011, 07:51AM

Wah-hoo! My thread made it to two pages :)

The Micro-Torch sounds interesting; maybe a lot like the non-transfered version of plasma arc welding.

The biggest thing I see about home-brewing a torch is the water cooled nozzle. Staring off with an existing tig or pac torch seems like a good thing.. then "just" build the nozzle. I supposed it might be fairly straight forward if one had a lathe.

220v.. Good thing it's inside the torch. I have seen "designs" for cheap DIY plasma cutters that used rectified mains voltages. The electrical safety people chime in loudly after such things are posted. I like the non-transfered mode of operation, because then the weldment does not need to be grounded, or fight with a ground clamp. Sadly, I don't think it's practical at higher currents. I have seen some plasma cutters that have HF internal to the torch.. so you can push the button and it will spray plasma out the nozzle even without having a work piece under it.

I couldn't quite work it out in my head and convince myself that a ZVS would work with such a small number of turns on the secondary. There are complexities related to the total number of turns and the core material that I do not understand. I guess that with an FBT, it has a large number of turns and will produce a long arc in air.. but we only really need a 6-10mm under argon.

Re: Alternative high voltage coupling - sparkgap to solid state.

Newton Brawn, Wed Feb 23 2011, 08:41PM

Hi 3L3 and Ash :

I just posted some mater on the Forum under " HV CAPACITOR dV/dt CAPABILITY estimation (or design)"

I hope it could be of your interest

Regards

Newton Brawn, Wed Feb 23 2011, 08:41PM

Hi 3L3 and Ash :

I just posted some mater on the Forum under " HV CAPACITOR dV/dt CAPABILITY estimation (or design)"

I hope it could be of your interest

Regards

Re: Alternative high voltage coupling - sparkgap to solid state.

Newton Brawn, Thu Feb 24 2011, 11:15AM

Hi 3l3 and Ash!

here is the schematic diagram:

]arc_starter_and_stabilizer.pdf[/file]

I made Copy and Past from previous post in order to put the information togheter:

The caps that shunt the buzzboz output high current terminals are normally paper-foil 400-600V. Polyester or polypropylrene METALIZED caps are not suitable. Some manufacturers use of 0.02uF. Other (Miller, Esab, etc) use caps up to 10uF.

0.02uF is enough to avoid the hv enter in the secondary coil or buzzbox diodes .

Also 2uF in series with 10 ohm 2w CARBON resistor bridges the hi current work terminal to the ground. This is the way to rf grounding the buzzbox secondary, avoiding the secondary 55V winding get the RF voltage.

Other interesting point is that for proper arc start, just one pulse of 10 kV 0.5 microsecond is required. this pulse tobe at each 8.333ms, for a 60Hz buzbox. Using only one pulse close the zero voltage passage a lot of energy is saved, reducing the size and ratings of conponents.

The ignition coil may be replaced for homemade pulse tranformer. 24turns in primary 400 turns at secondary, ferrite core from flyback. insulation 0.2mm polyester between layers. No more 20 turns per layer.

Glass capacitors 1000uuF, 10kV proper handymade are reliable.

Any comment??

Regards

Newton

Newton Brawn, Thu Feb 24 2011, 11:15AM

Hi 3l3 and Ash!

here is the schematic diagram:

]arc_starter_and_stabilizer.pdf[/file]

I made Copy and Past from previous post in order to put the information togheter:

The caps that shunt the buzzboz output high current terminals are normally paper-foil 400-600V. Polyester or polypropylrene METALIZED caps are not suitable. Some manufacturers use of 0.02uF. Other (Miller, Esab, etc) use caps up to 10uF.

0.02uF is enough to avoid the hv enter in the secondary coil or buzzbox diodes .

Also 2uF in series with 10 ohm 2w CARBON resistor bridges the hi current work terminal to the ground. This is the way to rf grounding the buzzbox secondary, avoiding the secondary 55V winding get the RF voltage.

Other interesting point is that for proper arc start, just one pulse of 10 kV 0.5 microsecond is required. this pulse tobe at each 8.333ms, for a 60Hz buzbox. Using only one pulse close the zero voltage passage a lot of energy is saved, reducing the size and ratings of conponents.

The ignition coil may be replaced for homemade pulse tranformer. 24turns in primary 400 turns at secondary, ferrite core from flyback. insulation 0.2mm polyester between layers. No more 20 turns per layer.

Glass capacitors 1000uuF, 10kV proper handymade are reliable.

Any comment??

Regards

Newton

Re: Alternative high voltage coupling - sparkgap to solid state.

3l3ctrici7y, Thu Feb 24 2011, 10:27PM

That's cool stuff, thanks for posting Newton :)

It had not occurred to me that running directly off of the line will cause it to run synchronously with an AC output buzzboz and that this would cause it to relight the arc at just the right time :)

3l3ctrici7y, Thu Feb 24 2011, 10:27PM

That's cool stuff, thanks for posting Newton :)

It had not occurred to me that running directly off of the line will cause it to run synchronously with an AC output buzzboz and that this would cause it to relight the arc at just the right time :)

Re: Alternative high voltage coupling - sparkgap to solid state.

Newton Brawn, Fri Feb 25 2011, 04:29AM

3L3, Ash:

Yes this is the big diference! just one pulse at right time. Save energy and a lot of component ratings.

There is a old patent 2880373 , Tajbl. It describes the art and technique how a pulse shall to start a arc. It is realy hi tech concept. Carefull revise how the pulse acts on the ignition.

However, do not consider the saturable transformer, it is something superseed, old tech...

look also

, general note 11, circuit show at figure E9.17. This circuit starts the sodium bulbs up to 1000W. I think I have some test sheet with documentation of the test results.

, general note 11, circuit show at figure E9.17. This circuit starts the sodium bulbs up to 1000W. I think I have some test sheet with documentation of the test results.

Regards

Newton

If u found a microwave in the street, just crrier it to home !

Newton Brawn, Fri Feb 25 2011, 04:29AM

3L3, Ash:

Yes this is the big diference! just one pulse at right time. Save energy and a lot of component ratings.

There is a old patent 2880373 , Tajbl. It describes the art and technique how a pulse shall to start a arc. It is realy hi tech concept. Carefull revise how the pulse acts on the ignition.

However, do not consider the saturable transformer, it is something superseed, old tech...

look also

, general note 11, circuit show at figure E9.17. This circuit starts the sodium bulbs up to 1000W. I think I have some test sheet with documentation of the test results.

, general note 11, circuit show at figure E9.17. This circuit starts the sodium bulbs up to 1000W. I think I have some test sheet with documentation of the test results.Regards

Newton

If u found a microwave in the street, just crrier it to home !

Re: Alternative high voltage coupling - sparkgap to solid state.

3l3ctrici7y, Sat Feb 26 2011, 11:24PM

Newton, thanks for the link.

I really like the clever circuits that get put in datasheets.

Using the sidac in place of a spark gap is a really nice simplification.

Though, it would probably take a hefty sidac to handle 20kV+ and 1kA+ that a gap would.

Going back up a few figured, E9.11 is pretty cool too :)

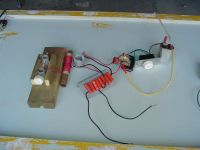

Some time ago when I was hunting down info about HF igniters I found a scan of a manual that showed the use of an autotransformer for the HF igniter portion. I have attached it to this post.

3l3ctrici7y, Sat Feb 26 2011, 11:24PM

Newton, thanks for the link.

I really like the clever circuits that get put in datasheets.

Using the sidac in place of a spark gap is a really nice simplification.

Though, it would probably take a hefty sidac to handle 20kV+ and 1kA+ that a gap would.

Going back up a few figured, E9.11 is pretty cool too :)

Some time ago when I was hunting down info about HF igniters I found a scan of a manual that showed the use of an autotransformer for the HF igniter portion. I have attached it to this post.

Re: Alternative high voltage coupling - sparkgap to solid state.

Newton Brawn, Fri Mar 04 2011, 02:01AM

Nice schematic !

Simple arrangement. It can work as a wellding arc starter or high pressure lamp starter. The transformer to have a magnetic shunt to limit the secondary short circuit current. Secondary to deliver more tham 5kV in order to trigger 1,0mm air gap. It may be a furnace ignition transformer @ old style version. It may produce 30~100 pulses at each 8.33ms, so the air gap shall have a heath sink.

Remenber that a sidac schema fig E9.11, prduces only 3 pulses each 8.33ms, saving a lot of energy.

The circuit "arc_starter_and_stabilizer.pdf" attached to thre thread Fri Feb 25 2011, 01:29AM produces only 1 pulse each 8.33ms, the air gap is always cool. This mean a LONG, LONG life for the spark gap tungsteniun electrodes. ( I use tungstenium carbite inserts from scraped cuting tools from the lathe... )

The "arc_starter_and_stabilizer.pdf" characteristics are:

Vtrigger=3600V, Cap = 700uuF.

The energy delivered in one pulse is in the range of:

0.5 x 3600^2 x 700 x 10^(-12) = 0.0045J

Triggering one pulse at each 8.33ms or 120 pulses per second...

0.0045J x 120 = 0.544J/s

Since 1watt is 1joule/second the power dissipated by the air spark gap power is 0.544watt. (it is less than 1W resistor)

If the cap is 1000uuF and the spark gap fire 30 pulses at each 8,33ms, the power dissipated by the spark gap is +- 23W (hot spark gap). It is the case of Miller HF 15 arc starter.

The characteristics of the air spark gap are really good. But is difficult to trigger at voltages lower than 3000V.

One single Sidac can fire at 120V up to 240V . Sidacs, have high "short circuit resistence" that sometimes reduces the efficience of tesla ckt. I have fired up to 6 sidacs in series (1380V) using the configuration E9.11, the caps capacitance are reduced to keep the energy and dv/dt lower.

Let me know the voltage delivered from the welding machine to the lamp. Also if it is DC or AC, and frequency.

Regards

Newton

Newton Brawn, Fri Mar 04 2011, 02:01AM

Nice schematic !

Simple arrangement. It can work as a wellding arc starter or high pressure lamp starter. The transformer to have a magnetic shunt to limit the secondary short circuit current. Secondary to deliver more tham 5kV in order to trigger 1,0mm air gap. It may be a furnace ignition transformer @ old style version. It may produce 30~100 pulses at each 8.33ms, so the air gap shall have a heath sink.

Remenber that a sidac schema fig E9.11, prduces only 3 pulses each 8.33ms, saving a lot of energy.

The circuit "arc_starter_and_stabilizer.pdf" attached to thre thread Fri Feb 25 2011, 01:29AM produces only 1 pulse each 8.33ms, the air gap is always cool. This mean a LONG, LONG life for the spark gap tungsteniun electrodes. ( I use tungstenium carbite inserts from scraped cuting tools from the lathe... )

The "arc_starter_and_stabilizer.pdf" characteristics are:

Vtrigger=3600V, Cap = 700uuF.

The energy delivered in one pulse is in the range of:

0.5 x 3600^2 x 700 x 10^(-12) = 0.0045J

Triggering one pulse at each 8.33ms or 120 pulses per second...

0.0045J x 120 = 0.544J/s

Since 1watt is 1joule/second the power dissipated by the air spark gap power is 0.544watt. (it is less than 1W resistor)

If the cap is 1000uuF and the spark gap fire 30 pulses at each 8,33ms, the power dissipated by the spark gap is +- 23W (hot spark gap). It is the case of Miller HF 15 arc starter.

The characteristics of the air spark gap are really good. But is difficult to trigger at voltages lower than 3000V.

One single Sidac can fire at 120V up to 240V . Sidacs, have high "short circuit resistence" that sometimes reduces the efficience of tesla ckt. I have fired up to 6 sidacs in series (1380V) using the configuration E9.11, the caps capacitance are reduced to keep the energy and dv/dt lower.

Let me know the voltage delivered from the welding machine to the lamp. Also if it is DC or AC, and frequency.

Regards

Newton

Re: Alternative high voltage coupling - sparkgap to solid state.

3l3ctrici7y, Sun Mar 06 2011, 10:28AM

Hi Newton,

I do not understand..

What lamp??

3l3ctrici7y, Sun Mar 06 2011, 10:28AM

Hi Newton,

I do not understand..

"Let me know the voltage delivered from the welding machine to the lamp. Also if it is DC or AC, and frequency."

What lamp??

Re: Alternative high voltage coupling - sparkgap to solid state.

Newton Brawn, Mon Mar 07 2011, 09:57PM

Hi 3L3 !

Sorry for the question. I was thinking that you are designing a starter for a xenon arc lamp.

Now I read again all the posts and I conclude that your project is for a welder machine. Can you confirm ??

As I said before, the ignition pulse of 0,006 joules is enough to start the arc. The pulses reaches 15000 volts during 0.5 to 1 microseconds at the welding torche / electrode. This pulse produces a spark of 3-4 mm in the open air or 12mm in argon/welding atmosphere (cool electrode, cool atmosphere ). Also you can touche the electrode, see the sparks going to yours fingers and you do not fill any electrical shock.

Also read the concepts of a arc starter written @ Google Patents, patent 2880376, by Franz Tajbl. It is the bible for construction of arc starters. The main concepts and technics for arc starter are spelled out. Of course, the saturated core tranformer used in that patent is something superseed.

Regards

Newton

EDIT: Please see the next post with the video clip "10kV in the hands"

Newton Brawn, Mon Mar 07 2011, 09:57PM

Hi 3L3 !

Sorry for the question. I was thinking that you are designing a starter for a xenon arc lamp.

Now I read again all the posts and I conclude that your project is for a welder machine. Can you confirm ??

As I said before, the ignition pulse of 0,006 joules is enough to start the arc. The pulses reaches 15000 volts during 0.5 to 1 microseconds at the welding torche / electrode. This pulse produces a spark of 3-4 mm in the open air or 12mm in argon/welding atmosphere (cool electrode, cool atmosphere ). Also you can touche the electrode, see the sparks going to yours fingers and you do not fill any electrical shock.

Also read the concepts of a arc starter written @ Google Patents, patent 2880376, by Franz Tajbl. It is the bible for construction of arc starters. The main concepts and technics for arc starter are spelled out. Of course, the saturated core tranformer used in that patent is something superseed.

Regards

Newton

EDIT: Please see the next post with the video clip "10kV in the hands"

Re: Alternative high voltage coupling - sparkgap to solid state.

3l3ctrici7y, Wed Mar 09 2011, 01:35PM

3l3ctrici7y, Wed Mar 09 2011, 01:35PM

Sorry for the question. I was thinking that you are designing a starter for a xenon arc lamp.Confirmed. My goal was for a welding machine.

Now I read again all the posts and I conclude that your project is for a welder machine. Can you confirm ??

As I said before, the ignition pulse of 0,006 joules is enough to start the arc. The pulses reaches 15000 volts during 0.5 to 1 microseconds at the welding torche / electrode. This pulse produces a spark of 3-4 mm in the open air or 12mm in argon/welding atmosphere (cool electrode, cool atmosphere ). Also you can touche the electrode, see the sparks going to yours fingers and you do not fill any electrical shock.I like those specifications. The low energy will limit its radiated EMI (something I hear can be quite a problem) and like you said, will limit the heating in the spark gap. I have seen videos of that where people run the HF to their hand; it's just incredible.

Also read the concepts of a arc starter written @ Google Patents, patent 2880376, by Franz Tajbl. It is the bible for construction of arc starters. The main concepts and technics for arc starter are spelled out. Of course, the saturated core tranformer used in that patent is something superseed.you for the link. That is very interesting reading.

PS: How can I attache a small clip video in this reply ??If the video is on your computer, and it is a .mpg or .avi, you can attach it using the dialog when composing a reply. If the video is hosted somewhere such as YouTube, you can simply link to it.